ok19_bop-ellipsometer

advertisement

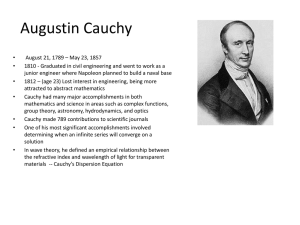

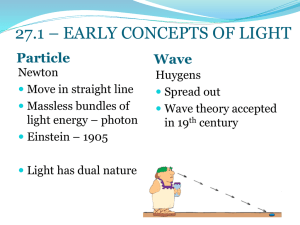

BOP – Ellipsometer Responsible person: Per-Anders Hansen Mob.: 4824 5746 Office: ØU35 Contents Doing a measurement .................................................................................... 2 Measurement sequence: ................................................................................ 2 Analysing ....................................................................................................... 2 Transparent films on silicon ........................................................................... 2 Al2O3, La2O3, MgO, SiO2, fully transparent. ..................................................... 2 TiO2 and other UV absorbing materials .......................................................... 3 NiO and other grey mirror-like semitransparent materials............................. 4 Apparently transparent films ......................................................................... 4 Absorbing films on silicon .............................................................................. 4 Transparent substrates .................................................................................. 7 For all non-Si substrates ................................................................................. 8 Checking the validity of your model ............................................................... 9 MSE (Mean Square Error)............................................................................... 9 Refractive index must be physical. ................................................................. 9 Parameter uniqueness ................................................................................. 10 Does it make sense? ..................................................................................... 11 Trouble shooting.......................................................................................... 11 I get an error when trying to measure.......................................................... 11 My green delta curve goes from 0 to infinite ................................................ 11 Risk assessment ........................................................................................... 11 Doing a measurement Measurement sequence: 1. Turn on the ellipsometer 2. Open CompleteEASE. 3. Put your sample in place. You can see where the beam hits your sample by holding a piece of paper in front. It anyway hits directly between the two small holes. And is shaped like a 2x4 mm ellipse. 4. In CompleteEASE, select 70°, Mode: Standard, Medium speed. Then press “Measure”. If you get an error, see the Troubleshooting section. 5. If you need multiangle measurements, select 65, 70 and 75° before pushing “Measure”. If you need transmission measurements, talk to me. 6. Save your file and turn of the ellipsometer to save the light bulb. 7. To analyse: Go back to your office, open CompleteEase and open the analysis tab. When done analysing, the MSE (Mean Square Error) of the fit should be between 1 and 3. It will be a bit higher for thicker films (>60 nm) and also a bit higher for multiangle measurements. Analysing This BOP is not meant as a complete guide on how to analyse any and all samples, but rather a quick guide to get started. You should read the manual (by pressing F1 in CompleteEASE or going to the Options tab and opening the manual) and the pdf’s that are relevant to your type of sample. I can help you figure out what is relevant and not. Transparent films on silicon Transparent films are anything that looks transparent to us. That is, Al2O3, TiO2, MgO, La2O3 etc. Al2O3, La2O3, MgO, SiO2, fully transparent. In the analysis window, press “open” under model. Go to “Basic” and select “Si with transparent film.mod”. This is a simple Cauchy function. It only models a thickness and a refractive index, fitted by 3 parameters. Press “Fit”. That’s it, assuming that you have a nice, flat, even film. If you think your film is rough, right-click on “Include Surface Roughness = OFF”. This is not a physical roughness like what AFM will give you. This is just some mathematical approximation to what roughness will do to the polarized beam. TiO2 and other UV absorbing materials For TiO2 and other materials that absorb UV, you may need to add another function to the Cauchy function. Left-click on the “+” next to “Layer # 1”, and right-click on “K Amplitude” and “Exponent”. This allows an absorbtion tail to extend into the measurement range. Even if the film doesn’t absorb in the measurement range, an absorbtion just outside the range will still affect the refractive index. Press “Fit”. Now you are done. NiO and other grey mirror-like semitransparent materials Some other materials may be fittet with this simple Cauchy approach as well. As long as the optical absorption of the film follows a nice exponential form (i.e. increases steadily towards the UV), the TiO2-approach can work. You may need to select a smaller range, for example 700-900 nm, if this approach doesn’t fit properly. If a smaller range doesn’t help, you need a different approach. Anyway, for these types of films it is really important that you check that the model makes physical sense, as described later. Apparently transparent films Some films can look transparent, but the Cauchy function will not give a satisfactory fit. This means that the model isn’t representative for your sample. The Cauchy function is representative for transparent films, with the exception of strongly IR-absorbing films like highly doped ZnO. Therefore, if Cauchy doesn’t fit properly, that means that your film either is absorbing, but too weakly for you to notice or it is not really flat or homogeneus (grading, surface oxidation etc.). Try to fit smaller sections of the spectra. Sometimes the film can be transparent in the blue region while other times in the red region. If you find a region where the Cauchy function fits, then that region is transparent (Cauchy will not be able to fit an absorbing region). Absorbing films on silicon Absorbing films are more tricky, and sometimes needs to be solved on an individual basis. There is however one standard attempt you can try. First, do the measurement with all angles (except 90°). This will save you time later, when you figure out you had to do it. More angles gives the models more data, which reduces the chance that you end up with many different, equally fitting answers. Select the “Si with transparent film.mod” model. Select a wavelength range that you think is more or less transparent. Usually, most absorptions lie in the visible range, so the IR range is usually safe to assume is transparent. But you know your material best! Fit the smaller, selected range with “Si with transparent film.mod”. If you only want to know the thickness of the film, this is all