Earthbag is a method of construction using plastic or textile casings

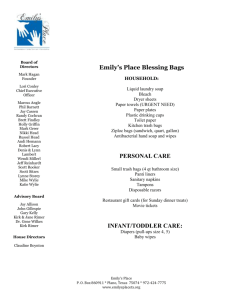

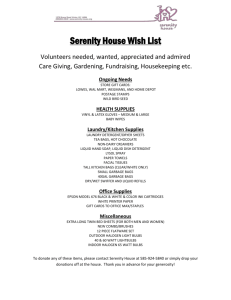

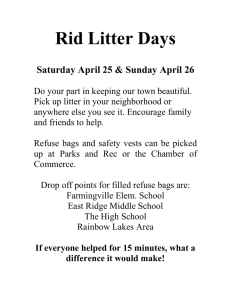

advertisement

Earthbag is a method of construction using plastic or textile casings (earthbags) packed with soil, and sometimes sand, gravel and cementitious materials. It has grown in popularity as a natural alternative building method primarily in the United Sates. It can be used to construct foundations, walls, and domed structures. Earthbag is one of the most inexpensive building methods, and is very valuable to areas that are prone to flooding, hurricanes, wildfires or areas with no wood or clay. Earthbag construction technique requires few skills, and if faster than other earth building methods. Few tools other than a shovel is necessary those can usually can be hand made. Architect Nader Khalili at Cal Earth in Hesperia has explored the use of earthbag construction both as residential houses and emergency shelters. Through his work and the work of students at the California Institute of Earth Art and Architecture, this technology is proven to be a viable solution for rebuilding communities after a war or major disaster. Earthbag construction is a very promising option for the rebuild in the Aceh area. For both temporary and permanent solutions. Emergency shelters made from sandbags and barbwire can be constructed in a few hours and have been proven to last for three winters. As a permanent solution, earthbag dome structure could be built that would be covered in cement or lime plaster. In the Aceh region, all of the other materials except for the bags can be found locally. Two types of bags are available: Hessian (burlap) or polypropylene. The polypropylene bags are the only sutable for the area of Indonesia because of the high levels of sand in the soil. Polypropylene bags are made of woven plastic. Polypropylene bags will deteriorate if exposed to (UV) rays. Steps should be made to protect the bags from sunlight both before and after construction. UV resistant bags are also available, however more expensive. In the United States, manufacturers sell the polypropylene bags for around 22 cents per year plus delivery. The sacks are available in a variety of widths. Recycled seed or feed sacks made of polypropylene can be obtained from factories or stores that bag these products. The bags can be sewn together to increase the length. A typical adobe mix of sand and clay soil is ideal for earthbag construction. A mixture of sand and lime or lime-rich coral sand that would be common in these regions is also sufficient. All organic matter, rocks, and sticks should be sifted out of the soil. Any material that degrades that is left in the bags could create pockets, weakening the structure. Also remove all topsoil and only use the substrate and fill material. After the fill material is sifted and lime or coral sand is add the bags can be filled. The fill can be used either wet or dry however when using lime the fill should be moist so that the material sets for structural support. The perfect moisture content is tested by grabing a hand full of the fill and sqeezing it. It shold hold its shape but not fell wet. 4-point barbed wire is laid between courses to keep the bags from slipping. As a rule of thumb, if the bag is less than 12 inches wide, only one row is needed. Two or more rows of barbed wire may be required for rows wider than 16 inches. The most important tool in earthbag construction is a shovel. Shovels are used to excavate the fill material, and fill the bags. Wheelbarrows are needed to transport the fill material and can be used to mix up the cement or lime into the soil mix. Coffee cans are useful to fill the bags. Cans or sturdy cardboard tubes are good for keeping the ends of the bags open as they are filled. Soil tampers are needed to compact the bags. Filling a plastic container with concrete and inserting a stick into it can make a tamper. The tamper should cure for two weeks before use. Heavy flat stones or bricks can be used. A hoe is helpful when mixing stabilizers like cement. A blade/scissors for cutting the bags, a level, tape measure, barbwire cutters, gloves, a trowel, and water hose and water bucks for carrying water are also needed. Forms for vaults, domes and arches are needed if creating any of these shapes. The forms can be made from metal or plywood. Bamboo plywood would also work well and these forms can be used over and over again. Used tires rammed with earth can treat impressive buildings, like the Earthship home. The 3-foot-thick walls create thermal mass that heats and cools the dwelling. The Earthship home heats itself in the winter and cools itself in the summer and maintains a relatively even temperature. There are probably hundreds if not hundreds of thousands of tires that are amongst the debris from the tsunami. These tires which would normally be considered garbage could be used to create new homes. The U module is the most commonly and efficient shape for earth-rammed tire construction. U modules should not be created larger than 18 feet wide and 26 feet deep. Structures larger than this should be made form several modules or another design. Other designs using many different shapes have also been built to best adapt to the climate. Also earth-rammed tire walls should not exceed 10 feet because of their massiveness. Cylinder home The automobile tires can be used as found. No modification to the tires is necessary. Wheelbarrows for hauling the fill, sledge hammers for compacting the earth inside the tires, and a level are all needed materials. Other helpful materials are; tampers as shown above, hoes for mixing fill, and used cans to fill the gaps in the tire walls. Bamboo has rapidly become a popular building material, proving to be a much more sustainable alternative to wood, it is valued for its strength and lightness. In comparison to the rigidity of steel or concrete, bamboo's high flexibility is well suited for earthquake prone areas. In Indonesia, it has proved to sustain storm and earthquake damage, however, its strength can be compromised with contact with wet soil and termites. It is a relatively strong material with a hard, clean surface, and can be easily cut with simple tools. Bamboo growth is fairly rapid, and is found throughout this region, making it an inexpensive alternative to timber, and can also be grown as a crop plant. Although bamboo is abundant in Sumatra, it is less so in the Aceh Province. uses : scaffolding/structural support : walls : roof material : flooring : infrastructure : and many others