Sugar Assay Standard Operating Procedure

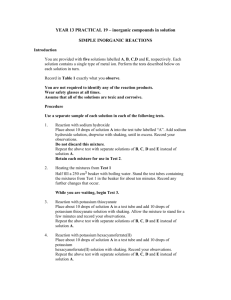

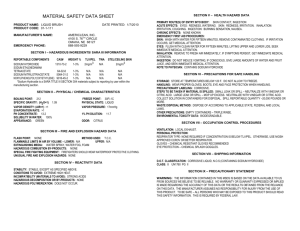

advertisement

Standard Operating Procedure Title: Sugar Assay Department: Agronomy Created by: Andrea Rouse Laboratory: Crop Production & Physiology Supervisor: Mark Westgate Lab Supervisor: Maria Hartt Date approved: Procedure Overview: Determination of soluble sugar content in maize samples Equipment and reagents necessary: Reagents: 80% Ethanol (15 ml per sample) Concentrated Trichloroacetic acid (a few drops per sample) 0.1N Hydrochloric acid (a few drops per sample) 5N Potassium Hydroxide (a few drops per sample) Dinitrosalicylic acid (10g per liter of stock solution) Sodium sulfite (0.5g per liter of stock solution) Sodium hydroxide (10g per liter of stock solution) Potassium sodium tartrate solution 40% (1ml per sample) Equipment: Balance Weigh boat Spatula Conical centrifuge tubes, 50ml (1 per sample) Pipettes, 5 ml, 1 ml & 20 ul & tips Conical centrifuge tubes, 15ml (3 per sample) Graduated cylinder Heat block Centrifuge Water bath Spectrophotometer (w/capability of reading 575nm wavelength) Cuvettes (1 per sample) Procedure: 1. Using balance, weigh 100mg of dried stalk tissue and place in a 15 mL conical tube 2. Pipette 5ml of 80% Ethanol into tube; cap 3. In a heating block, heat tube at 60oC for 20 minutes 4. Remove tube from block and centrifuge at 5500g for 10 minutes at room temp 5. Transfer supernatant to a properly labeled, clean 50ml conical tube 6. Repeat from Step 2 for a total of 3 ethanol extractions. supernatant in the 50 mL tube from step 5 Combine all the 03nov ar 7. Precipitate proteins by adding a few drops of concentrated Trichloroacetic acid (TCA) to tube containing the supernatant using a pipette (a typical drop is approximately 20ul); cap tube 8. Centrifuge tube at 5500g for 10 minutes to pellet the proteins. supernatant and place into a clean 15ml conical tube with cap Retain the 9. Hydrolyze sucrose by adding a few drops of 0.1N Hydrochloric acid (HCl) to tube containing the supernatant using a pipette 10. Place 3ml of above sugar solution in a clean 15mL conical tube and add 3ml Dinitrosalicylic acid reagent solution (1% DNS: 10g Dinitrosalicylic acid, 0.5g sodium sulfite, 10g sodium hydroxide, water to 1 liter). Tightly cap the tube or use parafilm to eliminate evaporation 11. Heat the tube containing the sugar/DNS mixture in a 90oC heating block for 5-15 minutes to develop red-brown color 12. Add 1ml of 40% potassium sodium tartrate (Rochelle salt) solution to stabilize the color 13. Cool sample to room temperature in a cold water bath 14. Transfer sample to a cuvette. Record absorbance using a spectrophotometer at 575nm. Compare absorbance to a glucose standard curve using the same procedure 15. Place all remaining samples in properly tagged waste container for EH&S pick up. Clean all work areas and lab ware. Personal Protective Equipment / Engineering Controls: Gloves Face mask when using Dinitrosalicylic acid in dry form Appropriate shoes Goggles Lab coat Safety shower and eye wash station Hazard Controls & Storage Precautions: 3,5-Dinitrosalicylic acid: Ethanol: Hydrochloric Acid: Potassium Hydroxide: Potassium Sodium Tartrate (Rochelle Salt): Sodium Hydroxide: Sodium Sulfite Anhydrous: Trichloroacetic acid: Waste Disposal & Decontamination Procedures: 3,5-Dinitrosalicylic acid: Ethanol: Hydrochloric acid: Potassium Hydroxide: Potassium Sodium Tartrate (Rochelle Salt): 03nov ar Sodium Hydroxide: Sodium Sulfite Anhydrous: Trichloroacetic acid: Health & Safety Info for Required Reagents: C a r c i n o g e n Chemical name 3,5-Dinitrosalicylic acid Ethanol Hydrochloric Acid Potassium Sodium Tartrate Potassium Hydroxide Sodium Hydroxide Sodium sulfite Trichloroacetic acid l e v e l T e r a t o g e n C o r r o s i v e T o x i c I r r i t a n t S e n s i t i z e r H i g h l y T o x i c C o m b u s t i b l e Target Organ C o m p r e s s e d G a s E x p l o s i v e F l a m m a b l e O r g a n i c P e r o x i d e s O x i d i z e r P y r o p h o r i c U n s t a b l e W a t e r R e a c t i v e H e a l t h Incompatibilities The above summary consists of guidelines for proper handling & disposal of chemicals used in this procedure. You must read complete MSDS(s) for more specific information before starting this procedure. 03nov ar F l a m m a b i l i t y R e a c t i v i t y