you need and you can be happy with the thickness you have. But you should be able to fit everything and get n and k for all wavelengths. So let’s do that. Now comes the tricky part. Right click “Cauchy film” and select “Parameterize layer”. Press “Open Material File”, select “Basic” and then “B-Spline”. Change “Resolution (eV)” to 0.05. It should say 4 Pts or more directly to the right. If it is less, you need to select a large range. Press “Fit” and then “Replace Layer”. When you are back to the normal window, press “Fit” again to fit the reduced data range with the new B-Spline model. To go back to the normal data graph window, select “Graph Type” in the top left of the graph, and select “Psi”. In the model window, expand your layer by pushing the red + and turn on “Show Advanced Options”, then “Assume Transparent Region” at the bottom, turn off “Assume Band Gap”, then finally select “Transparent Region” and type in the smallest value of the range you select. The large value can be 10000. So if you selected approximatly 750 – 900 nm like me, then type in 750 and 10000 here. Almost done. Expand “OTHER Options” and change “Increment (eV)” to 0.05 (the same as the resolution earlier). Right click the graph window and select “Zoom all”. Then left-click “Wvl. Range Expansion Fit” and watch the fun (or horror). Final thing to do is to turn off “Fit Opt. Const.”, turn on thickness and roughness and press “Fit” one last time. This it to optimise thickness and roughness, which shouldn’t change by more than 1 % (prefferably less). After doing this, the model should be stable. That means that nothing changes if you click “Fit” several times. It is really important that you check the validity of the model after doing something with the B-Spline function! When everything is ok, you now have the film thickness, refractive index and absorption coefficient for the whole range. n(λ) and k(λ) are correct, but you cannot assign much physical reason behind absorption peaks yet. To do that you need to convert this model (again) from B-Spline into Gen.Osc.. The general oscillator functions are real physical absorption mechanisms which can give you really good and detailed information about the electronic transistions in your film. But they can also be quite difficult to handle. Before starting to play with the Gen.Osc. functions, you should read through the pdf’s on absorbing films and Gen.Osc. in the ellipsometer folder in the ALD folder. You should also come talk to me as you can very easily interpret the data wrong. Transparent substrates The big (very big) problem here is that the detector also receives the reflection coming from the back surface of the substrate, which is depolarized and ruins everything. There are two ways to deal with this. One that works and one that doesn’t. The one that doesn’t seem to work well is to turn on “Include backside reflection”, but I have never managed to do a proper fit this way. The way that do work, and works very well, is to simply tape a piece of diffuse (whiteish) tape on the backside of the glass. Tape has about the same refractive index as glass, so the light is no longer reflected at the glass surface, but instead travels into the tape where it gets scattered and no longer hits the detector. For all non-Si substrates If you use a non-silicon sibstrate, like quartz or a metal, I strongly advice you to first measure an empty substrate. Do this as you would measure and model a sample, except for the model choose “Blank” and click on “none” after “Substrate:” to insert a fitting function for the substrate. When you are happy with your model, right click on your substrate and press “Save Layer Optical Constants” and select either parameterized or tabulated. I suggest parameterized. From now on, you can select this material (.mat) file instead of for example “Cauchy”. Checking the validity of your model MSE (Mean Square Error) The MSE is an estimate on how well the model kurve fit the data kurve. For flat homogeneous transparent film below 100 nm, it should be between 1 and 3. For thicker films or rougher, more absorbing, layered etc etc., you will have to accept a higher value. You should look at the kurves and see if your model seems to follow the curvatures of the data. Refractive index must be physical. You should always check that the refractive index is physical (increasing towards the UV), even for the simples models and the most perfect fits. Below is a physical and unphysical refractive index. The reason why the right one is unphysical is that n(λ) can only go down if k(λ) is going up. n(λ) will also start to turn back up again when k(λ) peaks as seen in the bottom picture. If this is not the case then the model is unphysical / not correct / not describing your sample and the results cannot be trusted. Parameter uniqueness In the model window, expand (+) “OTHER Options” and click “”Fit Parameter Uniqueness”. Select the parameter you want to chech, mostly the thickness, select the range and number of steps and press ok. For Cauchy fits, several hundred steps can be calculated in a matter of seconds. For more complicated function it will go slower. The reulsting graph should look something like this: Here it is clear that the model is really really happy with 260 nm, and so should you. Some times you will see several local minimas and the one you ended up with may not be lowest one. Then you need to change the starting values of your model. Other time you may experience that the curve is flat at, say, MSE = 6 after the minima. In that case you have a ununique result. Measuring at multiple angles may help, or do changes in the model. Sometimes variables gets correlated, for example that changing the density, n(λ) and thickness at the same time gives many possible answers that fit equally well. This could also be solved by fixing one of the values (de-clicking it as a fitting parameter). Does it make sense? You have to be the final judge of wether or not the model makes sense. You may get a perfect fit with a model of B-Spline function on top of a quartz substrate showing clear yellow absorption, but if your sample looks transparent and the substrate is silicon then the model doesn’t make sense. Trouble shooting I get an error when trying to measure If the program has been on for a long time, or the program was on before the ellipsometer was turned on, you will get an error message when trying to measure. Go to the “Hardware” tab and press “Re-initialize”. My green delta curve goes from 0 to infinite No it doesn’t, it goes from 0° to 360°. The delta curve is a function of the phase difference of the detected light. 0° and 360° are both in phase so it just rescales it. Risk assessment There is not risks regarding the use of this instrument, except looking directly into the light source. Be careful when moving the detector and light arms. Rough handling may damage the equipment.