494-294

advertisement

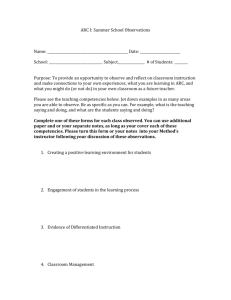

An Electric Arc Furnace Model for Flicker Estimation JOÃO PAULO M. SOUSA, ZÉLIA M. A. PEIXOTO, MARIO F. ALVES, CELSO P. GARCIA. Graduate Program in Electrical Engineering Pontifical Catholic University of Minas Gerais Av. Dom Jose Gaspar, 500 – Coração Eucarístico 30535-610 - Belo Horizonte - MG BRAZIL Abstract This paper presents an arc furnace model using the chaos theory and differential equations describing the arc furnace behavior, the flicker effect particularly. The arc voltage is simulated by solving a differential equation yielding the non-linear dynamic and multivalued v-i characteristics of the arc. In order to simulate the flicker a low-frequency chaotic signal is generated by Chua’s chaotic circuit to modulate this nonlinear system. A flickermeter was developed to calculate the Pst. A methodology is developed that allows for the adjustment of the parameters of Chua`s circuit, according to each particular furnace and feeding power system. Key-words: - Modelling, Arc Furnace, Chua’s Oscilator, Flicker, Flickermeter 1 Introduction The number of electric arc furnaces installations in the metallurgy industry has greatly increased in the last decades. Some reasons for this are the abundance of scrap iron, the necessity of recycling and the possibility of producing metallic leagues with high level of quality at relatively low cost when compared to other forms of energy [1][2][3]. An electric arc furnace transforms the electrical energy into thermal energy in the form of an electric arc to melt the raw materials held by the furnace. The used heat is transferred to the load by radiation and convection. The implantation of an arc furnace generates jobs and attracts new industrial installations, promoting the economic development mainly in the regions of lesser degree of industrial development. However, these furnaces have a great impact on power quality. The voltage fluctuation they impose on the supply system result in the well known flicker phenomena. It is reported that a low level frequency modulation of the supply voltage of less than 0.5% can cause annoying flicker in incandescent lamps when the frequency lies in the range of 6-10 Hz [1][4][5]. The development of an electric arc furnace model constitutes a great challenge. Besides the non linearity and random behavior presented by the arc, it is necessary that the model presents some means for setting its parameters according to each particular supply system feeding the furnace. This work presents the application of the chaos’ theory, more specifically the Chua’s oscillator, to modeling the electric arc furnace in time domain. The voltage signal calculated from the dynamic differential equations of the furnace [6][7][8] is modulated by the low frequency chaotic signal of the Chua’s oscillator output, yielding the random and nonlinear characteristics presented by the furnace`s voltage fluctuation, which is responsible for the resulting flicker. In order to estimate the flicker produced by the furnace in a given power system, a flickermeter was developed using the IEC/UIE Standard [9][10]. An approximated mathematical expression is used to predict the flicker level [11][12] and the resulting flicker value is compared to the value obtained from the flickermeter. The result of this comparison is there used to adjust the parameters of the Chua`s circuit. The arc furnace model and the flickermeter were implemented in the EMTP environment, and an application example used to demonstrate the proposed methodology. 