pola27339-sup-0001-suppinfo01

advertisement

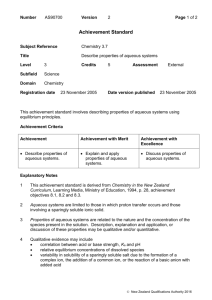

Supporting Information Poly(divinylbenzene-alt-maleic anhydride) Nanoparticles as a Novel Stabilizer for Pickering Polymerization of Styrene Jian He, Dong Chen, Kai Han, Xiaoxia Huang, Liwei Wang, Jianyuan Deng, and Wantai Yang* College of Material Science and Engineering, Beijing University of Chemical Technology, Beijing, 100029 State Key Laboratory of Chemical Resource Engineering, Beijing, 100029, China. Tel: + 86-10-64432262; Fax: +86-10-64416338 E-mail: yangwt@mail.buct.edu.cn (W. T. Yang) S1 Contents of Supporting Information FIGURE S1 OPTICAL IMAGES OF (A) THE ST LAYER ON TOP OF THE PDMNP COLLOID (B) PICKERING LATEX STABILIZED WITH PDMNPS (C) PICKERING LATEX DROP IN PURE H2O (D) PICKERING LATEX DROP IN PURE ST (PDMNPS COLLOID WAS PREPARED BY DISPERSING 0.01 G PDMNPS IN 20 ML H2O; THE PICKERING LATEX CONSISTED OF 2 ML ST AND 20 ML PDMNP COLLOIDS WITH A 15 MIN-ULTRASONIC DISPERSION TREATMENT; DIGITAL PHOTOS WERE TAKEN BY CANON IXUS 220HS CAMERA) 4 FIGURE S2 WATER CONTACT ANGLE OF (A) THE PDMNPS FILM AND (B) CLEAN GLASS AND WATER SURFACE TENSION OF (C) PURE WATER WITH NOTHING, (D) PDMNPS (0.01 G/20 ML) IN PURE WATER, AND (E) PDMNPS (0.01 G/20 ML) IN 0.1 M NAHCO3 AQUEOUS SOLUTION (THE PDMNPS POWDERS WERE PRESSED TO BE 11 CM TABLETS UNDER 10 MPA; BOTH CONTACT ANGLE AND SURFACE TENSION WERE ANALYZED BY DATAPHYSICS OCA20) 5 FIGURE S3 SEM IMAGES OF THE OBTAINED PS PARTICLES IN THE SYSTEM WITH (A) NACL (AQ.), (B) NH4CL (AQ.), (C) NAHCO3 (AQ.), AND (D) NAHSO3 (AQ.) FOR CALCULATING THE PARTICLE SIZE AND DISTRIBUTION INDEX2 (THE SAMPLES WERE PREPARED FROM ALL RESULTS IN TABLE 1 TESTED BY HITACHI S4700 SEM; THE SCALE-BAR REPRESENTS 5.00 ΜM) 5 TABLE S1 PARTICLE SIZE AND POLYDISPERSITY INDEX3 OF THE OBTAINED PS PARTICLES IN THE TABLE 1 MEASURED THROUGH DYNAMIC LIGHT SCATTERING BY BROOK HEAVEN INSTRUMENT ZETAPLUS PARTICLE SIZER 6 FIGURE S4 (A) OPTICAL IMAGES AND (B) ZETA POTENTIAL OF THE PDMNP COLLOIDS AT DIFFERENT PH VALUES. (C) OPTICAL IMAGES AND (D) ZETA POTENTIAL OF THE PDMNP COLLOIDS WITH DIFFERENT CONCENTRATIONS OF NAHCO3 (THE PREPARATION PROCEDURE OF THE PDMNP COLLOIDS WAS THE SAME AS THAT SHOWN IN FIGURE S1. THE PH VALUE WAS ADJUSTED BY NAOH AQUEOUS SOLUTION AND HCL AQUEOUS SOLUTION, RESPECTIVELY. DIGITAL PHOTOS WAS TAKEN BY CANON IXUS 220HS CAMERA AND ZETA POTENTIAL WAS CHARACTERIZED BY BROOK HEAVEN ZETA POTENTIAL ANALYZER) 6 FIGURE S5 FT-IR SPECTRA OF PDMNPS AFTER BEING DISPERSED IN DIFFERENT SALT AQUEOUS SOLUTIONS. (A) NACL (B) NH4CL (C) NAHCO3 (D) NAHSO3 (E) PURE WATER (THE PREPARATION PROCEDURE OF THE PDMNP POWDERS WAS AS FOLLOWS. EACH 0.05 G PDMNPS WAS DISPERSED INTO 0.1 M SALT AQUEOUS SOLUTION WITH STIRRING UNDER 75 °C FOR 7 H; THE RESULTED PDMNPS POWDER WAS DRIED AFTER CENTRIFUGATION) 7 FIGURE S6 OPTICAL IMAGES OF THE WATER CONTACT ANGLE OF THE PS FILM. (A) PS PARTICLES FABRICATED THROUGH PDMNP-STABILIZED PICKERING POLYMERIZATION (ENTRY 3, TABLE 1); (B) PURE PS MICROSPHERES (THE PS POWDERS WERE PRESSED