steam lta - past, present, and future

advertisement

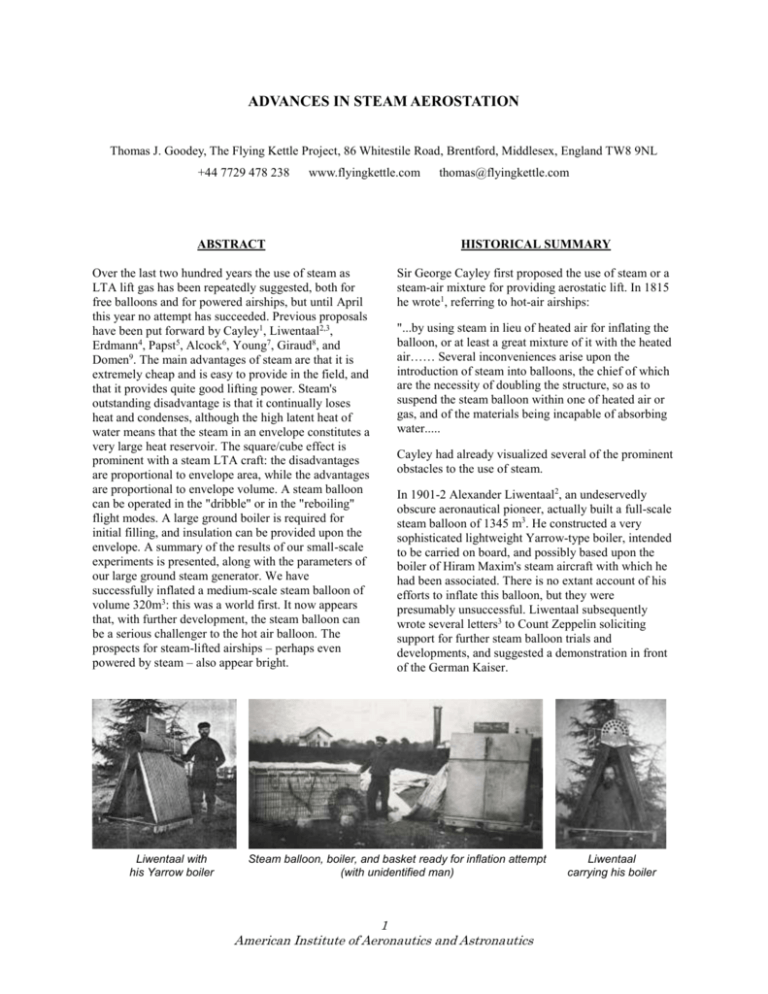

ADVANCES IN STEAM AEROSTATION Thomas J. Goodey, The Flying Kettle Project, 86 Whitestile Road, Brentford, Middlesex, England TW8 9NL +44 7729 478 238 www.flyingkettle.com thomas@flyingkettle.com ABSTRACT HISTORICAL SUMMARY Over the last two hundred years the use of steam as LTA lift gas has been repeatedly suggested, both for free balloons and for powered airships, but until April this year no attempt has succeeded. Previous proposals have been put forward by Cayley1, Liwentaal2,3, Erdmann4, Papst5, Alcock6, Young7, Giraud8, and Domen9. The main advantages of steam are that it is extremely cheap and is easy to provide in the field, and that it provides quite good lifting power. Steam's outstanding disadvantage is that it continually loses heat and condenses, although the high latent heat of water means that the steam in an envelope constitutes a very large heat reservoir. The square/cube effect is prominent with a steam LTA craft: the disadvantages are proportional to envelope area, while the advantages are proportional to envelope volume. A steam balloon can be operated in the "dribble" or in the "reboiling" flight modes. A large ground boiler is required for initial filling, and insulation can be provided upon the envelope. A summary of the results of our small-scale experiments is presented, along with the parameters of our large ground steam generator. We have successfully inflated a medium-scale steam balloon of volume 320m3: this was a world first. It now appears that, with further development, the steam balloon can be a serious challenger to the hot air balloon. The prospects for steam-lifted airships – perhaps even powered by steam – also appear bright. Sir George Cayley first proposed the use of steam or a steam-air mixture for providing aerostatic lift. In 1815 he wrote1, referring to hot-air airships: Liwentaal with his Yarrow boiler "...by using steam in lieu of heated air for inflating the balloon, or at least a great mixture of it with the heated air…… Several inconveniences arise upon the introduction of steam into balloons, the chief of which are the necessity of doubling the structure, so as to suspend the steam balloon within one of heated air or gas, and of the materials being incapable of absorbing water..... Cayley had already visualized several of the prominent obstacles to the use of steam. In 1901-2 Alexander Liwentaal2, an undeservedly obscure aeronautical pioneer, actually built a full-scale steam balloon of 1345 m3. He constructed a very sophisticated lightweight Yarrow-type boiler, intended to be carried on board, and possibly based upon the boiler of Hiram Maxim's steam aircraft with which he had been associated. There is no extant account of his efforts to inflate this balloon, but they were presumably unsuccessful. Liwentaal subsequently wrote several letters3 to Count Zeppelin soliciting support for further steam balloon trials and developments, and suggested a demonstration in front of the German Kaiser. Steam balloon, boiler, and basket ready for inflation attempt (with unidentified man) 1 American Institute of Aeronautics and Astronautics Liwentaal carrying his boiler A few years later, Dr. Hugo Erdmann proposed4 the use of superheated steam as lift gas in a balloon or rigid airship in German Patent 214,019 (1908). He suggested eiderdown as an insulating material. This patent application may well have been parasitic upon Liwentaal's work and inspired by Zeppelin, who was known for his tough patenting attitude. The concept appears to have become dormant until Hermann Papst became active5 in the sixties. He obtained a number of patents relating to steam lift gas, including US Patents 3,456,903, 3,897,032, and 4,032,085. None of his ideas was outstandingly practical, and no applications resulted. As for the use of steam as lift gas for a free balloon, the first modern suggestion seems to be due to W. Newman Alcock in a ballooning newsletter "Wingfoot" in 19616. And a couple of similar notes by David Young7 appeared in "Aerostat" in 1973/4. A very detailed and clear-sighted steam balloon proposal was set forth by Andre Giraud8 in French Patent 2,684,952 (1991). I don't know if Giraud made any steps toward practical implementation. He was actually the French Minister of Defense under Mitterand, so