15667 Demonstrate knowledge of surface extraction methods and

advertisement

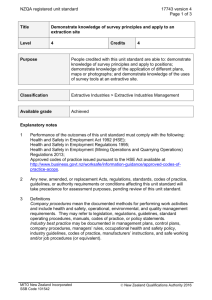

NZQA registered unit standard 15667 version 4 Page 1 of 3 Title Demonstrate knowledge of surface extraction methods and the effects of geological features on these methods Level 5 Credits 10 Purpose People credited with this unit standard are able to demonstrate knowledge of the effects of geological features on surface extraction methods, and demonstrate knowledge of surface extraction methods to produce end product in relation to geological conditions at extractive sites. Classification Extractive Industries > Surface Extraction Available grade Achieved Explanatory notes None. Outcomes and evidence requirements Outcome 1 Demonstrate knowledge of the effects of geological features on surface extraction methods. Evidence requirements 1.1 The effects of geological features at a surface extraction site are described in relation to extraction methods required to extract the economic material. Range 1.2 The geological features and physical characteristics of rock material at a surface extraction site are described in terms of their effect on fragmentation. Range 1.3 includes but is not limited to – faults, folds, joints, bedding planes, washouts, dykes, sills, weak and/or crush zones. includes but is not limited to – strength, bedding, jointing, bulking, fabric. Potential extraction methods are evaluated in relation to geological features and fragmentation. Range may include but is not limited to – drill and blast, digging, loading, scraping, dozing, ripping, crushing, screening, haulage, working surfaces. NZ Motor Industry Training Organisation (Incorporated) (MITO) SSB Code 101542 New Zealand Qualifications Authority 2016 NZQA registered unit standard 15667 version 4 Page 2 of 3 Outcome 2 Demonstrate knowledge of surface extraction methods to produce end product in relation to geological conditions at extractive sites. Evidence requirements 2.1 The effectiveness of different extraction methods is evaluated in relation to their ability to mine or quarry and load the material. Range 2.2 The effect of processing methods is evaluated in relation to the ability of the mined or quarried material to fulfil its end-product use. Range 2.3 may include but is not limited to – discharge, stockpiling, reclaim, screening, washing, crushing, dilution, product quality, product deterioration, contamination. The effect of extraction methods is evaluated in relation to effect on geography and topography. Range 2.4 includes but is not limited to – drill/blast, front-end loaders, hydraulic excavators, hydraulic and electric shovels, motor scrapers, draglines, bulldozers, bucket wheel excavators, suction and bucket wheel dredges. may include but is not limited to – dump heights, contouring, water management, diversions, rehabilitation, bunds, visual screening, re-vegetation, slope stability. The geology and surface features of a site are explained in terms of the design and layout of the site. Range Planned review date may include but is not limited to – flat site, gradient of site, benching, rock faces, slope stability, ponding, underwater excavations, location, site features, face height and slope, slope stability, water effects, underwater excavations, old workings. 31 December 2019 NZ Motor Industry Training Organisation (Incorporated) (MITO) SSB Code 101542 New Zealand Qualifications Authority 2016 NZQA registered unit standard 15667 version 4 Page 3 of 3 Status information and last date for assessment for superseded versions Process Version Date Last Date for Assessment Registration 1 25 July 1999 31 December 2017 Review 2 27 January 2005 31 December 2017 Rollover and Revision 3 16 July 2010 31 December 2017 Review 4 18 June 2015 N/A Consent and Moderation Requirements (CMR) reference 0114 This CMR can be accessed at http://www.nzqa.govt.nz/framework/search/index.do. Please note Providers must be granted consent to assess against standards (accredited) by NZQA, before they can report credits from assessment against unit standards or deliver courses of study leading to that assessment. Industry Training Organisations must be granted consent to assess against standards by NZQA before they can register credits from assessment against unit standards. Providers and Industry Training Organisations, which have been granted consent and which are assessing against unit standards must engage with the moderation system that applies to those standards. Requirements for consent to assess and an outline of the moderation system that applies to this standard are outlined in the Consent and Moderation Requirements (CMR). The CMR also includes useful information about special requirements for organisations wishing to develop education and training programmes, such as minimum qualifications for tutors and assessors, and special resource requirements. Comments on this unit standard Please contact the NZ Motor Industry Training Organisation (Incorporated) (MITO) info@mito.org.nz if you wish to suggest changes to the content of this unit standard. NZ Motor Industry Training Organisation (Incorporated) (MITO) SSB Code 101542 New Zealand Qualifications Authority 2016