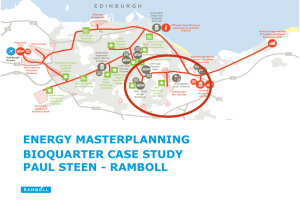

heat grid

advertisement

Verificatiebureau Benchmarking Vlaanderen 023-0093E EXPLANATION 09 COMBINED HEAT AND POWER Combined Heat and Power (CHP or Cogeneration) is in general much more efficient than conventional separate generation. Consequently the application of a CHP is considered as an energy saving option and calculated in the benchmark study. The efficiencies (electricity and heat) of the CHP are also important for the determination of the energy efficiency of the whole plant. To calculate the energy that is saved with CHP the following agreements are made: 1. For the determination of the Best International Standard in the benchmark, CHP is always calculated in the same way, for benchmark companies as well as for the own company. 2. Unless an existing benchmark was set up differently, the reference value in the benchmark for separate generation of heat is the measured boiler efficiency of the company and for separate generation of electricity 40%. 3. The reference efficiency for separate electricity generation of 40% is not representative for the electricity generation in Belgium. 4. The primary energy, saved with CHP, is immediately converted into improved efficiency. The calculation is based on a split of the component heat and the component electricity: - the part of the energy input given to the component heat, equals an efficiency of 90% for standard applications1; - the remainder of the energy input is given to the component electricity which creates an electricity efficiency significantly higher than 40%; - following data are required as input: the heat production of boilers, the boiler efficiency, the fuel input for CHP, heat and electricity output from CHP, net electricity from CHP delivered to the grid or electricity taken from the grid; - combined transformation efficiencies of heat and electricity generation are calculated; for the heat generation a CHP advantage only exists when the boiler efficiency is not 90%; the remaining CHP advantage goes to the component electricity; - the combined transformation efficiencies are valid for the whole plant and are therefore used in the benchmarks, best practices and audits of all processes. 5. In case of a joint venture where the CHP installation is owned and exploited by the power company, the calculation of CHP in the processes is done in the same way as for an industry owned CHP. This way the CHP of the power station is included in the benchmark process of the company. 1 for non standard applications: see explanation on the last page The explanations on the Covenant Benchmarking energy efficiency are drawn up and edited by the Flemish Verification Office. The purpose of these explanations is to inform the reader about a recent version on the interpretation of the covenant’s clauses. Statements of the Commission Benchmarking and recent verification practice are taken into account. The texts will be adapted as a result of advancing insight and experience. 15.05.2003 Page 1/4 Version 3 EXPL 09 Verificatiebureau Benchmarking Vlaanderen If the company consumes more electricity than the CHP produces, then the calculation under item 4 does not give any discussion. If the company consumes less electricity than the CHP produces, the remainder is returned to the grid. The corresponding part of the CHP installation and the CHP advantage is counted in the production park of the supplier. When a company attains the Best International Standard with a reserve, because of a joint venture CHP, this reserve can never be considered as an achievement of the company for which it should receive tradable emission rights. 6. When the CHP is property of the company and no electricity is returned to the grid the calculation of item 4 is clear. If electricity is returned to the grid, this is seen as a negative purchase and the CHP advantage will stay in the company. Mathematically this is carried out by bottom line addition of the sold electricity. (this approach is justified because the CHP cannot be benchmarked as a part of the power station park) When the company, due to this CHP, obtains a positive reserve in comparison with the Best International Standard, this reserve could be eligible for tradable emission rights. 