political tasks may have taken precedence. He died not long afterward. I believe that, if Giraud had lived, we would have a steam balloon in the air today. Further, there is an ingenious type of low-tech balloon pioneered by the French and called a "bulle d'orage", made of cheap black polythene, which is filled on the ground with warm air saturated with water vapor to a proportion of the order of 40 gm/m3. Thus this is not a steam balloon as such, but the concept is related. The bulle d'orage carries no fuel or burner. When such a balloon is released and rises, the adiabatic cooling of the warm wet air lift gas due to pressure reduction with increasing altitude is largely compensated by release of latent heat due to progressive condensation of the water vapor, and in fact the resultant lift gas cooling rate as the balloon rises is less than the rate at which the external atmospheric temperature drops with the altitude, so that the value of lift is maintained and even increases as the balloon rises. The solar heating effect is also important. A bulle d'orage is capable of attaining great heights. The premier apostle of the bulle d'orage is M. Jean-Paul Domen9. His European Patent 524,872 goes into great detail about various parameters of operation. In 1996 he built a large bulle d'orage which lifted a load of 270 kg to a height of 12 kilometers, the advantage of course being the extremely low cost. He also made a brief manned flight..... flying hanging from a bag made from black plastic garbage bag material and package shipping tape may not be to everybody's taste! THEORETICAL CONSIDERATIONS GENERAL PERFORMANCE COMPARISONS — As compared to the highest-lift gases - hydrogen and helium - the advantages of using steam as lift gas are that it is relatively safe and is so cheap that it may be vented without cost concerns. However its lift is not as good. Moreover for indefinitely continued flight the condensing water needs to be continually re-boiled, and the weight of the boiler and fuel required are substantial. So, for craft of similar volume, the payload and performance of a steam LTA craft must be much lower than those of a helium or hydrogen craft. But this may not be true when craft of similar cost (rather than volume) are considered, because the material for the envelope of a steam craft is expected to be much cheaper than helium-tight material, and of course the steam itself is extremely cheap. As compared to hot air, the merit of steam is that its lift is more than twice as great, so that for the same lift the envelope area is approximately halved. (This does not necessarily mean that the rate of heat loss is half, however; the situation is more complicated than that.) INITIAL FILLING — To produce the same amount of lift, about six times as much energy is required for boiling water to produce steam lift gas, as for heating air to produce hot-air lift gas. Therefore it is inevitable that, for the initial filling of a steam balloon or steam airship on the ground before takeoff, a large and heavy ground-based boiler of very high steaming capacity is required. This important point was first realized by Andre Giraud; Liwentaal doesn't seem to have appreciated it, and his attempt to use his flight boiler also for initial inflation may have been one cause of his lack of success. This fact constitutes a substantial barrier to practical implementation of a steam balloon or airship; you need to make a heavy and expensive ground steam generator before starting aerial trials. (Since the steam will be required in a field situation, it is not really practicable to use available steam from a factory or laundry, although perhaps geothermal steam could be employed.) THE OUTSTANDING ADVANTAGES OF LARGE SIZE — The lift of a steam balloon or airship is proportional to the cube of its characteristic linear dimension, while both the rate of total heat loss and the envelope weight are proportional to the square. Moreover, the incremental cost of the steam lift gas (whose volume varies as the cube) is utterly insignificant. This means that it is very advantageous for a steam balloon or steam airship to be large - as large as possible within the limitations of the equipment. 