Environmental Technology, Vol. 16. pp 000-000

advertisement

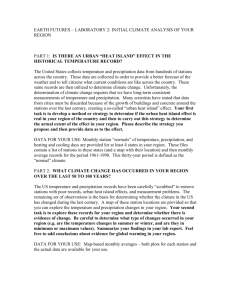

Environmental Technology, Vol. 22. pp 1287-1293 © Selper Ltd, 2001 APPLICATION OF INTEGRATED CHEMICAL - PHYSICAL PROCESSES MODELLING TO AERATION TREATMENT OF ANAEROBIC DIGESTER LIQUORS M.C. WENTZEL*, E.V. MUSVOTO AND G.A. EKAMA Water Research Group, University of Cape Town, Department of Civil Engineering, Rondebosch, 7701, South Africa (Received 14 February 2001; Accepted 16 May 2001) ABSTRACT A three phase (aqueous/solid/gas) mixed weak acid/base kinetic model developed by Musvoto et al. is applied to simulate the physical and chemical processes that occur on aeration of anaerobic digester liquors. Included in the model are the kinetic reactions for (i) weak acid/base dissociations (water, carbonate, ammonium, phosphate, and short-chain fatty acids), (ii) precipitation of struvite, newberyite, amorphous calcium phosphate, calcium and magnesium carbonate, (iii) ion pair formation and (iv) stripping of CO2 and NH3 gases. To generate data for model application, batch aeration tests were conducted on two anaerobic digester liquors from (i) a spent wine upflow anaerobic sludge bed (UASB) digester and (ii) a sewage sludge anaerobic digester. In the batch tests pH, Ca, Mg, PO 4-P, free and saline ammonia (FSA) and H2CO3* alkalinity (from which inorganic carbon is calculated) were measured. After establishing from the literature values for (i) weak acid/base equilibrium constants (pKa), (ii) weak acid/base kinetic rate constants (Kra), and (iii) ion pair stability constants (pKST), and trial and error determination of (iv) mineral solubility products (pKSP) (within the range reported in the literature), (v) ion pair kinetic rate constants (K rIP), (vi) mineral precipitation rate constants (K ppt) and (vii) gas stripping rates (KrG), a good correlation between predicted and measured data was obtained for all the parameters for both liquors. The solubility product values for the minerals that precipitated were the same for both liquors and fall in the range of values quoted in the literature, but the specific precipitation rate constants of the minerals differed for the two liquors. Keywords. Kinetic model, precipitation, weak acid/base, gas stripping, struvite. INTRODUCTION Loss of CO2 from anaerobic digestor liquor (ADL) through deliberate or inadvertent aeration causes an increase in pH; at higher pH various calcium and magnesium phosphates (and possibly carbonates) precipitate and NH3 stripping occurs. Loss of CO2 thus can be problematic, with magnesium phosphate precipitants such as struvite causing pipe blockages [1, 2]. However, this process has been exploited as a treatment method for removal of the high concentrations of N and/or P commonly found in ADL, particularly those from digestion of waste sludge from biological P removal activated sludge systems [3-5]. To optimize this system, and to develop and evaluate alternative treatment methods for ADL, a model that can conveniently handle three phase (aqueous/solid/gas) weak acid/base chemistry will be helpful. Musvoto et al. [6] describe the development of a kinetic model for the single aqueous phase behaviour of mixed weak acid/base systems and included precipitation of CaCO 3, CO2 gas exchange and ion-pairing effects. In the model, the weak acid/base equilibria have been formulated in terms of the kinetics of the forward and reverse reactions for the dissociation of the weak acid/bases. The compound H+ is explicitly included and pH is calculated from the H+ concentration via pH = -log fm [H+]. Similarly, ion pairing equilibria have been formulated in terms of the kinetics of the forward and reverse reactions for the ion pairs. This model was validated for the equilibrium (time independent) condition by comparing predicted steady state results with predictions from well established equilibrium chemistry based models in the literature, for the three phase behaviour of the carbonate system in pure water and single aqueous phase behaviour of mixed weak/acid base systems (carbonate, ammonium and phosphate). More extensive validation was not possible because suitable data were not available. Musvoto et al. [7] extended the model to describe the three phase weak acid/base reactions that occur when ADL are aerated. The resultant kinetic model was validated by comparing