Handling Your Precious Metal Labware

advertisement

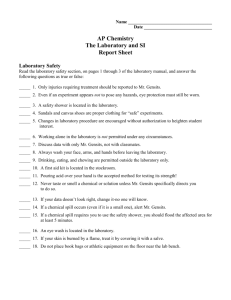

Handling Your Precious Metal Labware INTRO.....................................................................Page Two FUSIONS.................................................................Page Two Sodium carbonate Sodium carbonate mixed with sodium nitrate or nitrite Sodium borate or sodium metaphosphate Alkali bifluorides Alkali chlorides or alkaline earth chlorides Alkali bisulphate’s IGNITIONS..............................................................Page Three Ignition of filtered precipitates Determination of ash in organic materials Determination of volatile matter fuels EVAPORATIONS......................................................Page Three ELECTROLYTIC ANALYSIS......................................Page Four CONDITIONS TO AVOID.........................................Page Four Atmospheres Liquids Solids (inc fusions and vapours) CARE OF PLATINUM LABWARE..............................Page Five Cleaning of crucibles and dishes Cleaning of electrodes CORROSION...........................................................Page Seven Oxides Acids Atmospheres Alkali Metal Compounds Elements Miscellaneous 1 INTRO Pure platinum labware is suitable for numerous laboratory operations such as fusions, ignitions and evaporations that are carried out in oxidising atmospheres. Pure platinum also has exceptional qualities in the construction of electrodes by providing an excellent combination of mechanical strength, electrical conductivity and resistance to chemical and electrolytic attack. Both anode and cathode remain constant in weight during electrolysis, and deposits can be easily dissolved after weighing without damage to the electrodes. When properly used, pure platinum labware provides many advantages. For various applications the basic rules for use are outlined below: FUSIONS Fusions should always be done under oxidizing conditions using materials free from organic substances. During fusion and cooling, the material should only come in contact with platinum or a clean refractory. As a general rule, fusions made in platinum-rhodium alloy labware are not recommended due to the fact that rhodium is rendered partially soluble in certain compounds, i.e., alkaline bisulphates and pyrosulphates. Generally used fusion agents affect pure platinum in the following manner: Sodium carbonate The loss of weight of platinum amounts to a fraction of a milligram. Sodium carbonate mixed with sodium nitrate or nitrite Under ordinary laboratory conditions the loss of platinum is not likely to exceed two milligrams. Sodium borate or sodium metaphosphate Atlow temperatures, pure platinum is unaffected by borax. Sodium metaphosphate attacks the metal only at very high temperatures or under reducing conditions. Alkali bifluorides The loss of weight of platinum is practically nil. Alkali chlorides or alkaline earth chlorides Both attack platinum above 1000°C in the presence of air, which liberates chlorine from the fused salt in a neutral atmosphere, these chlorides are inert. Alkali bisulphates Platinum is attacked slightly above 700°C. This can be reduced by the addition of ammonium sulphate. With the exception of alkali bifluorides, traces of platinum should be sought when making an accurate analysis using any of the foregoing fusion agents. 2 IGNITIONS Platinum is subject to attack during ignition by any easily reducible substance. The risk of damage can be avoided by taking the proper precautions with the materials involved. Ignition of filtered precipitates Platinum labware can be used in ignitions of the following precipitates: Barium sulphate. Sulphates of metals not readily reducible. •Alkaline earth carbonates, oxalates, etc. •Oxides not readily reducible, such as Al2O3,MgO, BaO, CaO, SrO, TiO2,ZrO2, ThO2,MoO3,WO3,Ta2O5,Cr2O3,Mn3O4,and in the absence of carbonaceous matter: ZnO, CdO, NiO, CdO. Dry the precipitate contained on the moist filter paper in a platinum dish by a preliminary heating on a hot plate or similar source. After drying, transfer the dish to the area in front of the hot open muffle of a furnace operating at 800°C. Within 10 to 15 minutes, the paper will become completely charred. Next, place the dish approximately 5cm inside the muffle, where it should remain until nearly all carbonaceous matter has been burned off. Somewhat higher temperatures may be required to remove the last traces of carbon and the decomposition of the precipitate. This can be accomplished without detriment to the