to Manuscript Form

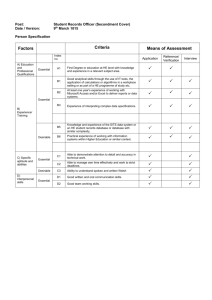

advertisement

Adsorption of Surfactant on Inks Related to Paper Recycling Thitipong Kornprapakul,* Kitipat Siemanond,* Kunchana Bunyakiat* and John F. Scamehorn† * The Petroleum and Petrochemical College, Chulalongkorn University, Bangkok, Thailand 10330; †Institute of Applied Surfactant Research and School of Chemical Engineering and Materials Science, The University of Oklahoma, Norman, Oklahoma 73019 Adsorption of surfactant at the solid-aqueous solution interface has been extensively studied to understand interactions between the surfactant and the solid surface. In the present study, the influence of pH and calcium concentration on the adsorption of sodium dodecyl sulfate (SDS) onto carbon black surface was investigated. Measurements of electrokinetic potential of suspensions of SDS-adsorbed carbon black particles were combined in order to monitor the variation in potential as a function of adsorption. The results showed that the adsorption of SDS onto carbon black gave strong interactions between the hydrophobic tail group of SDS and the carbon surface. The presumed configuration of the adsorbed SDS molecule was tail-down and/or laying down orientation. The effect of pH was not found to be significant on the adsorption of SDS while the addition of a calcium salt enhanced SDS adsorption. INTRODUCTION Adsorption of surfactants at the solid-aqueous solution interface has been extensively studied to understand interactions between the surfactants and the solid surface since surfactant adsorption can play a critical role in many important industrial applications of surfactants such as wetting, adhesion, flotation, dispersion stability, detergency, and thin-film formation (2). One of many substantial surfactant-based separation technologies, flotation or froth flotation is today considered one of the most efficient method for removing solid particles from suspensions such as ore pulps, algae, clays, and colloid precipitates. The principal area of flotation application is still in the mining industry. However, because a large amount of paper consumption and the use of recycled waste paper have numerous environmental and operating benefits, so the basic knowledge of flotation has been transferred and developed to the paper recycling process. In flotation deinking process, generally long chain fatty acid collectors are used as surfactant and also combined with calcium acting as an activator. Such collectors, for example oleic acid, have limited solubility at room temperature in the presence of calcium ions, due to a specific complexing reaction. The deinking flotation is carried out in the high pH range, which both ink particles and the collector species are negative charge, and it has been suggested that the calcium induces a bridging mechanism with the anionic fatty acid species. This idea was proposed by Hornfeck (4). Calcium ions may possibly interact with the negatively charge surface groups on the ink particles, and then the adsorbed calcium ions will reduce the negative charge and can lead to a carboxylic bridging mechanism with the calcium ions specifically adsorbed on the negatively charged sites of the ink particles. However, there is a possibility of the occurrence of calcium soap precipitate layers around the ink particles, micro-encapsulation, due to heterocoagulation of bulk precipitated calcium fatty acid soap particles. The latter † To whom correspondence should be addressed. concept was hypothesized by Larsson et al (5). In fact, there is a possibility of several mechanisms depending on the precise solution conditions and concentrations of fatty acid and calcium ions (11). The advantage of flotation process for removing ink particles from paper fiber is that it is more effective in the removal of large particles or aggregates of particles. In flotation process, there must be a driving force, which causes the particles floating from the solution and adhering to the surface of air bubbles of air rising through the liquid column (12). Though, from the extensively studied ore flotation process, numerous experiments demonstrate that there is a very strong correlation between flotation efficiency and the extent of equilibrium surfactant adsorption on the particles to be floated, but the flotation itself occurs far from equilibrium, and involves imposition of the third interface, the solid-gas interface (12). The