2 The electric arc The arc is an electric discharge, where the load carriers are mainly electrons. After the furnace is charged with scrap, operation begins by lowering the electrodes to strike electric arcs between the electrodes and the scrap. Ignition begins when instantaneous voltage grows beyond a critical value. The arc is extinguished at current zero and it is reignited again in the following semi-cycle. The arc operation is characterized by a low voltage and a high current. The arc presents distinct phases during a typical operation cycle of the furnace. However only the melting and refining phases are normally considered [2][4][5]. In the melting phase, after loading the scrap iron, the three electrodes are lowered, trying to get a stable arc. When fusing begins the scrap iron presents a very irregular surface, causing great current fluctuations since the electrodes regulators are not fast enough to respond to the current variations. In this phase, the arc furnace demands very high active power from the supply system. In the refining phase a longer and more constant arc is adopted. This arc, however, depends on the furnace’s power factor. With a high power factor, above 0.9, the voltage in the instant of the extinguishing of the arc is enough to immediate reignition, resulting in a practically steady arc. On the other hand, for power factors of 0.7 to 0.8, the voltage during the arc extinguishing are not enough for its immediate re-ignition, leading to an unstable arc [4]. 3 The electric arc model The arc furnace model will be developed in three parts. First, the differential equation that represents the dynamic and multivalue v-i electric arc characteristic, is considered. Second, a low frequency chaotic signal is used to represent the voltage fluctuations imposed by the arc. Finally, the chaotic signal is used to modulate the response given by the differential equations. 3.1 The arc furnace v-i characteristic The arc furnace v-i characteristic is obtained from the differential equation that represents the arc dynamics, based on the energy conservation law [13]. The electric arc power balance equation is, p1 p 2 p 3 (1) Where, to simplify the model. Thus the arc radius r appears only as a state variable. p1 k1 r n (2) k1 is an arbitrary constant and n represents the arc cooling constant. If the environment around the arc is hot the arc cooling may not depend on its radius at all, so in this case n=0. If this is not the case and the arc is long, then the cooling area is mainly its lateral surface, so n=1. If the arc is short, then the cooling area is proportional to its cross-section at the electrodes, so n=2. The term p2 is proportional to the derivative energy inside the arc, which is proportional to r 2 , p2 k 2 r dr dt (3) Finally, p 3 vi k3 / r m r2 i2 (4) k2 and k3 are arbitrary constants. In expression (4), the arc column resistance is assumed inversely proportional to r m , where the constant m varies from 0…2. This variance reflects the fact that the arc may be hotter in the interior if it has a larger radius. Substitution of equations (2), (3) and (4) into (1) gives the differential equation of the arc: k1 r n k 2 r k dr m3 2 i 2 dt r (5) The arc voltage is given by, v i g (6) p1 represents the transmission of energy in form g is defined as the arc conductance, and given by the following equation: of heat to the external environment; p 2 represents the internal energy of the arc that directly affects the radius of the arc; p3 represents the total energy developed in the arc and converted into heat. r m 2 g k3 The cooling effect is function of temperature, but this dependency is considered not significant in order (7) It is possible to represent the different phases of the arc modifying the parameters m and n. The complete combination of these parameters for the different arc phases can be found in [13]. In this work, this parameters are chosen as m=0 and n=2 to represent the refining stage and as m=1 and n=2 to represent the melting stage. Figure 1 shows the v-i arc characteristic resulting by solving equations (5) and (6) in time domain, and figure 2 shows the arc voltage waveform simulation to refining stage. 