Two-Phase Flow Split at T Junctions – CFD Study

advertisement

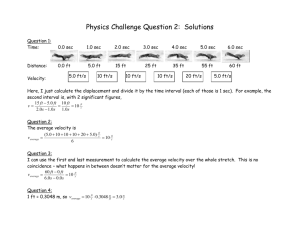

The Split of Horizontal Two-Phase Flow at a T- Junction – CFD Study Amir T. Al-Wazzan, Department of Mechanical Engineering, University of Malaya, 50603 KL, Malaysia ABSTRACT A procedure for simulation the split of horizontal two-phase flow at a T-junction was presented using the CFD aspects. Water was used as the liquid phase while the air was used as the gas phase. The values of the superficial velocities were ranging (2.0-10.0 m/sec) for the air and (0.2-1.0 m/sec) for the water. PHOENICS was used as the CFD code. The results were compared with experimental results obtained by some investigators and with theoretical models prepared by some investigators previously. reported that when annular flow approaches a tee, a sudden increase in the amount of liquid extracted for a small increase in the gas takeoff occurred. The film reacting to the pressure increase along the main pipe and slowing down explained this trend. Shoham et al.(10) and Hwang et al.(5) adopted a similar concept, but argued that more accurate predictions can be obtained if the dividing streamlines are different for each phase. This difference was proposed by Shoham to be the result of centrifugal separation of the phases produced by the fluids following a circular path into the side arm, whereas Hwang determined ‘zones of influence’ from a balance between the dominated forces acting on each phase, Azzopardi(2) improved the model of Azzopardi and Whalley (1) by predicting the critical gas take-off value at which film-stop occurred and the extra amount of liquid taken off. A’selfstanding’ model which has been rigorously compared with data is currently not available for implementation into the flow split model of Azzopardi(2). Hart et al.(4) proposed a model for separated flows with liquid hold-up values less than 0.06. This is based on the Bernoulli equations for each phase along the main pipe and from the main pipe to the side arm. Loss coefficients for the liquid were assumed equal to those for the gas phase, which were described by single-phase correlations. Ottens et al(6) extended the models range of applicability to all values of hold-up by developing correlations for the liquid-phase loss coefficients, however predictions were only compared with stratified-wavy air-water flow split data. A detailed discussion of these models and the inherent assumptions is presented by Roberts et al.(8). No universal agreement exists on the main parameters controlling the film thickness distribution. As explained by Flores et al.(3) and Sutharshan et al.(11), the physical mechanisms which have been proposed are the circumferential secondary gas flow, wave INTRODUCTION Junctions are an often-necessary feature of many pipelines or pipework systems. For single-phase flows, there are equations, which though empirical, enable engineers to carry out designs. In the case of two-phase flow, however, the number of variables is much larger; in addition there are complicating factors in the partition and mixing of the phases. When a two-phase mixture flows through a dividing T-junction, there is an almost inevitable, maldistribution of the phases between the outlets. The unequal splitting of gas and liquid at T-junction was observed to create problems in the industry where it may be found. For example, in gas distribution networks, condensate can be formed in pipelines in winter due to low temperature. It was found that the condensate appears at some delivery stations while the other stations receive only dry gas. This kind of uneven splitting may result in creating operational and separation problems. Large amounts of data have been acquired and a number of models have been developed so far, on two-phase flow splitting at Tjunctions. Azzopardi and Whalley (1) proposed that the fluids emerging through the branch outlet were extracted from a segment of the main pipe nearest the side arm. They also 1 spreading and transfer of liquid entrainment and deposition of droplets. Penmatcha et al(7) investigated two-phase splitting under stratified wavy flow conditions at a regular horizontal Tjunction with an inclined branch arm. They developed a mechanistic model for the prediction of the splitting phenomenon for both the horizontal and the downward orientations of the side arm. This model based on the momentum equations applied for the separation streamlines of the gas phase and the liquid phase. Roberts et al.