Lab #11 Help Document

advertisement

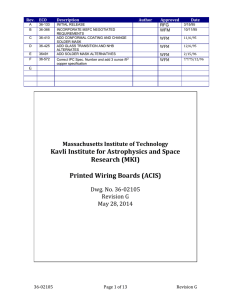

Lab #11 Help Document This help document will be structured as a walk-through of the lab. We will include instructions about how to write the report throughout this help document. This lab will be completed in room 260 CTB. You will need to partner up for this lab in groups of two. This lab will require the use of the following pieces of equipment: National Stereo Zoom Microscope Stereo Zoom Microscope Calibration slides Magnifying glasses Dial Calipers 6-layer PWB w/ j-lead memory on both sides, side section 6-layer PWB SIMM section at IC and chip 2-layer PWB sectioned at two holes FR4 substrate bare PWB Assembled PWB Procedure 1. Observe each of the PWB sections. Determine for each the board thickness, the number of copper layers, and the thickness of each prepreg layer. Take appropriate pictures, and give the dimensions. DO NOT just use the images on the class website – those are simply to help you prepare for the lab. Seeing something in the microscope for yourself is a MUCH better learning experience than just looking at the pictures. For this part of the lab, you will need the three sectioned samples: the 6-layer PWB w/ j-lead memory on both sides, side section the 6-layer PWB SIMM section at IC and chip 2-layer PWB sectioned at two holes Note: If you have the sample labeled 2-layer PWB sectioned at two holes, you can take the measurements for part 1 and also for part 2 of the lab. This is because part 2 requires specifically that you use this sample. For each sample, do the following steps: Measure the board thickness- For this part, measure the thickness of the board using the Motic grid. The thickness of the board is not the same as the thickness of the sample. The sample thickness includes the components mounted on the board. You want just the board thickness. The ends of the samples don't have components mounted on them, so you can make your measurements there if you want. Make sure to calibrate your grid by checking the scale against a calibration slide. Assuming nothing has changed since this document was written, the grid should measure 800x800 micrometers when the microscopes are set to 1x magnification. For Lab Report: Include the measured thickness of the board for each sample. Be sure to include your units as well. Count the number of copper layers- This may not be the easiest thing to see. What you should not count from the samples are the layers of copper that come from components mounted on the board. The board itself will have the layers. For boards with more than 2 layers, it may be easier for you to see the layers of copper if you look at the ends of the board instead of near the center where the components are mounted. Hint: the number of layers is included in the name. You still need to be able to identify these layers though since you will be measuring the distance between them in the next part. For Lab Report: Include the number of copper layers you see for each sample. Measure the thickness of each prepreg layer- This will be the distance between the copper layers that you just observed. The prepreg is composed of fiberglass sheets. Each layer may have one or multiple sheets of fiberglass. Each sample will have 1 less layer of prepreg than it has layers of copper. For Lab Report: Include all measured thicknesses for the prepreg layers for each sample. Be sure to include your units as well. Take appropriate pictures- Take a picture of each sample that you observed. For Lab Report: Include a picture of each sample that you observed. Give the dimensions of each sectioned sample- For this part, you will need to measure the width and thickness of each sample. Use the dial calipers for this part since the width is too large for the Motic grid to measure in one piece. For Lab Report: Include the dimensions (width and thickness) of each sample cross section as well as the units you used. 2. Observe the PWB hole section. Determine the thickness of the hole walls. Determine the thickness of the tin plating over the copper. Determine the thickness of the copper pad on each end of the hole. Take appropriate pictures. For this part of the lab, you will need the sample labeled as 2-layer PWB sectioned at two holes. For the sample, do the following steps: Determine the thickness of the hole walls- You will need the Motic grid to make these measurements. If you look at the sample under the microscope, you should see two silverish columns with copper ovals going through the sectioned PWB. Directly outside of each columns there should be a copper border. This border consists of the copper hole walls and the copper pads on the top and bottoms of the holes. You want to measure the thickness of the copper layer that lines the inside of the hole. For Lab Report: Include the thickness of the copper layer that lines the hole walls. Be sure to include the units that you used. Determine the thickness of the tin plating over the copper- The tin plating is the solder used to secure a component to the PWB, and to protect the copper from oxidation. The tin plating over the copper refers to the thickness of the solder that sticks out of the top and bottom of the holes. Measure from the copper pad to the top of the blob of solder. There are 4 to choose from and each one will have a different measurement, but you only need to worry about one for this part of the lab. For Lab Report: Include the thickness of the tin-solder cap that rests on top of the copper pad. Determine the thickness of the copper pad on each end of the hole- For this part, you will need to make two measurements. They will be the same kind of measurement. You will need to measure the thickness of the copper pads on each end of one of the holes. You will need to use the Motic grid for this measurement. The pads are the copper layers that rest on the surface of the board surrounding a hole. For Lab Report: Include the thicknesses of the two copper pads that you measured. Be sure to include the units that you used. Take appropriate pictures- Take a picture of the sample that you observed. For Lab Report: Include a picture of the sample that you observed. 