TO BE 11 CM TABLETS UNDER 10 MPA; CONTACT ANGLE WAS ANALYZED BY DATAPHYSICS OCA20) 7 FIGURE S7 DIGITAL PHOTO OF THE REACTION DISPERSION (A) THE CONTROL EXPERIMENT AND (B) ENTRY 3 IN TABLE 1 AND (C) SEM IMAGE OF THE PS PRODUCT IN THE CONTROL EXPERIMENT (THE COMPOSITION OF THE CONTROL EXPERIMENT WAS THE SAME AS THAT OF ENTRY 3 IN TABLE 1 BUT WITHOUT PDMNPS; CANON IXUS 220HS CAMERA AND HITACHI S4700 WAS USED TO TAKE THE PHOTOS OF THE REACTION DISPERSION AND PS PRODUCT) 7 FIGURE S8 VARIATION HYDRATED SIZE OF PDMNPS IN (A) NH4CL AQUEOUS SOLUTION AND (B) NAHCO3 AQUEOUS SOLUTION 8 FIGURE S9 AFM IMAGES AND THICKNESS&HEIGHT ANALYSIS OF THE HYDROLYZED PDMNPS FILM: (A) HORIZONTAL DISTANCE AND (B) VERTICAL HEIGHT OF A TYPICAL HYDROLYZED PDMNP (THE FILM OF THE HYDROLYZED PDMNPS WAS PREPARED S2 THROUGH DRYING THE DILUTED HYDROLYZED PDMNPS DISPERSION ON A FLAT CLEAN GLASS SLICE; DIGITAL INSTRUMENTS, VERSION 6.12 ATOM FORCE MICROSCOPE WAS USED TO TAKE THE PHOTOS) 8 REFERENCES AND NOTES 8 S3 Pickering polymerization process with PDMNPs as the stabilizer PDMNPs were fabricated as described in a previous study.1 The typical procedure of a Pickering polymerization using PDMNPs as the only stabilizer was as follows: PDMNPs was dispersed into salt aqueous solution under mechanical agitation. After few minutes, St and APS were added sequentially into the suspension under stirring. The polymerization was conducted at 75 °C for 7 h with agitation at a 300 r/min rate. The oxygen in the equipment was continuously removed by a nitrogen purge, which had started 20 min before the suspension was added. The polymer product was collected by repeating centrifugation and washing with deionized water, followed by a drying process under vacuum at 60 °C to constant weight. The yields of the PS particles were calculated gravimetrically. Figure S1 Optical images of (a) the St layer on top of the PDMNP colloid (b) Pickering latex stabilized with PDMNPs (c) Pickering latex drop in pure H2O (d) Pickering latex drop in pure St (PDMNPs colloid was prepared by dispersing 0.01 g PDMNPs in 20 mL H2O; the Pickering latex consisted of 2 mL St and 20 mL PDMNP colloids with a 15 min-ultrasonic dispersion treatment; digital photos were taken by Canon IXUS 220HS camera) S4 Figure S2 Water contact angle of (a) the PDMNPs film and (b) clean glass and water surface tension of (c) pure water with nothing, (d) PDMNPs (0.01 g/20 mL) in pure water, and (e) PDMNPs (0.01 g/20 mL) in 0.1 M NaHCO3 aqueous solution (The PDMNPs powders were pressed to be 11 cm tablets under 10 MPa; both contact angle and surface tension were analyzed by Dataphysics OCA20) Figure S3 SEM images of the obtained PS particles in the system with (a) NaCl (aq.), (b) NH4Cl (aq.), (c) NaHCO3 (aq.), and (d) NaHSO3 (aq.) for calculating the particle size and distribution index2 (The samples were prepared from all results in Table 1 tested by Hitachi S4700 SEM; the scale-bar represents 5.00 μm) S5 Table S1 Particle size and polydispersity index3 of the obtained PS particles in the Table 1 