Microsoft Word

advertisement

Productivity and Proximity

Don J. Webber1 and Paul White2

1

Department of Economics, Auckland University of Technology, New Zealand

2

Department of Statistics, University of the West of England, Bristol, UK

Labour productivity is known to be higher in the presence of

agglomeration economies. This paper presents an analysis of the

shape of the relationship between labour productivity and the

distance between the firm and the region’s central business

district. Based on plant-level data across England our empirical

estimates indicate that this relationship is non-linear.

Keywords: Labour productivity; Distance; CBD.

JEL classifications: C21; R32

Acknowledgements: This work contains statistical data from the Office for

National Statistics which is Crown copyright and reproduced with the

permission of the controller of HMSO and Queen’s Printer for Scotland.

The use of the ONS statistical data in this work does not imply the

endorsement of the ONS in relation to the interpretation or analysis of the

statistical data. This work uses research datasets which may not exactly

reproduce National Statistics aggregates. Any errors are the authors’

responsibility.

1

1.

Introduction

Empirical analyses of within country spatial labour productivity variations

typically focus on either agglomeration economies present within and

between conurbations, or the variation in and evolution of average labour

productivity at an aggregate geographical level, such as the county, state or

prefecture. This may be due to a chosen focus on administrative regions or

restrictive availability of data at a more disaggregated level.

Both of these approaches avoid the explicit calibration of the tradeoff between labour productivity and distance from the core of the market,

and the importance of this relationship has been alluded to in the theoretical

contributions of Hoover (1937), Smithies (1941), Anderson et al (1989),

Hsu (2006) and many others who emphasise the important of location.

Evidence of such a trade-off, essentially linking productivity to proximity,

has repercussions for economic theory (Bivand, 2008). For instance,

theories of monopolistic competition often cite space as an insulating factor

that allows spatially segregated firms to charge higher prices. The

frequently cited example is the petrol/gas station where greater distances

2

between forecourts mean drivers often pay higher petrol/gas prices in rural

areas rather than paying the additional cost of travelling to a cheaper

forecourt. As such spatially segregated firms typically produce low

quantities but charge high prices it may appear that their marginal

productivity is high. This points to the possibility of a U-shaped relationship

between productivity and proximity. Nevertheless the ability of a range of

firms to compete on price in a region’s core city’s central business district

(CBD) reduces with greater transportation costs, which suggests the

presence of a negative relationship as value added per worker would be

squeezed to compensate for transportation costs. These relationships could

have changed over time (Glaeser and Kohlhase, 2004) but the death of the

importance of distance may well be premature (Reitveld and Vickerman,

2004).

Although area based studies, such as Harris (1954), Clarke et al.

(1969), Keeble et al. (1982) and Overman et al. (2003), often examine

market-potential by weighting purchasing-power by transportation costs,

few studies consider the microeconomic foundations of productivity for

geographically defined economies. Despite generalisations there is a lack of

3

evidence supporting the presence of a productivity-proximity trade-off at

the plant-level. This paper fills this gap in the literature by presenting an

empirical investigation into the influence of distance on labour productivity.

We employ data for 16,410 plants within England which we match at the

district level to data relating to the distance between the district and the

region’s core city’s CBD.

2.

Model

Plant-level data for labour productivity is modelled below using OLS

regression. Potential explanatory variables include the number of workers,

capital stock per worker, distance to the CBD and a dummy variable to

indicate plant status. Here ‘plant status’ refers to whether there is more than

one plant within an establishment (firm). For instance, plants can be

location-specific outlets for identical goods produced by the establishment

(e.g. different outlets of a supermarket chain) or plants could specialise in a

different stage of the production process within an establishment (e.g.

where a firm’s R&D/product design takes place in one plant and its product

4

manufacture occurs in another plant). If the plant status is equal to 0, then

there is only one plant within the establishment; if the plant status is equal

to 1, then there is more than one plant within the establishment and this

could be associated with either scale or diseconomies of scale, which again

would depend on the nature of the establishment.

