The deterioration of silver alloys and some aspects of their

advertisement

The deterioration of silver alloys and some aspects of their conservation

Virginia Costa

Abstract

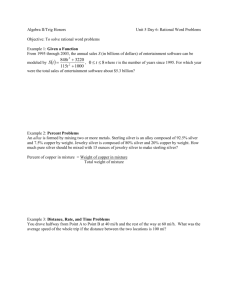

The present article aims to offer a comprehensive approach to the conservation of silver objects. It

is not intended to suggest or recommend any specific recipe or treatment for a given case. Instead,

the paper presents a range of possibilities to assist the conservator in defining the state of

conservation and the possible need for treatment and protection of an object. Besides giving the

background to the structural properties of alloys used in silver artefacts, the possible forms of silver

deterioration are presented, with special emphasis on tarnishing and mineralization. Less frequent

cases, such as selective, localized and stress corrosion are also discussed. A descriptive review of

materials and methods used for cleaning, consolidating and protecting silver artefacts follows,

accompanied by an extensive bibliography.

Introduction

Whether an object should undergo treatment can only be answered after assessing aesthetic,

technical and historical parameters and also taking into account how the object will be stored or

used after the intervention. Perhaps one of the most important considerations is the nature of the

object: from what material and with which techniques it was made, what has subsequently

happened to it and how it has been altered. These factors limit what conservation treatments may be

applicable, from a material and technical point of view. Additional aspects of the object's nature

may be revealed during the course of treatment, and may lead to a change in procedure; the

conservator must be alert to alternative options throughout the course of treatment.

After reviewing some properties of the alloys used in silver artefacts, and the causes and

mechanisms of the typical forms of silver deterioration, this paper will describe the materials and

methods used in the cleaning, consolidation and protection of silver objects. It is not the intention of

this paper to endorse specific treatment methods or to preclude others. Rather, the intent is to

acquaint the conservator with the range of published work available for consultation when he or

she, guided by a thorough examination of the object and its environment, evaluates the state of

conservation of a silver artefact and its possible need for treatment and/or protection.

Silver artefacts and alloys

Among all the metals, silver has physical and chemical characteristics which, combined with the

beauty of its surface appearance, make it an ideal material for producing decorative objects.

Silver was used in two principal forms: as so-called 'solid' silver objects and as a coating. Solid

silver articles actually consist of alloys with other metals, partly to make the alloy harder, and also

to economize on the amount of silver used [1]. These objects, often containing copper as a major

alloying element and lead and gold as impurities, can either be cast directly or cold-worked into the

final form [2, 3] (Fig. 1). Great

Fig. la Cross-section of a silver sheet from a Renaissance silver basin elaborated by repousse,

showing equiaxed grains [after D. Scott, 1991].

Fig. lb Cross-section of a silver-copper alloy sheet fragment: dendritic structure with minimal

distortion, showing that the Sican metalsmiths (Peru, AD 850-1050) have pre-cast the alloy into the

dimensions required for making the tumi, rather than carrying out the expected process of making

the idol from hammered silver-copper sheet [after D.Scott, 1996].

quantities of articles so made are decorated with gold coatings (usually by mercury-gilding or by

'fire-gilding') or with niello, which enhances surface details by contrasting clear and shadowed areas

[4, 5]. In general, the most commonly employed alloys used to produce objects are: so called

'sterling silver' (92.5% Ag, 7.5% Cu); 'coin silver' (90% Ag, 10% Cu); and eutetic or brazing alloy

(71.9% Ag, 28.1% Cu).

Silver was also intensively used as a coating on copper and iron alloys, to yield a rich appearance at

minimal cost [6]. The few and rudimentary early procedures of silver-coating that involved silver

foils attached mechanically or with silver-copper solders [7] were slowly replaced by more efficient

methods, such as mercury-silvering. Some specific applications were incrustations, such as those

found in Merovingian arms [8], metal threads [9| and 'depletion silver', used by native Latin

Americans to enrich the alloy's surface [10, 11]. Since the eighteenth century a plethora of new

techniques, including 'French plating', 'close plating', Sheffield and electroplating have been

introduced [12] (Fig. 2).

Stylistic and typological examination of silver objects can be complemented by laboratory analysis

[13]. The kind of alloy is often determined by elemental analysis [14] and hypotheses about the

provenance of the ore from which the alloy originated have been investigated by isotopic analysis

[15,16] and neutron activation [17]. Besides radiography, which gives information about the

fabrication of the object, other important information about shaping and decorative embellishing

can be obtained through structural examination by metallographic techniques [18, 19]. By means of

scanning electron microscopy (SEM) it is possible, not only to differentiate a chased from an

engraved object, but also to identify the kind of tool used for setting filigrees and granules [20-22].

Attention must be paid when choosing the sampling site where analysis is to be conducted: in

addition to the fact that ancient objects are structurally heterogeneous, deterioration often occurs in

a selective way [23].

Since most 'silver' objects are made from silver-copper alloys, it is important to know the structural

possibilities presented by this kind of alloy. The structure of a material defines not only its

properties, but can also explain the way it has deteriorated. The silver-copper phase diagram

provides insight into the structure produced for each alloy of these two metals (Fig. 3). The diagram

presents the phases existing as a function of the alloy composition and of the temperature

(horizontal and vertical lines respectively). The extreme left ordinate represents pure copper

(melting point 1083 °C), and the extreme right, pure silver (melting point 960 °C). Between both

extremities there is one liquid phase (L) and two different solid phases, from which one is copperrich (alpha) and the other silver-rich (beta). Depending on the composition of the alloy and

temperature it is possible to obtain a great variety of structures in the cold metal.

Fig. 2 Different forms of silver-coating: (a) Section through the rim of a forged denarius showing

how the silver foil has been wrapped round the core [from S. La Niece, 1993]; (b) Cross-section of

a silvered copper nose-ornament from Ecuador: the coating is a silver-copper alloy presenting a cast

structure [from D. Scott, 1996]; (c) Cross-section of a saxophone showing a silver electrodeposit on

brass [from C. Degrigny, 1993].

Fig. 3 Phase diagram for silver-copper alloys: (a) eutectic alloy: fine lamellae of phases alpha and

beta, disposed alternatively; (b) silver-richer alloy: primary beta phase within a eutectic matrix; (c)

even more silver-rich alloy: predominance of the beta phase.

To obtain insight into the solidification process, three cases of different alloy compositions will be

examined. The alloy of lowest melting point, called 'eutectic', is commonly used for solders and

contains approximately 70% silver and 30% copper (case a, Fig. 3). As this alloy cools from the

liquid state, solidification is instantaneous when a temperature of 780 °C is attained. The resulting

eutectic structure consists of very fine lamellae of both phases, alpha and beta, disposed

alternatively.

When the silver content is greater than in the eutectic alloy, not only does the proportion of beta

phase increase, but also the distribution of both is different (case b, Fig. 3). This is because, in this

case, the solidification does not occur instantaneously. The time period necessary to complete the

passage from liquid to solid allows the 'excessive' silver content (relative to the eutectic

composition) to solidify first, in the form of a primary beta phase. Only later, when cooled to a

temperature of 780 °C, does the eutectic solidification take place.

A third possibility, most frequently found in 'silver' objects, corresponds to copper contents up to 5

or 10%. In this case the proportion of the silver-rich (beta) phase is even greater, which reduces the

possibility of eutectic formation and limits the existence of the alpha phase to a few locations

between grains of the predominant beta phase (case c, Fig. 3).

In several alloys that are heated and then cooled very quickly it is possible to get an apparent

structural homogeneity, as only a single phase would exist at low temperature. However, as both

phases are immiscible at room temperature, this is not a stable condition and they have a tendency

to separate into two different phases with the passage of time. Once separated, the minor phase

diffuses to reach a more favourable environment, locating itself at the joints of grains in isolation

and causing weakness in the strength of the alloy [24, 25] (Fig. 4).

Fig. 4 Section of a silver earring from Tell Farah, Jordan (first half of the second millennium BC):

The 'wiggly' grain boundaries result from the precipitation of the copper-rich phase [from D. Scott,

1991].

Forms of deterioration of silver

Corrosion results from the interaction between the metal and its environment and can assume very

different forms as a function of the way in which this interaction takes place. It is a natural process

in which the metallic form obtained by metallurgical methods, tends to return to its original,

energetically more stable, state.

Examples of the typical forms of silver corrosion are given below and their possible causes and

mechanisms discussed briefly.

Tarnishing

Silver objects exposed to the atmosphere become covered by a dark film, which originates from the

interaction with air pollutants under certain conditions. The film growth is generally rapid at the

onset of the process, and tends to slow with time if relatively stable surface products are formed. As

the tarnish film thickens, the colour and reflection of the surface changes from light interference

tones, to a brown and, finally, black film [26, 27]. Excluding the case of very aggressive

environments, there is rarely great danger for the survival of the object. However, tarnish is

aesthetically displeasing and disturbs the legibility of many objects, from ancient works [28] to

daguerreotype images [29].

