Title

advertisement

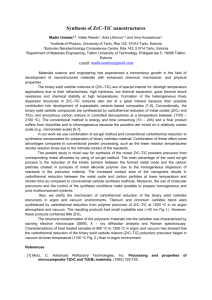

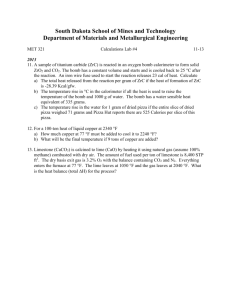

Proceedings of the 12th Conference of the European Ceramic Society – ECerS XII Stockholm, Sweden - 2011 Impact of the processing conditions on the specific surface area of carbides powders derived from a colloidal route Deschanels X.1, El Ghazzal M.1, Delchet C.1, Herault D.1, Hodaj F.2 and Zemb T1 – UMR CNRS 5266, Grenoble INP UJF, BP 75 1ICSM 2SIMaP CEA Marcoule - UMR 5257 BP 17171 30207 Bagnols-sur-Cèze (France) 38402 St Martin d'Hères Cedex (France) xavier.deschanels@cea.fr problem is to reduce the size of starting products from micrometric to nanometric scale3. Recently, several authors4-8 have used this route to obtain carbide. In this work, a process similar to that described by Martin6-7 has been used to synthesize carbides. It consists in the carbothermal reduction of the parent metallic oxide (colloidal or micrometric) by carbon obtained after the pyrolysis of a carbohydrate. This technique provides the ability to intimately mix the reagents and to encapsulate the oxide in a carbon matrix. The characteristics of the final products (surface area, crystallite size) were studied according to the size and the nature of the precursors. The main objective of this work was to study the relationship between the initial surface contact between carbohydrate and silica/zirconia, and the final surface area of the porous material obtained. Abstract Carbides compounds (SiC, ZrC) powders were synthesized by carbothermal reduction of corresponding metal oxides (colloidal or micrometric size) by carbon resulting from the pyrolysis of carbohydrate at temperatures ranging between 1300 and 1550°C under flowing argon. The specific surface area and the crystallite size of the final products were investigated as a function of the size of the starting oxides and the excess of carbohydrate used for the carboreduction. The final products elaborated from colloidal precursors have a mesoporous structure localised into the porous carbon matrix surrounding the carbides particles. SEM and TEM observations showed that the porosity of the samples is due to the release of gaseous species produced during the carbothermal process. The highest surface area measured is close to 300m2/g for a sample ZrC+C. The use of nanometric precursors could be an interesting way to control the pore size in these supported mesoporous carbon materials. Keywords: Carbides, Carbothermal reduction, Colloid Experimental The carbothermal reduction of metal oxides (ZrO2, SiO2…) leading to the synthesis of carbides can be described as depicted in equation (1) : MO2 + 3C → MC + 2 CO (1) It has been suggested that under reducing conditions, the mechanism of the silica carbothermal reduction is more complex and leads to the formation of the gaseous SiO species9. Thus, the carbothermal reduction of silica can be described as follow: SiO2 + C → SiO(g) + CO(g) (2) SiO + 2C → SiC(s) + CO(g) (3) Experimentally, the condensation of silica, indicating the presence of SiO gas, was observed on the crucibles after the pyrolysis of the samples. Sucrose was the carbohydrate used as carbon source for the carbothermal reduction of fumed silica (P1), micrometric silica (P2), colloidal zirconia (P3), micrometric zirconia (P4). Fumed silica is amorphous silica; it has a chain-like particle morphology composed of submicron-sized spheres (7 nanometers), which are highly branched (nominal size 0.1-0.2 microns). Its surface area is close to 360m2/g. The colloidal zirconia was purchased from Nyacol Company (particle size 10nm). These colloidal particles are stabilized by Mesoporous, Introduction Carbides constitute a class of materials that exhibit the characteristics of ceramic compounds such as high hardness, high melting point, high strength, good wear and good corrosion stability1. These properties allow them to be a good candidate for many technological applications in the field of advanced ceramic industry (cutting tools application, wear resistance….). Metallic carbide compounds are developed in the field of catalysis because of the availability of metal carbide with high surface areas2. Several approaches have been used to synthesize carbides. Direct