understanding of the mechanisms that result in surfactant adsorption at aqueous-solid interface is then important in applying flotation process. Measurements of adsorption isotherms will yield the adsorbed amount, while an understanding of the features of the isotherms can lead to a better understanding of configuration (3). The adsorption of surfactant can be controlled by several factors, including the nature of adsorbing surface (i.e., degree of hydrophobicity, ionic nature), structure of the surface active materials (i.e., character of hydrophobic and hydrophilic portions of the molecules), properties of bulk fluid phase (i.e., electrolyte concentration), and the temperature. The aim of this work is to investigate the flotation mechanism by concentrating on adsorption of surfactant and co-adsorption of calcium on model ink, carbon black, instead of real ink, which may consist of a complex mixture of various pigments and binders, and also attempt to correlate the electrokinetic behavior of surface samples with their adsorption behavior. EXPERIMENTAL A. Materials Carbon black The carbon black (type 400 R) used in the study was manufactured by Carbot Corporation. Because calcium concentration was one of some parameters which was considered, and ionic salts including calcium are present highly in the carbon black, so it was necessary to remove these ionic salts by washing. The carbon black was mixed with distilled and deionized water in the ratio of 1 to 4 and agitated thoroughly. After that the mixture was centrifuged at 2500 rpm for 15 minutes, and water was decanted off. This procedure was repeated 4 times which were sufficient to reduce the calcium concentration in the rinse water to less than 0.2 ppm. Finally the washed carbon was dried at 50 oC for 5 days. The surface area of washed carbon black, which was determined by BET surface area was 96 m2/g. Surfactant Sodium dodecyl sulfate (SDS, C12H25SO4Na) with a purity of 99 % was purchased from Sigma Chemical Company (St. Louis, MO) and used without further purification. Calcium chloride as counterion The reagent grade calcium chloride dihydrate (CaCl2.2H2O) obtained from Fluka Co., Ltd. (Switzerland) was used in the study. Due to the chemical hygroscopic nature, it was necessary to dry at 90 oC for 12 hours just prior to manufacturing the stock solution. pH adjusting solution Sodium hydroxide (NaOH) manufactured by J.T. Baker Chemicals B.V. (Deventer, Holland) was used as received. B. Surfactant Adsorption This experiment was carried out in order to find the amount of solution adsorbed on the solid surface as a function of solution concentration. Twenty ml of solution was added to 2.5 g of washed carbon black in a screw cap vial. The filled vials were allowed to equilibrate at 30 oC for 4 days in a shaking bath. After this time, the equilibrated samples were centrifuged twice by a high-speed refrigerated centrifuge (Sorval Super T21) at 30 oC, 16500 rpm for 20 minutes. The supernatant liquid was taken out by disposal pipette, and kept in screw cap vial for further analysis. The supernatant liquid was then analyzed for the residual concentrations of surfactant and calcium. SDS concentrations were determined by High Performance Liquid Chromatography or HPLC (Hewlett Packard series 1050) with an electrical conductivity detector (model 550 Alltech Associates, Inc.). The conductivity detector was set up at condition of positive signal and temperature of detector was adjusted at 30 oC. The sensitivity of detector for high surfactant concentration and low surfactant concentration was manipulated to 500 S and 100 S respectively. Because chloride salt was used in the experiments, it was necessary to separate the surfactant response from chloride response on the HPLC (1). The separation was accomplished using bicratic operation or gradient elution mode of two mobile phases through C18 reverse phase silica column. The primary mobile phase was 30% by volume of mixture of methanol in water. At this point, surfactant adsorbed on the reverse phase silica and chloride salt eluted from the column. During HPLC operation, the composition of mobile phase was changed gradually from 0 to 2.5 minutes. After that the composition was maintained at 80% by volume of methanol in water. Finally, the mobile phase was switched back to 30% methanol to complete cycle. The SDS concentration was analyzed twice in order to obtain average value of area under curve and the