SUSTAINABLE COMMUNITY ENERGY ANALYSIS

advertisement

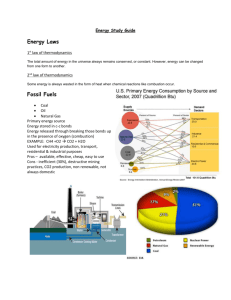

SUSTAINABLE COMMUNITY ENERGY ANALYSIS conducted for the WALDEN THREE FOUNDATION prepared by Thermal Conversion Corp A subsidiary of Nuvotec, Inc. 2345 Stevens Drive Richland, WA 99352 May 2004 Andreas S. Blutke President Thermal Conversion Corp J. Mark Henderson President & COO Nuvotec, Inc. 509-375-1940 office 509-375-0401 fax ablutke@thermalconversion.com 509-375-1940 office 509-375-0401 fax markhenderson@nuvotec.com Table of Contents 0.0 Disclaimer ............................................................................................................... 3 1.0 Description and Use of Model ................................................................................ 3 1.1 Introduction ......................................................................................................... 3 1.2 Inputs / Outputs ................................................................................................... 5 1.3 Instructions for Users .......................................................................................... 5 1.4 Recycling Management ...................................................................................... 7 1.5 Waste Management ............................................................................................. 8 1.5.1 Biogas Plant / Digester.................................................................................... 8 1.5.2 Plasma Gasification ........................................................................................ 9 1.5.3 Plasma Melter System................................................................................... 10 1.6 Energy Management ......................................................................................... 10 1.6.1 Combined-Cycle Gas Turbine (CCGT) and Combined Heat and Power ..... 12 1.6.2 High-Temperature Fuel Cell (HTFC) System .............................................. 13 1.6.3 Solar Energy Systems ................................................................................... 13 1.7 Transportation Systems ..................................................................................... 14 1.8 Imports / Exports............................................................................................... 15 2.0 Description of Subsystems.................................................................................... 17 2.1 Domiciles & Small Businesses ......................................................................... 17 2.2 Solar Installations.............................................................................................. 17 2.3 Farming ............................................................................................................. 18 2.4 Forestry ............................................................................................................. 19 2.5 Industry ............................................................................................................. 19 2.5.1 Food Processing..................................................................................... 19 2.5.2 Wood Processing ................................................................................... 19 2.5.3 Steel Production & Canning ................................................................. 20 2.5.4 Glass Production & Bottling .................................................................. 21 2.5.5 Aluminum Production ............................................................................ 21 2.5.6 Cement Plant .......................................................................................... 23 2.5.7 Lime Plant & Construction .................................................................... 24 2.5.8 Manufacturing & Assembly ................................................................... 24 2.5.9 Textile Industry ....................................................................................... 24 2.5.10 Solar System Manufacturing ................................................................ 25 2.5.11 Wind Energy System Manufacturing ................................................... 26 3.0 References ............................................................................................................. 27 4.0 Block Diagrams .................................................................................................... 30 4.1 Figure 1: First Level Overview ........................................................................ 30 4.2 Figure 2: Second Level Overview .................................................................... 30 4.3 Figure 3: Detailed Overview ............................................................................. 30 4.4 Figure 4: Model Housing Unit .......................................................................... 30 4.5 Figure 5: Waste / Energy Management Concept .............................................. 30 2 0.0 Disclaimer The information presented in this document is non-proprietary and based on publicly accessible data. Where public data was not available, assumptions were made to provide functionality to the developed computer model. Such assumptions are indicated in the model by color code. The model developed in this study is hypothetical in nature. Although an incorporation of improvements is planned as more data becomes available, the accuracy of the content is limited and is not necessarily comprehensive, complete, accurate, or up to date. To the full extent permissible by law, the developer of this information disclaims any liability for damages or losses arising from the use of the information. 1.0 Description and Use of Model 1.1 Introduction Sustainable living entails that human civilizations value, preserve, and protect their natural resources on the planet. Sustainable development is frequently described as “the development that meets the needs of the present generation without compromising the ability of future generations to meet their own needs”. Natural resources of clean air, clean water, fertile land, fossil fuels, metals and minerals may seem abundant, but in reality, world population growth and increased resource usage and consumption is leading to a depletion of many crucial resources for life as known today. For example, the extraction, conversion, and use of energy are the single largest cause of air and water pollution, as well as of emissions that may lead to global climate change [46]. Reviewing energy production in detail shows that most developed countries use primarily fossil fuels (coal, oil, and natural gas) and nuclear fuels for heating, cooling, manufacturing, and transportation. As the developing countries gradually grow their economies and improve their living conditions, they add to the rapidly growing world energy consumption. It is apparent that the high use and dependency on fossil fuels and nuclear power are hardly sustainable at today’s consumption rates and will be less so with further increases in demands of the coming years. Sustainability and sustainable urban existence equally include environmental, economic, and social aspects, also referred to as the “triple-bottom-line”. Environmental objectives include to maximize energy efficiency, to conserve resources, to minimize pollution/damage to the environment, and to conserve wildlife habitats. Economic objectives address the support of local economies and to provide dignifying employment opportunities, while social objectives include to improve the quality of life and to promote social fairness and equality for all people. Based on the vision by The Walden Three Foundation, Thermal Conversion Corp was contracted to generate a computer-based model that aims the simulation of sustainable living in communities without reducing the living standards typical in developed countries today. Such a sustainable community is designed with the most energy-efficient methods of production and living available to-date, maximum use of renewable energies, 3 minimization of materials usage combined with maximum materials and energy (heat) recycle, and highly integrated waste and energy concepts for energy production from organic waste materials. The city is simulated as “solar city”, utilizing a maximum of building surfaces for photovoltaic and hot water production and to minimize energy and time consumed in transportation. The emphasis on energy producing systems based on renewable energies, waste minimization, and maximum re-usage of wastes for energy and secondary usage provides a vision to minimize the use of and dependency on fossil fuels and nuclear power. The model is aimed to assist communities in developed and developing countries with information and assessment capabilities to gradually achieve higher levels of sustainability. The model described in this document focuses primarily on the technical aspects of sustainable living. However, social and economical sustainability aspects are equal motivators for the concepts proposed in this development. The model includes multi-family residences, businesses, industries, and an infrastructure typical for a selectable size of population; the model in its presented form is built for a community of 100,000 people. The sustainable community with its surrounding farm and forest land is self-sustained in terms of basic food supply and energy production, but it interacts with other communities and the environment in its mass and energy flows. Products and services are exported/ exchanged with imports of raw and processed materials and manufactured goods from other communities (see Figure 1). An emphasis