(9) presented a model for predicting the flow split of horizontal air-water annular flow at a T-junction with a side arm at an arbitrary inclination to the horizontal. They stated that under certain conditions, an abrupt increase in the amount of liquid extracted into the side arm was observed due to liquid coming to rest in the main pipe. Where: i : phase density COMPUTATIONAL FLUID DYNAMICS CFD codes are structured around the numerical algorithms that can tackle fluid flow problems. In order to provide easy access to their solving power, all numerical CFD packages include sophisticated user interfaces to input problem parameters and to examine the results. There are three distinct streams of numerical solution techniques: finite difference, finite element and spectral methods. The main differences between the three separate streams are associated with the way in which the flow variables are approximated and with the discretisation processes. In this study, PHOENICS was used as the CFD code. The finite volume method that was originally developed as a special finite difference formulation was implemented in this package. Considering the time average, the equation will be: vel : phase velocity vector W : mass flow rate of the entering phase t : time As the result base on above equation it becomes Cartesian form as follows: W ................ (2) Where: x , y , z : distances in three directions at right angle u i , v i , wi : phase velocity components W d ri i div ri i vel J i diff dt ................ (3) Where: J i diff : turbulent diffusion flux, representing transport by randommotion mechanisms. Momentum General Equation: B dpi Wi (ui ) Wi ui Fi ri i dx d ri i ui div ri i vel ui Vi ...............................(4) MATHEMATICAL FORMULATION The equations that have been implemented in PHOENICS for simulating the two-phase flow are as follow: d ri i d ri i ui d ri i vi d ri i wi dt dx dy dz Where: Vi : momentum transport by viscous action with phase i Fi : friction factor of all other phases present Phase-Mass General Equation: Bi : body force per unit volume of i p i : pressure of phase i d ri i W div ri i vel .............. (1) dt (ui ) : ui of inflow mass 2 The following relevant laws of physics were implemented as well: Conservation laws: 1. Newton’s second law of motion. 2. 1st law of thermodynamics. 3. Chemical-element balances. Transport laws: 1. Newton’s law of viscosity. 2. Fourier’s heat conduction law. 3. Fick’s diffusion law. phase maldistribution. Also, from the directions of flow shown in figure 1(*), we can predict confidentially how the phases would be distributed to the side arms. SIMULATION In this study, the simulation of the horizontal T-junction was done with the following details: 1. 3D turbulent two-phase air-water flow in 1.5 inches horizontal T-junction. 2. Cartesian computational grid was used for the domain setting (2.0, 0.15, 0.0381 m). 3. Turbulence represeted via the k-e EP turbulence model with additional setting on ENUT=GRND3 ‘ON’. 4. The following notes were considered: Air and water enter uniformly at inlet of various velocities. The inlet void fraction is taken according to the various velocities. Both phases are allowed to leave at the outlet of the pipe. The expected flow pattern is a logical two-phase flow pattern and logical pressure and velocity profiles. The pipe body is employed uses imported STL file from the AutoCad drawing. Figure (1): Mixture velocity vector (Vsl=0.2 m/sec) (Vsg=2.0 m/sec) From the pressure drop contour results, it is clear that the pressure drop can be predicted depending on the phase distribution. The maximum amount of pressure drop will be in the opposite part of the inlet section due to the impact effect and the minimum value will be in at the side corners due to the secondary flow. Figure 2 below shows this phenomenon: RESULTS The first step of simulation was with low liquid loading (Vsl=0.2 m/sec & Vsg=2.0 m/sec) in a T-junction of 0.038m diameter for the inlet and the side arms. The simulation gave the fact that the mixing will change slowly to an air predominant flow pattern. When it reaches the T-junction, the water will spread in the lower corner due to secondary flow. For the same reason, the velocity of the mixture will increase significantly at the inlet of the junction. It will reach its minimum value at the corners where the secondary flow occurs. This phenomenon can be justified logically by the turbulence and Figure (2): Pressure drop contour (Vsl=0.2 m/sec) Figure 5.4.2 (Vsg=2.0 m/sec) Pressure drop contour The contour of the void fraction will give a clear view about the maldistribution of the phases in the inlet section and in the side arms as well. This is shown in figure 3: (*): all the figures were generated with the top view 3 Figuredrop 5.4.5 Figure(5): Pressure contour (Vsl=Vsg=2m/sec) Figure (3): Void fraction contour (Vsl=0.2 m/sec) (Vsg=2 m/sec) Pressure drop contour Figure 6 below gives a clear view about the contour of the void fraction. The gradual decreasing in the void fraction before the connection point refers to the geometry of the slug flow such that the minimum concentration will be at the connection point and the maximum impacted the front of the pipe causing the highest pressure drop shown in figure 5 above. With equalizing the velocities of both air and water to 2m/sec, the slug flow pattern would be generated. This flow pattern is well known with its high degree of complication and disturbance. Figure 4 shows the concentrations of the insitu velocities on the neck