2 American Institute of Aeronautics and Astronautics MODES OF FLIGHT With a steam balloon there are two possible modes of flight: the simple "dribble mode", and the more sophisticated "reboiling mode". THE DRIBBLE MODE — Here, the balloon is filled with steam using the ground boiler and is then released, slightly lighter than neutrally buoyant, carrying the pilot and passengers and a large quantity of ballast water. There is no onboard boiler or fuel. As the steam in the balloon progressively condenses due to heat loss through the envelope, the resulting condensate water is drained from the bottom of the balloon and is ejected into the atmosphere, and simultaneously the pilot discharges ballast water so as to compensate for the progressive loss of lift. Thus the duration of the flight is limited by the amount of ballast which can be carried at takeoff; when the ballast gets low, the pilot must land. This type of flying will have a charm all of its own, because it will be utterly silent, and the altitude control will be superb. Although the "dribble" flight mode may seem crude – rather like the old smoke balloons – I think it has excellent possibilities. An important basic figure is the rate of loss of lift from a steam balloon as the steam condenses into water, in this "dribble" flight mode. If one kilo of steam in an envelope condenses into water, the loss of volume is 1.70 m3, so that the gross loss of lift in the ISA is 2.09 kgf. If the resulting one kilo of condensed water is retained on board, this 2.09 kgf constitutes the net lift loss. However if the condensed water is discharged, the net loss of lift becomes 1.09 kgf. Therefore, for lift loss to be compensated by ballast discharge to maintain level flight, 1.09 kg of ballast must be discharged for every 1 kilo of condensate released. It is interesting that these two figures are nearly equal. THE REBOILING MODE — Here, the balloon is filled with steam using the ground boiler and is then released for flight, carrying the pilot and passengers, an onboard burner/boiler unit, a quantity of fuel, and perhaps some ballast. As the steam condenses due to heat loss, the resulting condensate is drained from the bottom of the envelope and is reboiled by the onboard burner/boiler unit into steam, which is fed back into the envelope. Thus the duration of the flight is only limited by the amount of fuel which can be lifted at takeoff. Since one kilo of hydrocarbon fuel can be burnt to boil more than 15 kilos of water, it is evident that much longer flights can be made in this reboiling flight mode than in the dribble mode, even allowing for the weight of the onboard burner/boiler unit. Altitude regulation is performed by varying the rate of burner operation and accordingly the reboiling rate. CURRENT DEVELOPMENTS For some time it has been my personal hobby to promote the idea and the practice of using steam as LTA lift gas. It is a simple low-tech idea which has never been successfully tried. In terms of actual implementation, the use of steam lift gas in a balloon must surely come first in the logical development of the subject, before any airship application. If one can't get steam lift gas to work well in a balloon, it is not likely to work in an airship! Moreover, from the cost point of view, to develop and fly a balloon filled with steam is a project which can be tackled by an individual on a hobby basis, whereas to develop a steam airship promises to be a much more expensive proposition, one scarcely within the reach of a private individual. MY EXPERIMENTS — Previous theoretical proposals to use steam as lift gas have been vulnerable to the criticism of being rather deficient in concrete data. Particularly, the Papst patents and the Alcock article suggest many concepts which are ingenious in theory, but the numerical values given are extremely speculative and perhaps rather optimistic, particularly with regard to the all-important question of insulation performance. Therefore I have undertaken several sets of experiments in order to derive the numerical parameters which are necessary for planning steam flight seriously. Although this is by no means high technology - it's strictly kitchen/garage work - to the best of my knowledge this research is original. The goals of this experimental program were: (1) Steam filling the envelope of an LTA craft obviously will progressively condense into water and trickle downwards to the bottom of the envelope. The question is: how much parasitic weight is entailed? In other words, at any moment, what weight of water (per square meter) is thus trickling down? This weight is of course a dead load upon the craft, and it cannot be eliminated, although the Giraud patent8 suggests means for minimizing it. (2) With a "naked" steam balloon, at what rate does the steam condense? That is, how many kilograms of H2O per square meter of the envelope per hour condense from steam to water due to heat loss through the envelope? No attempt seems ever to have been made to quantify this rate of naked envelope steam condensation; published figures for the loss of heat from steam pipes etc. cannot reliably be applied to the cooling of a very large bag of steam in the outdoors, because of variations with scale in the complex processes of convective cooling. It is quite 3 American Institute of Aeronautics and Astronautics extraordinary that the steam airship and steam balloon concepts have been repeatedly proposed and discussed, for nearly two hundred years, without any effort being made to determine the value of this fundamental parameter experimentally. (3) How much can this condensation rate be reduced by fitting various types of insulation over the envelope? It is evident that in practice the steam balloon and steam airship concept really stands or falls upon the question of whether an insulation jacket can actually be manufactured, sufficiently effective in insulating performance to reduce the rate of condensation to an acceptable value, while still sufficiently light to allow the craft to fly. The normal methods for testing insulation materials are not very applicable for determining effectiveness in this special context. Published parameters such as "R-values" cannot be relied upon; rather, insulating performance must be evaluated during actual application for insulating the envelope of a steam balloon. SMALL-SCALE EXPERIMENTS — I first constructed a miniature test envelope of the classic ball-and-cone balloon shape made from twelve gores, of total area 3.5 m2, using a black siliconized nylon balloon fabric. I managed to inflate this envelope with steam from a small boiler system, and to keep it filled for several hours. This was the first time, as far as I know, that a flexible bag had ever been completely inflated with steam, at least for more than a transient period. The steam condensation rate for this small uninsulated black envelope was 1.43 kg/m2.hour. I was also able to measure the amount of water trickling down inside the envelope at any one time: it was about 80 gm/m2. I then insulated this envelope with an inner layer of simple bubble wrap and an outer layer of reflective aluminized polyester film (Mylar). The condensation rate with this quite unsophisticated insulation system was 450 gm/m2.hour. MID-SCALE EXPERIMENTS — I built a larger test envelope, approximately spherical, from the same material, of area about 9 m2, and glued reflective Mylar over substantially its entire outer surface. Thus this test envelope was silver on the outside and black on the inside. When it was inflated with steam, using no insulation jacket, the condensation rate was 935 gm/m2.hour. Thumping hard on this large envelope, inflated with steam and tight as a drum, vividly reinforced one's awareness of steam as a real substance. Then I manufactured an insulating jacket from a sophisticated fluffy insulation material known as Primaloft PL1, nominal density 133 gm/m2. (This material is used in high-quality sleeping bags and outdoor gear.) When this jacket was fitted over the above envelope inflated with steam, the condensation rate was 275 gm/m2.hour. I extrapolate that, with a somewhat thicker Primaloft PL1 insulating jacket, quilted in a more sophisticated way and weighing 250 gm/m2, the rate of steam condensation could be reduced to about 200 grams per square meter per hour. Making the jacket still thicker and heavier would probably become less and less effective. Finally, I made a new envelope from a cheap but relatively heavy woven polypropylene tape fabric (similar to that used for tarpaulins), covered with reflective Mylar film on one side and with a thin raw aluminum foil on the other. Buildings in New Zealand, Australia, and south-east Asia are often insulated with an inexpensive fabric of this type. The raw aluminum was of course on the outside and the Mylar on the inside. Without any insulation jacket, the condensation rate proved to be 640 gm/m2.hour. This