is placed on balancing a selection of industries in the community typical and necessary for a developed society with energy consumption by those industries. Residential living is modeled as multi-family dwellings to maximize energy efficiency. Renewable energy sources such as solar heating and electric power generation (photovoltaic), recycle of organic wastes for energy production, and use of waste heat are included for residences and businesses. The waste-to-energy concepts are based on technologies available today that maximize recycle and minimize the use of landfills. The energy analysis considers solar heating and power, total electric power, natural gas, coal and other fuels, and steam/heat. The model is intended for education, stimulation of discussions, and to become a tool in the efforts of further developments towards sustainable living. The model is gradually improved and developed to higher levels of accuracy and feasibility with the support of numerous individuals. We encourage persons who review and use the model to pass on any comments and critique so that corrections or missing inputs can be implemented. Ultimately, the model shall provide the information basis required for planning of new and upgrades of existing communities with higher levels of sustainability. The model can be downloaded and used for free by individuals. The user can review the information contained in the models current revision. Further, the model can be used by any person to study for example the impact of changes on demands or production rates, complex interrelations and effects on import/export of materials, fuels, and goods, the energy mix in the sustainable community, and many more aspects. A conscious effort was undertaken to select technologies and/or systems that could be economically competitive. However, this model does not provide the information of economical effects nor does it claim to be a most economical constellation at cost structures of to-date. A limited amount of data was available to expose a detailed listing on heat/steam demands and generation, staffing and skills requirements, and actual 4 hours of labor. 1.2 Inputs / Outputs The sustainable community is modeled in a MS Windows Excel program. A series of figures provide an overview of the community model. Figures 1 thru 3 provide progressively more details to materials, energy, and emission flows within the subsystems. Inputs and outputs to subsystems are categorized as follows: Inputs to a subsystem may include: Water (from aquifer or water treatment plant), Steam/heat (from industry) Electric power (from power plant or solar systems) Natural gas and other fuels (imports) Raw materials (imports), Manufactured goods (imports), Products (imports or from community). Outputs from subsystems may include: Waste water, Sewage/manure Fuel Waste, Non-Fuel Waste, Steam/Heat, Fuel Gas (syngas or CH4), Electric power, Recyclable materials (glass, metal/aluminum, paper, etc.), Products (for internal use or export), Air emissions. The emphasis in the study was to capture significant materials and energy flows and to provide transparency for these streams. Hence, data was gathered and analyzed to provide input values based on references or (where needed) to make reasonable assumptions. 1.3 Instructions for Users Individual Excel sheets have been generated for subsystems and summaries to provide a structured approach and overview to the collective data set included in the model. Subsystems include: Domiciles & small businesses, Farming (animals (including fish), vegetable, corn, and fruit), Forestry (tree farms), Food processing including meat processing, poultry dressing, dairy product, and vegetable & fruit processing plants, Wood processing including wood mills, pulp and paper production, and furniture manufacturing, 5 Aluminum production, Steel production, Canning plant, Cement production Construction business, Glass production, Bottling plant, Solar systems manufacturing, and General manufacturing and assembly. Waste water treatment plant, Digester (biogas) plant (for manure and sewage), Gasification plant (for fuel waste), Plasma melter system (for non-fuel waste), and Electric power generation (CCGT) plant. Summaries and Overviews are provided for: Fossil fuel usage (NG, gasoline and diesel fuel), Steam/heat (generation and usage), Import & export (materials and goods), Materials and Recycle, Energy power demand, and Energy balance. Subsystem sheets allow the user to study the material and energy inputs and outputs, assumptions made, calculations, and data sources. Input and output streams are not specified for individual small businesses. However, general model assumptions were made for energy requirements for small businesses and service infrastructure operations. Small businesses include (at a minimum): bakeries, banking, grocery stores, drugstores, restaurants, retail stores, hardware stores, insurances, arts and crafts business, entertaining businesses, beauty stores, travel agencies, coffee shops, tailoring, wood carving, etc. Service infrastructure operations include: heating/cooling, postal, water systems, transportation, delivery, receiving/storage, recycling, maintenance and repair (see Figure 4). A user of the model can change the inputs (e.g. the number of people in the community, the amount of wood products, individual quantities for food consumption assumptions, etc.) on individual sheets and review the effects on the overview sheets. For example, if the population changes the diet to current U.S. consumption rates, this will increase the demand for food, etc., which then will require more food production. This in turn requires more materials, energy demand, emissions, etc., but it also will lead to more waste, which in turn can be used for energy production, etc. Input fields have light blue or green background to signify various levels of confidence in the data used and/or for the referenced source of the information. Input fields with a light blue color indicate data inputs chosen as placeholders, data with lower certainty of accuracy, or a free selection of values without background source needed. Input fields with green color indicate that inputs chosen are backed up by a source and/or have a high level of accuracy. It should be noted that by making changes to fields other than input fields, the model may become partially impaired. 6 Input with high certainty Input with lower certainty Additionally, numbers with a clear background indicate a display of information or calculated values using data only from the given Excel sheet. A separate color scheme is used to denote cells using imported data from other sheets. Such imported data is indicated in a field with a yellow background. Data imported from other Sheet An important note for users is that some calculations are iterative and will require the user to enter recalculated values to bring the overall calculations to a higher level of accuracy. Instructions are provided in such sheets. The following sheets demand manual inputs: “CCGT System”, “Plasma Melter”, and “Waste Water Treatment Plant”. 1.4 Recycling Management Sheet “Materials & Recycle Overview” provides a summary for materials included or not included in the recycling/re-use concepts accounted for in the model. Recycle and re-use of materials has a significant effect on reducing the demand for materials and energy consumption and reduction of secondary emissions (to environment and landfill). The percentage of recycle versus production of virgin materials can be adjusted in the individual subsystems (e.g., pulp & paper production, steel production, etc.). Obviously, there are limitations to the amount of recycling due to materials degradation (paper fiber), availability of recycle materials (versus demands), and product quality (e.g., due to impurities in the recycle materials). The concept of recycle demands education, motivation, and efforts (e.g., separation) by all individuals in the community. Recycling is assumed for domiciles as well as for any type of business (e.g., manufacturing). The materials modeled for recycling include: Paper and cardboard, Aluminum (containers, sheets, etc.), Steel (containers, sheets, construction materials, etc.), Wood products, and Glass (containers, etc.). Note: The use of glass bottles was chosen over plastic due to the following reasons: The energy consumption associated with primary production of plastic containers is about 10% below the amount needed to glass containments of the same container volume. No functional recycle system for plastic bottles is in place yet to offer the re-use of plastic without complete re-processing. In contrast, multi-use of glass bottles for highdemand beverages (e.g., water, soda, etc.) has been implemented for over 25 years in Germany and other Western European countries with great success. Multi-use of glass containers (up to more than 25 times prior to re-melting) reduces the energy used for a calculated one-time usage to a fraction of the original primary energy spent. Hence, the use of plastic bottles was not selected as a viable recycling path and plastics (e.g. 7 imported from other communities) are assumed to be a fuel source in the gasification system or to be exported for recycling outside of this community. [Note: The model can easily be adjusted to include plastic re-processing, if desired.] References: [1], [2] 1.5 Waste Management See Figure 5 “Waste & Energy Management Concept”, including the waste-to-energy concept used in the model. See sheets “Gasification System”, “Plasma Melter”, “Waste Water Treatment Plant”, “Digester System”, and “Materials & Recycle Overview”. Highly organic waste streams (sewage, manure, etc.) are processed in a digester system (biogas plant) for methane production. A gasification system (based on plasma reforming) is selected for converting fuel waste (biomass, organic wastes, animal corpses, etc.) into synthesis fuel gas (syngas), such as hydrogen (H2) and carbon monoxide (CO). A plasma melter system was selected for converting non-fuel waste (residues from production, non recyclable wastes, inorganic materials, etc.) into slag materials. Fuel gas from the melter system is fed to the gasification system. All biomass is converted either to methane or syngas. The conversion of specific biomass streams to soil or fertilizer was not considered in the model. References: [3], [4], [5], [9], [40], [41], [42], [43], [44] 1.5.1 Biogas Plant / Digester Biogas can be produced from highly organic feed materials including animal manure (from cattle, pigs, and poultry), sewage, but also from a number of organic wastes (e.g., from fish and food processing and from medical industry). Biogas is the product of the digestion of soluble and suspended organic materials by naturally occurring anaerobic bacteria in an oxygen reduced atmosphere. At this point of development, the model only considers manure waste streams as inputs for the biogas plant; all other organic materials are processed in the gasification system. The dry composition of biogas typically consists of about 60 vol.