Programme - Alkali Manufacturers` Association of India (AMAI)

advertisement

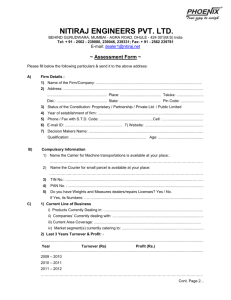

ALKALI MANUFACTURERS’ ASSOCIATION OF INDIA Seminar on “Environment Management for Chlor-Alkali Industry” and Exhibition 14 & 15 May, 2014, Seasons Banquet, Hotel Regenta, Bharuch, Gujarat (Followed by Plant Visit to Grasim Vilayat) PROGRAMME DAY 1 (14.05.2014) 08:30 AM – 09:30 AM REGISTRATION 09:30 AM – 11.15 AM Introductory Remarks by Mr. B.S. Gilra, Chairman Technical Committee & Past President, AMAI Technical Session I: Environment regulations and standards related to Chlor-Alkali Industries – Monitoring & Compliance Challenges and Opportunities for environment management in Membrane Cell based Chlor-Alkali Plants, Caustic Evaporation & Flaking Unit Session Chairperson : Mr. B. S. Gilra, Chairman Technical Committee & Past President, AMAI Standards and Regulations for discharge of liquid effluents and Gaseous Emissions related to chlor alkali industry (Mr. Paritosh Kumar & Mr. Dinabandhu Gouda, CPCB) Disposal & Storage of brine sludge from Membrane cell plants, guidelines & monitoring of existing secured landfill sites (for Mercury bearing brine sludge) (Mr. J. D. Kalyani, GPCB, Ankleshwar) Integrated solutions for Chlor-Alkali Industry (Mr. Gao Jian, Jiang Yin Ancan Electrochemical Equipment Ltd.) How green Chlor-Alkali Industry - what are the EMS challenges for Chlor-Alkali Industry – a sustainable approach (Mr. S. N. Sastry, Grasim Industries Ltd., Nagda) Q & A and Discussions 11:15 AM – 11:45 AM TEA BREAK 11:45 AM – 01:00 PM Technical Session II: Online Continuous Monitoring Analyzers for Liquid Discharge & Gaseous Emissions (To monitor pH, COD, BOD, TSS in liquid effluent and NOx, SOx, SPM, Cl2 & HCl in stack emissions and ambient air) Session Chairperson: Mr. Pavan Kumar Jain, President & Head DMD, Reliance Industries Ltd. 01:00 PM – 02:00 PM Regulatory requirements on online continuous monitoring system for emissions and effluents in chlor alkali industry (Mr. Dinabandhu Gouda, CPCB) EZ-BRINE® on-line full control brine purification process & Ü On-line hydrogen (H2) in WET chlorine (Cl2) to prevent explosion (Mr. Chris Du Bois, Applitek) Emission Monitoring in Captive Power Plants (CPP’s) (Mr. Akash Naidu, Forbes Marshall Codel Pvt. Ltd.) Presentation on Effectively containing HCl vapors in tail gas tower in hydrochloric acid unit (Mr. Yogesh Gujarathi, Graphite India Ltd.) Q & A and Discussions (Session continues after lunch) LUNCH 02:00 PM – 03:00 PM Technical Session II (continued): Online Continuous Monitoring Analyzers for Liquid Discharge & Gaseous Emissions (To monitor pH, COD, BOD, TSS in liquid effluent and NOx, SOx, SPM, Cl2 & HCl in stack emissions and ambient air) Session Chairperson: Mr. Pavan Kumar Jain, President & Head DMD, Reliance Industries Ltd. 03:00 PM – 04:00 PM Continuous Emission & Effluent Monitoring System (Mr. Pritesh M. Shah, Prima Equipment) Online continuous analyzers for chlor-alkali industry (Mr. A. Paul, Adage Automation Pvt. Ltd.) Analyzers for Chlor-Alkali Plants ( SO2,NOX,CL2,HCl) with maintenance free Non-Sampling technology (Mr. R. Kishor Kumar, OPSIS AB) Continuous Emission Monitoring & Analyzer Solutions (Mr. Sankar Kannan, Chemtrols Inds. Ltd.) Q & A and Discussions Technical Session III: Available Technology for Water & Waste Water Treatment (Suppliers for Chlor Alkali Industries) Session Chairperson: Mr. Subhash Tandon, Executive Vice President (Chlor-Alkali), DCW Ltd., Sahupuram Waste Water Recycling & Zero Liquid Discharge (Mr. Vinod Gadewar, Ion Exchange (I) Pvt.) Use of Porex TMF Membranes for Cooling Towers blow down Re-Use (Mr. Rajni Patel, Uniexcel Agencies & Services Ltd.) Q & A and Discussions 04.00 PM – 04:30 PM TEA BREAK 04:30 PM – 05:15 PM Technical Session IV: Technology for Zero Liquid Discharge (ZLD) Session Chairperson: Dr. R. P. S. Chauhan, Jt. Vice President (Chlor-alkali), DCM Shriram Ltd., Kota 07:30 PM Cost effective technologies for zero liquid discharge suitable for chlor alkali industry (Dr. J.V. Prasad, Advent Envirocare, Associate Company of Uniexcel & Mr. Rajni Patel, Uniexcel Agencies & Services Ltd. & Mr. Dhwanit Patel, Chem Process Systems) Zero Liquid Discharge – A case study (Mr. G Sankara Subramanian, Chemplast Sanmar Ltd.) Innovations done by DCW Ltd. to reduce water consumption – A case study (Mr. S. Murali, DCW Ltd.) Q & A and Discussions DINNER DAY 2 (15.05.2014) 09:30 AM – 11:00 AM Technical Session V: Reduction, Reuse & Disposal of Brine Sludge & Fly Ash Session Chairperson: Mr. R.S. Rajan, Sr. Vice President, Meghmani Finechem Ltd. Eco-friendly utilization of brine sludge (Mr. Arunesh Bhala, Gujarat Fluorochemicals Ltd.) Alternate use of brine sludge (Mr. Pradeep Joshi, Green Circle Inc.) Disposal & Reuse of Fly Ash generated in CPPs (Thermal Power Plants) (Mr. H.S. Sehgal, Consultant) Disposal & Reuse of Fly Ash generated in CPPs (Thermal Power Plants)- Case study (Mr. Suhas Patil, Meghmani Finechem Ltd.) Handling & Disposal of Fly Ash- Case study (Mr. R.R. Buldak and Mr. Manish Sheth, DCM Shriram Ltd.) Q & A and Discussions 11:00 AM – 11:30 AM TEA BREAK 11:30 AM – 01:00 PM Technical Session VI: Water Conservation, Water Footprint & Water Audit Session Chairperson: Mr. Paresh Trivedi, Executive President (Operations) and Whole Time Director Gujarat Fluorochemicals Ltd. Water Consumption, Recycle and Discharge of effluents in Indian Chlor Alkali Industry (Mr. H.S. Das, AMAI) Water Footprint and Water Audit (Mr. Pradeep Joshi, Green Circle Inc.) Roof Top Water Harvesting – Industry Experience (Mr. Ajay Kumar Kanotra, Siel Chemical Complex) Water Consumption and its Management in Caustic Evaporation and Flaking Unit (Mr. Vikram Bhatt, Bertrams) Q & A and Discussions 01:00 PM End of Conference followed by Lunch 02:00 PM Plant Visit to Grasim Vilayat A Mini- Exhibition of select vendors/ technology suppliers on environment management for chlor-alkali will be held on both days, concurrently with the Seminar and will close by 02:00 pm on Day 2 (15.05.2014).