was quite different from the rate for the above envelope which had a black interior. Opinions may differ as to whether the improvement (i.e. the reduction in heat loss) was due to the color of the interior, or was because the exterior was covered with raw aluminum rather than with reflective Mylar. Although the Mylar 4 American Institute of Aeronautics and Astronautics looks like a mirror at visible wavelengths, its emissivity for radiating heat in the infrared band may be completely different. The raw aluminum was quite vulnerable to damage during handling. THE GROUND STEAM GENERATOR — A high-capacity mobile Giraud-type steam generator is essential for the initial ground filling of a steam balloon or steam airship, so I tackled the ambitious task of building one. The entire design was dictated by the requirement to keep the total mass less than 3.5 tons, so that it could be towed on the road legally. In summary, I consider that 200 gm/m2.hour is the lower practical limit for the condensation value for a steam balloon, with any reasonable form of insulation. Piling on more and more insulation will only run into the phenomenon of diminishing returns. I constructed a fire-tube type boiler incorporating more than 700 kg of 22 mm copper pipe, wall thickness 0.1 mm. The heat exchange area is a whopping 90 m2. With sufficient firing, this should have a maximum steam production capacity of around 3 tons per hour. (The burner currently used provides a much lower firing rate, because we are not yet ready to use the full steam production capacity.) I employed this apparently primitive design because a water-tube boiler with steel tubes of similar heat exchange area would have been at least twice as heavy; steel tube of 0.1 mm wall thickness cannot be bent into coils. And I built a firebox insulated with a sophisticated high-temperature rock wool material, and mounted the boiler on it. As an experiment I tried loading up this unit with 250 kg of coal, and I started the fire off with 5 liters of diesel oil, which perhaps was a mistake…. The firemen were quite amused! The white cloud in the right hand picture below was steam, and the initial column of black smoke (maybe the fault of the diesel) had pretty well died away, so basically the unit was working well. There are, however, obvious disadvantages to coal.... it is hard to get perfect control of the combustion process... I have not yet done any experiments on insulating this last envelope; work is ongoing. 5 American Institute of Aeronautics and Astronautics Obviously coal-firing was impractical, so the next stage was to get the unit mobile and to convert it for oil firing. At present, fitted with an oil burner powered by a small gasoline engine, this ground steam generator is working smoothly on gasoil (i.e. diesel or heating oil), and produces large amounts of steam on demand. THE STEAM DISTRIBUTION SYSTEM — The next task was to build a steam distribution system to convey the steam to the balloon, since parts of the ground steam generator are at temperatures of several hundred degrees, and obviously the balloon must be kept well away from them. In order to stop it becoming waterlogged, this system needs to have quite sophisticated means for draining condensate. Also a large-scale steam control valve was required. The pictures show the solution I have reached. THE FIRST TRIAL ENVELOPE – With the help of the Alom Group of Sarawak, Malaysia, we built a trial envelope from a polypropylene fabric, like the one described above but this time laminated with reflective Mylar film on both its sides, and weighing about 175 gm/m2. The envelope volume was about 320 m3. We sealed the seams with common household silicon sealant. 6 American Institute of Aeronautics and Astronautics FIRST EVER STEAM BALLOON INFLATION We performed a successful tethered inflation of this envelope on 17 April 2003: the first inflation of a full-scale steam balloon in history. The arrangements for getting the steam into the envelope, and for controlling the envelope while it is being inflated, do actually require some further elaboration. As can be FUTURE POSSIBILITIES THE NEXT LARGE ENVELOPE — The above first small envelope goes against the principle that a steam balloon should be as large as possible. Since the potential of this ground steam generator is about 3 tons per hour of steam, which is a lot, we should