-% methane (CH4), 38 to 40 vol.-% carbon dioxide (CO2), and depending on the organic feed, up to 0.2 vol.-% of hydrogen sulfide (H2S). There are a number of options for the use of biogas, including the generation of heat and power by combustion, but also the production of industrial gases (CH4 and CO2). The model considers the biogas as fuel in the combined-cycle gas turbine for electric power and heat production. Typically, the H2S is removed from the biogas (prior combustion) with so-called iron sponge (wood shavings or wood chips impregnated with hydrated iron oxide, Fe2O3), which is reprocessed, resulting in elemental sulfur as by-product. The operation of a biogas plants (also called digesters) is determined by the selected operating temperature: mesophilic operations at 35 to 38ºC and thermophilic operations at 52 to 55ºC. The warmer process is typically chosen for high feed rates with shorter waste retention durations because of the higher bacteria activities at higher 8 temperatures. It also results in a a slight increase in biogas production. The most experience with such units is in Germany and Denmark. Thermophilic digesters use closed processing tanks compared to open or closed lagoons used for mesophilic digestion, which requires waste retention durations of 20 to 25 days. The mesophilic digester requires a larger floor plan but is less expensive and more forgiving with regard to process variations (e.g., weather influence on temperature). Biogas plants are motivated by a number of conditions: Raw manure can be a strong odor nuisance and can lead to over-fertilization of fields, resulting in nitrate and phosphate contaminated lakes and streams. Untreated, raw manure emits large amounts of methane, which have a tremendous greenhouse gas effect (21 times the effect of CO2). An equivalent CO2 emission reduction of over 7 tons/year for each cow and over 95% or odor reduction can be realized compared to untreated manure. It should be noted that the distance of the manure collection point to the treatment plant needs to be rather close (optimally less than 5 miles) to avoid loosing the benefit of bioenergy production due to the use of transportation energy. A second benefit of a biogas plant is the production of natural fertilizer, which improves the utilization of plant nutrients and reduces the consumption of mineral (chemical) fertilizer. In many cases the natural fertilizer reduces water pollution compared to mineral fertilizer. References: [3], [40], [41], [42], [43], [44] 1.5.2 Plasma Gasification An induction coupled plasma (ICP) reforming process is selected as the plasma gasification system for organic wastes in the community. Organic waste streams from agriculture (with the exception of manure treated in the biogas plant), forestry, industry, households, and businesses are converted into clean-burning synthesis gas, a mixture of hydrogen and carbon monoxide. The clean synthesis gas is used as fuel gas in the combined-cycle gas turbine (CCGT), and replaces and/or supplements natural gas as the fuel source. Synthesis gas use in high-efficiency, high-temperature fuel cells is still under development, but may offer more efficient electric power generation in the near future. Hence, in the model the technology chosen for power generation from syngas is the CCGT system. “Plasma” is the so-called fourth state of matter (the others are: solid, liquid, and gas). Plasma is a super-heated gas, similar to the surface of the sun. In case of steam plasmas, the super-heated gases are composed of atomic hydrogen (H+), atomic oxygen (O-), and hydroxyls (OH-). These are very reactive chemical species that are beneficial in the reforming reaction (or conversion) of organic feed materials (e.g., biomass, etc.) into hydrogen and carbon monoxide. Interestingly, if the plasma does not react with any material, it goes back to the state of the gas. In case of the steam plasma, it becomes again steam and with further cooling it becomes again water. The ICP torch system uses electric power and operates continuously at sustained plasma temperatures from 3,000 to over 10,000ºC, depending on the plasma gas selected. Steam reforming or combinations of steam and dry (CO2) reforming are best 9 suited for highly organic feeds. Compared to the typical combustion chamber of incineration plants, the plasma reforming reaction chamber is less than half the size. Combustion system use air to burn the organic materials. Because 79% of air is nitrogen, combustion produces secondary reactants of nitrogen oxides (NOx). The ICP Reforming Process can avoid the use of air and therefore produce very clean fuel gases that alternatively can be used for chemical feed stocks. Technically, gasification reactions can also be achieved in fuel-based partial oxidation process systems. One reason for choosing the ICP Reforming Process in the waste and energy system of the city model is the goal for minimization in use and imports of fossil fuels. In comparison, the ICP Reforming Process is expected to be a more flexible processing tool for the variety of organic waste materials that are generated in the operation of the city. Process heat is to be recovered for building heating purposes. References: [4] 1.5.3 Plasma Melter System A plasma melter or vitrification system is best suited for non-organic and very low organic wastes. The process uses electric power for joule heating and arc plasma electrodes to melt solid wastes, resulting in slag materials usable in building and road construction. The waste and energy management selected in the model considers feeding the process gas from the plasma melter system into the plasma gasification unit to fully convert carryover carbon typical for plasma melter systems to synthesis gas rather generating a secondary waste stream. Process heat is to be recovered for building heating purposes. References: [5] 1.6 Energy Management See Figure 5 “Waste & Energy Management Concept”. See sheet “CCGT System”, “Electric Power Demand”, “Fossil Fuel Usage”, and “Energy Balance”. Lifecycle analyses for electric power generation systems have been performed by the World Business Council for Sustainable Development and other organizations, considering aspects of materials consumption, waste generation, environmental compliance, and human health effects. In order to achieve more sustainable electric power generation systems, the efforts are frequently ranked from most sustainable to least sustainable solutions and practices consider energy savings, energy efficiency, use of renewable energy, waste to energy, gas fueled CHP, gas fueled CCGT, conventional gas power plant, cleaner coal plant, and older coal plant. Some studies review nuclear power plants as the least sustainable solution, whereas other studies (e.g., by British Energy [50]) point out the benefits of nuclear power systems (e.g., low emissions CO 2 abatement potential). The energy management system introduced in the model for the sustainable community 10 focuses on: avoiding and optimizing the use of energy, utilizing renewable energy systems (solar, wind, water, geothermic heat, etc.) based on the naturally given local conditions, converting organic and fuel wastes generated within the community into energy (in form of fuel gas including biogas and synthesis gas from gasification), and using fuel gas in combined heat and (electric) power (CHP) systems. Further, emphasis is given on minimizing the use (and therefore the dependency) of fossil fuels including coal, oil, and natural gas. Implementing these guidelines leads to the selection of electric power as the main form of energy within the community (with a reasonable amount of power back-up systems). It should be noted that heating of buildings and facility is primarily achieved (e.g., with hot water) by efficient use of solar energy and heat distribution from industrial operations. A community that generates sufficient electric power at all times will avoid the import of electric power from other communities and therefore the consumption of energy generated with possibly lesser sustainable power generation systems (e.g., nuclear power). Power generation systems selected in this model are based on best available systems today. However, new technologies like high-temperature fuel cell