predictions with equilibrium (time independent) data 1287 available in the literature. In this paper, the model will be described briefly and the validation extended to kinetic (time dependent) data obtained from aerated batch tests on two ADL. MODEL DESCRIPTION The three phase (aqueous/solid/gas) chemical processes that occur during aeration of ADL are the forward and reverse dissociation processes of the weak acid/base species, precipitation of various magnesium and calcium phosphates and carbonates, ion pairing and stripping of CO 2 and NH3. Weak Acid/Bases For the carbonate, phosphate, free and saline ammonia (FSA), short chain fatty acids (SCFA) and water weak acid/base systems, there are 16 forward and reverse dissociation processes; 4 for the carbonate, 6 for the phosphate, and 2 each for the water, SCFA and FSA systems. There are 13 compounds; 3 for the carbonate, 4 for the phosphate and 2 each for the water, SCFA and FSA systems. These are processes 1 to 16 and compounds 1 to 13 in the model matrix of Musvoto et al. [6]. Precipitation of minerals General Formulation In the precipitation of sparingly soluble salts from wastewaters, the crystal growth process is almost invariably rate limiting, and the kinetics of this process is mostly surface controlled (see Musvoto et al. [8] for a detailed review). For such processes, Koutsoukos et al. [9] have formulated a general equation for the rate of mineral precipitation [8]. This general precipitation equation can be modified by accepting that no seed material has been added; for this case, the precipitation rate no longer depends on the available growth sites (s) so that the rate constants ks in the equation can be replaced by a single precipitation rate constant Kppt [8]. This precipitation rate equation can also be derived from the hypothesis of Davies and Jones [10, 11] and, accordingly, was accepted for use in the model to describe the kinetics of mineral precipitation. Mineral Precipitation from Anaerobic Digester Liquors Under aeration conditions of ADL, the solids most likely to precipitate are various magnesium and calcium carbonates and phosphates. Domains for precipitation of the various forms of these minerals have been delineated in the literature and are reviewed by Musvoto et al. [8]. From these, struvite (MgNH4PO4), newberyite (MgHPO4), amorphous calcium phosphate (ACP, Ca3(PO4)2.xH2O), calcite (CaCO3) and magnesite (MgCO3) were identified as the minerals most likely to precipitate and precipitation processes for these were included in the model (processes 42 to 45; Musvoto et al. [7]). Solubility Products A range of solubility products (pKSP) for the five mineral salts identified above (struvite, newberyite, ACP, calcite and magnesite) as likely to precipitate on ADL aeration were found in the literature. These solubility products are at infinite dilution, i.e. for ideal solutions. To account for the effect of ionic strength in non-ideal solutions, the solubility products were adjusted following the Debye-Hückel theory for low and medium salinity waters (for details, see Musvoto et al. [8]). Ion Pairing Ion pairing effects become significant at ionic strength () > 0.025 [12]. The values of the wastewaters where the model was to be applied, i.e. ADL, were anticipated to be greater than 0.025 so ion pairing effects were included in the model. From Musvoto et al. [6], the ion pairing equilibria were described in terms of the kinetics of the forward and reverse reactions and included in the same manner followed for weak acid/bases. For solutions containing Ca, Mg, FSA and PO4-P, from the literature eleven ion pairs were identified and included in the model as processes 20 to 41 [6]. The stability constants for the ion pairs (pKST) were obtained from the literature [13, 6] and adjusted for ionic strength effects with the Debye-Hückel theory. Gas Stripping Gases expected to be stripped are CO2 and NH3. The exchange of CO2 and NH3 between the liquid and gas phases has been outlined by Musvoto et al. [6, 7]. For NH3 it was assumed that the atmosphere acts as an infinite sink; thus the dissolution of NH3 from the atmosphere into solution was not included in the model, only NH3 expulsion. Processes 18 and 19 [6] and process 46 [7] describe CO2 liquid/gas exchange and NH3 stripping respectively. MODEL APPLICATION The model was applied to describe the time dependent