experimental error was less than 5%. Calcium concentrations were analyzed by Atomic Absorption Spectrophotometer (AAS Varian 300). The accuracy from measurement was less than 3%. C. Zeta potential determination The zeta potential of carbon particles in aqueous solution was determined by Zeta Meter 3.0+. The suspension placed in the electrophoresis cell was prepared by placing 1.5 mg of carbon black in 40 ml of solution. The suspension was required to equilibrate at 30 oC for 24 hours. The pH of equilibrated samples was measured. Before measurement, the electrophoresis cell was cleaned with distilled and deionized water and dried thoroughly. Approximately 5 ml of suspension was rinsed through the cell, and then remainder was loaded into the cell. Before tracking the particles, the appropriate tracking voltage for the colloidal system was selected. For the suspension, which had a high specific conductance, low voltage was required. For each sample, the zeta potential was measured about 12 values, in order to take an average mean value of zeta potential with small standard deviation. Final surfactant concentrations were calculated by assuming an adsorption of surfactant on the basis of the separately determined adsorption data. RESULTS AND DISCUSSION Surfactant adsorption isotherms There are several factors strongly influencing surfactant adsorption at the solid-liquid interface such as nature of structural groups on the surface, molecular structure of surfactant and the environment of aqueous solution. For this work, pH of system and electrolyte content (calcium concentration) were selected to elucidate the adsorption behavior of surfactant on carbon black. Effect of pH of suspension In this section, pH of 7 and 9 were selected for moderate basic pH condition to imitate conditions of traditional deinking operations. Figure 1 illustrates the adsorption of sodium dodecyl sulfate (SDS) versus equilibrium concentration at pH of 7 and 9 in the absence of calcium. Comparing the adsorption isotherms, the adsorption at pH of 7 was slightly greater than the adsorption at pH of 9 in all regions. As the pH of the aqueous phase was reduced, the solid surface became more positive or less negative due to the adsorption of protons onto charged sites. This consequence led to increase in the adsorption of anionic surfactants. For carbon black in water, the point of zero charge (PZC) was determined to be approximately 2.3 indicating that the carbon black had a net negative charge at pH levels above 2.3 (5). Results of adsorption isotherms on carbon black at both pH of 7 and 9, plotted on log-log scale, were different from typical adsorption isotherms, which were observable the four distinct regions. At small equilibrium SDS concentration (from point A to B shown in Figure 1), the isotherm shape was similar to Langmuir-type isotherm. The slope of isotherm from A to B was linear. It was expected that the monomeric surfactants adsorbed on the surface without significant association or aggregation of adsorbed surfactants. The horizontal or laying-down configuration of adsorbed surfactants was possible to occur, and the interaction of adsorbed surfactants might be hydrophobic chain/surface interaction. The adsorption of surfactants in this orientation might remain until complete monolayer coverage (from B to C). Beyond this stage, the slope of isotherm was steep again as surfactant concentration increased. The marked inflection point occurred at C. The adsorption of surfactants might be more close packing, and the interaction of adsorbed surfactants might be hydrophobic chain/chain interaction. However, from log-log adsorption isotherm at pH of 7 and 9, the slope of such area (from point C to D) was not greater than unity. It might be indicated that the adsorption of SDS on carbon black was mainly unassociative or at least not strongly associative. The plateau or maximum adsorption of SDS at pH of 7 and 9 was approximately 2.06 mole/m2 and occurred near CMC of SDS, 8300 M (6). The approximate adsorption corresponding to saturation of surface by either a monolayer or a bilayer can be determined from the area of single adsorbed surfactant molecule. The approximate value for area per molecule of SDS adsorbed in close-packed perpendicular orientation on surfaces such as carbon black was 53 Ao2 (9). Calculating this value, the closepacked monolayer coverage would require 3.13 mole/m2. Bilayer coverage would give in the