systems, expected to be available in a few years may support the production of electricity as a clean and convenient primary source of energy for distribution within the sustainable community with higher power efficiencies than currently available. Such maturing technologies are planned to be implemented in future upgrades in this model as those systems are gradually further improved. In this model, the syngas from the gasification system and methane from the digester (biogas) plant (see Waste Management) provide the fuel basis for a combined-cycle gas turbine (CCGT) system. The CCGT system is the primary electric power generation system for the community. Electric power generators are driven by a combination of gas turbine (fuel combustion) and steam turbine (recovery of sensible energy). Natural gas is used as start-up and backup gas, and can be used as supplemental fuel should peak demands not be achievable with the fuel mix produced by the community. In principle, the CCGT system could be replaced with a high-temperature fuel-cell (FC) system (e.g., molten carbonate fuel cell systems) at a point that these systems become available at the power levels demanded by the community. FC systems have the potential for even higher electric power generation efficiencies compared to CCGT systems, reducing the need for fuel production (or use of NG). Both CCGT and FC systems are considered high-efficiency combined heat and power (CHP) systems with the potential of using the residual sensible heat for building and facility heating purposes. [Note: At the current set of input assumptions, replacing CCGT with FC systems would result in increased electric power availability and potentially export capacities.] The sustainable community is designed to maximize the use for solar energy in form of photovoltaic (PV) electric power generation and solar heating. All buildings (domiciles and industry) provide surfaces (roofs, south side walls) for solar energy collection. PV electric power is naturally used for peak electric power demand during daytime. Energy storage in batteries and underground heat storage systems are assumed but not built into the model at this time. The design of the sustainability model allows choosing the 11 fraction of building surfaces that are either used for PV or solar heat to optimize the usage for solar energy. [Note: A solar system production plant was included as one of the key industries of the sustainable community.] Additional renewable energy systems, especially wind power, but also geothermal, hydro, and other forms of renewable energy will be gradually integrated with future upgrades to the model. In most industrial operations heat is generated as waste heat. A sustainable industrial complex takes into account that such heat can be used e.g., in form of steam, for heating of surrounding buildings and structures. As more detailed information is made available, the model is gradually upgraded to identify the generation of heat in industrial processes and to optimize the usage of steam of different qualities (temperature, pressure). The largest amounts of process heat for secondary use are generated in the organic waste gasification and CCGT system. Another use for pressurized steam is for cooling of buildings by integration of absorption refrigeration systems. More data is currently investigated to integrate this system for energy conversion. References: [6], [7], [8], [9], [10] 1.6.1 Combined-Cycle Gas Turbine (CCGT) and Combined Heat and Power Combined cycle electric power generation systems represent the most advanced power generation systems available to-date. A combined-cycle gas turbine (CCGT) power plant is essentially an electrical power plant in which a gas turbine and a steam turbine are used in combination to achieve greater efficiency than would be possible with one system only. The gas turbine power by the fuel gas (syngas) drives the electrical generator. The hot gas turbine exhaust is then used to produce steam in a heat exchanger, which supplies a steam turbine which, by expansion of the compressed steam generates additional electric power. Using the residual heat from the combustion gases for heating purposes, the CCGT system becomes a fully integrated combined heat and power (CHP) plant. Condensed steam is recycled for the steam cycle; residual waste water is fed to the treatment plant [6]. The variety of technical configurations of CCGTs is primarily driven by the form and type of fuel selected (e.g., coal, natural gas, synthetic gas/biogas), the output power required, and the selection of product mix (electric power, steam (high and low pressure). Net thermal efficiencies of 60% for electric power generation can be achieved for natural gas. CCGT systems from General Electric and few other companies can be applied to fuel gas from gasification systems and digester plants. Net thermal efficiencies selected in the model are at 53%. In addition to electric power production, the computer model accounts for the direct use of heat in form of steam for heating of buildings and process heat required in other manufacturing plants. With proper installations, steam can be easily transported over reasonable distances even at lower temperatures. 12 More data is still required to fully integrate steam as a heating medium in the community model. References: [6], [9] 1.6.2 High-Temperature Fuel Cell (HTFC) System Fuel cells are an emerging technology in the energy sector that offer very low to zero emissions of harmful pollutants at the location of electric power production. A fuel cell is an electrochemical device that converts hydrogen or hydrogen/carbon monoxide fuels directly into energy without combustion. The only products of the fuel cell electrochemical reaction are electricity, heat and water, if complete conversion of the fuel gas can be achieved. Various fuel cells are under development for mobile or stationary applications at a wide range of power output levels. Proton exchange membrane (PEM) fuel cells require high purity hydrogen as fuel and operate at net power efficiencies of less than 40%. The most promising high temperature fuel cell systems (HTFCs) include solid oxide fuel cells (SOFCs) and molten carbonate fuel cells (MCFCs) with expected net power efficiencies up of 65 to 75%. SOFCs and MCFCs can convert hydrocarbon fuels, such as natural gas, carbon monoxide, and hydrogen, directly into electrical power without the use of an external fuel-processing step (required in most cases with PEM fuel cells). HTFCs are expected to come on-line within the next 10 years offering an alternative to today’s CCGT systems. As these systems are coming closer to commercialization, this technology will be included in the computer model. References: [7], [8], [9] 1.6.3 Solar Energy Systems Solar power is, next to wind power, the most important renewable energy source. The year-round production of 1 MW (electrical) from renewable sources avoids yearly air emissions of 600 to 2,300 tons of CO2, 16 tons of NOx, 9 tons of SO2, and 600 kg of other particulate from the combustion of fossil fuels [45]. Solar systems may still be expensive today, but they are sustainable energy production systems, if care is given to the method of production to minimize energy consumption as well as emissions during the production process. As development efforts to reduce energy consumptions and methods in production of solar systems mature, the model will be revised to reflect such improvements. Solar systems can be used for the production of electric power or various forms of heat (e.g., hot water, steam, etc.). Solar systems for electric power production (photovoltaic) are generally based on crystalline and amorphous (thin-film) silicon cells, but also nonsilicon solar cells with semiconductor materials are used. As of 2000, the highest power efficiencies are produced with crystalline Si-cells: 16.5% with mono-crystalline and 14.5% with multi-crystalline Si-cells industrially. The highest efficiencies achieved in 13 laboratory tests are at 24.7% [35]. The computer model accounts for electric power generation from crystalline Si-cells and solar heat for hot water production, utilizing rooftops and façades of all low-energy buildings and a selectable additional area designated for solar power production in the sustainable community. This for example allows the user to calculate the required area to eliminate the imports on natural gas as supplemental fuel in the CCGT system. It is recognized that for electric solar systems to provide the power required for the daytime peak demand in the city, a certain amount of energy storage (e.g., in battery systems) is required. Each world region has distinct solar power potentials. A solar coefficient of 5.0 kWh/m 2day is assumed in the model; adjustment to specific locations can be made easily. References: [9], [35], [45] 1.7 Transportation Systems See sheet “Transportation”. Transportation systems such as light and heavy duty motor vehicles, rail systems, aircraft, freight ships, and recreational boats provide a wide range of benefits, but it is recognized that they also generate unintended adverse impacts on environmental quality and human health. These impacts include direct or indirect effects on human and animals, clean air and water, environmentally sensitive habitats and species. Impact factors include gaseous emissions such as air pollutants, toxic emissions, and greenhouse gases, noise pollution, solid wastes, and various liquid emissions (e.g., oil, de-icing materials, etc.). Key air pollutants include carbon monoxide (CO), ground level ozone (O3) and its precursors such as volatile organic compounds (VOCs) and oxides of nitrogen (NOx), lead (Pb), particulate matter (PM10 and PM2.5), and sulfur dioxide (SO2). Today’s transportation systems primarily consume petroleum products: about 2/3 of the petroleum used in the US in 1997 was consumed by transportation systems. In the same year, transportation systems caused about 61% of all US CO emissions, 31% of VOCs, 36% of NOx, and contributed to a smaller percentage to emissions of lead and particulate matter. Cities usually have higher pollution concentrations compared to rural areas. In cities, as much as 95% of all CO emissions may come from on-road vehicles. In 1997, more than 100 million people in the US lived in counties with O3 concentrations above the National Ambient Air Quality Standards (NAAQS) established by the US Environmental Protection Agency (EPA). Hazardous air pollutants (HAPs), commonly referred to as toxic air pollutants, are regulated in the US under the EPA Clean Air Act, listing 188 pollutants or chemical groups as HAPs that are known or suspected to cause cancer or other serious human health effects or to cause damage to (e.g., aquatic) ecosystems. In 1993, mobile sources released about 21% of HAPs of a total 8.1 million tons of air toxics released US nationwide. In urban areas, the concentration of HAPs is generally higher with up to 40 percent of emissions from mobile sources. 