Sample of Invited Plenary Lectures (Keynote Speaker)

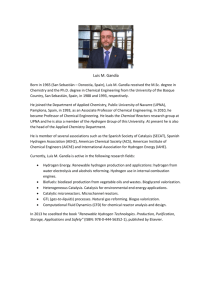

advertisement