separation h2

advertisement

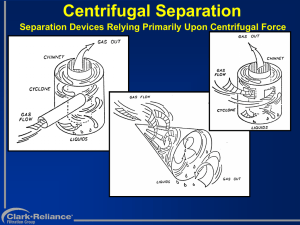

CURRICULUM-VITAE N.LAKSHMANAN, 5/2, Sindu Siva Appartement, Soundra Pandian Road, Virudhunagar – 626001, (Tamilnadu - India). Contact No. : (INDIA) 00919486287483. E-mail : lakshmananspic@rediffmail.com nlameen@yahoo.com OBJECTIVE To contribute relevant oil &gas, refinery and petrochemical industry operating experience and expertise to a challenging position that allows for growth. To seek career opportunity in a company that will utilize my education and experience in crude oil separations, oil &gas treating, gas compression, gas sweetening & dehydration unit, utilities operations. PERSONAL DETAILS Birth date : 27th may, 1974 Sex/Marital status : Male/Married. Languages known : English, Tamil Nationality : Indian Passport Details : F 7383603 (Expiry Date) 22-03-2016. QUALIFICATION BACHELORE OF SCIENCE (B.SC) IN CHEMISTRY (1991-1994), M.K.University India. TRAINING COURSES ATTENDED PROCESS TRAINING: 6 months class room training conducted by SPIC Ltd, INDIA (UNIT OPERATION&CALCULATIONS, ELECTRICAL, MECHANICAL, SAFETY, HUMAN RELATIONS) Control room training conducted by SPIC Ltd, INDIA (CENTUM XL & Delta-V) PDH operation and safety training by UOP One year Naphtha base NH3 plant training from SPIC Ltd, INDIA SAFETY TRAINING: First aid, Fire fighting training Atmospheric gas test training (MULTI GAS MONITORING) PTW, SCBA, LOTO, Emergency Response Chemical handling & storage training SKILLS Experience in the area of DCS Control room, Crude distillation (pressure, atmosphere and vacuum), oil & gas separator, gas amine treating, Gas dehydration, Gas compression, Utilities and Pigging operations, hydrogen generation & separation, Hydrotreater, Amine regeneration, Sulfur recovery unit Familiar with use of Safety procedures like Permit to work system, Job safety analysis, Preparation of standard operating procedures etc. Familiar with usage of Electrical Lock out System Pre commissioning and commissioning activities and troubleshooting operations checking of plant layout as per P & ID Active team member of Safety Committee Very good in Team work and experiencing its good results WORK EXPERIENCE Total 14 years Experience Present Employer: SNAMPROGETTI SAMIR REFINERY UPGRADING PROJECT --- MOROCCO (from; OCT 2008 to April 2010) POSITION AREA : PROCESS PANEL OPERATOR : Panel operator (YOGOKAVA-- CS-3000) Crude distillation Unit (Vacuum and Atmospheric) Hydrocracker (Chevron Lummus Global licensor) Hydrogen Production Unit (KTI STEAM REFORMING) Distillate Hydrotreater Unit (UOP licensor) Amine Regeneration Unit (DEA absorbent) Sulphur Recovery plant EQUIPMENT HANDLED: YOGOKAVA-- CS-3000, Vacuum, Atmospheric and pressure distillation columns, Steam ejectors, Condensers, Gas and Oil fired heaters, Fractionators, Multi stage centrifugal and reciprocating hydrogen handled compressors, Steam turbines, PSA (pressure swing absorbers), LPG Caustic wash system, Multi stage centrifugal high pressure pumps, high and low pressure 3-phase separators, feed filters with automatic backwash system, strippers, splitters, storage tanks (Kerosene, Naphtha, Diesel, LPG), Absorbers, Regenerators, Amine storage tanks, re boilers, Sulphur storage, Thermal oxidation, Steam reformers and reactors. Previous Employers: NATIONAL PETROCHEMICAL COMPANY -- SAUDI ARABIA (2007 TO 2008) POSITION : CONTROL ROOM OPERATOR (PDH) AREA : Propane de hydration plant (UOP licensor) (DELTA- V EMERSON SYSTEM) Propane Feed treatment Separators (Hydrogen separation & purification units) Compressors (Centrifugal & positive displacement compressors driven by Turbine & motors) Refrigeration system (propylene as a coolant) H2s Removal system (Caustic wash) Boilers EQUIPMENT HANDLED: DELTA- V EMERSON SYSTEM , Steam ejectors, Condensers, Gas and Oil fired heaters, Fractionators, Cold box, PSA (pressure swing absorbers), Multi stage centrifugal and reciprocating hydrogen handled compressors, Steam turbines, LPG Caustic wash system, Multi stage centrifugal high pressure pumps, high and low pressure 3-phase separators, feed filters with automatic backwash system, strippers, splitters, storage tanks (Propane and Propylene), Absorbers, Regenerators, Amine storage tanks, re boilers, and reactors, boilers. OIL & NATURAL GAS CORPORATION ( DEPUTATION) ( 5YEARS)--INDIA (2000-2005) Position : CONTROL ROOM OPERATOR AREA : Gas Dehydration (Glycol regeneration unit) Separators (two & three phase separators) Gas sweetening (Amine regeneration unit) EQUIPMENT HANDLED: Condensers, Multi stage centrifugal and reciprocating compressors, Steam turbines, LPG Caustic wash system, Multi stage centrifugal high pressure pumps, high and low pressure 3-phase separators, feed filters with automatic backwash system, strippers, splitters, storage tanks , Absorbers, Regenerators, Amine storage tanks, re boilers, and reactors, boilers. SOUTHERN PETROCHEMICAL INDUSTRIES CORPORATION LTD (SPIC) ----INDIA (1995-2000) and (2005-2007) Position : SENIOR OPERATOR Area : DCS Panel (Centum-XL) & field operation Hydro