In most cases, the principal component of the tarnish film has been identified as acanthite (alpha

Ag2S) [30]. The associated species in the atmosphere are reduced sulfur gases, such as H2S, and

organic sulfur compounds, such as carbonyl sulfide (OCS) [31-36] and dimethyldisulfide (Me2S2)

[33]. Sources of these species are oil refineries, paper treatment plants, kitchens, rubber, paints, etc.

In several cases chlorargyrite (AgCl) has also been identified as a major component [37-39]. Its

origin could be explained by the deposition of chloride-containing airborne particles from

combustion processes, dispersion of marine salts or even from the purification treatment of water in

urban areas [38, 40].

The mechanism by which tarnish occurs is explained schematically in Figure 5. Although silver is

considered a noble metal, silver surfaces are very reactive. The non-equilibrated atoms at the

surface easily capture oxygen from the air [41,

Fig. 5 Successive stages of formation of a tarnish layer: the clean Ag surface (a) reacts with

oxygen in the air to form an oxide (b), which is transformed into a more stable specie, Ag2S, by

dissociation of a reduced sulfur molecule in the presence of humidity (c).

42], forming a thin and irregular oxide film (Fig. 5b). In this state, if a molecule of reduced sulfur is

available in the proximity, another reaction will take place, so that more stable surface bonding

forms. The resulting compound is silver sulfide (Ag,S), and a water molecule (Fig. 5c). Inevitably,

the whole process will be accelerated by the presence of humidity.

From these three elements responsible for silver tarnishing -oxidant, pollutant and relative humidity

(RH) - the most investigated is H2S, whose typical indoor concentration is reported from 50-100

parts per trillion (ppt) [36] to 300 ppt [35]. Without exception, its harmful effects are confirmed in

the literature [31, 32, 35, 37, 39, 43-45]. Some authors attributed to carbonyl sulfide (OCS) a central

role in the tarnish process, because it is present in the atmosphere in great quantities, recorded as

from 300-500 ppt [36] to 600 ppt [35] and, in the presence of water, decomposes to yield H2S and

CO2 [31, 32, 46]. Although these pollutants are normally present in very small quantities in the

atmosphere, indoor

environments can include material from which noxious gases evolve, that allow for greater than

expected corrosion rates [44]. Under other circumstances, different rules may apply. For example,

the chloride ion, Cl-, contributes to the deterioration by forming AgCl, and in this way accelerates

sulfuration in the presence of H2S [35, 39, 40].

Oxidants play an essential role in initiating the tarnishing process, confirming that there is no direct

pathway for the reaction between the silver surface and H2S [35, 41-43, 47-50]. The presence of

NO2, either as an initial reactant [48, 51], or indirectly as a catalyst for H,S dissociation [39],

increases the sulfuration. Ozone, O3, in the presence of H2S [40] and ultraviolet (UV) radiation [52]

also has this effect.

The increase in the rate of sulfuration with RH was also demonstrated by several authors, regardless

of the test conditions [31-33, 40, 43, 53]. Condensation of humidity on the surface (50% RH

corresponds to more than one adsorbed water monolayer) forms an electrolyte that can quickly

dissolve gaseous pollutants and accelerate ionic mobility, both factors important for the reactions

that conduce to tarnishing. However, if oxidants are present in great excess, this acceleration effect

can be masked [40].

It is important to remember, when evaluating the harmfulness of an atmosphere, that most

components of 'silver' objects -particularly solders - are actually silver alloys. Although some

pollutants that exist in large quantity, like SO2, are said not to be dangerous for silver [32, 54], they

could be for its alloys, especially those with copper. In this case the less noble part of the alloy will

react preferentially and considerable quantities of Cu2S can be produced [55].

Mineralization

Considerably less investigated than tarnishing, the mineralization process occurs with objects that

have remained under the earth or sea for a long time. Both are chloride-rich environments and the

process goes on continuously, albeit slowly, due to the large ionic mobility of silver. This condition

preserves the marks left by tools, deformation and decoration on the object. In some published cases

the metal is only partially mineralized, for example, in the case of a sieve [56], coins [57] and a

canopic vessel [58]. In other cases objects are completely transformed into AgCl, as in the case of a

lyre [59, 60], a silver bowl from Ur [61] and other objects cited by Rathgen [62].

These reports show that very little was done to characterize the mineralized material and understand

what has happened as a result of the conditions to which the objects have been subjected. Most of

the analyses were conducted to obtain insight into ancient techniques, some involving

metallographic examination of the transverse section [45, 59, 61] and radiography [58]. Current

investigations are providing a more complete characterization, with computer topography, trace

element and isotopic analysis [63].

The defining characteristic of this kind of deterioration is the long duration of exposure to adverse

conditions. Independent of the harmful ion present in the soil, it is possible to say that its corrosivity

increases with the oxygen and water concentration. Particularly for acidic soil, there is a preferential

dissolution of the copper-rich phase, producing cracks, and, in the presence of salts, a large amount

of silver chloride (horn silver) is formed [64]. Air-deficient soils that are pH neutral or basic will,

on the other hand, favour biodegradation, adding factors to the initial corrosion process in the form

of organic decomposition products (ammonia, nitrates, acetic acid, H2S) [45, 65]. In visceral vessels

the decomposition of tissues as well as mummification salts accelerated the corrosion reactions

[58]. In some cases, conversion to silver sulfide might have been due to sulfide-reducing bacteria

[61,66]. A significant amount of silver bromide was also found in corrosion layers on buried

ancient silver [67].

The effects of the fundamental role played by time in this deterioration process can be seen in the

stratified structure of the corrosion products [34]. During the mineralization process there is

migration of material both inwards and outwards. Silver and other elements go outwards, whereas

ions like chloride and impurities from the environment diffuse inwards and replace the original

silver. A redistribution takes place and silver, now in the form of silver chloride, occupies a volume

approximately double the original size. The result is that part of the artefact remains roughly in

place while another part extends beyond the original surface (Fig. 6).

Localized corrosion

This kind of corrosion is not usual in silver objects, and has only been observed in cases where the

RH was very high and sulfur was present [68]. The corrosion products can look like very narrow

filaments (filiform corrosion) or like dendrites ('whiskers'), which project beyond the impermeable

film that covers the metal. Although many instances have been reported in fundamental research

papers [69] and in electronic industry reports [70], only a few examples from museums are related

in detail [71, 72].

It is evident that tiny holes in the lacquer covering the silver surface are very suitable sites for

humidity to condense and to initiate the dissolution of the metal. Silver ions have a high ability to

migrate and move quickly to the surface, where they can accumulate in the form of dendrites or

filaments [33]. The presence of sulfur gases will accelerate these reactions and dissolved SO2 will

even increase the silver solubility from 20 to 3000 mg/L [68]. If the coating has good adhesion to

the rest of the surface, in spite of any holes, the preferred growth direction is outward and whiskers

must form. In the case of bad adhesion, the migration of silver takes place beneath the coating, in a

filiform manner (Fig. 7).

Fig. 6 Mineralization process: migration of material occurs both inwards and outwards; the

original surface is often preserved.

Fig. 7 Localized corrosion takes place when the surface coating is defective: corrosion evolves by

migration beneath the coating or develops outwards.

Selective corrosion

This kind of corrosion occurs in alloys or structurally heterogeneous materials that, like the name,

suggests, deteriorate in preferred areas. As most 'silver' ob]ects are really alloys, usually with

copper, this phenomenon is often observed, even in the cases of light corrosion described in the

literature. Selective corrosion has been observed as a green surface layer, probably of copper

carbonate [51, 56], or as a dark red deposit, due to formation of copper oxides [73]. This means that

the less noble (copper-rich) phase reacts preferentially with pollutants at the surface, forming

corrosion products [55, 74]. They can be cleaned off and the 'new' surface will be rougher and

richer in the more noble element, silver. This phenomenon was known by native South Americans,

who used it superficially to enrich their alloys [6, 10].

Alloys often present chemical or structural peculiarities dependent, in particular, upon which phases

are present, their size and distribution. When exposed to a harmful environment, a difference in

electrochemical potential will be created between the different phases and, as in a battery, electrical

charges will separate, defining anodic and cathodic regions. The less noble phase (copper rich) will

behave as an anode and dissolve preferentially. The surface underneath will be rougher and

enriched with the more noble phase (Fig. 8a).

