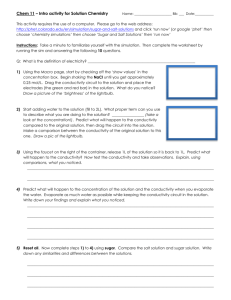

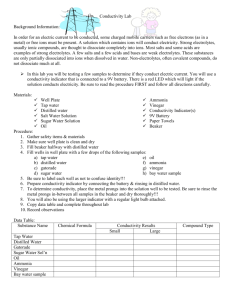

1-57

advertisement

MODELING PHYSICAL PROPERIIES OF MOLTEN FLUORIDEOXIDE MELTS A. Redkin, Yu. Zaikov, O. Tkacheva, A.Dedyukhin Institute of High Temperature Electrochemistry Ekaterinburg, Russia INTRODUCTION Fluoride and oxide melts have some common features because they are ionic liquids but at the same time they have differences, first of all molten oxides are glass-like viscous liquids. Fluoride–oxide molten systems such as calcium fluoride based fluxes and cryolite alumina melts are often used as a media for different technological processes therefore the properties of these systems are very important. At present the modeling methods describing properties of halide melts from one hand and oxide melts from other hand are very different. There is a necessity to find some common points for modeling physical properties of halide-oxide melts. Such common point can be the periodical table of elements. Bockris et.al. (1) found that influence of different components of molten glasses on electrical conductivity depends on the valence of cation. All cations were divided into 3 groups. The first group is of alkali cations: Li+, Na+, K+. The second intermediate one is formed by divalent cations: Mg2+, Ca2+, Sr2+, Ba2+, Mn 2+ and Fe2+. Al3+ and Ti4+ belong to the third group. The most conductive are cations of the first group and the less conductive are cations of third group. The close regularity connecting valence and electrical conductivity was found by Biltz and Klemm (2). They divided all molten chlorides according to the place of cation at Periodic Table on good and bad conductors. This classification can be explained by ionic potential (IP) of cations (3). According to this approach all molten salts can be divided into 4 groups: 1. Ideally conducting salts; 2. Good conductors; 3. Bad conductors; 4. Isolators. Electrical conductivity of molten salts is determined by cation mobility which depends on electronic structure of cation. Ionic potentials of cations which reflect their structure are presented in Table 1. In order to compare electrical conductivity of different salts obtained at different temperatures the electrical conductivity values were divided on temperature vales at which it was measured. These “related” values are presented in Table 2. The certain values of ionic Li(+) Be(2+) B(3+) C(4+) LiF 17 Na(+) 10 K(+) 8 Rb(+) 7 Cs(+) 6 64 Mg(2+) 31 Ca(2+) 20 Sr(2+) 17 Ba(2+) 15 150 Al(3+) 66 Sс(3+) 40 Y(3+) 33 La(3+) 28 250 Si(4+) 110 Ti(4+) 61 Zr(4+) 55 Hf(4+) 55 7,4 NaF 3,9 KF 3,1 RbF 2,7 CsF 2,9 BeF2 1·10-4 BF3 C(4+) MgF2 2,3 AlF3 ? Si(4+) CaF2 3,5 SrF2 3,2 BaF2 2,9 SсF3 0,3 YF3 0,5 LaF3 0,8 Ti(4+) ZrF4 0,01 Hf(4+) Table 2.“Related” electrical conductivity (Ohm-1.cm-1·T-1·103) Table 1. Ionic potential of cations (IP)(nм-1) 1-57 potential correspond to the certain values of electrical conductivity. Cations with ionic potential less than 30 nm-1 form the first group of ideally conducting salts, that is systems with the lowest ionic potential and highest conductivity. Salts with IP more 30 nm-1 and less then 50 nm-1 form the second group of good conductors. Salts with IP in range 50-100 nm-1 are bad conductors. Certainly, this classification is rather relative. In order to describe the properties of salts in accordance with their structure it is better to base on the real measured property such as molar volume which is determined by ionic potential. Hence, the electrical conductivity can be also presented as a function of molar volume and temperature. ELECTRICAL CONDUCTIVITY OF MOLTEN FLUORIDES Alkali fluorides have lowest ionic potentials and form the first group of ideally conducting salts. Alkaline earth fluorides also possess high electrical conductivity with exception of BeF2 and MgF2. BeF2, AlF3, ZrF4, HfF4, TaF5 and NbF5 form the group of bad conductors. The dependence of specific conductivity for molten alkali fluorides on molar volume at constant temperature is presented in Fig. 1. It can be described by logarithmic equation at constant temperature. As the conductivity is temperature depending property it can be presented as function of temperature and molar volume by the following equation: 6,666 exp( 13487 V ) exp( 9,52 276 ) T V V2 1052 [1] where V – molar volume (cm3/mol); - specific conductivity, Ohm-1·cm-1; T temperature, K The equation [1] is valid in temperature rang from melting point to 1400 K. In Fig. 1 the extrapolated values of electrical conductivity and molar volume of alkali earth fluorides are also shown. It is possible to apply the equation [1] to the alkaline earth fluorides conductivity (at high temperature) excepting MgF2. 