aim at a steam balloon of great capacity. ENVELOPE DIMENSIONS — My plan for a full-sized steam balloon is to utilize the time-tested ball-and-net gas balloon constructional formula. Thus the envelope should be nearly spherical, and I plan its approximate parameters as being: diameter 23 m, area 1,660 m2, and volume 6,370 m3. When filled with steam this envelope should provide gross lift of about 4,000 kgf. At full blast, the steam generator should take two to three hours to fill this balloon. Envelope weight with net (without any insulation) will be about 350 kg and parasitic water about 150 kg, so the envelope net lift will be about 3,500 kgf. This envelope offers the following flight possibilities. Uninsulated "dribble" flight According to my experiments, without any further insulation, this envelope, if white inside and covered on the outside with a reflective "Mylar" type material, may be subject to a condensation rate of about 700 gm/m2.hour, i.e. about 1,160 kg/hour in total. For a "dribble" flight, allowing a few hundred kilos for seen from the left-hand picture, it was a bit of a struggle to control the envelope while it was partially inflated. and as it transited from lying down to standing up. When completely full the envelope stood nicely and tugged upwards strongly, even though quite a quantity of air had gotten into the envelope along with the steam. For the first time ever, the lifting power of steam was manifested to the naked eye! basket, pilot, several passengers, and ballast water tankage, it will therefore be possible to carry 3,100 kg of ballast water, which will be easily enough for two hours flight. This will be a pretty decent performance, considering that the only cost for a flight will be that of about 600 kg of gasoil fuel for the ground fill. Double envelope – "dribble" flight If this envelope were to be doubled, i.e. if another similar envelope were mounted over its outside with an intermediate air gap, which is not a simple construction to implement, the envelope weight would be roughly doubled, and the heat loss would be expected to be reduced to below half, so that about four hours "dribble" flight duration could be anticipated. Insulated envelope – "dribble" flight If a Primaloft insulating jacket as described above of weight 250 gm/m2 and thus of total weight 400 kg, were fitted over the first (single layer) envelope, the net lift would be reduced to about 3,100 kgf, so only about 2,700 kg of ballast water could be carried. But the condensation would now be only about 200 gm/m2.hour, i.e. about 330 kg/hour in total. "Dribble" flight duration would now be about 8 hours, which is extraordinary, considering that no flight boiler is being used. 7 American Institute of Aeronautics and Astronautics The problem with this type of insulating jacket would be, not its weight, but its bulk. The volume might be 30 m3 or more. This would present something of a problem upon retrieval. Personally, I am not convinced of the practicability of a bulky insulation jacket of this type upon a balloon, which needs to be retrieved after every flight. The case with an airship is quite different; a relatively thick insulation jacket is very practicable. Possibilities for the "reboiling" flight mode Allowing 200 kilos for an onboard burner/boiler system (which is ample with a sophisticated unit), and supposing a high boiler efficiency of 80% so that the combustion of 1 kilo of onboard gasoil fuel reboils about 15 kg of water, the following approximate figures for "reboiling" flight performance are easily derived: UNINSULATED SINGLE ENVELOPE Fuel load Fuel consumption Flight duration 2,900 kg 80 kg/hour 36 hours DOUBLE ENVELOPE Fuel load Fuel consumption Flight duration 2,500 kg 40 kg/hour 60 hours INSULATED ENVELOPE Fuel load Fuel consumption Flight duration 2,100 kg 21 kg/hour 100 hours These flight durations are greater than could ever realistically be required, except in long-distance balloon racing. It should be noted that the solar heating effects which torment a conventional gas balloon as it goes under clouds and comes out again do not affect the actual lift of a steam balloon operating in the reboiling mode at all, but only cause its rate of fuel consumption to vary. We see that, as an alternative possibility, a large number of passengers could be carried for an all-day flight. These performance extrapolations are