methods consist of the reaction of the oxide or the metal oxide with solid carbon at high temperature (~ 2000°C). The main drawback of these routes is the use of high temperature (>2000°C) which leads to coarsegrained powders with particle size higher than 1 micron. These methods lead to compounds with low surface area. One possibility to overcome this 1 Proceedings of the 12th Conference of the European Ceramic Society – ECerS XII Stockholm, Sweden - 2011 Table 1 Phases detected by XRD, C and O analyses of the powders elaborated at 1550°C-4h Ar (M=Si for P1 and P2; M=Zr for P3 and P4). acetate ions. Micrometric silica and zirconia powders were purchased from Aldrich Company. The grains size of these powders is in the order of 1-10 micrometers. The synthesis of the precursors was done by mixing the oxide particles together with a quantity of sucrose solution corresponding to the target final stoichiometry. The suspension obtained guarantees a homogeneous dispersive mixing in a simple way. The amount of sucrose is adjusted in a proportion ranging between 1 and 8 times the quantity needed by the reaction (1) to obtain a complete conversion of the parent compounds. The ratio C/M quantifies the deviation from stoichiometry, i.e. C/M=3 means the reagents are mixed together in the proportion of the reaction (1). In a second stage, the suspension is freeze dried to obtain a powder. In a last step, the powders were pre-heated at 800°C during 3 hours in flowing argon to decompose the sucrose into carbon, and then the carbides formation was carried out at higher temperature. Thermal analyses were carried out with a Netzsch STA 409 thermo gravimetric analyzer. The specific surface areas were obtained by BET on a Micromeritics ASAP after 4h vacuum (10-2 mbar) at 350 ºC. Elemental analyses (C, O) were performed respectively by LECO CS230 and TCH600. The oxygen content in the powder was determined by combustion analysis under helium and IR detection of the CO2-vibration. Combustion method was also used to determine the carbon content. The carbides powder was heated in an oxygen flow. Added Fe powder was used to assist the combustion. The formed CO2 was used again to detect the carbon content. Transmission Electron Microscopy (TEM) observations were carried out at 100 kV (JEOL 1200 EXII). Samples for TEM measurements were prepared by milling of the samples in a agate mortar, followed the dispersion of such powder in a ethanol under ultrasonification and deposition on copper grids. Powder X-ray diffraction patterns were measured on a Bruker D8 advance diffractometer using CuK radiation in Bragg-Brentano geometry. SEM analyses were obtained with a FEI QUANTA FEG 200 ESEM environmental scanning electron microscope. C/M 3 6 9 12 15 18 24 4.5 9 12 4.8 6 9 12 21 24 6 12 24 P1 P2 P3 P4 SBET (m2/g) 18 16 194 194 173 136 69 15 53 29 39 128 251 305 243 248 3.4 20 6 C (wt.%) 28.3 28.2 50.2 54.9 73.6 78.1 80.1 28.8 51.7 58.0 12.0 19.1 28.6 38.1 52.8 57.1 11.6 32.7 37.8 O (wt.%) 2.1 1.3 1.5 1.1 1.1 0.7 0.4 3.1 5.0 n.d. 4.3 5.1 5.3 4.8 4.0 3.5 4.8 6.1 2.9 XRD SiC SiC SiC SiC+C SiC+C SiC+C SiC+C SiC SiC+SiO2 SiC+C ZrC+m-ZrO2 ZrC ZrC ZrC ZrC ZrC ZrC ZrC ZrC Consequently a slightly higher temperature (1550°C-4h) was chosen for samples heat-treated in the furnace. The conversion of these precursors has required a flow of argon higher over 30 l/h to evacuate the gaseous species produced during the heat-treatment. Below this flow the reaction yield is very low and it remains primarily the oxide in the product pyrolyzed. In these conditions, X-Rays diffraction patterns show the formation of carbides (Table 1). No change in the temperature conversion of the carbides has been observed according to the size of the oxides (colloidal, micrometric). Fig. 1 TGA analysis of P1 and P3 under argon flow. Results and Discussion x TGA analysis under flowing argon revealed a first weight loss below 800°C attributed to the evacuation of the water adsorbed on the precursors and to the decomposition of sucrose and acetate present in the colloidal zirconia. A second weight loss was observed above 1300°C, it can be attributed to the carbothermal reduction. The mass of the final products is stabilized at 1500°C, indicating that the reaction is complete (Fig. 1). x Cubic SiC a Amorphous carbon holder C/Si=12 C/Si=6 C/Si=15 C/Si=9 C/Si=18 u.a. x x a x 10 20 30 40 50 60 70 80 2q(°) Fig. 2 X-rays diffraction pattern of heat-treated precursors P1 versus the ratio C/Si (1550°C-4h-Ar). 