double of this value. The plateau adsorption from the experiment corresponded to 65.73% of monolayer coverage for SDS. Effect of calcium concentration In the adsorption and electrophoretic experiments, SDS and calcium concentrations were controlled so that no precipitation of calcium didodecyl sulfate complexes occurred. On the phase boundary, the precipitate phase is in equilibrium with dissolved surfactant and calcium. For systems consisting of a divalent cation such as Ca2+ and a monovalent anionic surfactant, the concentration-based solubility product constant (Ksp) is defined as follows; Ksp = [Ca2+][DS-] 2 (1) where the bracketed values represent the concentration of species in the solution at equilibrium with the calcium didodecyl sulfate precipitate. The concentration-based Ksp of the calcium didodecyl sulfate at 30oC was 6.0x10-10 M3 (8) and the activity-based Ksp was 5.02x10-10 M3 (13). Figures 2 and 3 depict the adsorption of SDS on carbon black at constant pH of 7 and 9 as varying calcium concentrations. In all experiments, the initial calcium concentrations were varied from 100 to 1000 M, and SDS concentrations were varied from 8000 to 60000 M and from 14000 to 45000 M for initial calcium concentration 100 and 1000 M, respectively. Therefore, the concentrations of calcium and SDS at equilibrium remained below the Ksp value. At increasing calcium concentration levels, the adsorption of SDS on carbon surfaces increased, because an increase in ionic salt led to a decrease in the repulsive forces between the head groups of surfactants. Moreover, decreasing the electrical repulsion between the similarly charged adsorbed ions permitted closer packing. From the experiments, the plateau adsorptions of SDS at initial calcium concentration of 100, 700, and 1000 M were 2.10, 2.11 and 2.18 mole/m2, respectively for pH of 7 and 2.08, 2.09, and 2.13 mole/m2, respectively for pH of 9. Figures 4 and 5 demonstrate the relationship of calcium adsorption and SDS adsorption with varying equilibrium SDS concentration at pH of 7 and 9. The results showed that at constant equilibrium SDS concentration when the adsorption of calcium increased, the adsorption of SDS also increased. In the same way, when the adsorption of SDS increased, the adsorption of calcium also increased. This might indicate the cooperative adsorption with ionic surfactants in the presence of oppositely charged ions. The electrostatic repulsion was diminished among the head groups of surfactants by association of the counterion, and this association was not precipitation process. The adsorption of calcium on the carbon black in the absence of SDS at pH of 7 and 9 is shown in Figure 6. The result of calcium adsorption isotherms was also Langmurian shape, indicating that the adsorption of calcium was monolayer coverage. The adsorption of calcium ions was attracted by negatively charged sites on the carbon surfaces resulting from surface oxidation. The ionic radius of calcium was 0.099 nm (10). The close-packed monolayer coverage of adsorbed calcium from calculation was 167.8mole/m2. The plateau adsorptions of calcium ions on carbon surface at pH of 7 and 9 were approximately 0.36 and 0.79 mole/m2 corresponding to 0.21% and 0.47% of close-packed monolayer coverage, respectively. Generally, bare cations are smaller than anions, and they bond tenaciously to hydrating water molecules (7). The interaction between adsorbed calcium ions was not able to occur since aqueous molecules surrounded adsorbed ions and the lateral interactions were repulsive, not attractive. Consequently, it could be concluded that the adsorption of calcium on carbon surfaces was purely electrostatic and non-associative. Electrophoretic determination Zeta potential is an approximation of surface potential. It is the electrical potential at the shear plane between Stern layer and diffuse layer. It is an important feature because zeta potential can be measured in a fairly simple manner, while the surface potential cannot. Zeta potential is an effective tool for coagulation control because of changes in the repulsive force between colloids. Figure 7 illustrates the zeta potential of carbon black as a function of equilibrium SDS concentration without calcium addition at pH of 7 and 9. The results indicated the positive effect of SDS on the measured zeta potential. While the equilibrium SDS concentration increased, the absolute zeta potential of carbon also increased. Since