Over time, and as function of the corrosiveness of the environment, the phenomenon initially

observed only at the

Fig. 8 Schematic structure of a silver-copper alloy: grey grains represent a dispersion of the minor

phase (alpha, copper-rich) within the beta matrix (silver-rich). As a consequence of the preferential

dissolution of the less noble phase, its corrosion products cover the surface (dark grey layer),

leaving the underlying surface richer in silver (white grains), (a). If the copper-rich phase is

accumulated at the grain boundaries, the corrosion process will be localized there, leading to

intergranular embrittlement (b).

surface propagates into the body of the material. The net result is that a macroscopic specimen

disintegrates along its grain boundaries. [75, 76] (Fig. 8b).

Stress-induced corrosion

In the case of stress-induced corrosion, the remarkable brittleness of the artefact can be attributed to

previous intensive cold work to shape and/or decorate it. Examples demonstrated in the literature

include a ewer and a rhyton shaped by hammering [77] and two paired Sarmatian plaques [78],

More complete investigations were undertaken in the case of an Egyptian vase [79].

Intensive cold working leaves residual stresses and induces structural modifications. One symptom

is the precipitation of a less soluble phase, previously maintained in a metastable form in the matrix.

Another is the appearance of strain lines, preferentially concentrated in the overworked regions.

These slip lines act as a barrier for the migration of impurities and minor phases, which accumulate

there, forming a region mechanically weakened and susceptible to corrosion (Fig. 9a).

Fig. 9 Structural modification introduced by cold working: precipitation of a phase and appearance

of strain lines (a). Annealing leads to recrystallization, the new grains forming twins (b).

This effect could be reduced by annealing severely cold-worked objects, but the new recrystallized

grains always maintain traces of the previous work, in the form of twinned grains, which also

concentrate impurities. Furthermore, repeated heat treatment can lead to excessive grain growth,

which also contributes to the brittleness of the material (Fig. 9b).

Materials and methods of restoration

The crucial factor guiding decisions about cleaning and/or consolidation of an object is its stability.

Priority should be given to stabilization and only later can questions about appearance and

legibility, which are generally more subjective, be addressed. In some cases, the preservation of

details such as evidence of manufacturing techniques may guide the selection of methods of

treatment.

In making such an evaluation, it is important to identify the materials that constitute the object and

also its corrosion products: considerable time may be necessary for examination and analysis.

Different approaches may apply, for example, in the treatment of a solid silver object and of what is

merely a thin coating that can be removed completely if care is not taken. Before any treatment

commences, certain technical and aesthetic decisions must be made, because even a minimal

intervention removes a little metallic silver and the repetition of cleaning procedures inevitably

causes progressive wear to the object, corresponding in several cases to a mean loss of 1 to 3 % of

the artefact's weight in a period of 200 to 300 years [64]. Moreover, it should be kept in mind that

corrosion products existing at the surface can act as a barrier for further reaction with the

environment, and that their removal therefore makes the object more reactive [80].

Review of earlier work shows that the historic evolution of cleaning procedures has involved not

only the development of new methods, but moreover their adaptation to each individual object, with

increasing care to neutralize and rinse away the materials used [22, 50, 63, 81]. Bearing this in

mind, no suggestion will be made here about the suitability of a specific product or technique. The

materials and methods most frequently used and reported in the literature will be presented below in

a systematic form, followed by examples, with the aim of showing how each works, the reason for

its choice and, less frequently reported, the consequences of its use.

Removal of surface grime

Before addressing removal of corrosion, it is important to emphasize the first step of most silver

treatments: the removal of accumulated dust and dirt on the object that hinder not only a correct

evaluation of its condition, but also the access of products used for cleaning.

In many cases a simple dusting [64, 82] followed by a rinse with water and neutral detergent [65,

83, 84] and then wiping with a soft cloth are sufficient [64, 85, 86]. All manipulations should be

carried out wearing clean cotton gloves, which prevent subsequent stains from residues of chlorides,

grease and organic acids from the hands [82-84, 87, 88]. Light cleaning can be done with an anionic

detergent [83, 87]. Commercial detergent formulations should be avoided, because they often

contain phosphates and bleaching agents, which can react with silver to produce dark spots [49, 84].

There are very few reports in the literature concerning previous surface coatings. Normally,

solvents must be used to remove wax and/or lacquer [89]. Steam and electrolytic cleaning have also

be employed to remove old lacquer from silver objects [90,91]

Treatment of corrosion products

To simplify, the techniques employed to treat or remove corrosion products are classified in three

principal groups, mechanical, chemical and electrochemical, which are described below, together

with examples of their application. A comparative table of certain characteristics of these methods

is presented at the end of the section (Table 4).

Table 1 Abrasive compounds cited in the literature

Mechanical cleaning

This consists in the removal of the undesired corrosion product through picking off with a tool or

rubbing with other material. Skill is needed to use scalpels or micro-rotary tools. The abrasive

systems most often employed for mechanical cleaning consist of three basic components: an

abrasive, a fluid to maintain it in suspension (usually water or alcohol) and a support to carry the

mixture to the object (soft cloth). In addition to these, commercial products often have detergents,

inhibitors, perfumes, etc. [50, 87, 88] and typically offer fabric or cotton impregnated with

abrasives and additives [82, 83, 92].

Some investigations have been carried out to evaluate and compare commercial products [82, 92]

and also simple abrasive materials of well-defined chemical composition [93]. Table 1 provides

examples of the use of abrasive compounds; their properties may be found in the tables of review

articles, which provide a good basis from which to choose in each particular case [50, 87]. In

practice, in order to avoid scratching the surface, two aspects should be considered: the

homogeneity of the particles size and their hardness. Softer particles require longer polishing time

but avoid scratches.

Chemical cleaning

This procedure consists in bringing the object into contact with a solution that dissolves the

alteration products from the surface and that should be removed carefully after the treatment. The

more suitable solution will be that which removes the maximum of corrosion products while

dissolving a minimum of silver metal. Again, it should not be forgotten that most objects really

consists of alloys with copper, forming phases that could be attacked by several products to which

silver alone is resistant. Niello decorations are in fact silver sulfide films and are indiscriminately

dissolved by all the chemical cleaning solutions commonly in use. Contact must be as quick as

possible, because there is always a danger of corroding the object, with an increase in surface

roughness and retention of cleaning products.

The cleaning solution may be applied by immersion if the object has simple forms, without crevices

or other applied materials. Otherwise, it may be applied locally with a swab or thickened with

gelatine.

An efficient cleaning solution should not only remove the undesirable alteration products from the

surface, but also ensure that they stay in solution, so that largely they can be eliminated.

Very few one-component solutions have this property. Cyanide solutions are an example; however,

in this case the toxicity is so high that its use is not recommended [98].

The presentation here of all recipes cited in the literature is not possible, because there is a huge

number, especially if small variations are considered. On account of this, only some of their

components are presented individually in Table 2, together

Table 2 Products used in chemical cleaning

with remarks on specific applications and the corresponding reference. It should be stressed once

more that this table aims at presenting the variety of chemicals that have been used for cleaning,

which should not be applied indiscriminately.

Care must be taken because of the toxicity of some chemicals: work must be done with an

extraction hood and safety data sheets for the materials used should be followed and kept readily

available.

Electrochemical cleaning

Ideally this technique should reverse the oxidation process, in which the metal had been

progressively transformed into an ionic form, losing its electrons. To allow it to come back into the

metallic state - to 'reduce' its chemical oxidative state - it is necessary to supply electrons by one of

three basic methods. They are named chemical, galvanic (or electrochemical) and electrolytic

reduction, and are distinguished from one another by the type of electron source.

In the first case, a solution containing a reducing agent, such as sodium dithionite (Na2S2O4) is used

[110]. This product oxidizes easily in alkaline medium and in this way supplies the necessary

electrons to the object. As reducing agents also react with oxygen from the air, precautions must be

taken to eliminate the surrounding air with its oxygen.

In the case of galvanic reduction, a less noble metal, such as aluminium or zinc, is brought in

contact with the silver artefact in a conductive solution. A difference in electrochemical potential

will be established between both metals, the less noble being the anode, or the pole where oxidation

takes place. As it corrodes, electrons are liberated to the surface of the artefact where they can

reduce the silver to a metallic state in a direct way, or indirectly, through hydrogen atoms existing

in an intermediary state, which are attracted to the surface. [111].

In the third method, electrolytic cleaning, the electrons are supplied to the object by an external

source. When using a current generator, such as a battery, the object is connected to the negative

pole (cathode) and an inert counter electrode, such as platinum, stainless steel or graphite, is

connected to the positive pole (anode). A conducting solution (electrolyte) is also necessary to close

the circuit. Given a small current applied between both electrodes, the reduction reactions take place

on the object at the cathode. This method, called galvanostatic cleaning, enables the silver ions to

reduce to metallic silver, but, along with any other reducible ionic species at the cathode,

indiscriminately.