The modelling strategy is to extend the regression model by

including a quadratic term for the distance to the region’s CBD, and to

further extend it by including a cubic term for the distance to the region’s

CBD. The inclusion of the quadratic and cubic terms has the potential to

induce a high degree of undesirable correlation between explanatory

variables. For this reason we isolate the unique quadratic and cubic effects

using an orthogonal quadratic and orthogonal cubic term using the GramSchmidt orthogonalisation process (see Draper and Smith, 1981).

The model is further extended through the inclusion of interaction

terms between the multi-plant dummy variable and all other explanatory

variables so as to ascertain whether the rate of change of labour productivity

varies differentially with the explanatory variables according to plant status.

5

3.

Data

Analyzing business performance at the plant-level overcomes the

shortcomings of working with aggregate data, in particular by providing an

unambiguous association between output and the workforce responsible for

generating it. In this analysis we use data held by the UK’s Office for

National Statistics in their Annual Respondents Database (ARD2) (ONS,

2002), which includes data on the number of employees, gross value added

and the amount of capital stock which relates to individual business units.

Data on firm-specific capital stock is obtainable from the ONS and is

matched with plant-specific data within the ARD2.

Factors affecting labour productivity ultimately act by influencing

the operational performance of firms. Our sample is comprised of all firms

across all industrial sectors of England, and is therefore of interest to policy

makers associated with infrastructure and local economic development.1

The district in which the plant is located is identifiable from the

ARD2. For simplicity, UK districts are sub-divisions of counties, and

1

An analysis that disaggregates by sector could be carried out if the policy maker were

only interested in firms from that specific sector.

6

counties are subdivisions of regions – the UK has 9 administrative regions.

We calculate the distance between each plant’s district location and the

region’s core city’s CBD. Distance data is sourced separately from the AA

website (www.theAA.com). Essentially this distance reflects the level of

past infrastructural investments and is responsive to long term policy

initiatives to improve transport infrastructure. The longer the period of time

it takes to move goods to the location of consumption or intermediate

productive use then the greater will be the incurred transportation costs and

the less competitive the firm will be in the region’s core market place.

Table 1 provides mean and median values for labour productivity

and for all potential explanatory variables. The average distance from a

plant’s district to a region’s core city’s CBD is 34 miles, but this distance

varies from zero (where the plant is located in the region’s core city’s CBD)

to 195 (where the plant is located in the Isles of Scilly).

{Table 1 about here}

7

4.

Results

Table 2 summarises the regression models without consideration of

interaction terms involving plant status. In Model 1a there is a statistically

significant average increase in (the logarithm of) labour productivity with

labour productivity increasing by a factor of 1.06 for multi-plant

organisations compared with single-plant organisations (p<0.001). In

regression Model 1a a doubling of capital stock per worker is associated

with labour productivity increasing by a factor of 1.2 (p<0.001). Also note

that there is evidence of decreasing returns to scale from the employment

variable. These effects are essentially constant irrespective of whether

quadratic or cubic terms for the Euclidean distance to the CBD are included

in the model (see Model 1a to 5a, Table 2).

{Table 2 about here}

In the fitted model (Model 1a, Table 2) there is a statistically

significant negative linear association between distance and labour

8

productivity (p<0.001), with a ten mile decrease in distance being

associated with labour productivity increasing by a factor of 1.03. The

square of distance produces an additional statistically significant unique

effect (see Model 2a and Model 4a, Table 2) and the same can be seen for

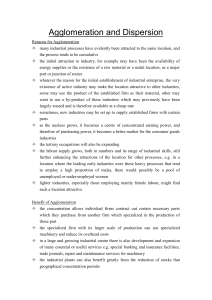

the cube of distance (see Model 3a and Model 5a, Table 2). A graphical

summary of the cubic model (for single- and multi-plant firms) is given in

Figure 1, where this graphic is based on the logarithm of capital stock per

worker and the logarithm of employment held at mean values. The graph

illustrates that there is neither a simple linear nor a simple quadratic

relationship between labour productivity and distance; instead it appears

that there is a combination of these two effects suggesting that the

relationship between distance and labour productivity is complex. Further it

indicates that a simple one-size-fits-all model may be systematically biased

and it questions whether scale economies are uniform across locations, as

the gap between single- and multi-plants become very small in very

peripheral locations.