2 Proceedings of the 12th Conference of the European Ceramic Society – ECerS XII Stockholm, Sweden - 2011 Complied with the reaction (1), a ratio C/Si higher than 3 is necessary to obtain silicon carbide, for the zirconia it has been necessary to increase the ratio C/Zr up to 6 in order to completely transformed ZrO2 in ZrC. When the ratio C/Si increases above 9, amorphous carbon has been detected on the X-Rays patterns (Fig. 2). Elementary analyses confirm the presence of residual carbon in such samples, jointly with a decrease of the amount of oxygen (Table 1). The specific surface area (SBET) of the materials P1, P3 and P2, P4 elaborated respectively from the nanometric and the micrometric oxides are plotted versus the volume fraction of residual carbon on Fig. 3. The volume fraction of carbon is inferred from the results of the elementary analysis of carbon, by considering that the final material consists of only 2 phases, i.e. carbides (SiC or ZrC) and carbon. The evolution of the surface area is correlated with the size of the initial oxides. The specific surface area SBET of P1 and P3-type materials increases up to 200 and 300 m2/g respectively and then decreases for higher carbon content to tend to the value measured on pyrolyzed sucrose (2m2/g). These materials exhibits, especially for samples with the highest specific area, a mesoporous structure which is located in the matrix of residual carbon as it can be seen on the SEM observations (Fig.4). No significant change has been observed on the grain size of the carbides particles according to the volume fraction of residual carbon. Such particles present a grain size of 100nm and 50nm respectively for P1 and P3type powders (Fig. 5). The calculated outer surface (S) which is developed by a SiC powders with a particle size of R=50 nm is close to 20 m2/g (S=3/(R), SiC=3.2g/cm3). This value is one order of magnitude lower than the maximum surface area developed by SiC P1-type material (195m2/g). This point supports the hypothesis of the localization of the porosity in the matrix of residual carbon. The N2 adsorption-desorption isotherm of the P1-type sample for a ratio C/Si=12 (Fig. 6) undergo abrupt changes when the relative pressure is in the medium range from 0.7 to 0.9, and this is salient feature of mesoporous materials. 350 d) c) Fig. 5 TEM observations of powders pyrolyzed at 1550°C C/M=24, a)P1-type (SiC+C), b) P3-type (ZrC+C). The shape and the hysteresis loop of P1 and P3type powders (Fig.6) suggest that these samples possess a mesoporous structure. In contrast, the N2 adsorption-desorption isotherms of powders made from micrometric oxide (P2, P4) do not show hysteresis loops which indicate they are not mesoporous. This evolution of the surface area (SBET) versus the volume fraction of residual carbon (%vol. Cres.) can be explained if one considers that the formation of the mesoporosity is a consequence of the release of CO gas produced by the carbothermal reduction of the oxides at high temperature. For low volume fraction of carbon, SiC grains are bonded together by a thin layer of amorphous carbon and the gases produced during the carboreduction can percolate by the interstices between these grains. Therefore the specific surface area is close to the external surface of the carbides particles, i.e. 20m2/g for P1type powder as noted above, and roughly the same value for P3-type powder if one considers a particle size of 50nm and a density of 5.85 g/cm3 for ZrC compound. P1 P2 P3 P4 Sucrose 300 250 300 200 P1 P2 P3 P4 250 150 Vads. (cm3/g) Specific area (m2/g) a) b) Fig. 4 SEM observations of powders pyrolyzed at 1550°C C/M=24, a)P1-type (SiC+C), b) P3-type (ZrC+C). 100 50 0 0 20 40 60 80 200 150 100 50 100 %vol Cres. 0 0 Fig. 3 SBET of precursors P1, P2, P3, P4 pyrolysed at 1550°C versus volume fraction of residual carbon. Specific surface area of pyrolyzed sucrose is 2 m2/g. 0,2 0,4 0,6 P/P0 3 0,8 1 Proceedings of the 12th Conference of the European Ceramic Society – ECerS XII Stockholm, Sweden - 2011 carbides are <20 and about 250-300 m2/g respectively. The increase of the volume fraction of the residual carbon up to of 50 vol.