14 It is undisputed that conventional transportation systems based on fossil fuels not only produce tremendous amounts of pollutants, they can cause short- and long-tem adverse health effects for people and greatly impact environment and habitats. Hence, the sustainable city in this model is designed to keep car and truck traffic outside the city to provide a healthier and more amenable way of living. A modern transportation system can be designed to include a series of electrical transportation systems such as commuter buses (of various sizes), rail, transport belts, elevators, etc. provided for personnel and material transportation. Transportation pathways may be largely under ground, avoiding excessive pavement, keeping a maximum of recreational spaces above ground, and offering pathways primarily for more recreational, non-motorized transportation methods (walking, bicycling, etc.) but also for emergency vehicles. The concept includes a plan for terminals at the city limits (ports) for import and export of goods. Automobiles may be parked at or near these terminals for owners for travel outside the city limits. The vision includes an integrated transportation system that would allow the individual to travel conveniently and expeditiously from one location (e.g., terminal) to another (e.g. entrance of business and domiciles). As most of the transportation systems rely on stored or on-line electric power (with appropriate back-up systems), a power generation system (see 1.6 Energy Management) has to be sustainable in itself to avoid or minimize gaseous, liquid, and solid emissions. In summary, eliminating traffic from the inner city keeps more natural spaces untouched from the construction of roads and increases the recreational value inside the community. A smart design for the city layout minimizes the travel distances and the time and energy spent for transportation. All transportation systems operate on electric power (and possibly on hydrogen in future layouts), creating a clean atmosphere free of fossil fuel combustion products and noise. Experience with electric vehicles is been reported by a number of organizations to-date. Energy storage in lighter batteries at higher energy densities is the main challenge in the development. However, to-date the following aspects are already achieved: 35% fuel economy improvement over conventional delivery trucks, up to 250 miles per gallon with light-weight city cruisers (3 wheels, 30 miles, 1 person) and 3.5 to 5.5 kWh / 100 km (~ 60 miles) Energy density of lead battery: ~0.030 kWh/kg (~400 times lower than gasoline) Energy density of modern batteries: Ni ~0.060 kWh/kg, Lithium-Ion ~0.120 kWh/kg (~100 lower than gasoline at typically 12 kWh/kg) Usage typically ~ 20 kWh/100 km in city traffic (compared to ~175 kWh/100 km for sport utility vehicles (SUVs) Typical car battery (1995) 14 kWh loading => 70 to 90 km / load Loading: ~ 2.5 kW at a regular outlet => ~4 hrs for a reach of 50 km. References: [11], [12], [51] 1.8 Imports / Exports See sheet “Materials Import & Export”. The sustainable community exchanges goods and services with other communities for import and export of materials and manufactured products. Energy system selection was 15 based on the minimization of imports of fossil fuels and use of renewable energies, combined with the minimization of power demand. The overview sheet in the model provides a summary of the main imports and exports. The model supports variations of production and consumption rates which generally will result in the balance of imported and exported goods and materials. The subsystems impacts of such changes (e.g., waste water generation, syngas production, etc.) and the influence on materials and energy flows can be readily explored. Goods and services imported to the community may include: Fuel, including natural gas, oil, and coal. Fuel waste and non-fuel waste streams from surrounding communities, including bio-waste, sewage waste, plus farming and forestry wastes. Raw and processed materials and manufactured goods and services, including and associated with chemicals, processing materials, metals, living and luxury goods, etc. The list of goods exported by the community may include: Farming goods, including fresh and processed (e.g. canned, frozen, etc.) red meat (beef, pork), poultry (chicken, turkey), fish, milk and other dairy products, eggs and egg products, fruits, vegetables, corn, livestock, etc. Forestry and processed wood products, including hardwood and softwood, lumber and wood products for construction and other uses, paper and paper board. Solar energy (PV and hot water) generation systems, including photocells, hot water panels, etc. Primary and processed materials, including aluminum, steel, glass, cement, etc. Electric power. Additional exports may include special recyclable materials (e.g., batteries, etc.). Export services may include: Engineering and services (incl. installation) of renewable energy systems (e.g. solar power) Waste and energy management and systems expertise, e.g. for organic wastes such as sewage sludge, farming wastes, bio-waste. Engineering services (e.g. process engineering & construction) of waste/sustainable energy management systems. Training/education associated with sustainable living, farming and forestry. Tourism, expositions, trade shows, conferences, education, etc. 16 2.0 Description of Subsystems 2.1 Domiciles & Small Businesses See sheets “Domiciles Input & Outputs”, “Domiciles & Small Businesses”, “Consumption by Domiciles 1”, “Consumption by Domiciles 2”, “Energy Consumption”, and “Consumption Overview”. One base assumption for the sustainable community is that the community has the capability of producing at a minimum the basic goods and services needed. This includes food, clean water, living quarters, health care, education, transportation, energy (electric power), waste management, etc. Inputs and outputs for domiciles and small businesses are configured in the sheets “Domiciles Inputs & Outputs”, “Domiciles & Small Businesses”, and “Consumption by Domiciles“. Referenced data or assumptions were made to include specific energy requirements (electric power, water heating), clean water consumption (purpose, hot/cold) and waste generation (fuel waste, non-fuel waste, sewage). Based on the consumption by individuals in households, the personnel-related consumptions were estimated for communal organizations and other industries (see sheet “Domiciles Inputs & Outputs”). Basic assumptions and adjustments for the inputs pre-setting the demand by domiciles for foods, clean water, and energy/fuels are provided in sheet “Consumption by Domiciles”. Per capita consumption of basic goods in the U.S. is (far) higher than in other hightechnology countries (e.g. in Europe) (see sheet “Energy Consumption”). Based on referenced U.S. consumption, the model allows to pre-set individual demands by selecting a percentage value (of the U.S. value) for each category. This establishes the basis for demands in production within the farming, forestry, energy production, heating/cooling, etc. Note: The percentages selected for the first analysis are based on typical European consumption levels. For example, higher prices for primary energy services in Europe have led to more energy-conscious behavior and reduced per capita usage of primary energies. References: [13], [14], [15], [23] 2.2 Solar Installations See sheet “Domiciles Inputs & Outputs”. The above sheet provides the inputs to configure population demographics and buildings for residential, municipal, and commercial occupation. The selection for the building design allows determining building surfaces usable for solar installations. The 17 population demographics and building occupation include assumptions/selections for: Number of individuals in community (e.g., 100,000 persons) People per family, Families per multi-family home, Number of single- or multi-family homes, and apartments, Number of communal, governmental, and industrial buildings. Number of small businesses within apartment complex building, Occupied floors by apartment buildings, small businesses, community (schools, hotels, etc.) and governmental organizations, and industry. In addition, the inputs for technical assumptions for the buildings are provided in the same sheet. Technical assumptions include solar