3.2 Chaotic Responses in Arc Furnaces As demonstrated in [8], the electric fluctuation in the arc furnace’ s voltage is of a chaotic nature, and chaos theory [2] may be used to model it. The Chua’s oscillator circuit is used to establish the random and nonlinear characteristics presented by the furnace’s voltage fluctuation. Fig. 3. Chua’s Circuit. The nonlinear element is the Chua's diode (NR). This element has a piecewise linear characteristic and supplies energy to the system guaranteeing the independent oscillation of the circuit. Varying the chosen parameters (L, R, C1 and C2), the circuit can present different dynamics, such as steady fixed points, periodic oscillations and chaotic dynamics [6][7]. 3.3 The Arc Furnace Model The current absorbed from the power system bus is injected as the input model. The electric arc voltage is obtained from the simultaneous solution of equations (5) and (6), and the low-frequency chaotic signal that is generated by the simulation of Chua’s chaotic circuit. The solution of these equations is modulated by the chaotic signal producing the final arc furnace voltage output. The model behaves as a controlled source, with the system current as an input and the terminal voltage value resulting for each time step. Fig. 1. Dynamic v-i characteristics of electric arc. 4 The Flickermeter Model 1000 [V] 750 The IEC flickermeter [9][10][11][14] is used. It has five basics blocs as show figure 4. They are described below. 500 250 0 -250 -500 -750 -1000 0.50 Fig. 4. The IEC flickermeter block diagram. 0.54 0.58 0.62 0.66 [s] 0.70 (f ile MFEAP_PADRAO_ajusteFO.pl4; x-v ar t) v :AFORA Fig. 2. Voltage wave form of electric arc. It has been shown in [6] that for an autonomous circuit consisting of resistors, capacitors, and inductors to exhibit chaos; it has to contain the following components: 1) at least one locally active resistor; 2) at least one nonlinear element; 3) at least three energy-storage elements. The Chua’s circuit shown in figure 3 satisfies the above listed conditions. More details can be found in [6][7]. 4.1 Block 1 - Input voltage adaptor A first step in the meter is to adapt the measured voltage to the internal reference level of the flickermeter. This is done with a transformer connected between the bus voltage and the first block of the meter. An amplifier with adjustable gain (10% to 90%) and a response time of 1 minute to a step of the RMS imput voltage value is used to normalize the voltage signal. The output of this block is a normalized signal. The time constant is sufficient long to make the output signal insensitive to fast changing modulating signal, and short enough to follow slow voltage changes. non-linear visual perception eye-to-brain. The filter (so called sling mean filter) is used to simulate the brain memory. The output of this block represents the bulb-eye-brain sensibility i.e. instantaneous flicker level. 4.2 Block 2 - Squaring operator The output of block 1 feeds block 2. The purpose is to square the input signal. As the incandescent light bulb can be considered as an ohmic load, the output of block two corresponds to the electrical power absorbed by the lamp, which is representative of the flicker. The block 3 has three filters. Two of these constitute a band-pass filter, in order to eliminate the DC components and those components with double fundamental frequency. The first filter is a RC highpass first order with a cut-off frequency of 0.05Hz. The second is a 6th order Butterworth low-pass with a cut-off frequency of 35Hz to a network frequency 50Hz, and 42Hz to network frequency 60Hz. The third filter is a band-pass filter that emulate the transfer function of the bulb-to-eye, and has a cut-off frequency of 8.8Hz that is the max perception bulbto-eye. The transfer function is, K 1 s G ( s ) 2 2 s 2s 1 s 1 2 (1 s )(1 s ) 3 4 (8) with the filter constants as show Table 1. k w1 w2 w3 w4 This block perform a statistical evaluation of the instantaneous flicker perception, represented by the short term perception of the human eye - Pst. The Pst is calculated according to the following relation: Pst 0,1 0,1 1 1 3 3 10 10 50 50 4.3 Block 3 - Filters Constant 4.5 Block 5 – Statistical analysis Incandescent lamp 230V/60W 120v/60W 1,74802 25,50853854 57,5221845 14,32434303 7,699101116 137,6017582 1,6357 26,18438937 57,03353489 18,47194905 8,761700849 108,7941076 Table 1. The filter constants. 