% induces an increase of the surface area of both carbides elaborated with the nanometric precursors. For higher amount of carbon the surface area decreases to tend to the value of pyrolyzed sucrose (2m2/g). Mesoporosity was observed on these samples. The porosity is mainly located in the residual carbon phase resulting from the pyrolysis of the sucrose. A mechanism based on the release of CO gas during the carboreduction of the oxides has been proposed to explain the formation of the mesoporosity in the nanosized carbides. Fig. 6 Nitrogen adsorption-desorption isotherms of precursors P1, P2, P3, P4 after pyrolysis at 1550°C-4h in flowing Ar (C/M=12 for all the samples). Increase in the volume fraction of residual carbon Carbide Carbon + Porosity References Fig. 7 Schematic formation of porosity due to the release of CO gas during the carboreduction process. 1. S.T. Oyama, Introduction to the chemistry of transition metal carbides and nitrides, in S.T. Oyama (ed. Chapman & Hall), The chemistry of transition metal carbides and nitrides. Blackie Academic & Professional, Glasgow (1996) pp1-27. As the volume fraction of carbon increases, the gases produced by the carbothermal reaction escape from the samples by creating narrow channels through the carbon matrix. The size of the channels is related to the size of parent oxide particles, so the compounds elaborated from the P1, P3 precursors (nanometric size) develop a much higher surface area than the powders elaborated from the micrometric precursors. Beyond this value, the specific surface area decreases until it reaches the surface area of pyrolyzed sucrose because there is not enough gas produced by the carbothermal reaction to increase the porosity volume. This process is shown schematically in Fig.7. In contrast for a same volume fraction of carbon, P2 and P4type materials exhibit a much lower specific surface area. For these samples, the silica or zirconia particles are agglomerated in clusters whose characteristic size is micrometer. These particles are much less well distributed in the volume of sample, and therefore the channels created by the release of the gases during the carbothermal reaction are larger, leading to a material with lower specific surface. 2. S.T. Oyama, Preparation and catalytic properties of transition-metal carbides and nitrides, Catal. Today, 15[2] (1992), 179-200. 3. R.J.P. Corriu, Ceramics and nanostructures from molecular precursors, Angew. Chem. Int. Ed., 39 (2000), 1376-1398. 4. M. Dollé, D. Gosset, C. Bogicevic and al, Synthesis of nanosized ZrC by a sol-gel route, J. Eur. Ceram. Soc., 27[4], (2007) 2061-2067. 5. X. Deschanels, M. el Ghazzal and al., Synthesis of carbide compounds derived from colloidal oxide and carbohydrate, Progr. Coll. Polymer Sci., 137, (2010), 47-52. 6. H-P Martin, E. Müller, Y. Knoll and al., Silicon carbide derived from silica sol and sugar, J. Mater. Sci. Lett., 14, (1995) 620-622. Conclusions 7. H-P. Martin, R. Ecke, E. Müller, Synthesis of nanocrystalline SiC powder by carbothermal reduction, J. Eur. Cer. Soc., 18, (1998) 1737-1742. The synthesis of carbide powders (SiC, ZrC) from oxide (colloidal or micrometric precursors) and sucrose mixture is confirmed. This novel route allows an easy adjustment of carbon content in the compound and could be interesting to elaborate in one pot new supported porous carbon materials. No change was observed in the temperature of the carbothermal reaction when varying the precursor grain size (micrometric, nanometric) or the quantity of sucrose surrounding the oxide grains. The initial contact surface between oxide and sucrose is in the range 1-5 m2/g for a micrometric precursor powder, and 20-100 m2/g for the nanoscale precursor, whereas the macroscopic surface areas of the final 8. G.C. Wei, C.R. Kennedy, L.A. Harris, Synthesis of sinterable SiC powders by carbothermic reduction of gel-derived precursors and pyrolysis of polycarbosilane, Am. Ceram. Soc. Bull., 63[8], (1984) 1054-1061. 9. V.D. Krstic, Production of fine high-purity beta silicon carbide powders, J. Am. Ceram. Soc. 75[1] (1992), 170-174. 4