2,5 Li 2,3 lnχ , Ohm-1. cm-1 2,1 1,9 Na 1,7 CaF 2 K 1,5 1,3 Rb Cs 1,1 SrF 2 BaF 2 MgF 2 0,9 0,7 0,5 0,01 0,02 0,03 0,04 0,05 0,06 0,07 1/V, V (cm3/mol) Fig. 1. Electrical conductivity of molten alkali and alkali-earth fluorides at 1400 K [4]. 1-58 The equation [1] is also valid for fluoride mixtures such as LiF-NaF, NaF-KF. The comparison of experimental [4] and calculated on equation [1] values of the NaF-LiF and NaF-KF conductivity is given in Table 3. The electrical conductivity values agree within 10 %. KF, mol.fr. 0 0,12 0,2 0,25 0,37 0,4 0,5 0,63 0,88 1 Table 3. The calculated and experimental [4] conductivity in NaF-LiF and NaF-KF systems at 1273 K NaF-KF LiF-NaF χcalc – χexp χcalc – χexp __________ , __________ , χcalc, χexp. NaF, χcalc, χexp. eq. (1) [6] χexp. mol.fr. eq. (1) [6] χexp. % % 5,14 5,39 4,6 0 9,55 9,97 4,2 4,84 0,15 8,32 8,64 3,7 4,68 4,69 0,2 0,3 7,41 7,52 1,5 4,52 0,375 7,05 7,04 0,1 4,35 0,5 6,52 6,75 3,4 4,31 4,49 4,0 0,6 6,16 6,00 2,7 4,20 0,8 5,57 5,83 4,5 4,07 1 5,09 5,28 3,6 3,89 4,26 8,7 3,82 4,27 10,5 ELECTRICAL CONDUCTIVITY OF THE GLASS-LIKE FLUORIDES There are some fluoride melts which are glass-like, such as BeF2. Their properties are very similar to glasses: high viscosity, high temperature coefficient of electrical conductivity and so on. The electrical conductivity change with melt composition in system LiF-BeF2 is shown in Fig.2. The isotherm can be divided into two parts. The mixture has high conductivity in the concentration range up to 50 mol.% of BeF2. The properties of such mixtures are determined mainly by the lithium fluoride properties. It is seen from dependences of conductivity (χ) and density (ρ) temperature coefficients (5, 6) (ρ = ρo – BT and lnχ = A – B/T), see Fig 3. The temperature coefficients of physical properties reflects structure peculiarities of any system. The temperature coefficients in the LiF rich region don’t change essentially and are close to the coefficients of pure lithium fluoride. Conductivity, Ohm-1Cm-1 10 8 6 4 2 0 0 0,2 0,4 0,6 BeF2, mole fraction 0,8 1 Fig. 2. Specific conductivity of LiF-BeF2 molten system at 1273 K (5). 1-59 The absolute values of electrical conductivity also reflect the difference between ionic and glass-like melts (beryllium fluoride rich region) in the LiF-BeF2 system (see fig.3). Thus, the electrical conductivity of this system at concentration rang 0-50 mol.% BeF2 can be described by the equation (3): 6,666 exp( 13487 V ) exp( 9,52 276 ) exp( 1,65 N ) T V V2 1052 [2] where V – molar volume (cm3/mol); - specific conductivity, Ohm-1·cm-1; T temperature, K; N - BeF2 content, mole fraction. The comparison of experimental and calculated data is given in Table 4. conductivity 25 0,6 0,5 20 0,4 15 0,3 10 0,2 5 0,1 0 Density temperature coefficient, -4 10 Electrical conductivity temperature 3 coefficient, 10 density 0 0 0,2 0,4 0,6 BeF2, m.fr. 0,8 1 Fig. 3. The electrical conductivity and density temperature coefficients in the LiF-BeF2 system. Table 4. The calculated and experimental (5) conductivity in the LiF-BeF2 system at 1200 K χcalc – χexp __________ , BeF2, χcalc, χexp. mol.fr. eq. (2) [6] χexp. % 0 0,1 0,2 0,3 0,4 8,91 6,94 5,42 4,03 3,27 8,93 6,42 4,97 4,03 3,37 0,3 7,4 8,2 0,01 3,1 ELECTRICAL CONDUCTIVITY OF THE CAF2-AL2O3 MOLTEN SYSTEM The LiF-BeF2 system can be used as a model system for describing fluoride-oxide melt properties. There are electrical conductivity data (14, 15) for system CaF2- 1-60 MeOx, where MeOx = CaO + MgO+Al2O3+FeO+Fe2O3+SiO2+MnO. The dependence of electrical