three phase weak acid/base reactions that occur when ADL are aerated, using the Computer Program Aquasim [14]. No suitable data in the literature are available on this process, so that an experimental investigation had to be undertaken to gather the appropriate data. Experimental Investigation Aeration of ADL from a spent wine UASB digester (UASBDL) and an anaerobic digester treating sewage sludge (SSADL) were investigated. Five litre samples of each wastewater were placed in a batch reactor and aerated for at least 24 hours. Temperature was controlled at 20C. The pH in the reactor was recorded throughout the experiment. At frequent intervals, 100 ml and 10 ml samples were drawn 1288 from the batch reactor; the 10ml samples were immediately analysed for free and saline ammonia (FSA), and the 100ml samples 0.45µm filtered and analysed for Ca, Mg, total phosphate system species (PT), total inorganic carbon species (CT) and short chain fatty acids (SCFA). Four batch tests were performed on SSADL (Batch tests 11, 12, 13 and 14) and three on UASBDL (Batch tests 16, 17 and 18). Details of methods are given in Musvoto et al. [7]. Model Calibration (i) (ii) (iii) (iv) (v) (vi) (vii) In the model, values are required for: weak acid/base equilibrium constants (pKa), weak acid/base kinetic rate constants (Kra), ion pair stability constants (pKST), mineral solubility products (pKSP), ion pair kinetic rate constants (KrIP), mineral precipitation rate constants (Kppt) and gas stripping rates (KrG). In the calibration, constants (i), (ii) and (iii) were regarded as model constants and not changed; values for these constants were obtained from the literature [6]. Constants (v), (vi) and (vii) were regarded as calibration constants and were changed to provide a close correlation between theoretical model predictions and experimental results. Constants (iv) were considered model constants, but a range of values are quoted in the literature so that the final values had to be determined by calibration within the literature range. Changes to constants were made both by visual trial and error fitting and the parameter estimation facility in Aquasim; visually there was little discernable difference between results from the two calibration methods, and so only the visual fit calibration data are reported (for details see Musvoto et al. [15]). In the calibration exercise, the importance of ion pairing in the model predictions was not fully appreciated, and to improve the correlation between predicted and measured results the values for the rates of ion pair formation (K rIP) were adjusted separately for each ion pair, but keeping the rates the same for all batch tests. This meant that the formation of the ion pairs was not effectively instantaneous as should be. In subsequent modelling exercises it has become apparent that under some conditions ion pairing effects have a significant influence on predicted results when the rates of ion pair formation are made effectively instantaneous. A comprehensive study on this aspect will form the basis for a future paper. RESULTS AND DISCUSSION As examples, Figures 1 and 2 show measured and predicted results for batch test 12 on SSADL and batch test 18 on UASBDL respectively. Good correlations were obtained between experimental and theoretical model predictions for both liquors. Some of the constants and results obtained from the model simulations for both SSADL and UASBDL are shown in Table 1. From a comparison of results on the two ADL, the following conclusions can be drawn (see Table 1). Solids most likely to Precipitate The same solids, viz. struvite, ACP, newberyite, CaCO3 and MgCO3, were identified from the literature as most likely to precipitate in both SSADL and UASBDL and on this basis were included in the model (see above, and [8] for details). With these precipitants, the consistency between predicted and measured soluble species concentrations (Figs 1 and 2) indicates that no precipitants of importance have been omitted from the model. From the simulations, in both liquors struvite formed the bulk of the precipitate followed by ACP (Table 1). MgCO3 was predicted to precipitate in UASBDL, but not in SSADL. Conversely, CaCO3 was predicted to precipitate in SSADL, but not in UASBDL. In both sets of experiments, newberyite was predicted not to precipitate significantly. The predicted precipitants are