platinum providing there is a free access of air. Precipitates such as MgNH4P04,MgNH4AsO4,and CaWO4may be used without unnecessary danger if suitable care is exercised to assure safety. Determination of ash in organic materials A shallow dish should be used and the contents heated well forward in a hot open muffle until combustion is nearly complete. If the surface is disturbed from time to time, combustion can be accelerated. After all carbonaceous matter has been burned away, final combustion can be conducted in the hot zone of the muffle. Determination of volatile matter in fuels Particular care should be exercised in this operation. There is a danger in contaminating the platinum dish because it is essential that a non-oxidizing atmosphere be maintained in the crucible to prevent loss of free carbon. This is particularly true if the fuel is rich in sulphur or phosphorous compounds. EVAPORATIONS Platinum labware can be used in evaporations containing the following: •Sulphuric acid with or without hydrofluoric acid •Hydrofluoric acid •Hydrofluoric and nitric acid when other halides (especially chlorides) are present •Hydrochloric acid in the absence of oxidising agents that yield nascent chlorine •Alkali hydroxides or carbonates where contamination of the solution with silica must be avoided •Sodium peroxide solutions. 3 ELECTROLYTIC ANALYSIS Electrochemical methods of analysis are widely used because of their speed, simplicity and economy. In multiple analysis of a routine nature, several solutions can be electrolysed simultaneously. In single determinations, the analyst can attend to other operations while electrolysis is in progress. Platinum electrodes can be used to advantage in numerous applications: As anodes in most electrolytes except strongly acid chloride solutions. As cathodes for the deposition of metals from acid, alkaline or ammoniacal solutions. For the deposition of zinc, gallium, and bismuth, the platinum should first be copperplated to prevent superficial alloying with the deposited metal. CONDITIONS TO AVOID When platinum is heated to high temperatures, it can be attacked by certain atmospheres, solids, fusions and vapours. Under these circumstances, the following should be avoided: Atmospheres 1. Ammonia - darkens the surface,making it less lustrous. In time, it will develop pores and create a crystalline appearance. 2. Sulphur dioxide - promotes the formation of sulphur trioxide,which results in platinous sulphide coating. 3. Chlorine - converts the metal into a mass of crystals due to the alternate formation and decomposition of platinous chloride. 4. Volatile chlorides - especially those that readily decompose. 5. Gases and vapours containing high contents of free carbon, because Platinum disintegrates if it comes into contact with carbon. Therefore, platinum should never be heated in the reducing zone of a gas flame. Liquids 1.Aqua regia 2. Hydrochloric acid with oxidizing agents. 3. Concentrated sulphuric acid - harmful when extended periods are involved. In most laboratory applications, the action is so slow that it is usually of negligible importance. 4. Concentrated phosphoric acid - action is noticeable only after very prolonged heating. 4 Solids (including their fusions and vapours) 1.Sulphur, selenium and tellurium - action of sulphur is very slow, with prolonged heating required to produce any serious effects. Selenium and tellurium combine readily with platinum. 2. Phosphorus, arsenic and antimony - combine readily with platinum. 3. Magnesium pyrophosphate - harmful above 900°C. 4. Silica and borax - harmful at high temperatures. 5. Molten lead, zinc, tin, bismuth, silver, gold or copper - or mixtures that form these metals by reduction. 6. Fused alkali oxides and peroxides - and, to a lesser degree, alkali hydroxides inthe presence of air. 7. Fused nitrates - action intensified by the presence of alkali hydroxides or carbonates, though not severe in any case. 8. Phosphorus pentoxide or phosphoric acid - action relatively slight. 9. Fused cyanides - platinocyanides are formed. Iron oxide above 1200°C - oxygen is liberated and the iron combines with the platinum. Silica, silicates, alumina and magnesia above 1600°C -no action occurs at lower temperatures. Fused alkali and alkali chlorides - in the presence of air at 1000°C or above. Lead and bismuth oxides above 1250°C. CARE OF PLATINUM LABWARE The life of platinum labware can be extended by making it a practice to observe some fundamental rules: 1.Avoid the unnecessary prolonged heating of platinum as it tends to promote crystal growth that eventually produces cracks. 