Duty to Accommodate Action Plan

advertisement

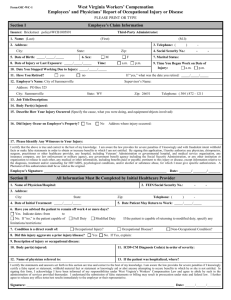

DUTY TO ACCOMMODATE By Jane Dekeyser R.N., BA,COHN© and Toni Whibbs Human Resources Professional OOHNA Journal • SPRING 2006 The legislative requirements of “duty to accommodate” as applied in a manufacturing environment are sometimes unwieldy and challenging when applied to the normal day to day operations in a production environment. In our roles as a human resources manager and occupational health nurse, we have found that certain approaches and applications create a proper fit when striving to meet the needs of the individual employee while balancing the requirements of production and the legislation. In application, we found success in using the following practices. EMPLOYEE TRAINING AND DEVELOPMENT Employee training and development was broken down into several different modules:one module for managers, one for shop floor supervisors,and one for production employees. We found that the best approach was to prepare the management team first using a business case type of argument demonstrating the ultimate cost that would be incurred by the company if accommodation did not take place. We demonstrated how one Workers’ Compensation claim could cost the company $275,000 if the injured employee was not appropriately re-integrated into the workplace through accommodation. Accommodating employees can become complex and costly if it is not properly managed. We also provided some clarification on duty to accommodate as a legal requirement under Human Rights and associated issues such as what constitutes undue hardship,employer obligations, the expanding scope of “disability”, and the practical interpretation of accommodation. This training provided our managers and supervisors with a sound working knowledge of their roles and responsibilities in supporting our policy concerning duty to accommodate. In addition, they gained a much better understanding of the legal requirements of duty to accommodate. We designed a basic training module for all employees at all levels on duty to accommodate legislation and its application. Training was also provided on the fundamentals of workers’ compensation legislation. The Workplace Safety & Insurance Board videotape, Early & Safe Return To Work-Developing a Return To Work Program was used to complement the training. Managers and supervisors were introduced to the concept of an ergonomic program as a tool to prevent injuries and to facilitate successful return to work following an occupational injury. Employees underwent training in ergonomic principles including identification of risk factors and prevention measures. THE TRANSITIONAL RETURN TO WORK PLAN When an employee returns to work following a workplace injury and he or she has certain restrictions, the occupational health nurse interprets those restrictions in relation to jobs. At this point, the occupational health nurse, in partnership with the employee and employee’s supervisor prepares a documented transitional return to work plan. The return to work plan is the KEY. It should include things like: hours of work, the timeframe for the restrictions, production restrictions and gradual production increases. This plan serves as an essential reference going forward. The plan needs to be signed by the employee, the employee’s supervisor and the occupational health nurse; the employee’s supervisor assumes responsibility for the practical application of the plan as it applies to the employee. The plan can only be changed with the agreement of all three parties. It is up-dated periodically to ensure new rehabilitation goals are incorporated into the plan as progress is made toward a return to full time duties. Duty to Accommodate Action Plan • Employee Training and Development • Transitional Return to Work Plan • Statistical Injury Analysis • Preventative Programs STATISTICAL INJURY ANALYSIS One of the most difficult challenges for supervisors is to find meaningful modified work for employees needing temporary accommodation. To assist them in this regard the occupational health nurse performed an extensive injury trend analysis utilizing all of the relevant employee injury statistics such as type of injury, injury location, mechanism of injury and dates, times and shifts. Among other things, the trends analysis indicated the high-risk jobs and which body parts were affected by specific jobs. It was determined that some of the low risk jobs would be set aside to be performed by workers on modified duty. Because this was a unionized environment, the union’s co-operation needed to be secured before proceeding with this plan. The union understood and supported the plan. The trends analysis results also prioritized ergonomic projects for the occupational health nurse and the ergonomics committee consisting of the plant engineer, a production manager and employee volunteers. Occasionally with high-risk jobs, professional ergonomic services were retained and subsequent changes to the job method and/or change to the workstation were recommended. PREVENTATIVE PROGRAMS An ergonomic program was designed by the occupational health nurse to include job demands analysis and identification of ergonomic risk factors in those jobs analyzed. The program emphasized early reporting of injuries and early placement on modified duty. Job rotation was introduced and support garnered from both employees and managers. The Plant Engineer was instrumental in the introduction of more engineering controls to minimize risk while at the same time maintain production requirements. CONCLUSION Every workplace is going to experience situations involving “duty to accommodate.” We have learned that the best way to manage these issues is to be prepared in a proactive manner. Accommodating employees can become a complex and costly issue if it is not properly managed. We have tried to share some of the strategies that were successful for us. We believe that the emphasis needs to be placed on creating a practical model for helping employees with disabilities return to the workplace and resume their positions as valuable members of the production team.