In potentiostatic cleaning a potentiostat provides a more selective way to control what happens at

the object's surface than a current generator. The arrangement requires a third, reference electrode,

enabling one to apply and maintain a well-defined potential to the cathode (object). A preliminary

scanning of a wide range of negative electrode potentials, while controlling the current variations,

gives a so-called 'polarization plot'. This indicates the relative reduction potentials of the different

corrosion products for a particular solution employed (Fig. 10) [39, 112]. This solution should be

chosen so that the desired reaction - the reduction of silver ions - takes place preferentially (more

positive potentials) to other, concurrent reactions. Once these parameters have been defined, it is

possible to set the object's potential to a value corresponding to the desired reaction, and electrons

will be supplied only at the corresponding level. In this manner other reactions that

Fig. 10 Potentiostatic polarization plots of different silver coupons in a NaNO3 0.1M solution: (a)

for a chlorinated plate a reduction peak is observed at c. 0 mV NHE; (b) for a sulfurated coupon the

reduction peak occurs at c. -1000 mV NHE. The area beneath each peak is related to the thickness

of the reduced layer. Scan rate: 2 mV/s.

could disturb the main processes, such as hydrogen evolution, can be prevented, and monitoring the

current gives information about the completion of the reduction of a specific corrosion product.

Due to its fineness, this method has been used for the cleaning of thin coatings on metals, such as

silver on cuprous alloys or gold on silver [105, 113]. Moreover, the treatment can even be used on

small, localized areas if an 'electrolytic pencil' is used [114].

Table 3 presents a summary of electrolytic cleaning methods reported in the literature, together with

the solutions used. In 2001, a comparative study of the effect of several cleaning methods on silver

chloride removal was reported [115].

What really happens during the electrochemical reduction is the transformation of the corrosion

product, which changes from resistant and insoluble, into a finely divided metallic form having no

cohesion. It can then easily either be removed in cleaning or 'glued together' by consolidation

treatment.

Comparison of the cleaning methods

To conclude, Table 4 compares important parameters from each cleaning method discussed above,

including process characteristics, removal of material (both corrosion products and metal), residues

left and appearance after treatment.

Besides these methods, the plasma method was successfully used for cleaning thin tarnish layers on

well-preserved silver artefacts and daguerreotypes [121]. In the case of heavily corroded objects,

where the corrosion layers extend over several tenths of millimetres in depth, there are additional

difficulties with this technique [122].

Table 3 Materials and methods of electrochemical cleaning

Consolidation

Consolidation is widely used in conservation as a means of imparting structural strength to an

object that has deteriorated and is in danger of disintegrating. In a material requiring consolidation,

many of the bonds that hold it together have been broken, to the point where the structure can no

longer support its own weight and retain its shape.

Contrary to cleaning, which is an intervention at a surface level, the consolidation goes deep into

the object, sometimes even through it. Its purposes could be several, from structural to cosmetic:

reconstitution of the object to allow its legibility, to restore its malleability or solidity, to 'restore' it

to become closer to its original form.

If the object has fragmented, gluing is often preferable to soldering for re-assembly of parts [76,

123]. In the case of mineralized objects that are porous and should be joined together for subsequent

mechanical cleaning of accretions, impregnation is commonly used. Usually, adhesives such as

epoxy resin [81, 94, 99], polyester resin [25, 124J, Paraloid B72 (Rohm and Haas) [99], Paraloid

B48 (Rohm and Haas) [77] or cellulose nitrate lacquer [99] are used, sometimes with a tissue

support [25, 81, 95, 124].

In the past, in the case of a compact but nonetheless fragile object, malleability used to be restored

through heat treatment. The examples in the literature are various, from treatment immediately

following excavation using fire and alcohol in a hole in the ground [149], to controlled heating

operations, in some cases in combination with chemical and/or mechanical treatments for reshaping

[34, 61, 65, 16, 81, 100, 125-7].

Currently, however, it has been recognized that heating the object can present certain dangers, not

only because the melting points of the existing compounds are quite different and there is a danger

of melting one of them, but also because heating can obliterate the signs of former work [78]. Even

a simple soldering operation [128] can lead to undesirable grain growth, if the object had been

severely cold-worked, or even artificial ageing and its consequences for the stability of the artefact

Table 4 Comparison of the principal characteristics of cleaning methods

[24]. In addition, heat treatment may damage mercury-gilded silver by causing blisters [129].

Moreover, in cases of severe corrosion where there is no longer coherence between grains because

of the amount of corrosion products, annealing is useless, even in a reductive atmosphere [125]. As

noted in Table 5, electrolytic treatment has also been carried out in several instances.

It is important to remember that corrosion reactions are not truly reversible, because metal has

moved from its original site during corrosion. Furthermore, after a long time in burial conditions,

some corroded parts of the object have already washed away or are in a swollen state, such that the

whole object no longer can be regenerated.

A great contraction can take place during the reduction, and dimensional changes must occur due to

considerable differences between the densities of the materials (pAg = 10.5 g/cm3; pAgCl = 5.6

g/cm3). Although the corrosion products can be transformed into a metallic form, they stay,

however, in a powdery condition and for this reason, in most cases, a further treatment of

consolidation or sintering is carried out in order to hold the particles together.

Conservation

The basic rule, independent of the ambient conditions and the type of protection applied, is that the

object should be kept clean, by preventing accumulation of dust and dirt on the surface. Both, even

if they are not particularly harmful in themselves, act as nuclei that capture other particles and

condense humidity [35].

Protection is the prevention of undesired interactions between the object and its environment and

the consequent repeated cleaning procedures. For protection, it is preferable to reduce the

aggressiveness of the environment by eliminating pollutants and adjusting its RH. Where this is not

possible, a barrier must be created on the object's surface with lacquers, waxes or inhibitors.

Environmental protection

To influence the environment it is essential to know its nature. The three elements recognized as

harmful to silver - reduced sulfur gases, oxidants and RH - should each be monitored and their

synergetic effect considered. The scarce information about the composition of museum air shows

that the internal sources of certain elements could be more significant than the external [36, 54,

132]. Because of this, the presence of materials that produce reduced sulfur gases and their

influence on the degradation of materials leading to corrosive off-gassing must be taken into

account [54, 87, 132, 133]. To identify and quantify chemical pollutants in museums a European

study is in progress at time of writing [134]. The effect of light on the tarnishing of silver has also

been investigated [48] and the results show that relatively short wavelengths (2537 A, ultraviolet)

could be more harmful than longer ones.

The effect of specific materials in contact with silver objects, in display or storage, can be evaluated

through simple tests that can quickly show what materials are most reactive, although such tests

may not indicate reactions in the long term. The usual method of testing the material to be

investigated was to keep it in a closed vessel at 60°C and 100% RH for a period of time, together

with a freshly polished silver coupon [135]. Later, other variants were proposed and tested [136,

137]. More recently, electrochemical methods have been proposed as a more quantitative and rapid

alternative: they are based on polarization resistance tests in an aqueous extract of the investigated

material [138] and tarnish stripping on sensitized coupons [117, 139].

Regarding packing, the objects can be put in sealed polyethylene bags or wrapped in paper or tissue

[83, 87,140]. In this case, silver objects should first be wrapped in several layers of pH-neutral

tissue paper that contains no chemicals, such as corrosion inhibitors or buffers, and no sulfur. Only

then should they be protected by an outer wrapper of special cloth and/or paper, acting by one of

two means. These either contain metallic oxides or salts or fine silver particles, which

Table 5 Materials and methods of consolidative reduction

react preferentially with the sulfur-containing gases, or alternatively they contain activated carbon

to adsorb the gas or compounds such as zinc carbonate or oxide that react with the gases to form

metal sulfides [64,141], Logically, these sulfur-absorbing materials should never be used in direct

contact with silver [84].

During display, the use of adsorbents is recommended: silica gel to reduce the humidity, and

activated carbon [83]. For this, impregnated tissues are preferred to papers [87], which lose their

effectiveness more quickly [84].

Surface coatings

To create a barrier between the object and its environment, the coatings most commonly used are

lacquers, waxes and inhibitors. The degree of protection depends on the uniformity and thickness of

the applied layer. Although other suggestions are found in the literature, such as the use of

passivating films (chromates, beryllium, etc.), that chemically increase the resistance to tarnish [42,

65, 142-144], almost no reference has been made to their use with museum objects [127].

Research to compare the performance of surface coatings has evaluated different properties such as

resistance to tarnishing, resistance to abrasion, facility of application and acceptability of

appearance [145], along with permeability to H2S, H2O and water vapour, elasticity, adhesion and

hardness [146]. Also, tests have been carried out in chambers with specific aggressive environments

- sulfurous, carbonic, saline, thermal shock, UV radiation [115, 147-149].