the adsorbed SDS on carbon exposed the negatively charged group to the solution, and the hydrophobic tail group interacted with the surface, therefore the absolute zeta potential of carbon increased with increasing SDS concentration. At constant equilibrium SDS concentration, the absolute zeta potential of carbon at pH of 9 was slightly greater than one at pH of 7. Because the effect of pH between 7 and 9 was not significant to the SDS adsorption on carbon surface, the net negative charge on carbon surface at pH of 9 remained higher than one at pH of 7. Figures 8 and 9 depict the zeta potential of carbon versus equilibrium SDS concentration as varying calcium concentration at pH of 7 and 9. With constant equilibrium SDS concentration, the absolute zeta potential of carbon decreased at increasing calcium levels. It was probably because calcium ions neutralized the negatively charged sites on carbon surfaces and hydrophilic groups of SDS, consequently, the net negative charges on carbon adsorbents decreased. Figure 10 shows the relationships of adsorption isotherms and zeta potential versus equilibrium SDS concentration at pH of 7 and 9 in the absence of calcium. At low SDS adsorption, the negative zeta potential increased slightly from -23.8 to -27.1 mV at pH of 7 and from -26.8 to -28.7 mV at pH of 9. After that the negative zeta potential decreased significantly from -27.1 to -38.6 mV at pH of 7 and from -28.7 to -39.8 mV at pH of 9 as increasing SDS adsorption more. Finally, the zeta potential was fairly constant at SDS concentration slightly beyond the CMC of SDS. Calcium adsorption isotherms The purpose of this experimental part is to study the role of small concentrations of SDS to calcium adsorption on carbon black. Many research works indicate that electrolytes or counterions show dramatically on the adsorption of surfactants. Addition of neutral electrolyte such as NaCl or KBr causes a decrease in the adsorption of the ionic surfactants onto the oppositely charged adsorbents and an increase in their adsorption onto the similarly charged adsorbents. Conversely, the addition of surfactants such as anionic surfactants should obtain whether positive or negative effect on the adsorption of counterions. Effect of surfactant concentration Figures 11 and 12 illustrate the effect of SDS concentration on the adsorption of calcium at pH of 7 and 9. The results of calcium adsorption isotherms at varying SDS concentration were Langmurian curves, and the adsorption of calcium ion decreased at increasing SDS concentration. Because the monomeric SDS probably adsorbed onto carbon surface in the horizontal or laying-down configuration, some parts of hydrophobic tail group might locate at negatively charged sites, which might consequently be the barriers for calcium ions to adsorb the remaining negatively charged sites as calcium adsorption decreased. Another possible reason to explain was that the amount of SDS added was very small, when the surfactant adsorbed on the surface without the interaction between individual adsorbed surfactants, the cooperative adsorption with ionic surfactants in the presence of ionic salt rarely occurred. From the result, the adsorption of calcium on the carbon in the presence of small amount of SDS was less than the adsorption of calcium without SDS addition. Electrophoretic determination Figures 13 to 14 illustrate the zeta potential of carbon black versus equilibrium calcium concentrations as varying SDS concentration at pH of 7 and 9. When calcium was added to the system, the magnitude of zeta potential decreased dramatically because of the adsorption of calcium onto oppositely charged sites of carbon surfaces. However, at constant calcium concentration, the change in the magnitude of zeta potential was small with increasing amount of SDS. It was possibly because the amount of SDS added was too small to produce a net change in the zeta potential magnitude. CONCLUSIONS The adsorption of sodium dodecyl sulfate (SDS) onto carbon black surfaces displayed strong interaction between hydrophobic tail groups of surfactants and carbon surfaces. The presumable configuration of adsorbed surfactants was tail-down and/or laying down orientation. The plateau adsorption of SDS in the absence of calcium salt at pH of 7 and 9 occurred near the CMC of SDS, and was approximately to 2.06 mole/m2 that corresponded to 65.73% of closepacked monolayer coverage of SDS on surfaces. The