UP-GRADES: - The Astro Home Page

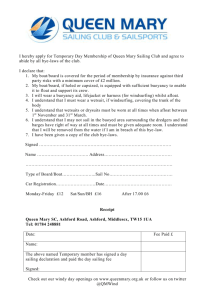

advertisement