conductivity temperature coefficient on composition of fluxes is given in Fig.4. The change of the temperature coefficient with oxide composition is similar the change of the temperature coefficient with beryllium fluoride content in the LiF-BeF2 system. Thus the equation [1] with additional coefficient can be applied to describe the electrical conductivity of CaF2-Al2O3 system: 6,666 exp( 13487 V ) exp( 9,52 276 ) exp( 2,5 N ) T V V2 1052 [2] where N - Al2O3 content, mole fraction. The coefficient (-2,5) was obtained for cryolite-alumina melts (7). The comparison of experimental and calculated electrical conductivity values is presented in Fig. 5. Data on density and electrical conductivity were taken from (8, 9). 14 Electrical conductivity temperature 3 coefficient, 10 12 Fig. 4. Electrical conductivity temperature coefficient in calcium fluoride based flux depending on oxide content (14, 15) 10 8 6 4 2 0 0 0,1 0,2 0,3 0,4 0,5 0,6 0,7 0,8 0,9 1 Content of oxides, m.fr. -1 6 Electrical conductivity, Ohm cm 7 -1. 8 calculation experiment 5 4 3 2 1 0 0 0,1 0,2 0,3 0,4 Al2O3, m.fr. 1-61 0,5 0,6 Fig. 5. Comparison of calculated [eq.2] and experimental (14) electrical conductivity in system CaF2Al2O3 ELECTRICAL CONDUCTIVITY OF CRYOLITE-ALUMINA MELTS Cryolite-alumina melts are the basic electrolytes for industrial production of aluminum. The effect of alumina concentration on their electrical conductivity is very important. There are a lot of investigations into the electrical conductivity of alumina containing cryolites (10-13). It is a matter of fact that conductivity values decrease with alumina content. The analysis of existing information allows derivation of the following equation: 13487 V )exp( 9,52 + 276 ).exp(-1,65N )exp(-2,5N ) [3] 1 2 T V V2 1052 χ = 6,666exp(- where N1 и N2 – AlF3 and Al2O3 concentrations, mole fraction. The comparison of experimental and calculated data are shown in Fig. 6. Conductivity, Ohm-1.cm-1 3 calculation [10] [11] 2,8 2,6 2,4 2,2 2 0 0,02 0,04 0,06 0,08 0,1 Al2O3, mole fraction Fig. 6. The specific electrical conductivity of Na3AlF6-Al2O3 system CONCLUSION The preliminary knowledge of some properties of fluoride-oxide melts allows evaluating the possibility of technological usage of new compositions. The approach proposed in this paper makes it possible modeling physical properties of new compositions which are perspective for industrial applications. REFERENCES 1. 2. 3. 4. Bockris J. O’M. , Kitchener J.A., Ignatovich S. and Tomilson J.W. Trans. Faraday Soc., 1952, 48, 75 W. Biltz und W. Klemm. Z. Anorg. Alg. Chem., 1926, 152, 267 A. Redkin, Yu. Zaikov , O.Yu. Tkacheva, V. Kryukovsky. Proceedings of 7th International Conference on molten salts chemistry and technology, Toulouse, France, 2005 G.J. Janz et al. Electrical conductance, density, viscosity and surface tension data. J. Phys. Chem. Ref. Data, V.3, 1, 1-115, 1974 1-62 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. 15. V.N. Desyatnik , A.P. Koverda, G.P. Bystray. Russian Journal of Applied Chemistry, 1979, 52, 2, 316-319 S. Cantor, W.T. Ward and C.T. Moynihan J. Chem. Phys. 1969, 50, 2874 A.P. Apisarov et al. Russian journal of Electrochemistry 2007, 43, 8,870 A. A. Akberdin , I.S. Kulikov, V.A. Kim, A.K. Nadyrbekov, and A.S. Kim. Physical properties of CaO-SiO2-Al2O3-CaF2 molten system. Moscow. Metallurgia, 1987 B.M. Lepinskikh, A.A. Belousov, S.G. Bukhalov, A.A. Vostryakov, E.A. Pastukhov , and E.A. Popova. Transport properties of metallic and slag melts. Moscow. Metallurgia, 1995 E.W. Jim and M. Feinleib. J. Electrochem. Soc. 1957, 104, 626 K.Grothiem, C.Krohn, M.Malinovsky, K. Matiashovskyand J. Thonstad, Aluminium Electrolysis. Fundumentals of Hall-Heroult Process, 2nd ed., Aluminium Verlag GmbH, Dusseldorf, 1982 J.Hives, J. Thonstad , A. Sterten , and P. Fellner. Light Metals, 1994, 187 Danek, M. Chrenkova and A. Silny. The International Harald Oye Symposium, Trondhiem-Norway, Febriary 2-3 , 83,1995 P.P. Evseev, and A.F. Filipov. Izvestia Vuzov, Tsvetnaya Metallurgia, 1965, 3, 70 P.P. Evseev, and A.F. Filipov. Izvestia Vuzov, Tsvetnaya Metallurgia, 1965, 3, 76 1-63