in agreement with the domains of precipitation in the literature [8]. Solubility Products For each precipitate formed, the values for the solubility products were the same for both the SSADL and UASBDL, and all fall within the range of literature values (Table 1). Specific Rate Constants for Precipitation For each type of wastewater, the same set of specific precipitation rate constants was found for all the batch tests on that wastewater, except for batch test 13 for SSADL where a CaCO3 precipitation rate of 2 instead of the 50 (d-1) for the other three batch tests was required to give a good correlation. The specific precipitation rate constants found for struvite, ACP and CaCO3 differ significantly between the SSADL and UASBDL (Table 1); the rates for struvite and ACP are much higher in the UASBDL than in the SSADL, while the rate for CaCO3 is lower for the UASBDL than for SSADL. Gas Stripping The specific rates for gas stripping for both CO2 and NH3 differed for each individual batch test (Table 1). This is not unexpected as the aeration conditions (gas flow rates, mixing, solids, etc.) differed in each batch test; in hindsight this is an omission as aeration rates in the batch tests should have been controlled to be the same. Comparing the stripping rates for CO2 with those for NH3, the values for CO2 were much higher, by two orders of magnitude. This is in agreement with the literature, where it is evident that the volatility of CO2 is much higher than NH3. CONCLUSIONS The kinetic model developed by Musvoto et al. [6, 7] was applied to simulate the chemical and physical reactions which occur on batch aeration of anaerobic digester liquors (ADL) from a spent wine UASB digester (UASBDL) and an 1289 anaerobic digester treating a blend of primary and waste activated sludges (SSADL). From a comparison of model predictions with measured data, the following conclusions can be drawn: Figure 1. Predicted () and measured () soluble concentrations for calcium (Ca, Fig 1a, top left), magnesium (Mg, Fig 1b, top right), total phosphate (PT, Fig 1c, middle left), total carbonate (CT, Fig 1d, middle right), free and saline ammonia 1290 (FSA, Fig 1e bottom left) and pH (Fig 1f, bottom right) for aerobic batch test 12 on anaerobic digester liquor from Cape Flats sewage treatment (Cape Town, South Africa) digester treating primary and waste activated sludge. 1291 Figure 2. Predicted () and measured () soluble concentrations for calcium (Ca, Fig 2a, top left), magnesium (Mg, Fig 2b, top right), total phosphate (PT, Fig 2c, middle left), total carbonate (CT, Fig 2d, middle right), free and saline ammonia (FSA, Fig 2e bottom left) and pH (Fig 2f, bottom right) for aerobic batch test 18 on anaerobic digester liquor from Stellenbosch Farmers’ Winery (Wellington, South Africa) spent wine UASB digester. Table 1. Values of model constants for simulation of physical and chemical processes for aerobic batch tests on SSADL and UASBDL. Constant Batch tests on SSADL Batch tests on UASBDL Batch Test 11 Batch Test 12 Batch Test 13 Batch Test 14 Batch Test 16 Batch Test 17 Batch Test 18 13.16 5.8 25.46 6.45 7 13.16 5.8 25.46 6.45 7 13.16 5.8 25.46 6.45 7 13.16 5.8 25.46 6.45 7 13.16 5.8 25.46 6.45 7 13.16 5.8 25.46 6.45 7 13.16 5.8 25.46 6.45 7 300 0.05 150 50 50 300 0.05 150 50 50 300 0.05 150 2 50 300 0.05 150 50 50 3000 0.05 350 0.5 50 3000 0.05 350 0.5 50 3000 0.05 350 0.5 50 Rate of gas stripping (KrG1d-1) O2 CO2 NH3 300 273 1.1 225 204 1.2 550 500 1.05 600 545 0.9 670 610 1.92 400 365 2.5 670 610 1.92 Solids precipitated (mg l-1) Struvite Newberyite Amorphous Calcium phosphate (ACP) CaCO3 MgCO3 1236 3.8 140 58 0 1140 2.8 170 46 0 1250 2.8 160 43 0 1270 2.6 50 98 0 677 2.1 91 0 30 532 1.2 98 0 30 528 0 92 0 21 -Log Solubility product (pKSP) Struvite Newberyite Amorphous Calcium phosphate (ACP) CaCO3 MgCO3 Rate constant of precipitation (Kppt d-1) Struvite Newberyite Amorphous Calcium phosphate (ACP) CaCO3 MgCO3 1) 2) 3) 4) 5) A good correlation between predicted and measured data was obtained for all batch tests. A single set of solubility product values for the five minerals that precipitated (struvite, ACP, newberyite, CaCO3 and MgCO3) applied to both liquor types. Furthermore, the solubility product values all fall within the range of values quoted in the literature. A single set of precipitation rate constants was found for all batch tests