7. In case of a joint venture CHP with combined ownership formula the CHP advantage of the returned electricity and the participation in emission trading is regulated conform the contractual agreements. Example In this example the following efficiencies are used: efficiency in % 40% efficiency of electrical generation in the power stations electrical efficiency CHP installation thermal efficiency CHP installation 30% 57% thermal efficiency boiler installation 85% From this calculation results (see spreadsheet) that the "combined electrical efficiency" becomes 81,8% and the "combined thermal efficiency" 87,7%. For the accounting of the process consumptions the combined efficiencies are used, instead of the default 40% and 85%, in case there was no CHP. Remark: The calculation sheet is available as an Excel-sheet "TLG0092- appendix.xls" on the website. If you fill in the grey areas (red figures) the other figures are calculated automatically by the program. The explanations on the Covenant Benchmarking energy efficiency are drawn up and edited by the Flemish Verification Office. The purpose of these explanations is to inform the reader about a recent version on the interpretation of the covenant’s clauses. Statements of the Commission Benchmarking and recent verification practice are taken into account. The texts will be adapted as a result of advancing insight and experience. 15.05.2003 Page 2/4 Version 3 EXPL 09 Verificatiebureau Benchmarking Vlaanderen Calculation of non-standard applications As mentioned above, it is assumed that the heat component is calculated with an efficiency of 90%, because this is the standard efficiency for a boiler, used as reference for separate generation. In some cases it is better to adjust the reference to the specific requirements of the application. A few examples: 1. The heat is consumed by the process on a high temperature, for example 400° C; even a boiler could only provide this heat with an efficiency of 80%, so it is better to adjust the reference and to calculate the heat component of the CHP with an efficiency of 80%. 2. The heat of the CHP is not used with steam or hot water as a carrier, but the exhaust gasses of the turbine are directly used in the drying process. Here the reference for separate generation is a burner, which doesn’t lose flue gas heat and therefore has an efficiency of 100%. The CHP heat component is calculated with 100%. If the CHP heat is partly delivered as steam or hot water and partly as flue gasses for a drying process, both are calculated with 100%. If only a part of the flue gasses is used, the efficiency of the heat component is chosen accordingly between 90% and 100%. The explanations on the Covenant Benchmarking energy efficiency are drawn up and edited by the Flemish Verification Office. The purpose of these explanations is to inform the reader about a recent version on the interpretation of the covenant’s clauses. Statements of the Commission Benchmarking and recent verification practice are taken into account. The texts will be adapted as a result of advancing insight and experience. 15.05.2003 Page 3/4 Version 3 EXPL 09 Verificatiebureau Benchmarking Vlaanderen General Electricity Supply Fuels: input electricity 0 TJ Electricity 0,4 For the conversion of process electricity consumptions to primary energy, the combined electricity generation efficiency will be used: E = ( 0 + 300 ) / ( 0 + 367 ) = 0,818 0 TJ 100 electr. component = 1000 - 633 = heat component = 570 / 0,90 = heat 450 / 0,85 = = 367 TJ 1000 633 TJ 529 TJ Primary energy consumption for electricity 75 / 0,818 = = BOILER 200 TJ 570 570 TJ = 0,85 For the conversion of process heat consumptions to primary energy, the combined heat generation efficiency will be used: Q = ( 570 + 450 ) / ( 633 + 529 ) = 0,877 450 TJ Electr. consumption (secondary) 92 TJ 300 CHP 75 TJ Heat consumption (secondary Primary energy consumption for heat 350 TJ 399 TJ Process A E = 50 / 0,818 = 61 TJ 50 TJ 500 TJ 570 TJ 170 TJ 194 TJ Process B = 75 / 0,818 = 92 TJ 75 TJ Process C Total = 244 TJ total 200 TJ total 1020 TJ total 1.163 TJ Ifor the comparison with the primary consumption of the processes in the benchmark, these results will be used The explanations on the Covenant Benchmarking energy efficiency are drawn up and edited by the Flemish Verification Office. The purpose of these explanations is to inform the reader about a recent version on the interpretation of the covenant’s clauses. Statements of the Commission Benchmarking and recent verification practice are taken into account. The texts will be adapted as a result of advancing insight and experience. 15.05.2003 Page 1/4 Version 3 EXPL 09 W