4.4 Block 4 - Squaring multiplier and sliding mean filter This block contains a squaring multiplier and a first order low-pass filter with 300ms of cut-off frequency. The purpose of squaring the signal is to simulate a (9) where Pi is the flicker level exceded during a particular percent of the observation time and ki is the weighting coefficient. These Pi values are taken from the comulative distribution curve in 0.1, 1, 3, 10 and 50 % of the simulated time. The flickermeter was calibrated according to standard [9]. 5 ATPDraw implementation The furnace arc model and the flickermeter were implemented in the EMTP environment. The furnace voltage output is the result of the solution of the differential equation (5) combined with a chaotic modulation introduced by voltage Vc1 across capacitor c1 in Chua’s circuit [2]. The amplitude of the system’s voltage fluctuation, and thus, the flicker level, can be adjusted to a higher or lower value, by modifying the value of a gain which is the Chua’s circuit output. Adjusting the values of the elements L and C in Chua’s circuit controls the flicker dominant frequency. It is possible to get an estimation of the flicker level caused by a new installation from statistical analysis of the flicker caused by a large number of arc furnace already in operation. The data needed for this estimation are the parameters of the impedances in the grid [11][12]. The estimation is given by: Pst (99%) K st Pst (95%) X k , grid X k , grid X k , furnace 1 Pst (99%) 1,25 (8) (9) The corresponding data for the studied case (figure 5) are Xk,grid =0,0555 pu and Xk,furnace=0,4154 pu. The furnace factor , which is different for each arc furnace installation, has a typical value of 75. Using these data, equation (8) gives a flicker level estimation given by Pst(95%) =7,072. The voltage waveforms, at the primary of the 138 kV transformer, can be seen in figure 8. 200 [kV] 150 100 6 Simulation Results Figure 5 shows the arc furnace transformer connected to an equivalent power system supply. System data for this configuration can be found in the Appendix. The point of common coupling (PCC) corresponds to the primary of the 138kV transformer. 50 0 -50 -100 -150 -200 2.0 2.2 2.4 2.6 2.8 [s] 3.0 (f ile MFEAP_PADRAO_ajusteFO.pl4; x-v ar t) v :PCCA Fig. 8. Voltage waveform at the primary. Fig. 5. Arc Furnace connection to the power system supply. Figure 6 shows the furnace current waveform in the melting phase. The voltage waveforms, at the secondary of the arc furnace transformer, can be seen in figure 7. 250.0 [kA] 187.5 A simulation for a period of ten minutes (as per IEC 61000-4-15) was carried out, and the flickermeter results on the 138 kV side are indicated by a Pst equal to 6,9798. The calculation uses an iterative process. A first iteration is calculated with the parameters of Chua´s circuit set to a certain value. If the simulated Pst is not the same as that estimated by equation (8), the parameters of the model are adjusted until the two values converge, as shown the diagram in figure 9. 125.0 62.5 0.0 -62.5 -125.0 -187.5 -250.0 3.2 3.3 3.4 3.5 3.6 3.7 [s] 3.8 (f ile MFEAP_PADRAO_ajusteFO.pl4; x-v ar t) c:XX0025-AFORA Fig. 6. Arc Current obtained by simulation. 1500 [V] 1000 500 Fig. 9. Adjusting diagram model. 