From all the possible types of organic coatings, only two are currently employed by conservators:

cellulose nitrate and acrylics. Although a lot of research has been undertaken in the industrial field,

few articles concern museum objects, where important aspects, like surface preparation and

removability, dictate a totally different approach [150]. Most authors agree that applying two layers

is advisable, to ensure complete covering [86]. In museums, the two principal problems of the use

of lacquers must be considered: alteration of the object's appearance and imperfect covering of the

surface, after the evaporation of the solvent leaves behind a solid coating.

Cellulose nitrate lacquer is only used indoors, because it decomposes rapidly when directly exposed

to UV radiation [150]. In some cases application by spray results in better film formation than by

brush [149]. When examining examples of successful long-term use of this material, the facts that

support the choice are a reduced (5- to 10-fold) frequency of treatment in comparison to non-treated

museum objects, the ease of application, and improved appearance when compared with other

lacquers [52, 84, 151, 152].

The other type of resin used in metals conservation is acrylic. It is a co-polymer, a mixture of a hard

and rigid component with another, soft and elastic. The various molecular weights of the

components make it possible for them to tolerate weather outdoors relatively well. There are

numerous examples of application in the literature [98, 99,104,109], where it is cited that they do

not degrade to the extent of cellulose nitrate lacquers, and consequently have to be replaced less

frequently [64]. It is also noted that a plasma method was tried to apply polymers, but adhesion

problems were found, attributed to silver diffusion through the organic film [153].

Although their application is easier than that of lacquers [85], waxes are generally considered less

protective, because there is less cohesion between wax and metal. Nevertheless, they are intensively

used by conservators [154] and the preferred forms are microcrystalline [83, 155] and wax from the

carnauba tree [87]. A few comparative tests show a good performance in showcases [117] and even

in some aggressive conditions [147, 148]. However, the ease of scratching or locally rubbing off the

wax coatings, and their tendency to collect dust can be a disadvantage if they are much handled or if

levels of dust are not kept to a minimum.

Corrosion inhibitors are usually organic compounds: mercaptans or thiols. They are long-chain

molecules, which stick to the silver surface at one extremity (sulfur group) and make the surface

hydrophobic by means of a methyl termination at the other extremity. The exact mechanism is

complex and often very specific to a particular metal-inhibitor-environment. Generally, the degree

of protection given depends on the extent of the surface covering, which is a function of the type of

molecule and its affinity for silver. A poor covering is worse than none, because, where small areas

are left exposed, the corrosion reaction will occur much faster than elsewhere.

Different inhibitors may be applied in various ways: as coatings by impregnation or by dipping after

cleaning, or directly in storage and exhibition enclosures by delivery in the vapour phase. The

properties of inhibitors have been evaluated through standard methods, but almost all tests were on

clean surfaces, and their effects on museum objects, especially archaeological objects, are less well

understood [33,156,157].

Among the few references in the literature, benzotriazole (BTA), known to protect cuprous alloys,

is mentioned [70, 145, 158]. It may be adapted with caution to silver objects, and in the case of

silver-plated brass, it might protect the brass in detriment to the silver. Reference to 2mercaptobenzothiazole has been made, but its use has not yet been evaluated [117]. As an

alternative to BTA, PMTA (l-phenyl-5-mercaptotetrazole) has been suggested, for its superior

resistance to UV radiation and better surface covering power [48, 51].

Regarding the numerous possibilities raised several years ago [65], such as morpholine, chlorophyl,

pyridine, cysteamine [159] and other organic inhibitors, no research has yet been undertaken or

published.

Volatile inhibitors (VPI) have been tested in a more systematic way [65,117,160], although

investigations have only examined commercial products. As the effectiveness of all of these has

been demonstrated, their suitability must be determined for each case [160], They can be used in a

confined space where an equilibrium can be reached, with the vapours present in sufficient

concentration to give protection. The protection is only effective while the vapour supply is

sufficient and attention must be paid to the possible harmful consequences to other objects or

people.

Conclusion

This review article was written in the belief that is possible to learn from the experience of others

who, before us, involved themselves in the conservation of the objects that we have inherited.

It has been shown that 'not everything that glitters is silver'. This assessment actually concerns

silver alloyed with different elements, especially copper, and of course each alloy reacts in a

particular way with its environment. Depending on the conditions, a different form of deterioration

(or even a mixture of several forms) will be active. It is therefore fundamental to gather all possible

facts from the literature and by direct examination and analysis of the object, to reach a better

understanding of the particular case under study.

As for the materials and methods employed for the restoration of silver objects, an evolution can be

observed over the years. Nowadays, new chemicals and recipes are used with more care, and

treatments that were often employed in the past, such as heat-treating or cyanide cleaning, are no

longer used, in view of their harmful effect, either for future study of the object or for the restorer.

On the other hand, the fact that 'the more it is cleaned, the more is worn away' from the artefact

itself has been well understood and increasing importance has been given to preventive

conservation, with considerable research about environmental pollutants and possible ways of

minimizing their effects.

Although the evolution in this area has been positive, an important point remains to be developed

further. It concerns co-operative research between restorers and scientists, whose main goal would

not be the discovery of a new procedure or formula, but a real understanding of the consequences of

using given products or applying certain techniques. This step is a fundamental one towards valid

preventive conservation.

Acknowledgements

Thanks to Christopher Augerson for the fruitful discussions and to Pau Gorostiza for the handsome

drawings presenting the deterioration cases. Thanks also to Gilberte Dewanckel and Annick Texier,

who made possible my direct participation in case studies of ancient silver artefacts. I would like to

acknowledge Lyndsie Selwyn, Robert Organ and Francois Schweizer for their careful reading of the

text and very valuable comments.

Thanks to the team from the Gerald Ford Conservation Centre, Omaha, and all participants of the

workshop 'Recent advances in silver conservation" for a very agreeable and profitable week. I am

also grateful to all those that contribute sending an important number of references that constitute

this paper and to those authors who allowed reproduction of their illustrations.

References

1

Blair, C, ed., The history of silver, Macdonald and Co., London, 1987.

2

Riederer, J., 'Metallanalysen von Silber- und Messingeinlagen aus merowingenerzeitlichen

tauchierten Eisenfunden', in Menghin, W., ed., Tauschierarbeiten der Merowingerzeit,

Bestandskataloge Band 2, Staatliche Museen zu Berlin, 1994, pp. 159-62.

3

Costa, V., Synthese des rapports d'analyse des objets en argent 1960-1998, compte-rendu

d'etude C2RMF/2953, Centre de Recherche et Restauration des Musees de France, Paris, 1999.

4

Schweizer, F., 'Nielle byzantin: etude de son evolution', in Eluere, C, ed., Outils et ateliers

d'orfevres des temps anciens, Saint-Germain-en-Laye/Societe des amis du Musee des Antiquites

Nationales, 1993, pp. 171-84.

5

Oddy, W.A., Bimson, M. and La Niece, S., 'The composition of niello decoration on gold,

silver and bronze in the antique and medieval periods', Studies in Conservation 28, 1983, pp. 29-35.

6

La Niece, S., 'Silvering', in La Niece, S. and Craddock, P., eds, Metal Plating and Patination,

Butterworth Heinemann, Oxford, 1993, pp. 201-10.

7

Zwicker, U., Oddy, A. and La Niece, S., 'Roman techniques of manufacturing silver-plated

coins', in La Niece, S. and Craddock, P., eds, Metal Plating and Patination, Butterworth

Heinemann, 1993, pp. 223-46.

8

Menghin, W., 'Der silberglanz der Merowingerzeit', in Menghin, W., ed., Tauschierarbeiten

der Merowingerzeit, Bestandskataloge Band 2, Staatliche Museen zu Berlin, 1994, pp. 9-32.

9

Darrah, J.A., 'The microscopical and analytical examination of three types of metal thread',

Conservation of Metals, International Restorer Seminar, Veszprem, 1989, pp. 53-63.

10 Scott, D.A., 'Gold and silver alloy coatings over copper: an examination of some artefacts

from Ecuador and Colombia', Archaeometry 28, 1986, pp. 33-50.

11 Bray, W., 'Techniques of gilding and surface-enrichment in pre-Hispanic American

metallurgy', in La Niece, S. and Craddock, P., eds, Metal Plating and Patination, Butterworth

Heinemann, Oxford, 1993, pp.182-92.

12 Turner, E., 'Silver Plating in the 18th century', in La Niece, S. and Craddock, P., eds., Metal

Plating and Patination, Butterworth Heinemann, Oxford, 1993, pp. 211-22.