on a specific ADL type, but the constants differed between the two ADL types. Most likely the precipitation rates were influenced by particulate organic concentrations; SSADL contained considerably more particulate organics than UASBADL. The types of minerals predicted to precipitate for the conditions present are in agreement with information in the literature. The CO2 stripping rates were two orders of magnitude higher than the NH3 stripping rates, in agreement with the literature. Literature value 9.94 - 13.16 5.51 - 5.8 24 - 32.7 6.3 - 8.5 5 - 8.2 6) The effect of ion pairing on model predictions requires further investigation. The three phase kinetic based weak acid/base chemistry model and the approach on which it is based is proving to be a useful tool for research into, and design of wastewater treatment systems. For research, the model helps to focus attention on issues not obvious from direct experiment and allows multi-mineral precipitation to be investigated in an integrated and consistent manner. For design, by conducting a number of tests on a particular wastewater, the model can be calibrated for the particular wastewater and treatment process. Once calibrated, this kind of model can be used for predicting the outcome of different treatment processes to identify for investigation those that hold promise. 1292 ACKNOWLEDGEMENTS This research was supported financially by the Water Research Commission, National Research Foundation and University of Cape Town and is published with their permission. REFERENCES 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. 15. Borgerding J., Phosphate deposits in digestion systems. J. Water Pollut. Control Fed., 44, 813-819 (1972). Mamais D., Pitt P.A., Cheng Y.W., Loiacono J. and Jenkins D., Determination of ferric chloride dose to control struvite precipitation in anaerobic sludge digester. Water Environ. Res., 66, 912-918 (1994). Pitman A.R., Deacon S.L., Alexander W.V., Nicholls H.A., Boyd R.S.A. and Minson D., New methods for conditioning and dewatering sewage sludges in Johannesburg. Proc. Water Institute of Southern Africa (WISA) 1st biennial conference & exhibition. NISA, Cape Town, South Africa, pp 1-18 (1989). Pitman A.R., Management of biological nutrient removal plant sludges - Change the paradigms? Water Res., 33, 1141-1146 (1999). Stratful I., Brett S., Scrimshaw M.B. and Lester J.N., Biological phosphorus removal, its role in phosphorus recycle. Environ. Technol., 20, 681-695 (1999). Musvoto E.V., Wentzel M.C. and Ekama G.A., Integrated chemical-physical processes modelling I. Development of a kinetic based model for weak acid/base systems. Water Res., 34, 1857-1867 (2000a). Musvoto E.V., Wentzel M.C. and Ekama G.A., Integrated chemical-physical processes modelling II. Simulating aeration treatment of anaerobic digester supernatants. Water Res., 34, 1868-1880 (2000b). Musvoto E.V., Wentzel M.C., Loewenthal R.E. and Ekama G.A., Mathematical modelling of integrated chemical, physical and biological treatment of wastewaters. Research Report W97, Dept. Civil Eng., Univ. Cape Town, Rondebosch 7701, Cape Town, South Africa (1998). Koutsoukos P., Amjad Z., Tomson M.B. and Nancollas G.H., Crystallization of calcium phosphates: A constant composition study. J. Am. Chem. Soc., 27, 1553-1557 (1980). Benjamin L., Loewenthal R.E. and Marais G.v.R., Calcium carbonate precipitation kinetics, Part 2, Effects of magnesium. Water SA, 3, 155-165 (1977). Sturrock P.L.K., Benjamin L., Loewenthal R.E. and Marais G.v.R., Calcium carbonate precipitation kinetics. Part 1. Pure system kinetics. Water S A, 3, 101 (1976). Loewenthal R.E., Wiechers H.N.S. and Marais G.v.R., Softening and stabilization of Municipal Waters. Water Research Commission, P O Box 824, Pretoria, 0001, South Africa (1986). Ferguson J.F. and McCarty P., Effects of carbonate and magnesium on calcium phosphate precipitation. Environ. Sci. Technol., 5, 534-540 (1971). Reichert P., Concepts underlying a Computer Program for the Identification and Simulation of Aquatic Systems. Swiss Federal Institute for Environmental Science and Technology (EAWAG). CH-8600 Dübendorf. Switzerland (1994). Musvoto E.V., Ekama G.A., Wentzel M.C. and Loewenthal R.E., Extention and application of the three-phase weak acid/base kinetic model to the aeration treatment of anaerobic digester liquors. Water SA, 26, 417-438 (2000c). 1293 1294