of the junction. Figure (4): Mixture velocity Figure 5.4.4vector Air &(Vsl=Vsg=2 m/sec) water velocity vector Also, from figure 4 above, the phenomenon of the secondary gas flow is quite clear and the location of its occurrence can be determined confidentially. The irregularity of the velocity distribution will cause differences in the pressure drop profile. The liquid slug generates a high pressure drop at the internal face of the pipe close to the connection point as it is shown in figure 5 : Figure (6): Void fraction contour Figure 5.4.6 Void (Vsl=Vsg=2 m/sec) fraction contour Within further increments in gas phase velocity to 10 m/sec and decreasing the water velocity to1 m/sec, the same criterion would appear with more significant and noticeable features. This would change the velocity distribution and pressure drop profiles. The maximum velocity would be in the center of the main pipe at the area that produces the 4 highest amount of pressure drop due to the high degree of turbulence. At the connection point, a small amount of pressure drop will occur because of an immediate change in the phase distribution. These phenomena are obvious in figures 7 & 8: The void fraction simulation shown in figure 9 reflects the spatial distribution caused by the turbulence. Figure (9): Void fraction contour Figure 5.4.9 Void(Vsl=1 m/sec) fraction contour (Vsg=10 m/sec) The gradual decrement towards the connection point refers to the nature of slug flow that has been generated within these flow conditions. For determination the mixture velocity along the section, PHOENICS produced the velocitydistance graph (figure 10) below. For the second and third cases of simulation, the mixture velocities are almost the same. There is a wide gap between them and the velocity profile of the first case because within low liquid loading, the liquid would occupy the bottom of the pipe and the high velocity comes from the high gas velocity. Air water Figure (7):Figure Mixture 5.4.7 velocity vector (V& sl= 1m/sec) velocity vector (Vsg=10 m/sec) From figure 7 above, the secondary flow phenomenon is clear as well. 18 10 air & 1 water velocity inlet Vel. Vs Dist. T-junction Pipe 2 air & 0.2 water velocity inlet 2 air & 2 water velocity inlet 16 14 Velocity (m/s) 12 Figure (8): Pressure drop contour (Vsl=1 m/sec) (Vsg=10 m/sec) 10 8 6 The unsteady state of the flow can be determined from the pressure drop profile above. 4 2 0 0 0.02 0.04 0.06 0.08 0.1 Distance (m) 0.12 0.14 Figure (10): Velocities plot 5 0.16 0.18 0.2 6. Ottens et al. (1994) “ Gas-liquid flow splitting in regular, reduced and impacting T-junctions” 14th Int. Congress on Fluidodinamica Multifase nell’Impiantistica Industriale, Acona Italy. 7. Penmatch et al. (1996) “ Two-phase stratified flow splitting at a T-junction with an inclined branch arm” Int. J. Multiphase Flow 22, 6, 1105-1122. 8. Roberts et al. (1994) “Two-phase flow at Tjunctions” PhD thesis, University of Nottingham, UK. 9. Roberts et al. (1995) “ The split of horizontal semi-annular flow at a large diameter T-junction” Int. J. Multiphase Flow 21, 455-466. 10. Shoham et al. (1989) “Two-phase flow splitting in a horizontal reduced pipe tee” Chemical Engineering Science 44, 23882391. 11. Sutharshan et al. (1995) “Measurements of circumferential and axial film velocities in horizontal annular flow” Int. J. Multiphase Flow 21, 193-206. CONCLUSIONS In order to avoid the slug flow that is unfavorable from both an operational and a safety point of view, the velocities of both phases should be controlled. This will help also in reducing the pressure drop especially at the junction. The sudden change in the velocity profile represents a significant change in the flow patterns which requires more attention during the time of operation. PHOENICS can provide the main objectives of the two-phase flow simulation and can predict the maldistribution of the phases in the pipe during the flow. The capabilities of PHOENICS include the ability to predict all the important factors in the two-phase flow phenomenon like the pressure drop, void fraction and phase distribution. The simulation results acquired from PHOENICS are quite close to the results acquired from experiments and the theoretical models. PHOENICS can be used for designing a two-phase flow system. REFERENCES 1. Azzopardi,B.J. & Walley,P.B. (1982) “The effect of flow pattern on two-phase flow in a T-junction” Int. J. Multiphase Flow 8, 481507. 2. Azzopardi,B.J. (1989) “The split of annularmist flows at vertical and horizontal Ts” Proc.8th Int. Conference on Offshore Mechanics and Arctic Engineering. 3. Flores,A.G. et al. (1995) “Gs-phase secondary flow in horizontal stratified and annular two-phase flow” Int. J. Multiphase Flow 21, 207-221. 4. Hart,J. et al. (1991) “ A model for predicting liquid route preference during gas-liquid flow through horizontal branched pipelines” Chemical Engineering Science 46, 16091622. 5. Hwang et al. (1988) “ Phase separation in dividing two-phase flow” Int. J. Multiphase Flow 14, 439-458. 6