13 Stern, W.B., 'Zur zerstorungsfreien Zustandsdiagnose: Metallkundliche Untersuchungen an

antiken Silberlegierungen', in Schweizer, F. and Villiger, V., eds, Methoden zur Erhaltung con

Kulturgiitern, Verlag Paul Haupt, 1989, pp. 181-92.

14 Carley, E.A., Analysis of ancient metals: silver and silver alloys, Pergamon Press, Oxford,

1964.

15 Berthoud, T, Hurtel, L.P. and Menu, M., 'Etudes analytiques d'objets en argent romains /

bilans et perspectives', in Baratte, F., ed., Argenterie romaine et bizantine, actes de la table ronde,

Paris, 11-13 Octobre 1983, De Boccard, Paris, 1988, pp. 35-49

16 Gale, N. and Stos-Gale, Z., 'Lead and silver in the ancient Aegean', Scientific American 244,

no. 6, pp. 70-81.

17 Barrandon, J.-N., 'L'analyse par activation' in Meyer-Roudet, H., ed., A la recherche du metal

perdu, Errance, 1999, pp. 79-82.

18 Scott, D., Metallography and microstructure of ancient and historic metals, The Getty

Conservation Institute, Marina del Rey, 1991,pp. 11-21.

19 Scott, D.A., 'Technical study of a ceremonial Sican tumi figurin', Archeometry 38 (2), 1996,

pp. 305-11.

20 Foltz, E., 'Antike Goldschmiedetechniken und ihre Erkennung', Arbeitsbldtter fiir

Restauratoren 2, Gr. 3, 1981, pp. 50-63.

21 Larsen, B., 'SEM-identification and documentation of tool marks and surface textures on the

Gundestrup Cauldron', in Black, J., compiler, Recent advances in the conservation and analysis of

artifacts. Jubilee conservation conference, London, 6-10 July 1987, University of London, Institute

of Archaeology, Summer Schools Press, London, 1987, pp. 393-409.

22 Slesinski, W., 'Entwicklung der Reinigungsmethoden von Silbererzeugnissen', Conservation

of Metals, International Restorer Seminar, Veszprem, Hungary, 1989, pp. 108-10.

23 Linke, R. and Schreiner, M., 'Energy dispersive x-ray fluorescence analysis and x-ray

microanalysis of medieval silver coins', Mikrochimica Ada 133, 2000, pp. 165-70.

24 Schweizer, F. and Meyers, P., 'Structural changes in ancient silver alloys: the discontinuous

precipitation of copper', International Council of Museums (ICQM) Committee for Conservation,

5th Triennial Meeting, Zagreb, 1978, 23/5, pp. 1-16.

25 Nosek, E., 'The investigation and conservation of early medieval silver chalices and paten', in

Mazur, M., Mazur, A. and Grimstad, K., eds, /COM Committee for Conservation, 8th Triennial

Meeting, Sydney, Australia, 6-11 September 1987, Getty Conservation Institute, Marina del Rey,

1987, pp. 1093-5.

26 Raub, E. and Engel, M., 'Reflexionsmessungen an Silberlegierungen', Zeitschrift fiir

Metallkunde 11, 1939, pp. 339-44.

27 Kutzelnigg, A., 'Die Farbe des Silbers als Funktion seiner Oberflachenbeschaffenheit',

Kolloid-Zeitschrift 61,1932, pp. 48-50.

28 Conrad, S., 'Die silberne Mumienmaske aus Hildesheim', Restauro4, 1993, pp. 256-9.

29 Daniels, V., 'Plasma reduction of silver tarnish on daguerreotypes', Studies in Conservation

26, 1981, pp. 45-9.

30 Sharma, R.C. and Chang, Y.A., 'The Ag-S system', Bulletin of Alloy Phase Diagrams 7, 1986,

pp. 263-9.

31 Graedel, T.E., Franey, J.P., Gualtieri, G.J., Kammlott, G.W. and Malm, D.L., 'On the

mechanism of silver and copper sulfidation by atmospheric H2S and COS', Corrosion Science 25,

1985, pp. 1163-80.

32 Franey, J.P., Kammlott, G.W. and Graedel, T.E., 'The corrosion of silver by atmospheric

sulfurous gases', Corrosion Science 25, 1985, pp. 133-43.

33 Sinclair, J.D., 'Tarnishing of silver by organic sulfur vapors: rates and film characteristics',

Journal of the Electrochemical Society 129, 1982, pp. 33-40.

34 Plenderleith, H.J., The conservation of antiquities and works of art. Treatment, repair and

restoration, Oxford University Press, London, 1956, pp. 212-31.

35 Graedel, T.E., 'Corrosion mechanism for silver exposed to the atmosphere', Journal of the

Electrochemical Society 139, 1992, pp. 1963-70.

36 Stirling, D., Noble, G., Tennent, N. and Kennedy, R., 'Sulfur: from industry to museum',

SSCR Journal (Scottish Society for Conservation and Restoration) 11, no. 3, 2000, pp. 12-13.

37 Fukuda, Y., Fukushima, T., Sulaiman, A., Musalam, I., Yap, L.C., Chotimongkol, L.,

Judabong, S., Potjanart, A., Keowkangwal, O., Yoshihara, K. and Tosa, M., 'Indoor corrosion of

copper and silver exposed in Japan and ASEAN countries', Journal of the Electrochemical Society,

138, 1991, pp. 1238-43.

38 Bouquet, S., Bodin, C. and Fiaud, C, 'Influence relative des composes soufres et chlores sur le

ternissement de l'argent en milieu atmospherique', Comptes Rendus de I'Academie des Sciences

Pans 316, 1993, pp. 459-64.

39 Guinement, J., Etude en laboratoire et sur site, de I'influence de I 'inter'action entre sulfure

d'hydrogene, dioxyde d'azote et chlore sur la corrosion atmospherique de l'argent et du cuivre,

Ph.D. thesis, Universite Pierre et Marie Curie, Paris, 1985.

40 Rice, D.W., Peterson, P., Rigby, E.B., Phipps, P.B.P., Cappell, R.J. and Tremoureux, R.,

'Atmospheric corrosion of copper and silver', Journal of the Electrochemical Society 128, 1981, pp.

275-84.

41 Davies, R.L. and Etris, S.F., 'The development and functions of silver in water purification

and disease control', Catalysis Today 36, 1997, pp. 107-14.

42 Raub, E., 'Das Anlaufen

von Metallen und Anlaufschutzverfahren', Handbuch

der Galvanotechnik Band 111, Carl Hanser Verlag, Munchen, 1969, pp. 210-23.

43 Kim, H. and Payer, J.H., 'Tarnish process of silver in lOOppb H,S containing environments',

The Journal of Corrosion Science and Engineering 1, paper 14, at

http://www.umist.ac.uk/corrosion/ JCSE/voll/paperl4/vlpl4.html, submitted March 1999.

44 Rice, D.W., Cappell, R.J., Kinsolving, W. and Laskowski, J.R., 'Indoor corrosion of metals',

Journal of the Electrochemical Society, 127, 1980, pp. 891-901.

45 Holm, S.J., Silver, Institute of Archaeology, University of London, 1969.

46 Graedel, T.E., Kammlott, G.W. and Franey, J.P., 'Carbonylsulfide: potential agent of

atmospheric sulfur corrosion', Science 212, 1981, pp. 663-5.

47 Zabarnick, S., Zelesnik, P. and Whitacre, S., 'Silver corrosion and sulfur detection using a

quartz crystal microbalance with silver electrode surfaces', Industrial Engineering Chemical

Research 35, 1996, pp. 2576-80.

48 Jing Li, F. and Zi, C, 'Tarnishing protection for silver electrodeposits', Plating and Surface

Finishing 85,1998, pp. 24-7.

49 Burg, B., Harer, J., Jeschke, P., Speckmann, D. and von Rybinski, W., 'Korrosionsphanomene

an Silberoberflachen beim maschinellen Geschirrspulen',/owrmj/.Se//e«, Ole, Fette, Wachse 120,

1994, pp. 400-6.

50 Krehon, V., 'Die Reinigung von Silberoberflachen', Restauro 4, 1991, pp. 237-45.

51

Zhu, H., 'A new treatment for silverware', in Current problems in the conservation of metal

antiquities, 4-6 October 1993, Tokyo National Research Institute of Cultural Properties, 1993, pp.

163-72.

52 Inaba, M., 'Tarnishing of silver: a short review', V&A Conservation Journal, January 1996,

pp. 9-10.

53 Reagor, B.T. and Sinclair, J.D., 'Tarnishing of silver by sulfur vapor: film characteristics and

humidity effects', Journal of the Electrochemical Society 128, 1981, pp. 701-5.

54 Brimblecombe, P., 'The composition of museum atmospheres', Atmospheric Environment

24B, 1990, pp. 1-8.

