Sanitation Program

advertisement

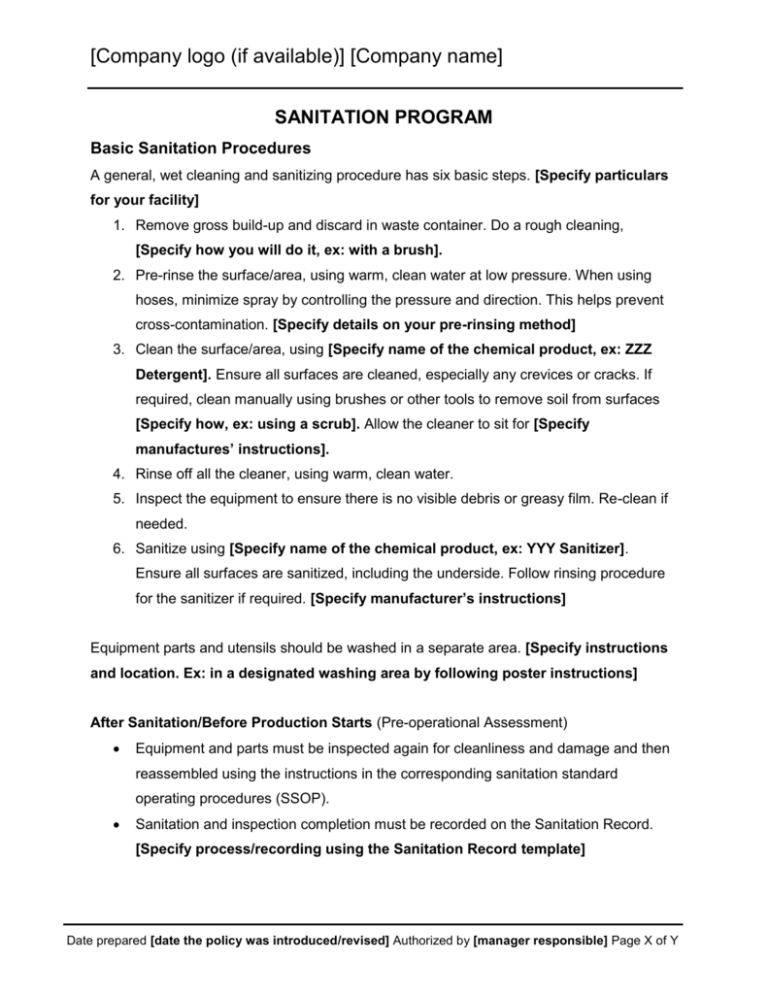

[Company logo (if available)] [Company name] SANITATION PROGRAM Basic Sanitation Procedures A general, wet cleaning and sanitizing procedure has six basic steps. [Specify particulars for your facility] 1. Remove gross build-up and discard in waste container. Do a rough cleaning, [Specify how you will do it, ex: with a brush]. 2. Pre-rinse the surface/area, using warm, clean water at low pressure. When using hoses, minimize spray by controlling the pressure and direction. This helps prevent cross-contamination. [Specify details on your pre-rinsing method] 3. Clean the surface/area, using [Specify name of the chemical product, ex: ZZZ Detergent]. Ensure all surfaces are cleaned, especially any crevices or cracks. If required, clean manually using brushes or other tools to remove soil from surfaces [Specify how, ex: using a scrub]. Allow the cleaner to sit for [Specify manufactures’ instructions]. 4. Rinse off all the cleaner, using warm, clean water. 5. Inspect the equipment to ensure there is no visible debris or greasy film. Re-clean if needed. 6. Sanitize using [Specify name of the chemical product, ex: YYY Sanitizer]. Ensure all surfaces are sanitized, including the underside. Follow rinsing procedure for the sanitizer if required. [Specify manufacturer’s instructions] Equipment parts and utensils should be washed in a separate area. [Specify instructions and location. Ex: in a designated washing area by following poster instructions] After Sanitation/Before Production Starts (Pre-operational Assessment) Equipment and parts must be inspected again for cleanliness and damage and then reassembled using the instructions in the corresponding sanitation standard operating procedures (SSOP). Sanitation and inspection completion must be recorded on the Sanitation Record. [Specify process/recording using the Sanitation Record template] Date prepared [date the policy was introduced/revised] Authorized by [manager responsible] Page X of Y [Company logo (if available)] [Company name] Housekeeping Trash and waste materials include [Specify what is trash and waste and how each material is to be handled, ex: food waste goes in sealed plastic bags, paper goes in recycle bins] Waste containers must be emptied and cleaned daily by [Specify person/title responsible]. Keep containers well maintained (no cracks or leaks) and clean. Ensure areas such as washrooms, locker rooms, lunch room, office, are kept clean. [Specify person/title responsible] The exterior of the facility must be kept clean and tidy. [Specify person/title responsible] No equipment, pallets, etc, can be stored near the building. The grounds must be kept clean to minimize pests. The trash dumpster must be emptied [Specify how often, ex: weekly] by [Specify company name]. Vehicles used to transport food products must be kept clean. Cross-contamination of ingredients, food products, packaging materials and chemicals used in sanitation or maintenance must be prevented during transportation. [Specify how, ex: separating incompatible products or not transporting incompatible materials at the same time] Storage areas of the facility must keep clean and tidy. Health and Safety Information Any equipment with sensitive electrical panels must be wrapped with plastic to prevent moisture damage. Follow equipment lock-out/tag-out procedures where necessary. [Specify your procedure] Chemical supplier(s) must provide current Material Safety Data Sheets (MSDSs) for all chemicals. Keep them readily accessible in [Specify location, ex: blue binder main office]. Date prepared [date the policy was introduced/revised] Authorized by [manager responsible] Page X of Y [Company logo (if available)] [Company name] All employees must wear appropriate personal protective equipment (PPE), ex: gloves, goggles/face masks, etc. Specific Sanitation Standard Operating Procedures A list of sanitation standard operating procedures (SSOPs) including detailed assembly and disassembly instructions for individual equipment and areas, includes: [Specify all that apply to your facility and write down the specific procedures] – production room – walls, ceilings and floors – equipment 1 – equipment 2…etc Refer to the List of Chemicals sheet for a list of authorized chemicals for use in this facility. [Complete a List of Chemicals template] Refer to the Master Sanitation Schedule to determine cleaning frequency of equipment and structures other than those cleaned daily. [Complete the Master Sanitation Schedule template] Monitoring Sanitation and pre-operational activities must be monitored [Specify frequency], by [Specify name/title, ex: supervisor, manager]. The information must be recorded on the sanitation record [Specify, using the Sanitation Record template]. Date prepared [date the policy was introduced/revised] Authorized by [manager responsible] Page X of Y