fining (Sulfur removal as H2S from feed stock) Reformer (Steam reforming hydrogen generator) Compressors (Multi stage centrifugal compressor driven By turbine handle Both seal oil system & dry gas seal system) Utilities (Boilers, H2 separation, CO2 removal (Amine process), Nitrogen unit, Gas turbine, tank farm (8 tanks, floating roof, fixed roof) Terminal operation (Ship loading and unloading of LPG, FUEL OIL & NH3, Storage tanks & Refrigeration system, tanker loading operation) EQUIPMENT HANDLED: YOGOKAVA—CENTUM XL, Vacuum, Atmospheric and pressure distillation columns, Steam ejectors, Condensers, Gas and Oil fired heaters, Fractionators, Multi stage centrifugal and reciprocating hydrogen handled compressors, Steam turbines, Cold box, PSA (pressure swing absorbers), LPG Caustic wash system, Multi stage centrifugal high pressure pumps, high and low pressure 3-phase separators, feed filters with automatic backwash system, strippers, splitters, storage tanks (Kerosene, Naphtha, Diesel, LPG), Absorbers, Regenerators, Amine storage tanks, re boilers, Sulphur storage, Thermal oxidation, Steam reformers and reactors PROCESS OPERATION DCS Control room (Emerson DELTA-V, CENTUM-XL, YOGOKAVA_ CS _3000) Separate the three phase flow by using three Phase separators. Distillation Column operation Sour gas sweetening unit by using amine Gas dehydration by using TEG Gas compression by centrifugal compressors Storage of stabilized crude in floating roof tanks Propane pre-treatment (moisture, metals, heavies & lighter removal) Refrigeration system by using propylene Steam reformers, Reactors PSA (Pressure swing absorber) Hydrogen purification operation Cold box Hydrogen separation operation Strippers JOB PROFILE & RESPONSIBILITIES Start up & shutdown activities, Operation & trouble shooting of the units Monitor the overall operation of the unit equipment, ensuring that pressures, temperatures, flow rates and all other variables are within normal operating parameters. Log any leaks malfunctions and irregular operating occurrences. Monitor all rotating equipment for undue noise and vibration Check oil levels on pumps, compressors etc Ensure all sight glasses are clear and the level corresponds with the level indicator Monitor the chemical levels, replenish stocks as required Blowing, Flushing the lines, Leak check, Air freeing the system, Functional test, loop test, prepare punch list, PSSR punch list preparation, Air freeing of system, solo run, Performance test Pre-commissioning & commissioning activities of PETROCHEMICAL PLANTS, REFINERIES AND OIL & GAS. Ensure that all logbooks are up to date and contain sufficient detail of the plant status, including any deviation from normal operations such as equipment and safety system isolations Check all gas cylinders in the unit ensure they are stored correctly, Valves are capped and certification and colour code are valid Check and ensure all safety systems are in service, check UVs are not obstructed. Check all escape routes are clear of any obstructions Check all scaffold is correctly tagged and ladders secure Monitor all maintenance work in the unit ensure all permit conditions are enforced Raise PTW/work orders for maintenance to respective department. Isolating and handing over of Equipments for major maintenance. Start up, Shutdown and troubleshooting operation and House Keeping. Perform regular activities like plant round, pump/equipment changeover, monitoring of parameters, running rotary equipments, process instruments, maintain good housekeeping and maintain a logbook / reading log sheet / activity checklist. To maintain good communication between field activities and control room also coordinate with other connected units. Follow Safety and Permit to Work procedure (Hot / Cold work, Confined space entry, Vehicle entry to plant area, Electrical lockout etc.). Handling of chemicals which are using for process, prepare chemical solutions properly and ensures that correct dosages maintained Inspection and testing of fire fighting equipments, F & G system, Deluge water system, Gas detectors and personal protective equipments in accordance with the checklist provided. Checking of instruments like Level / Pressure / Flow / Temperature transmitters, Control valves, ON – OFF valves, Alarm switches First line maintenance such as Topping up lube oil Fitting hose connections required for flushing Greasing of valve stems and easing of valves Greasing of structure foundation bolts and flange bolts Cleaning of strainers less than 2in Arresting of minor gland leaks wherever possible DECLARATION With an experience of about 14 years and has qualification as a Process Plant Operator (field and control room), I can work excellently to your entire satisfaction in any plant. I hereby declare that all my operations and activities are aiming towards the modern concepts of industrial growth to obtain best on stream efficiently / capacity utilization, improved working environment with maximum pollution control / effluent control. Thanking You, Yours faithfully, N.LAKSHMANAN