effect of pH between pH of 7 and 9 to the adsorption of SDS on carbon was not considerable, however, at pH of 7 the SDS adsorption was slightly greater than the SDS adsorption at pH of 9. In the presence of calcium ions, the adsorption of SDS increased at increasing calcium concentration because the addition of calcium salt led to the decrease in repulsive forces between head groups of SDS. From the experiments, SDS and calcium concentrations had impact on the zeta potential. With increasing SDS concentration, the zeta potential increased and with increasing calcium concentration, the zeta potential also decreased. With the adsorption of calcium onto carbon substrate, the result indicated that the interaction of calcium adsorption was purely electrostatic and non-associative. The influence of SDS concentration and pH of suspensions resulted in calcium adsorption. From the experiments, the presence of small amount of SDS in the system diminished the calcium adsorption. It was probably because some parts of hydrophobic tail groups might locate on negatively charged sites that might consequently be the barriers for calcium to adsorb. It was also found that the adsorption of calcium ions at high pH was greater t h a n t h a t a t l o w p H . REFERENCES 1. B i t t i n g , D . , a n d H a r w e l l , J . H . , L a n g m u i r , 3 , 5 0 0 , ( 1 9 8 7 ) . 2. Harwell, J. H., and Scamehorn, J. F., in "Mixed Surfactant Systems" (K. Ogino, and M. Abe, E d s . ) , M a r c e l D e k k e r , I n c . , N e w Y o r k , 1 9 9 3 . 3. Hoeft, C. E., and Zollars R. L., J. Colloid Interface Sci. 177, 171 (1996). 4. H o r n f e c k , K . , C o n s e r v a t i o n a n d R e c y c l i n g 1 0 ( 2 / 3 ) , 1 2 5 ( 1 9 8 7 ) . 5. Larsson, A., Stenius, P., and Ödberg, L., Sven. Papperstidn. 87(18), R165 (1984). 6. Mukerjee, P., and Mysel, K. J., "Critical Micelle concentrations of Aqueous Surfactant Systems," Department of Commerce, U.S. Government, Washington D. C., 1970. 7. Oldham, K. B., and Myland, J. C., "Fundamentals of Electrochemical Science," Academic P r e s s , L o n d o n , 1 9 9 4 . 8. Riviello, Jr. A. E., "Surfactant behavior in the mechanisms of ink removal from secondary fiber in flotation deinking," Ph.D. dissertation, University of Oklahoma (1997). 9. Rosen, M. J., "Surfactants and Interfacial Phenomena," 2nd ed., John Wiley and Sons, Inc., N e w Y o r k , 1 9 8 9 . 10. Russell, J. B., "General Chemistry," 2nd ed., McGraw-Hill, Inc., New York, 1992. 11. Rutland, M., and Pugh, R. J., Colloids Surf. A: Physicochem. Eng. Aspects 125, 33 (1997). 12. Scamehorn, J. F., and Harwell, J. H., in "Surfactant in Chemical/Process Engineering" (D. T. Wasan, M. E. Ginn, and D. O. Shah, Eds.), Marcel Dekker, Inc., New York 1988. 13. S t e l l n e r , K . L . , a n d S c a m e h o r n , J . F . , L a n g m u i r 5 ( 1 ) , 7 0 ( 1 9 8 9 ) . LIST OF FIGURES FIG. 1. The adsorption isotherms of SDS versus equilibrium SDS concentration at pH of 7 and 9. FIG. 2. Adsorption isotherms of SDS on carbon black at pH of 7 with varying initial calcium concentration. FIG. 3. Adsorption isotherms of SDS on carbon black at pH of 9with varying initial calcium concentration. FIG. 4. SDS adsorption versus calcium adsorption at pH 7 with varying equilibrium SDS concentration. FIG. 5. SDS adsorption versus calcium adsorption at pH 9 with varying equilibrium SDS concentration. FIG. 6. Adsorption isotherms of calcium on carbon black at pH of 7 and 9 in the absence of SDS. FIG. 7. Zeta potential of carbon black versus equilibrium SDS concentration at pH of 7 and 9 without calcium addition. FIG. 8. Zeta potential of carbon black versus equilibrium SDS concentration at pH of 7 with varying initial calcium concentration. FIG. 9. Zeta potential of carbon black versus equilibrium SDS concentration at pH of 9 with varying initial calcium concentration. FIG. 10. SDS adsorption and zeta potential of carbon versus equilibrium SDS concentration at pH of 7 and 9. FIG. 11. Calcium adsorption on carbon black at pH of 7 with varying initial SDS concentration. FIG. 12. Calcium adsorption on carbon black at pH of 9 with varying initial SDS concentration. FIG. 13. Zeta potential versus calcium concentration at pH of 7 with varying initial SDS concentration. FIG. 14. Zeta potential versus calcium concentration at pH of 9 with varying initial SDS concentration. Fig.1 Fig. 2 Fig. 3 Fig. 4 Fig. 5 Fig. 6 Fig. 7 Fig. 8 Fig. 9 Fig. 10 Fig. 11 Fig. 12 Fig. 13 Fig. 14