measured through dynamic light scattering by Brook Heaven Instrument Zetaplus Particle Sizer Entry Salt D a eff. (nm) Polydispersity Index a (CV, %) 1 NaCl 389.4 15.4 2 NH4Cl 512.9 13.9 3 NaHCO3 623.6 16.3 4 NaHSO3 676.5 20.9 Figure S4 (a) Optical images and (b) zeta potential of the PDMNP colloids at different pH values. (c) Optical images and (d) zeta potential of the PDMNP colloids with different concentrations of NaHCO3 (The preparation procedure of the PDMNP colloids was the same as that shown in Figure S1. The pH value was adjusted by NaOH aqueous solution and HCl aqueous solution, respectively. Digital photos was taken by Canon IXUS 220HS camera and zeta potential was characterized by Brook Heaven Zeta Potential Analyzer) S6 Figure S5 FT-IR spectra of PDMNPs after being dispersed in different salt aqueous solutions. (a) NaCl (b) NH4Cl (c) NaHCO3 (d) NaHSO3 (e) pure water (The preparation procedure of the PDMNP powders was as follows. Each 0.05 g PDMNPs was dispersed into 0.1 M salt aqueous solution with stirring under 75 °C for 7 h; the resulted PDMNPs powder was dried after centrifugation) Figure S6 Optical images of the water contact angle of the PS film. (a) PS particles fabricated through PDMNP-stabilized Pickering polymerization (Entry 3, Table 1); (b) pure PS microspheres (The PS powders were pressed to be 11 cm tablets under 10 MPa; contact angle was analyzed by Dataphysics OCA20) Figure S7 Digital photo of the reaction dispersion (a) the control experiment and (b) Entry 3 in Table 1 and (c) SEM image of the PS product in the control experiment (The composition of the control experiment was the same as that of Entry 3 in Table 1 but without PDMNPs; Canon IXUS S7 220HS camera and Hitachi S4700 was used to take the photos of the reaction dispersion and PS product) As Shown in Figure S6, the yield in control experiment was obviously lower than that of Entry 3 and no-particle could be found in the SEM image. The experimental result provided direct evidence that the PDMNPs could serve as an effective Pickering stabilizer during the emulsion polymerization. Figure S8 Variation hydrated size of PDMNPs in (a) NH4Cl aqueous solution and (b) NaHCO3 aqueous solution Figure S9 AFM images and thickness&height analysis of the hydrolyzed PDMNPs film: (a) horizontal distance and (b) vertical height of a typical hydrolyzed PDMNP (The film of the hydrolyzed PDMNPs was prepared through drying the diluted hydrolyzed PDMNPs dispersion on a flat clean glass slice; Digital Instruments, Version 6.12 atom force microscope was used to take the photos) REFERENCES AND NOTES S8 1. J. He, D. Chen, X. M. Fan, L.W. Wang, J.Y. Deng, W. T. Yang, Chin. Chem. Lett. 2013, 24, 970-974. 2. Diameter distribution index (U) was calculated as follows: U k Dw Dn Dw ni D4i i 1 k n D i k Dn niDi 3 i i 1 i 1 k n i i 1 The statistical number of the PS particles was 250 and the particles were chosen randomly. 3. Polydispersity index (CV) was calculated as follows: k D eff . niDi i 1 1 k 2 n D D eff . i i k i 1 100 n i CV D eff . i 1 S9