not particularly speculative; they are solidly supported by our experiments, as far as they go. At the very least, they show that the steam ballooning concept is well worth pursuing further. POSSIBLE AIRSHIP DEVELOPMENTS Any possible actual development of a steam airship is a long way off, but the general outlines of what might be possible are emerging. Within limits, the picture is encouraging. First, the obvious disadvantages of using steam lift gas in an airship are relatively low lift, and the necessity for reboiling the condensate water. The advantages are cheapness, and the ability to deflate the airship after each flight, thus obviating the need for a hangar or mast. A rigid airframe would sacrifice this second great advantage of steam lift gas while preserving all its disadvantages, and so I think that the idea of a rigid steam airship is a non-starter. The problem of the bulk associated with an insulating jacket, which might give trouble with a steam balloon, does not apply to a non-rigid steam airship, because airships virtually always return to base after a mission. So we can assume that a steam airship would be fitted with something like the Primaloft insulating jacket detailed above weighing about 250 gm/m2, and that the rate of steam condensation would be about 200 gm/m2.hour. In order to minimize condensation the volume of the envelope relative to its area ought to be maximized. The ideal is a sphere, but this is not a very practical shape for an airship. A lenticular configuration could be interesting. At least a steam airship could not be of the conventional Hindenburg-type shape with fineness ratio about 4:1; there would be too much area to lose heat. Therefore a high-speed steam airship is impracticable. The compromise might be a dumpy shape like a puffer fish, presumably pitch-stabilized by pendulum action. Or a lenticular…. For discussion let us consider an airship of volume similar to our large balloon envelope, i.e. 6,370 m3, and with area now about 2,400m2 since it is no longer spherical, made from the same fabric as above and fitted with a Primaloft insulating jacket. (It is probable that ballonets could be dispensed with, because the volume of the steam lift gas can easily be varied by changing the boiler operating rate.) The total envelope and insulation weight is now about 1,060 kg, and the parasitic water will be about 200 kg, so that the net envelope lift will be about 2,800 kgf and the steam condensation rate will be about 500 kg/hour. It will take about 30 kg/hour of fuel to reboil this condensate, so fuel for a ten hour mission will weigh about 300 kg, and the burner/boiler should not weigh more than 200 kg. We are therefore left with about 2,300 kg available for the empennage, gondola, engines, engine fuel, pilot and flight gear, and payload. This seems 8 American Institute of Aeronautics and Astronautics quite adequate for an airship adapted for advertising or camera platform missions. And the price will certainly be right! In capital and operating cost, such a steam airship would more closely resemble a hot-air airship than a helium airship. STEAM PROPULSION FOR A STEAM AIRSHIP Such an airship filled with steam lift gas could of course be powered by a conventional gasoline or diesel aeronautical engine, but the intriguing possibility arises of using a steam engine. The spent exhaust steam from the engine would naturally be discharged into the envelope to replenish the lift gas. Since a steam airship must in any case carry a boiler for reboiling the condensate water, and since the envelope itself would function as the condenser for the steam engine, only the actual steam engine itself would be required in addition. A steam reciprocating engine can be quite lightweight and is very reliable, and its high torque and low rpm characteristics are very suitable for airship application. Moreover, maneuvering thrusters could be driven by steam vane motors, which are very light indeed, so they could be mounted at any convenient point on the envelope. However such vane motors could not be used as the main airship engines, because their thermodynamic efficiency is poor. An idea of what is possible can be gathered from the details of the first and only flight of a steam powered airplane, performed by Besler in 1933 - a little-known episode in aviation history. The Besler brothers participated in bringing