2. Place hot platinum vessels on a clean refractory material. Never place them on acold metallic or dirty surface. 3. Heat platinum ware under oxidizing conditions whenever possible. When heated over a Bunsen or Meker Burner, only the upper nonluminous cone should be employed - not the inner cone. Avoid using a smoky flame because the free carbon will embrittle the platinum. 4. Always use clean platinum-tipped tongs to handle hot platinum vessels. When base metal tongs are the only implements available, allow the vessel to cool before handling. 5. When dislodging melts from crucibles, exercise care to avoid distorting the vessel. If distortion does occur, reshape the crucible. 5 6. Use clean triangles (porcelain, alumina or preferably platinum) to support crucibles when making fusions. 7. New platinum crucibles and dishes can exhibit adhesiveness at temperatures higner than 1000°C. This is mainly a surface phenomenon which vanishes gradually as the material becomes older. For this reason, it is advisable not to place new crucibles and dishes in a furnace in such a way that they can come into contact with each other. During the initial ignitions, a new crucible should be covered with a previously used lid. Cleaning of crucibles and dishes Platinum vessels should always be cleaned after use. They can be immersed in a chromic acid cleaning mixture to remove many impurities, particularly organic matter. Boiling in hydrochloric acid may be required to remove insoluble carbonates or metal oxides. This treatment can be followed by boiling in nitric acid, but the article should first be thoroughly rinsed. Thorough rinsing avoids the presence of hydrochloric acid in a nitric acid solution, which would attack the platinum. The solvent action of fused potassium bisulphate can usually be employed to remove adherent silica, silicates, metal and metal oxides. After fusion, carefully run the molten bisulphate over the inner surface, allow to cool, dissolve the melt in boiling water and rinse thoroughly. Boiling in hydrochloric acid may be required to supplement this procedure. After cleaning, the platinum crucible or dish may be polished by rubbing it gently with recommended mild polish. Please contact GLC for their recommendation. Cleaning of electrodes A platinum electrode should be washed with water after removal from the electrolyte. It should then be washed with alcohol and dried in a stream of warm air at a temperature below 100°C. Electrodes should not be dried by vigorous shaking as this action tends to bend the stem. Repeated bending and straightening will eventually fracture the stem. 6 CORROSION OXYDES REMARKS iron, lead and bismuth oxide reaction occurs above 1200°C ZnO, CO3O4, NiO, CdO and other reducible oxides incineration must occur inder oxidizing circumstances more stabile oxides such as Al2O3, MgO, TiO2 and ZnO2 incinerations possible without attack SiO2 (and silicates) attack under reducing circumstances above 1220°C ACIDS REMARKS concentrated phosphoric acid or reaction observable after prolonged P2O5 heating H2SO4, HF and HNO3 evaporations can be carried out without much loss of platinum HCl & oxidizing acid (e.g. nitrohydrochloric acid) fast attack organic acids no attack ATMOSPHERES REMARKS ammonia, sulphur dioxide, chlorine, bromine, fluorine and volatile chlorides these atmospheres attack platinum air, nitrogen, oxygen, NOx, iodine vapours, and CO2 negligible effect hydrogen, carburetted gases promote the reduction of a large group and vapours,lighting gas flames of substances and thus to be avoided and reducing gases ALKALI METAL COMPOUNDS REMARKS Na2CO3 or K2CO3, mixtures of them, alkali bifluorides KHSO4, and BORAX alkali nitrates and nitrates only slight losses during normal fusions 1-2 mg loss of platinum per fusion alkali chlorides and alkali earth attack above 1000°C, particularly at the chlorides metal line (3phases) alkali bisulphates alkali oxides, peroxides, hydroxides, sulphides attack occurs above 700°C if liquid: all attack platinum alkali phosphites no attack at any temperature sodium hypochlorite no attack at 100°C ELEMENTS REMARKS 7 Se, Te, As, Sb, Pb, Sn, Zn, Bi, etc... MISCELLANEOUS magnesium pyrophosphate in fact, all elements in their elementary state have to be avoided REMARKS attack occurs above 900°C molten cyanides formation of platinum cyanides, severe attack organic incinerations, carbon pre-heat carbonaceous materials to very moderate temperatures under an excess of oxygen 30% H2O2 attack at 100°C 8