systems (solar energy potential, system efficiencies, etc.), building configuration, and building surface usage and areas for photovoltaic versus hot water production. Solar radiation parameters can be chosen to apply the model for a specific location. Background information and sources of data are available at references [52] thru [55]. Data used for the energy requirement in houses are based on proven designs and performances in “Low-Energy-Houses” and specifically on the German design “Passivhaus” [58]. It is assumed that building materials are to be selected based on principles of sustainability and health effects. This leads to the use of ecological materials in construction, avoidance of chemicals in wood treatment, paint, etc. Natural construction materials such as clay, adobe, recycled paper, untreated wood, and other biomaterials could be considered and may be included in the materials balance at a later time. Upgrades to the model will be performed on a regular basis to account for any significant improvements in the use of solar systems. References: [16], [17], [18], [19], [20], [52], [53], [54], [55], [58] 2.3 Farming See sheets “Animal Farms 1”, “Animal Farms 2”, “Grain Production”, “Fruit & Vegetable Farms”, and “Energy Usage”. Production rates of meat, fish, milk, vegetable, fruit, and grain are based on the demands by the population. Energy and water consumption and waste generation depend directly on production rates. Additional production for export of farming goods can be achieved by indicated inputs. The model is set up to consider the reproduction lifecycles of animals with various types of waste generated (manure, corpses, etc.). Distinctions are made for the use of meat (OTM rule forbids to use meat of animals dying a natural death to be consumed by people). Whereas the model does not select one farming method over another, ecological or biofarming is to be applied with a minimum use of pharmaceutical products or chemical fertilizer. 18 References: [21], [22], [24], [25] 2.4 Forestry See sheets “Tree Farms” and “Consumption by Domiciles“. Trees are grown for wood and wood chips used in the production of construction materials, pulp and paper, and wood furniture (and for export, if selected). No data was found to indicated a “typical” demand by the community, because the demand is highly dependent on the wood usage and the level of recycle of wood products (e.g., for pulp production). The model includes an assumed consumption rate for the community. Sustainable forest practices are assumed. References: [26], [27] 2.5 Industry Input/output sheets for the various industries are structured in a similar fashion to allow easy overviews. Input materials (type, quantity, etc.), specific energy requirement (type, amount), water and steam consumption, waste generation (fuel, non-fuel, etc.), and additional outputs (e.g., process steam, secondary products) are specified for each industrial process. Production rates are either determined by the demands of city residents, by a typical size plant, or by assumption. Export of goods can be established by increasing production levels higher than the consumption requirements of the community. 2.5.1 Food Processing See sheet “Food Processing”, and “Energy Usage”. Food processing plants consist of meat processing, dairy product plants, grain processing, and fruit and vegetable plants. Meat plants process beef, pork, chicken, turkey and fish. Dairy products plants process raw milk to cheese (natural or processed), fresh milk (beverage), processed milk (condensed or evaporated), and frozen products (yogurt, etc.). Grain processing plants produce wheat flour, corn, rice, and other products. Fruit and vegetable plants produce fresh products and processed (cut, pealed, sugared, etc.) fruit and vegetable products. The production rates are based on the demands of the sustainable community. Export of goods can be achieved by increasing the total production levels higher than the consumption requirements of the community. References: [28], [29], [30], [31] 2.5.2 Wood Processing See sheets “Wood Mill”, “Pulp & Paper Production”, and “Furniture Production”. The use of wood is divided into three categories: a) lumber and wood products (e.g., for 19 housing construction), b) pulp, paper, and cardboard, and c) furniture and fixtures. Lumber can be treated, but is very much ready as end product leaving the mill. Wood planned for furniture production is passed on to the furniture manufacturing plant. Another fraction of the raw wood is passed onto the chipping and pulping process. Pulp can be sold as a product or further processed to cardboard and paper. Wood is ideal material for recycling and depending on the processing step, up to 75% of the primary energy can be saved (if cardboard and paper are the end products). Wood “waste” can be produced in form of: Sawdust, bark, and wood chips (wood mill), Wood chips and left-over wood (furniture plant), Lumber, sheets, etc. (construction sites), and Wooden products (domiciles and businesses). Most of these streams can go directly to the chipping process, preceding the pulping process. Recycled paper and cardboard are added here to produce pulp, the base product for cardboard material. Paper production requires further thermal/chemical processing as a function of paper quality required. Note 1: For simplicity the model does not make a distinction between paper and cardboard. The paper production process from pulp is via the Kraft process. (Model upgrade possible). Note 2: Recycling rate, wood production rate, and wood product export quantities are linked. More than one adjustment may be needed if changes are made. References: [32], [33] 2.5.3 Steel Production & Canning See sheets “Steel Production” and “Canning Plant”. The model includes the full spectrum of steel production including: Coke production (from coal) and sinter production (from iron ore), Pig iron production in a blast furnace (BF, from sinter) and molten steel production in a basic oxygen furnace (BOF, from pig iron), Molten steel production in electric arc furnace (EAF, from scrap metal), Thin slab casting followed by cold rolling, and Continuous casting followed by hot rolling. The main materials for producing raw iron (pig iron) in a blast furnace are sinter and coke. Sinter is made from iron ore and coke; coke itself is made from coal. Crude steel is produced from pig iron (w/ or w/o scrap iron) in a basic oxygen furnace (BOF) or alternatively in an electric arc furnace (EAF) from (up to 100%) scrap metal. The model assumed a mix of primary crude steel production in a BOF and in the EAF, since the planned rates of metal recycling shall be maximized in the model community. 20 The EAF saves up to 40% of primary energy compared to molten steel production from raw iron. Crude steel is then processed primarily to cold and hot rolling products: Cold rolling products include coils, strips, and sheet metal, while hot rolling products generally include wire, bars, rods, rails, profiles, and beams. Typical small-size steel production plants have a yearly capacity between 50,000 and 100,000 ton per year. Due to the various applications of steel and the dependency of industries in general, a data point for how much a community (of 100,000 persons) would actually “consume” on steel products was not found. It can be assumed that much of the steel would be exported. The canning plant allows the community to produce containers needed in food processing. Steel cans are easy to produce and to recycle. No specific data was found to specify energy requirement, inputs are assumptions and subject to revision. However, the canning plant is not expected to make a significant difference in the overall energy balance. References: [34], [38] 2.5.4 Glass Production & Bottling See sheets “Glass Production” and “Bottling Plant”. The production rate for glass (primary use containers) consists of the amount of glass produced from raw materials, from recycled glass (crushed and re-melted), and from bottle recycling (intact, chemical cleaning only – see also Section 1.4 Recycling). Glass, aluminum, and steel (and not plastic) are assumed to be the key materials used for containers. The primary energy reduction potential for multi-usage of bottles can exceed 95% depending on the lifetime of the container (compared with glass production from raw materials). Glass production from raw materials is a process using high amounts of (primarily electric) energy. Since the primary energy reduction in glass recycling (crushing and remelting) can exceed 20%, it is expected that 100% of the glass will be recycled in the sustainable community. For simplicity, the model is set up such that all glass is used as containers (so-called hollow glass (which are primarily bottles)). The bottling plant can fill-up beverages consumed in the community. However, there was no data available for the specific energy requirement for bottling. Hence, inputs are preliminary and are subject to revision. Note: Sheet glass (e.g., for windows) production is assumed to have a lower specific energy requirement. Such variations could be included at a later date. References: [34] 2.5.5 Aluminum Production See sheet “Aluminum Production”. 