0 -500 7 Conclusion -1000 -1500 1.5 1.6 1.7 1.8 1.9 [s] 2.0 (f ile MFEAP_PADRAO_ajusteFO.pl4; x-v ar t) v :AFORA Fig. 7. Voltage waveform in the secondary of the furnace transformer. The electric arc furnace model using a combination of the dynamic/multivalue v-i arc characteristics, described by a differential equation, combined with a modulation of chaotic nature, modeled by Chua’s circuit, was implemented. A methodology to adjust the arc-power system model to expected flicker levels was demonstrated, and the results indicated the validity of the model. The model was constructed in time domain and can be easily connected to the electrical net as part of an integrated power system, allowing for broader system’s studies. The authors are working in the implementation of the model in the EMTP computational environment, where it will be integrated to a static flicker compensation system, resulting in a computational program for the analysis of the impact of the connection of an arc furnace to the utility network. Appendix Parameters of the studied system shown in Fig. 7 are shown here: The base pu values were referenced to 100MVA. Source: Ideal sinusoidal ac voltage source with 138 kV and zero phase shift. Zthevenin: resistance R=0.3691 and inductance L=28.0356 mH. Transformer: Two windings linear transformer. Nominal power: Pn=40 MVA (three phase). Winding 1 parameters: V1(Vrms)=138 kV, R1(pu)=0.0096, L1(pu)=0.275 Winding 2 parameters: V2(Vrms)=33 kV, R2(pu)=0.0096, L2(pu)=0.275 Magnetization resistance and reactance: Rm(pu)=50, Lm(pu)=50. Arc Furnace Transformer: Two windings linear transformer. Nominal power: Pn=30 MVA (three phase). Winding 1 parameters: V1(Vrms)=33 kV, R1(pu)=0.0049, L1(pu)=0.1404 Winding 2 parameters: V2(Vrms)=700 V, R2(pu)=0.0049, L2(pu)=0.1404 Magnetization resistance and reactance: Rm(pu)=50, Lm(pu)=50. Arc Furnace: (Parameters for corresponding differential equation) k1=-3000.0, k2=12.5, k3=12.5. (Chua’s circuit) C1= 0.575 nF, C2=150 F, L=2 H with a series resistor, R0= 1634.95 , G=6.1164E-4 mho. Acknowledgements The authors take the opportunity to thank the PPGEE and financial aid by CAPES and CEMIG. References: [1] R. Bellido, T. Gómes, Identification and Modelling of a Three Phase Arc Furnace for Voltage Disturbances Simulations. IEEE Transactions on Power Delivery, Vol. 12, No. 4, 1997. [2] O. Ozgun, A. Abur, Flicker Study Using a Novel Arc Furnace Model. IEEE Transactions on Power Delivery, Vol. 17, No. 4, 2002. [3] C. A. S. Leandro, Fabricação de Aços em Fornos Elétricos. Programa de Educação Continuada, Siderurgia para não Siderurgistas, Capítulo 7, pp. 123-133. Associação Brasileira de Metalurgia e Materiais 1999. [4] T, Zheng, E. B. Makram, An Adaptive Arc Furnace Model, IEEE Transactions on Power Delivery, Vol. 15, No. 3, 2000. [5] G. C. Montanari, M. Loggini, A. Cavallini, ArcFurnace Model for the study of Flicker Compensation in Electrical Networks, IEEE Transactions on Power Delivery, Vol. 9, No. 4, October 1994. [6] M. P. Kennedy, Three Steps to Chaos – Part I: Evolution. IEEE Transactions on Circuits and Systems, Fundamental Theory and Applications, Vol. 40, No. 10, 1993. [7] M. P. Kennedy, Three Steps to Chaos – Part II: A Chua’s Circuit Primer. IEEE Transactions on Circuits and Systems. Fundamental Theory and Applications, Vol. 40, No. 10, 1993. [8] E. Acha, A. Semlyen, N. Rajakovié, A Harmonic Domain Computtional Package for Nonlinear Problems and It`s Aplication to Electric Arcs, IEEE Transactions on Power Delivery, Vol. 5, No. 3, 1990. [9] IEC 61000-4-15. Flickermeter – Functional and Design Specifications, IEC 61000-4-15 International Standard, Electromagnetic Compatibility (EMC) – Part 4: Testing and Measurement Techniques – Section 15, 1st Ed, 1997. [10] UIE Part 5 Flicker and Voltage Flutuation. Prepared by de travail GT “Qualité de l’alimentation” “Power Quality” Working Group WG 2, 1999. [11] T. Larsson, PhD. Theses, Voltage Source Converters for Mitigation of Flicker Caused by Arc Furnaces, Kungl Teknisha Högskolan, 2003. [12] A. Robert, M. Couvreur, Recent Experience of Connection of Big Arc Furnaces with Reference to Flicker Level. CIGRE 1994, Paper 36-305. [13] P. E. King, T. L. Ochs, A. D. Hartman, Chaotic Responses in Electric Arc Furnaces. Journal Applied Physics, vol. 76, no. 4, pp. 2059-2065, 1994. [14] M. Rogós, The IEC Flickermeter Model, AGH Univerity of Science and Tecnology AGH – UST. March 2003.