3. Using the FR4 substrate bare PWB, determine the process Cpk: Cpk = |(χ – NSL) / 0.5 PW| For this part of the lab, you will need to determine the Cpk of the bare PWB sample (FR4 substrate bare PWB). Unlike in the previous time when we calculated Cpk, this time you will need to take 5 measurements instead of 3. The reason for this is that taking only 3 measurements sometimes results in a Cpk of 0 or infinity. You will need to use the calipers to make your measurements since it is not really possible to measure this with the microscope. First, measure the thickness of the PWB at 5 different areas. Once you have your measurements, you can use them to find the values for calculating the process Cpk. Start by finding the process mean (χ). Do this by adding your 5 measurements together and dividing by 5 (if you do more than 5 measurements, divide by the number of measurements that you made.) Now find the process width (PW). Do this by subtracting your lowest measurement from your highest one. Now find the nearest specification limit (NSL). This will simply be the one measurement you took that is closest to your calculated process mean. Now that you have all of the components, plug them into the equation to find Cpk . Cpk = |(χ – NSL) / 0.5 PW| For lab report: Include a picture of the PWB. Include your 5 or more measurements. Include your calculations and equations used for process mean, process width, and Cpk and specify which value you chose for your nearest specification limit. 4. Observe one of the assembled PWBs; please do not choose one someone else has already done and then just copy their information. Determine the number of ICs, the number of chip components (resistors or capacitors; you do not need to differentiate them), the number of discrete transistors, the number of surfacemount components, the number of through-hole components, the smallest chip component and its dimensions, and the largest component and its dimensions, and any other types of components on the PWB. Take appropriate pictures. For this part of the lab, you will need one of the two PWB samples that has IC's mounted on it and isn’t embedded in black plastic. This part of the lab will basically be counting the number of certain components that you see on the board. Some of the components will double count, meaning that they will count for more than one category, so don't worry if this happens. If there are no components of a certain type on the board, specify 0 for that component. For the sample, do the following steps: Count the number of ICs- Remember that IC's will be packaged so that they can be mounted. For Lab Report: Include the number of IC's that you counted. Count the number of chip components (resistors or capacitors; you do not need to differentiate them)Remember that these components are small and rectangular. They also only have one input and one output. For Lab Report: Include the number of chip components that you counted. Count the number of discrete transistors- A discrete transistor will usually have 3 leads only coming off of it. For Lab Report: Include the number of discrete transistors that you counted. Count the number of surface-mount components- A surface-mount component is any component that does not go through a hole when mounted. It’s contacts are pads on the surface of the board, hence the name “surface mount.” For Lab Report: Include the number of surface-mount components that you counted. Count the number of through-hole components- A through-hole component is any component that goes through a hole when mounted. For Lab Report: Include the number of through-hole components that you counted. Identify the smallest chip component and its dimensions-You can use either the calipers or the Motic grid to measure this. For Lab Report: Tell what the smallest chip component was and give its dimensions. Be sure to include your units. Identify the largest component and its dimensions-You can use either the calipers or the Motic grid to measure this. For Lab Report: Tell what the largest component was and give its dimensions. Be sure to include your units. Identify any other types of components on the PWB not already mentioned- If there is anything on the board that has not already been included in one of the other categories, say what type of component it is here. For Lab Report: Identify any components not previously identified. If there aren't any, say that there were no components left for this section. Take appropriate pictures- Take a picture of the sample that you observed. For Lab Report: Include a picture of the sample that you observed. Equipment The only piece of equipment for the lab report that needs a manufacturer is the microscope. Say: National Stereo Zoom Microscope (these don’t seem to have serial numbers or model numbers on them so don’t worry about those.) List any other pieces of equipment that you used as well. Conclusion Tell what this lab has taught or reinforced. Try to be insightful in recognizing the things you really did learn or verify. Self-explanatory