{Figure 1 about here}

9

Table 3 summarises the regression models which include interaction

effects with plant status and all other explanatory variables. All models in

Table 3 capture a statistically significant interaction between plant status

and capital stock per worker on labour productivity with a doubling of

capital stock per worker being associated with labour productivity

increasing by a factor of 1.19 for single-plant firms and increasing by a

factor of 1.24 for multi-plant firms; this difference in effects is statistically

significant (p<0.001). Interestingly there is evidence from the interaction

between plant status and logarithm of employment that single-plant firms

do not suffer from diseconomies of scale and that this is a characteristics of

multi-plant firms in general. Nevertheless in all models in Table 3 there is

no differential effect between linear (p=0.245), quadratic (p=0.527) and

cubic (p=0.614) distance with productivity and plant status.

{Table 3 about here}

A repercussion of these results is that technological improvements

that have facilitated declines in distance costs have not resulted in an

10

eradication of the spatial labour productivity divide across English regions,

and therefore are in line with Reitveld and Vickerman (2004).

5.

Conclusion

Accessibility to the core of the market is known to affect pricing decisions

and is embedded in much of the literature on location theory. However most

empirical analyses that address spatial variations in labour productivity

typically focus on either agglomeration economies or the variation in and

evolution of average labour productivity at an aggregate geographical level.

This paper presents an empirical investigation which sought to

identify the shape of the relationship between labour productivity and the

distance to the core of a region’s central business district using plant-level

data across England. The results from our regression analyses suggest that a

plant’s labour productivity is negatively and non-linearly related to its

distance to its region’s core city’s central business district.

11

References

Anderson, S. P., de Palma, A. and Thisse, J.-F. 1989. Spatial price policies reconsidered.

Journal of Industrial Economics 38(1), 1-18

Bivand, R. 2008. Implementing representations of space in economic geography. Journal

of Regional Science 48, 1-27

Clarke, C., Wilson, F. And Bradley, J. (1969) “Industrial location and economic potential

in Western Europe”, Regional Studies 3, 197-212

Draper, N. and Smith, H. 1981. Applied regression analysis, John Wiley and Sons, New

York

Glaeser, E. L. and Kohlhase, J. E. 2004. Cities, regions and the decline of transport costs.

Papers in Regional Science 83, 197-228

Harris, C. (1954) “The market as a factor in the localisation of industry in the United

States”, Annals of the Association of American Geographers 64, 315-48

Hoover, E. M. 1937. Spatial price discrimination. Review of Economic Studies 4(3), 182191

Hsu, S.-K. 2006. Simple monopoly price theory in a spatial market. Annals of Regional

Science 40, 531-544

Keeble, D., Owens, P. L. And Thompson, C. (1982) “Regional accessibility and economic

potential in the European Community”, Regional Studies 16, 416-432

Overman, H. G., Redding, S. And Venables, A. J. (2003) “The economic geography of

trade, production and income: A survey of empirics” in Handbook of International

Trade (eds.) Kwan-Choi, E. And Harrigan, J. Basil Blackwell, Oxford, pp. 353-387

Reitveld, P. and Vickerman, R. 2004. Transport in regional science: The “death of

distance” is premature. Papers in Regional Science 83, 229-248

Smithies, A. 1941. Optimal location in spatial competition. Journal of Political Economy

49(3), 423-439

12

Table 1: Descriptive statistics

Mean

Median

Log of labour productivity

3.289

3.342

Log of capital stock per worker

3.297

3.373

Log of employment

3.804

4.025

Distance in miles

34.290

28.000

2

Distance in miles

2111.991 784.000

Distance in miles3

176844

21952

Log of capital stock per worker * multi-plant dummy

1.254

0

Log of employment * multi-plant dummy

1.974

0

Distance in miles * multi-plant dummy

11.649

0

2

Distance in miles * multi-plant dummy

711.675

0

Distance in miles3 * multi-plant dummy

59445.36

0

n=16,410

13

Table 2: Regression Models

Distance in miles

1a

0.275**

(0.005)

-0.015**

(0.004)

-0.003**

(2.35e-04)

Distance in miles2

–

Distance in miles3

–

–

Orthogonal distance2

–

–

–

Orthogonal distance3

–

–

–

Log (capital stock per

worker)