55 Raub, E. and Polaczek-Wittek, A., 'Das Anlaufen von Silber-Kupfer-Legierungen', Zeitschrift

fiir Metallkunde 12, 1942, pp.

275-85.

56 Dewanckel, G., 'Un riche mobilier funeraire en argent provenant de la necropole

merovingienne de Saint-Brice a Tournai', Bulletin Institut Royal du Patrimoine Artistique (KIKIRPA) 20, 1984, pp. 204-11.

57 Lykiardopoulou-Petrou, M. and Beloyannis, N., 'Experimental comparative study of three

different cleaning processes on Athenian silver coins (tetradrachms) from classical times', in

Goodburn-Brown, D. and Jones, J., eds, Look after the pennies, Archetype, London, 1998, pp. 85-8.

58 Sramek, J., Jakobsen, T.B. and Pelikan, J.B., 'Corrosion and conservation of a silver visceral

vessel from the beginning of the seventeenth century', Studies in Conservation 23, 1978, pp. 11417.

59 Organ, R.M., 'The reclamation of the wholly-mineralized silver in the Ur lyre', Application of

science to examination of works of art, Museum of Fine Arts, Boston, 1965, pp. 126-44.

60 Formigli, E., 'Restaurierung eines etruskischen Diadems aus vergoldetem Silber',

Arheitsblatter fiir Restauratoren 2, Gr. 3, 1974, pp. 15-19.

61 Organ, R.M., 'The current status of the treatment of corroded metal artifacts', National Bureau

of Standards special publication 479, Corrosion of Metal Artifacts, 1977, pp. 107-42.

62 Rathgen, F., Die Konservierung von Altertumsfunden: II und III Teil Metalle und

Metallegierungen organische Stoffe, Walter de Gruyter and Co., Berlin, 1924, pp. 37-40, 102-7.

63 Born, H., 'Troianische Silbergefasse. Forschungsprojekt zu Material und Herstellung und

Moglichkeiten der Restaurierung', Ada Praehistonca et Archaeological^, 1997, pp. 110-21.

64 Richter, E.-L. and Schmidt-Ott, K., 'Zur Oberflachenbehandlung von Silber', in Heinrich, P.,

ed., Metallrestaurierung - Beitrage zur Analyse, Konzeption und Technologie, Callwey, Munchen,

1994, pp. 182-95.

65 Stambolov, T., The corrosion and conservation of metallic antiquities and works of art,

Central research laboratory for objects of art and science, Amsterdam, 1985, pp. 153-67.

66 McNeil, M.B., 'Microbiologically influenced corrosion of silver in the marine environment', in

Dowling, N.J., Mittelman, M.W. and Danko, J.C., eds, Microbially influenced corrosion and

biodeterioration, Knoxville, Tennessee, 1990, pp. 8.17-8.21.

67 Hedges, R.F'.M., 'On the occurrence of bromine in corroded silver', Studies in Conservation,

21, 1976, pp. 44-6.

68 Bar, G., 'Die Silbermigration - istsie vergessen?', Metall52, 1998, pp. 292-6.

69 Fischmeister, H. and Drott, J., 'Reaction rate and growth forms of reaction product in the

system Ag-H2S', Ada Metallurgica 17, 1959, pp. 777-81.

70 Brusic, V., Frankel, G.S., Roldan, J. and Saraf, R., 'Corrosion and protection of a conductive

silver paste', Journal of the Electrochemical Society 142, 1995, pp. 2591-4.

71 Sease, C, Selwyn, L.S., Zubiate, S., Bowers, D.F. and Atkins, D.R., 'Problems with coated

silver: whisker formation and possible filiform corrosion', Studies in Conservation 42, 1997, pp. 110.

72 Jaro, M. and Toth, A., 'Deterioration of metal threads and other metallic decorations made of

gold, silver or gilt silver on museum textiles', in MacLeod, I.D., Pennec, S.L. and Robbiola, L., eds,

Metal 95: Proceedings of the international conference on metals conservation, Setnur en Auxois,

25-28 September 1995, James and James, London, 1997, pp. 201-8.

73 Raub, C.J. and Blumer, R.D., 'Thermal oxidation of antique gold-copper and silver-copper

alloys during manufacturing and its importance to restoration and conservation', in MacLeod, I.D.,

Pennec, S.L. and Robbiola, L., eds, Metal 95: Proceedings of the international conference on

metals conservation, Semur en Auxois, 25-28 September 1995, James and James, London, 1997, pp.

67-70.

74 Condamin, J. and Picon, M., 'Notes on diffusion in ancient alloys', Arcbeometry 8, 1965, pp.

110-14.

75 Thompson, EC. and Chatterjee, A.K., 'The age-embrittlement of silver coins', Studies in

Conservation 1, no. 3, 1954, pp. 115-25.

76 Oddy, A. and Holmes, R., 'The Hockwold treasure', in Oddy, A., ed., The art of the

conservator, British Museum Press, 1992, pp. 137-50.

77 Jett, P.R., 'Two examples of the treatment of ancient silver', Current Problems in the

conservation of metal antiquities, 4-6 October 1993, Tokyo National Research Institute of Cultural

Properties, Tokyo, 1993, pp. 173-87.

78 Ravich, I.G., 'Annealing of brittle archaeological silver: microstructural and technological

study', ICOM Committee for Conservation, 10th Triennial meeting, Washington DC, 22-27 August

1993, Pans, 1993, pp. 792-6.

79 Wanhill, R.J.H, Steijaart, J.P.H.M., Leenheer, R. and Koens, J.F.W., 'Damage assessment and

preservation of an Egyptian silver vase (300-200BC)', Archaeometry 40, 1998, pp. 123-37.

80 Jaro, M., 'Re-corrosion of silver and gilt silver threads on museum textiles after treatment', in

International Restorer Seminar, Veszprem, Hungary, 1989, pp. 95-8.

81 Schweizer, F. and Witschard, D., 'De l'argent dans tous ses etats', Preprints of ARAAFU's 4th

International Symposium (Association des Restaurateurs d''Art et d'Archeologie de Formation

Vniversitaire), Paris, 1995, pp. 203-12.

82 Schmidt-Ott, K., Reinigung von Silberoberfla'chen, diploma thesis, Institut fur Technologie

der Malerei, Staatlichen Akademie des Bildenden Kiinste, Stuttgart, 1993.

83 Institut Canadien de Conservation, 'Le soin de l'argent', in Notes delTCC9/7, Ottawa, 1997.

84 Majewski, L., 'On conservation', Museum News 51, no. 8, 1973.

85 Rowe, R., 'The display of silver', Museums Journal 58, 1959, pp. 271-4.

86 Wharton, G., 'The cleaning and lacquering of museum silver', Western Association for Art

Conservation Newsletter 11, no.l, 1989, pp. 4-5.

87 Selwyn, L.S., 'Historical silver: storage, display and tarnish removal', Journal of the UCCanadian Group 15, 1990, pp. 12-22.

88 Krehon, V., 'Zur Pflege von Silberobjekten', Restauratorenblatter Band 11, 1990, pp. 64-9.

89 Masschelein-Kleiner, L., 'Les solvants', Cours de conservation, Institut Royal du Patrimoine

Artistique (1RPA), Brussels, 1981.

90 Ankersmit, H.A. and van Langh, R., 'The removal of lacquers from silver by steam', in

Mourey, W. and Robbiola, L., eds, Proceedings of the international conference on metals

conservation, Draguignan-Figanieres, France, 1998, p. 192.

91 Haberland, A., Jahresbencht Bayerisches National Museum: Restaurierungsateliers,

Bayerisches National Museum, 1994, pp. 45-9.

92 Selwyn, L.S. and Costain, C.G., 'Evaluation of silver-cleaning products', Journal of the IlCCanadian Group 16, 1992, pp. 3-16.

93 Wharton, G., Maish, S.L. and Ginell, W.S., 'A comparative study of silver cleaning abrasives',

Journal of the American Institute of Conservation 29, 1990, pp. 13-31.

94 Felten, S., 'Die Restaurierung von drei Silberbechern aus dem Schatz von Boscoreale',

Arbeitsblatter fiir Restauratoren 2, Gr. 3, 1993, pp. 120-30.

95 Stawinoga, G., 'Die Tasse des Khans: die Restaurierung einer mittelalterlichern Silbertasse',

Arbeitsblatter fiir Restauratoren 2, Gr. 3, 1997, pp. 137-42.

96 Crevat, S., Du nettoyage des orfevreries, Memoire, Ecole Nationale Superieure des Arts

Visuels de la Cambre, Belgique, 1988.

97 North, N.A., 'Proprietary silver cleaners', Australian Institute for the Conservation of Cultural

Materials Bulletin 6, no. 3-4, 1980, pp. 41-5.