21 Aluminum is produced from the ore bauxite in three main processing steps: 1. Bauxite extraction and alumina refining (Bayer Process), 2. Alumina smelting (mostly in: HallHeroult Process), and 3. Final Aluminum Processing. Bauxite extraction typically is performed in open-pits and is either processed into alumina near the mining location or shipped to smelting markets around the world for processing. Bauxite mining causes large area land use (e.g., in natural forests) and erosion with the associated impacts on vegetation and wild life. Since the 1990s, some aluminum companies (e.g., Alkem) started to apply sustainability development principles to a number of bauxite extraction fields with the goal to return land after use back to the original conditions (reforestation, re-introduction of flora and fauna). In the Bayer process, bauxite crushed, digested (washed with a hot sodium hydroxide solution (NaOH) at 250 ºC), precipitated (cooled), and calcined (reheated to 1050 ºC) resulting in alumina (Al2O3). Bauxite extraction and the Bayer process require large amounts of energy, process water (steam), process materials (caustic soda and lime), land usage, and even the relocation of tribes and communities. Emissions include waste water, heat, (metal) particulate emissions and dust, mine tails (bauxite contains 10-40% impurities), and spent sodium. In addition, the transportation of bauxite or alumina requires large amounts of fossil fuels. Alumina is reduced to aluminum (Al) mostly in the Hall-Heroult process. It takes over 13 MWh electric power to produce 1 metric ton of raw aluminum. (The world average is at 16 MWh per ton due to use of a range of production processes and operations of older, frequently inefficient plants). The smelting process requires large volumes of carbon (0.4 to 0.5 ton carbon / ton aluminum) and cryolite (Na3AlF6). Aluminum fluoride (AlF3) is used to reduce the melting point of the cryolite. Alumina smelting results in large aluminum ingots (slabs, rolls, bars, blocks, etc), that are then transported to the manufacturing plants for final processing. Frequently, hot aluminum is transported over shorter distances to some aluminum product manufacturers. Primary emissions from the smelting process include carbon dioxide, heat, waste water, potliner, spent carbon, and perflourocarbon emissions (e.g., CF4 and C2F6). Finally, the manufacturing plants of aluminum products reheat and form purchased aluminum ingots to a wide variety of products, including automobiles, windows, doors, frames, construction materials, and beverage containers. The manufacturing of aluminum products requires different amounts of energy and produce different types and amounts of wastes and emissions (aluminum scrap and dust, etc.). The model does not account for energy or materials inputs/outputs associated with bauxite extraction, alumina production, and transportation of alumina ingots to the smelting plants. It is assumed that aluminum plants in the model receive alumina in the desired shape and size for the production of aluminum or used secondary aluminum (scrap, recycle) in the production of aluminum ingots. At this point, the model includes the aluminum product manufacture and formation primarily of beverage containers (cans) and frames in solar modules. For energy and materials flows associated with the manufacture of the final aluminum products, see “Canning Plant” and “Solar Systems”. Emphasis is put on the recycle of aluminum products due to the tremendous ecological (and economical) benefits. At a value of over $1,000 / metric ton, aluminum is the most valuable commodity waste material. Re-melting aluminum takes only 5 to 10% of the 22 smelting energy in comparison to primary smelting of alumina into aluminum due to the relatively low melting temperatures of 700-800 ºC. Hence, 90-95% of the primary energy required to produce aluminum ingot can be avoided by introducing a functional aluminum collection and recycle system. In addition, every ton of recycled aluminum avoids the extraction of several tons of bauxite, tremendous amounts of energy, environmental impacts, and emissions. Aluminum is recycled from cars, doors, structural frameworks, windows, and beverage cans. Each category has different recycling rates and quantities and the rates vary quite strongly in different countries and states. For example, in the US aluminum recycling from cars in 2002 was at about 85 to 90%. In 1998 the recycle rate for aluminum cans in the US was at 63% (compared to values over 90% in Western European states, e.g., Norway). At a recycle rate of 60%, the material of 100 newly produced cans are remanufactured to a total of 150 recycled cans. Every new can is therefore 2.5 times used before it finally ends up on the landfill. In comparison, a recycle rate of 90% calculates to 11 times use prior to final disposal. The model accounts for aluminum recycling of cans and other containers (domiciles and businesses) as well as for waste aluminum from manufacturing and construction businesses. The production rate for aluminum may have to be increased to account for higher materials consumption in manufacturing (e.g., of solar systems). References: [34], [36], [37] 2.5.6 Cement Plant See sheet “Cement Plant”. Various methods for cement production and cement products are possible. The production process chosen for cement products is a high-temperature, dry process using a pre-calciner, including preheating. This configuration has lower operating costs and energy consumptions than more simple process designs. Clinker, the rough precursor to cement, is made from minerals containing calcium, silicon, aluminum, and iron. Limestone, marl and chalk are the major sources of calcium. Clay, shale, bauxite, and iron ore provide silicon, aluminum and iron components. Cement is produced by mixing finely ground clinker with a small amount of calcium sulphate (gypsum). Depending on the type of cement produced, additional components such as fly ash, furnace slag, or filter dust, are added. For example, standard Portland cement is a 95% clinker with 5% gypsum mixture. So-called blast furnace cement can contain up to 95% slag with 5% clinker. Within the range of cement products, concrete is a mix of 11% Portland cement, 16% water, 6% air, 26% sand (fine aggregate), and 41 gravel or crushed stone (coarse aggregate). Specific energy requirements and materials inputs are used for Portland cement production. The model could be upgraded to reflect a higher product range, if desired. It should be noted that concrete as building material for buildings and structures as well 23 for roads have several benefits in a life-cycle analysis due to long-term use and properties on heat capacity, strength, durability, etc. For example, concrete streetscapes need 40% less lighting, concrete buildings can minimizes or even eliminate the need for air conditioning due to temperature regulating effects, and concrete roads lead up to 10% lower fuel consumption (and far longer use) compared to the fossilbased tar pavement mixtures. References: [34], [52] 2.5.7 Lime Plant & Construction See sheet “Lime Plant” and “Construction”. Lime is a product derived from high temperature calcination of limestone (CaCO 3). Natural resources are required for lime production, since the transportation of limestone is expensive. To be classified as limestone, the rock must contain at least 50% calcium carbonate. When the rock contains 30 to 45 % magnesium carbonate, it is referred to as dolomite or dolomitic limestone. Lime can also be produced from aragonite, chalk, coral, marble, and seashells. Equal to the range of raw input materials is the range of lime products: calcium lime, dolomitic lime, and hydraulic lime. Hydraulic limes are partially hydrated and contain cementations compounds, and are used exclusively in building and construction. The main uses of (all the various types of) lime include: metallurgical, environmental, construction, and agricultural purposes. Specific energy requirements and materials inputs are used for quicklime (or burnt lime, CaO) production. The model could be upgraded to reflect a higher product range, if desired. The model allows for construction of buildings and structures (e.g., bridges). The data inputs are subject to change because multiple applications are not defined; the model is based on steel-reinforced concrete structures. References: [34] 2.5.8 Manufacturing & Assembly See sheet “Manufacturing & Assembly”. The manufacturing and assembly of goods can involve a wide range of products (which are therefore not specified). However, allowances for energy and other material consumption, and for waste generation from manufacturing are included in the model. References: [34] 2.5.9 Textile Industry See sheet “Textile Production”. 24 This section is under construction. 