Log (employment)

2a

0.275**

(0.005)

-0.015**

(0.004)

-0.004**

(0.001)

1.33e-05**

(4.55e-06)

3a

0.275**

(0.005)

-0.015**

(0.004)

-0.008**

(0.001)

9.37e-05**

(2.07e-05)

-3.66e-07**

(9.19e-08)

4a

0.275**

(0.005)

-0.015**

(0.004)

-0.003**

(2.35e-04)

5a

0.275**

(0.005)

-0.015**

(0.004)

-0.003**

(2.35-e04)

–

–

–

–

1.33e-05**

(4.55e-06)

1.34e-05**

(4.54e-06)

-3.66e-07**

(9.19e-08)

0.057**

(0.019)

2.517*

(0.022)

636.22**

(<0.001)

0.189

0.058**

0.058**

0.057**

0.058**

(0.019)

(0.019)

(0.019)

(0.019)

2.513**

2.538**

2.574**

2.515**

Constant

(0.022)

(0.024)

(0.025)

(0.022)

946.95**

759.61**

636.22**

759.61**

F (prob.)

(<0.001)

(<0.001)

(<0.001)

(<0.001)

R2

0.188

0.188

0.189

0.188

Notes: n=16,410. ** indicates statistical significance at the 1% level.

Multi-plant dummy

14

Table 3: Regressions with compound variables

Distance in miles

1b

0.257**

(0.005)

-0.005

(0.005)

-0.003**

(2.87e-04)

Distance in miles2

–

Distance in miles3

–

–

Orthogonal distance2

–

–

–

1.57e-05**

(5.63e-06)

Orthogonal distance3

–

–

–

–

0.055**

(0.008)

-0.031**

(0.006)

5.41e-04

(4.66e-04)

0.054**

(0.009)

-0.032**

(0.007)

0.001

(0.001)

-5.81e-06

(9.19e-06)

0.053**

(0.009)

-0.034**

(0.007)

0.002

(0.002)

-2.81e-05

(4.12e-05)

9.45e-08

(1.87e-07)

0.055**

(0.008)

-0.031**

(0.006)

0.001

(4.66e-04)

1.68e-05**

(5.64e-06)

-4.16e-07**

(1.13e-07)

0.055**

(0.008)

-0.032**

(0.006)

6.14e-04

(4.66e-04)

–

–

–

–

-8.38e-06

(9.54e-06)

1.18e-07

(1.95e-07)

2.552**

(0.023)

386.93**

(<0.001)

0.191

Log (capital stock per worker)

Log (employment)

Log (capital stock per worker)

* Multi-plant dummy

Log (employment)

* Multi-plant dummy

Distance in miles

* Multi-plant dummy

Distance in miles2

* Multi-plant dummy

Distance in miles3

* Multi-plant dummy

Orthogonal distance2

* Multi-plant dummy

Orthogonal distance3

* Multi-plant dummy

–

3b

0.257**

(0.005)

-0.005

(0.005)

-0.009**

(0.001)

1.06e-04**

(2.51e-05)

-4.08e-07**

(1.11e-07)

4b

0.257**

(0.005)

-0.005

(0.005)

-0.003**

(2.87e-04)

5b

0.257**

(0.005)

-0.005

(0.005)

-0.003**

(2.87e-04)

–

–

–

–

–

–

–

–

–

-6.38e-06

(9.53e-06)

–

–

–

–

2.575**

(0.025)

481.06**

(<0.001)

0.190

2.615**

(0.027)

386.90**

(<0.001)

0.191

2.550**

(0.023)

481.07**

(<0.001)

0.190

2.547**

(0.023)

639.59**

F (prob.)

(<0.001)

R2

0.189

Notes: see notes on Table 1

Constant

2b

0.257**

(0.005)

-0.005

(0.005)

-0.004**

(0.001)

1.55e-05**

(5.56e-06)

15

20.0

Single Plant

Multi-Plant

Labour Productivity

17.5

15.0

12.5

10.0

7.5

5.0

0

40

80

120

160

200

Local Distance

Figure 1: Distance and labour productivity

16