the Doble steam car to its very high pinnacle of development, and then they turned their attention to steam power for aircraft. Their trials were successful: the airplane was eerily quiet and could land in a very short distance with engine reverse thrust – but the concept was not adopted commercially. The Besler Corporation worked on an improved version of this steam aircraft power plant in 1958, and the system produced is now on exhibit in the Smithsonian Institution. Salient points from the test data were (in Imperial units): Engine and auxiliaries, weight Boiler/burner and auxiliaries, weight Power output (max at 2000 rpm) Specific fuel consumption (cruise) Steam production (max) 160 lbs 170 lbs 160 hp 0.8 lb/hp.hour 2100 lb/hour The weights could be considerably reduced with modern practice and materials. The specific fuel consumption is not as good as that of an internal combustion engine, but for the steam airship application this is irrelevant, since the vented steam is required in any case for lift purposes. The above figures prove conclusively that a boiler/burner unit can 9 American Institute of Aeronautics and Astronautics be built sufficiently light to be used in a steam balloon or airship, and that a steam engine system weighing about an hundred kilos, fed by such a boiler, can provide more than a hundred horsepower. The entire plan appears quite viable, although rather outré . ground handling of a Steam Airship will, in this restricted operational context, more than compensate for its deficiencies. —o0o— THE STEAM AIRSHIP MISSION Obviously the non-rigid steam airship does not have the potential to displace the helium airship in every application. However I think that it will have its niche. Specifically, I think that a steam airship will be able to satisfy the demands that hot-air airships try to satisfy but fail. Consider the following mission requirement: During reasonably fine weather, to fly over a major sporting event and maintain station for a few hours, displaying advertising or carrying a news camera. A hot-air airship is not able to meet this requirement. Theoretically it might be capable, but in practice the wind is usually too strong - because a hot-air airship is defeated by even a light wind. At present a helium airship is the only possibility for this mission, and they are extremely expensive to operate, fundamentally because they must be kept inflated indefinitely. I believe that, with development, a steam airship will be able, in average good weather, reliably to: Arrive from base, deflated and packed in a single vehicle, at an unprepared launch site in a park within a few kilometers of the target area; Be inflated with steam from a ground boiler carried upon or towed with the same vehicle, by a small ground crew; References: (1) Sir George Cayley - letter dated 24 December 1815 in the "Philosophical Magazine". (2) Jean-Claude Cailliez – "Alexander Liwentaal, a European aeronautical pioneer from Geneva", pub. SECAVIA, Geneva (ISBN 2-8293-0260-5). (3) Letters exchanged between Alexander Liwentaal and Count Zeppelin, in the Zeppelin Archives at the Zeppelin Museum at Friedrichshafen. (4) Hugo Erdmann - German Patent 214,019 (1908). (5) Hermann Papst - US Patents 3,456,903 (1969), 3,897,032 (1975), and 4,032,185 (1977). (6) W. Newman Alcock - article in "Wingfoot" (1961). (7) David Young, articles in "Aerostat", 1973/74. (8) Andre Giraud - French Patent 2,684,952 (1991). (9) Jean-Paul Domen - European Patent 524,872 (1993). ------ Fly to the target area and hold station over it for several hours; Return to the launch site and be deflated and returned to base. And I believe that the cost may be perhaps twice that of a hot-air airship, but much less than that of a helium airship. And I think that the up-wind performance of a steam airship will be sufficiently reasonable for this mission to be possible on, perhaps, 80% of days. In fact for a limited mission such as the one specified above, the full capabilities of a helium airship - such as long-term endurance, high airspeed, and poor-weather flight capability - are not actually needed. The steam airship will have the most important qualities necessary for advertising and camera platform work: hover capability in moderate winds, and large size. And I think that the low cost and the convenience in 10 American Institute of Aeronautics and Astronautics