2.5.10 Solar System Manufacturing See sheet “Solar System Production”. Solar energy for heating or production of electricity provides an important input in the sustainable city concept. Electricity produced in photovoltaic (PV) systems can provide the peak power required during the daytime. Hence, baseline power production systems (see Waste & Energy Management System, Figure 5) can operate more efficiently at relatively constant power production capacity. The production of hot water from solar cells reduces the need for combustion-based water heating using fossil fuel in residential and industrial buildings. Because solar energy systems are integrated as a basic element in the energy management system, a solar system plant is included in the industrial mix. Basic materials production of raw silicon and the production of PV modules (e.g., polycrystalline Si cells) and solar heating elements were included. The city may become a supplier of solar systems production and may install, operate, and maintain solar systems of other communities. Hence, the community should become a leader in the development and manufacturing of solar technologies. As of 2002, 98% of all solar cells are silicon-based. Crystalline silicon cells are dominant, but the introduction of thin-film solar cells and the development of non siliconbased solar cells are rapidly progressing. Higher systems efficiencies and improved production methods are progressively offering a wider range of applications for solar systems. At this point of development, the model includes only the production of poly-crystalline solar cells. The production of complete systems consists of three main steps: production of silicon, manufacturing to solar modules, and assembly to the final solar system. The main materials used beside silicon are glass (cover) and aluminum (frames). Silicon from sand (silica) or other silicon-rich raw materials needs to be purified, which is typically performed in a high-temperature chemical vapor deposition process, using chlorine as the binding medium. Chlorine can largely be recycled and “waste” hydrogenchloride (HCl) can be re-used in other industries. The specific energy requirement in silicon production is very high. Typically, an operation of 3 to 7 years of power generation is required to recover the energy required in the production of new crystalline solar units. The purity of silicon required for solar cells are significantly lower than silicon used in computer chips, which results from the fact that the solar industry is the largest user of “waste” computer chips. [Note: the use of alternative materials (e.g., carbon) and production methods for silicon are in the development phase.] More text will be added. References: [17], [18], [19], [20], [35], [45] 25 2.5.11 Wind Energy System Manufacturing See sheet “Wind Energy Systems”. Wind energy is considered the most sustainable form of energy production. Life cycle analyses [57] indicate that a modern wind turbine system produces about 80 times the total life-cycle energy used for manufacture, installation, operation, maintenance, and scrapping/recycle with an operation of 20 years. It takes only about 3 months of wind turbine system operations to recover all the energy used in this entire life-cycle. Wind power units have a wide range of commercial availability from several kWh to multiple MWh electric power production capacity per wind turbine system. AS of May 2004, the 3 largest individual wind turbine systems are installed in Northern Germany by Enercon [56] with a capacity of 4.5 MW. Today’s typical on-land installations use individual wind turbines of 1.0 to 2.0 MW. Wind farms have been built with capacities up to 600 MWh in the US and up to… Wind turbines avoid CO2 emissions by sustainable production of electric power. A 1 MW wind turbine typically generates over 3,300 MWh per year - enough to supply 940 households (at 3.5 MWh each). Given a typical energy mix in a western European country, a 1 MW wind turbine annually avoids 21,700 tons of CO2 equivalent. References: [56], [57] 26 3.0 References [1] [2] [3] [4] [5] [6] [7] [8] [9] [10] [11] [12] [13] [14] [15] [16] [17] [18] [19] [20] [21] [22] [23] Information on “Recycling”, Internet link: http://www.climnet.org/publicawareness/waste.html Information on “Recycling”, Internet link: http://www.newtonkansas.com/dep/san/page14.html Information on “Digester System”, TCC Proprietary Information Information on “Plasma Gasification”, TCC Proprietary Information Information on “Plasma Melter”, Internet link: http://www.inentec.com/pemprocess.html Information on “CCGT’s”, Internet link: http://www.asme.org/igti/resources/articles/intro2gta.htmlsfd Information on “Fuel Cells”, Internet link: http://www.fe.gov/techline/tl_fuelcellhybrid_start-up.shtml Information on “Fuel Cells”, Internet link: http://www.princeton.edu/~humcomp/sophlab/ther_58.htm “Assessment of Electric Power Conservation and Supply Resources in the Pacific Northwest”, Battelle/PNL 1982 Information on “Absorption Refrigeration”, Internet Link: http://geoheat.oit.edu/pdf/tp51.pdf Information on “Electric Vehicles”, Internet link: http://www.calstart.org/resources/papers/four_year_report.html Information on “Electric Vehicles”, Internet link: http://www.solectria.com http://www.solectria.com/downloads/ac55.pdf “Energy and Materials Consumption and Production in the USA”, Internet link: http://www.eia.doe.gov/oiaf/archive/aeo01/supplement/supref.html Information on “Energy Consumption”, Internet link: http://www.eia.doe.gov/emeu/mecs98/datatables/d98n11_3.pdf Information on “Energy Consumption”, Internet link: http://enduse.lbl.gov/info/lbnl-35475.pdf Information on “Solar Systems/ Wind Energy”, Internet link: http://www.ecomall.com/biz/solarcat.htm Information on “Solar Systems”, Internet link: http://www.solarbuzz.com/applications.htm Information on “Solar Systems”, Internet link: http://www.udel.edu/ceep/papers/InternationalComparison.pdf Information on “Solar Systems”, Internet link: http://www.sfv.de/sob99334.htm Information on “Solar Systems”, Internet link: http://shop.store.yahoo.com/etaengineering/kc80.html “Livestock manure production rates and nutrient content”, Internet link: http://ipmwww.ncsu.edu/agchem/chptr10/1011.PDF “Agricultural Fact Book 2000”, U.S. Department of Agriculture, Internet link: http://dir.yahoo.com/Science/Agriculture/Statistics/USDA_Agriculture_Fac t_Book/ “Umweltökonomische Gesamtrechnungen 2001” (Statistics on energy 27 [24] [25] [26] [27] [28] [29] [30] [31] [32] [33] [34] [35] and water consumptions, and emissions for Germany and Europe), Internet link: http://www.destatis.de/presse/deutsch/pk/2001/ugr_bericht_01.pdf “An Analysis to Develop a Program for Energy-integrated Farm Systems”, PNL, 1981 Information on “Farming”, Internet Link: http://www.strickhof.zh.ch/avbetrie/unsbetr/lindau.htm Information on “Forestry”, Internet link: http://www.eia.doe.gov/emeu/mecs/iab/forest_products/index.html “Technology Assessment of Solar Energy Systems: Availability and Impacts of Woody Biomass Utilization in the Pacific Northwest”, PNL, 1981 “Renewable Energy Resource Options for the Food Industry”, Battelle/PNL 1981 “Energy Conversion Equipment Applications in the Food Processing Industry”, Battelle/PNL 1981 “Survey of Energy Conversion Equipment Applications in the Food Processing Industry”, Battelle-NW, 1981 “Cogeneration Handbook for the Food Processing Industry”, PNL, 1984 Information on “Wood Processing”, Internet link: http://www.csa.com/routenet/epan/pulppasnIIa.html Information on “Wood Processing”, Internet link: http://www.unido.org/ssites/env/sectors/sectors51.html Information on “Industrial Processes”, Internet link: http://www.belspo.be/belspo/ostc/geninfo/publ/pub_ostc/CG2131/rappCG 31Ann1_uk.pdf Information on “Solar Industry and Systems”, Internet link: http://www.intercortex.com/solar/pdf/EU16Glasgow.pdf [36] [37] [38] [39] [40] “Aluminum Recycling in the US in 1998”, Internet link: http://www.aluminum.org/Content/NavigationMenu/The_Industry/Recyclin g/Recycling.htm Information on “Aluminum Recycling”, Internet link: http://www.world-aluminum.org/environment/climate/lifecycle1.html “Effluent Streams in Steel Production (4/2003)”, Internet link: http://www.aise.org/magazine/03april25_35.pdf Information on “Water Consumption” (in German), Internet link: http://www.mev.etat.lu/admenv/eaux/wasser/versorgung.html “Biogas Plants in Denmark”, Internet link: http://websrv5.sdu.dk/bio/pdf/rap2.pdf [41] Information on “Biogas Plants in the US”, Internet link: http://www.econ.duke.edu/Journals/DJE/dje2001/lewis.pdf [42] “Biogas Systems in the Northwest of the US”, Internet link: http://www.climatesolutions.org/pubs/pdfs/Biogas.pdf [43] [44] [45] [46] Information on “Biogas Technology”, Internet link: http://www.epa.gov/agstar Information on “Biogas Implementation”, Internet link: http://www.epa.gov/agstar/library/nydairy2003.pdf Information on “Photovoltaic Systems”, Internet link: http://www.nrel.gov/ncpv/value.html Information on “Solar Electric Power”, Internet link: 28 [47] [48] [49] [50] [51] [52] [53] [54] [55] [56] [57] [58] http://www.sandia.gov/pv/docs/PDF/PV_Road_Map.pdf Information on “Solar Power”, Internet link: http://www.fv-sonnenenergie.de/publikationen/th9798/th9798_068073.pdf “Photovoltaics for Buildings”, Internet link: http://www-cenerg.ensmp.fr/ease/photovoltaic.pdf Information on “Heat Treatment of Steel”, Internet link: http://www.zianet.com/ebear/metal/heattreat1.html “Environment and Sustainable Development: Challenges and Opportunities”, Internet link: http://www.britishenergy.com/environment/downloadable_items/sustainable_development/ environment_and_sustainable_development.doc “Indicators of the Environmental Impacts of Transportation”, Internet link: http://itre.ncsu.edu/cte/indicators.PDF Information on “Concrete Sustainability”, contact the Environmental Council of Concrete Organizations (ECCO) at http://www.ecco.org “Consumer Energy Information/Solar Radiation for Energy”, Internet link: http://www.eere.energy.gov/consumerinfo/refbriefs/v138.html “Link to Solar Data (North America)”, Internet link: http://maps.nrel.gov/annualdir.html Link to Solar Data (worldwide-limited), Internet link: http://wrdc-mgo.nrel.gov/ Insolation Map (America, Africa, Middle East, Indonesia), Internet link: http://www.atlanticsolar.com/technical/insol.htm “4.5 MW Wind Power System by Enercon“, Internet link: http://www.enercon.de/englisch/produkte/fs_start_produkte.html “The Energy Balance of Modern Wind Turbines“, Internet link: http://www.windpower.dk/en/publ/enbal.pdf Information on “Low-energy houses (in Switzerland)“, Internet link: http://www.energienetz.ch/SonnenArchitektur/Text/Energieinfos/Energiein fos_index.html 29 4.0 Block Diagrams Block diagrams are provided to describe the structure of the model. 4.1 4.2 4.3 4.4 4.5 Figure 1: Figure 2: Figure 3: Figure 4: Figure 5: First Level Overview Second Level Overview Detailed Overview Model Housing Unit Waste / Energy Management Concept 30