98 Strahan, D.K., 'Treatment of a silver dragon for the removal of silver cyanide and

chalconatronite', Journal of the American Institute for Conservation 25, 1986, pp. 73-81.

99 Niemeyer, B., 'Zur Restaurierung archaologisher Silbergefasse um die Jahrhundertwende',

Arbeitsblatter fiir Restauratoren 1, Gr. 3, 1997, pp. 131-6.

100 Bakhtadze, R.A., 'Restauration de l'argent archeologique par methode thermochimique',

ICOM Committee for Conservation, 4th Triennial Meeting, Venice, 1975, 25/4, pp. 1-8.

101 Gedye, I., Hodges, H. and Oddy, A., eds, 'The conservation of silver and gold', Notes for a

short course in conservation, The British Museum Research Laboratory, 1973, pp. 1-7.

102 Bathy, G., 'Restoration of the Turkish-age treasure find from Ozora', Conservation of Metals,

International Restorer Seminar, Veszprem, 1989, pp. 115-17.

103 Heinrich, P., 'Die Restaurierung eines silbernen Vortragekreuzes (Reliquars)', Arbeitsblatter

fiir Restauratoren 2, Gr. 3, 1984, pp. 70-77.

104 Emmerling, J., 'Die Verwendung von Komplexon III in der Museumswerkstatt', Arbeitsblatter

fiir Restauratoren 1, Gr. 16, 1969, pp. 3-6.

105 Jahr, U., 'Zur Problematik der Sulfidabnahme von kunsthandwerklichen

Silberobjekten', Arbeitsblatter fur Restauratoren 1, Gr. 3, 1988, pp. 93-8.

106 Schweizer, F. and Witschard, D., 'Aborder la restauration de Porfevrerie religieuse (La grande

chasse reliquaire de la Cathedrale de Sion)', in Mourey, W. and Robbiola, L., eds, Metal 98:

Proceedings of the international conference on metals conservation, 27-29 May 1998, Draguignan,

James and James, London, 1998, pp. 197-201.

107 Laver, M.E., Rampel, S., 'A study of daguerreotype cleaning solutions', ICOM Committee for

Conservation, 6th Triennial meeting, Ottawa, 21-25 September 1981, Paris, 1981, 23/1, pp. 1-9.

108 Brenner, H., 'Silver dips', Soap and Sanitation Chemistry 29,1953, pp. 161-83.

109 Karl, H., 'Bericht uber die Restaurierung eines silbernen Weihrauchfasses aus der Zeit um

1600', Arbeitsblatter fiir Restauratoren 2, Gr. 3, 1987, pp. 89-92.

110 MacLeod, I.D. and North, N.A., 'Conservation of corroded silver', Studies in Conservation 24,

1979, pp. 165-70.

111 Eggert, G., 'Metallreduktion in Fliissigkeiten', in Heinrich, P., ed., Metallrcstaurierung Beitrage zur Analyse, Konzeption aund Technologie, Callwey, Miinchen, 1994, pp. 127-37.

112 Degrigny, C, Jerome, M. and Lacoudre, N., 'Surface cleaning of silvered brass wind

instruments belonging to the sax collection', Corrosion Australasia 18, no. 2, 1994, pp. 16-17.

113 Degrigny, C, Wery, M., Vescoli, V. and Blengino, J.M., 'Alteration et nettoyage de pieces en

argent dore', Studies in Conservation 41, 1996, pp. 170-8.

114 Aldaz, A., Espana, T., Montiel, V. and Lopez-Segura, M., 'A simple tool for the electrolytic

restoration of archaeological metallic objects with localized corrosion', Studies in Conservation 31,

1986, pp. 175-6.

115 Gasteiger, S. and Eggert, G., 'How to compare reduction methods for corroded silver finds',

Metal 2001: International conference on metals conservation, Santiago do Chile, April 2001, in

press.

116 Nosek, E., 'The conservation of a silver chalice and paten from the tomb of bishop Maurus in

Wawel cathedral in Cracow', Studia Waweliana 2, 1993, pp. 31-40.

117 Lacoudre, N., Beldjoudi, T. and Dugot, J., 'Influence des conditions d'exposition et de

protection des surfaces sur ['alteration de plaquettes en laiton argente au Musee de la Musique a

Paris', in Mourey, W. and Robbiola, L., eds, Metal 98: Proceedings of the international conference

on metals conservation, 27-29 Mai 1998, Draguignan, James and James, London, 1998, pp. 265-70.

118 Degrigny, C. and Witshard, D., 'La chasse des enfants de Saint Sigismond de PAbbaye de

Saint Maurice: traitements electrochimiques des reliefs en argent en cours de restauration',

Colloque international chasses-reliquaires et orfevrene medievales, Musee d'Art et d'Histoire,

Geneve, 12-15 September 2001, in press.

119 Costa, V., Vergouwen, N. and Dewanckel, G., 'Restauration de la casse de Saint Domitien:

etude comparative des methodes de nettoyage de I'argent', Colloque international chassesreliquaires et orfevrerie medievales, Musee d'Art et d'Histoire, Geneve, 12-15 September 2001, in

press.

120 Degrigny, C. and Jerome, M., 'Mise au point d'une procedure de traitement d'instruments de

musique en laiton argente sulfure', S.T.C.R., no. 3, September 1993, pp. 60-5.

121 Daniels, V.D., Holland, L. and Pascoe, M.W., 'Gas plasma reactions for the conservation of

antiquities', Studies in Conservation 24, 1979, pp. 85-92.

122 Veprek, S., Eckmann, C. and Elmer, J.T., 'Recent Progress in the restoration of archaeological

metallic artifacts by means of low pressure plasma treatment', in Schweizer, F. and Villiger, V., eds,

Methoden zur Erhaltung von Kulturgiitern, Verlag Paul Haupt, 1989, pp. 171-80.

123 Wendt, C, 'fiber die Restaurierung eines Indo-persischen Perlmutterkastchens in einer

deutschen Siiberfassung des 16. Jahrhundcrts', Fourth International Restorer Seminar, Vol. 1,

Vezprem, Hungary, 2-10 July 1983, pp. 205-11.

124 Zoll-Adamikowa, H., Dckowna, M. and Nosek, E., The early medieval hoard, Institute of

Archaeology and Ethnology, Polish Academy of Sciences, Warsaw, 1999.

125 Werner, A.E., 'Two problems in the conservation of antiquities: corroded lead and brittle

silver', Application of science to examination of works of art, Museum of Fine Arts, Boston, 1965,

pp. 96-104.

126 Durand, H., 'Restaurierung von byzantinischem Silber', Arbeitsblatter fiir Restauratoren 1,

Gr. 3, 1980, pp. 34-40.

127 Minzhulin, A.I., 'Restoration of ancient archaeological granulation jewellery', 1COM

Committee for Conservation, 9th Triennial meeting, Dresden, GDR, 26-31 August 1990, pp.

740-4.

128 Krehon, V., 'Das beniitze Silberobjekt', Konservieren, Restauricren, Mitteilungen des

Osterreichischen Restauratorenverbandes 5,1995, pp.91-3.

129 van Langh, R., 'The delamination of mercury-gilded silver', Met objectives, Sherman Fairchild

Center for Objects Conservation, Metropolitan Museum, New York, 1999, pp. 8-9.

130 Charalambous, D. and Oddy, W.A., 'The consolidative reduction of silver', Conservation in

Archaeology and the Applied Arts, I1C Congress, Stockholm, 2-6 June 1975, London, 1975, pp.

219-27.

131 Werner, A.E., 'Einige Probleme bei der Konservierung antiken Silbers', Arbeitsblatter fur

Restauratoren 1, Gr. 3, 1969, pp. 4-10.

132 Brimblecombe, P., Shooter, D. and Kaur, A., 'Wool and reduced sulphur gases in museum air',

Studies in Conservation 37, 1992, pp. 53-60.

133 Lins, A. and McMahon, N., 'The inhibition of silver tarnishing', Current problems in the

conservation of metal antiquities, 4-6 October 1993, Tokyo National Research Institute of Cultural

Properties, pp. 135-61.

134 European Commission DG-Research, Environment Programme, 'The protection of Silver

Collections from Tarnishing' (Contract ENV-CT98-0709, 1998-2001)2001.

135 Oddy, W.A., 'The corrosion of metals on display', Conservation in Archaeology and the

Applied Arts, Stockholm Congress 2-6 June 1975, IIC, London, 1975, pp. 235-7.

136 Daniels, V. and Ward, S., 'A rapid test for detection of substances which will tarnish silver',

Studies in Conservation 27, 1982, pp. 58-60.

137 Bamberger, J.A., Howe, E.G. and Wheeler, G., 'A variant Oddy test procedure for evaluating