doc - PublicationsList.org

advertisement

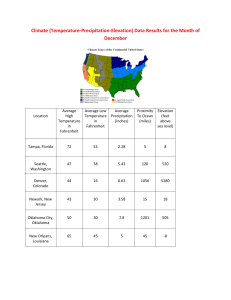

INFLUENCE OF THE ADDITION OF TIN IN THE STATE OF TRACKS ON THE KINETICS OF PRECIPITATION IN THE ALLOY Al-Ag F. LOURDJANE *, A. RAHO, Lourdjane_faiza@yahoo.fr, raho_ azzeddine@yahoo.fr University of Sciences and the Technology HOUARI BOUMEDIENE,BP 32 ALLIA BAB EZZOUAR ALGIERS. Faculty of physics, USTHB Abstract In this study, we are study the influence to addition the tin on the kinetics of formation of the G.P zones in Al-Ag alloy. The precipitation of the G.P zones is governed by diffusion of atoms of solution. Their kinetics of the precipitations is influence by the thermal excitement and the concentration to the gaps in alloy. In this study. We establish kinetics of precipitation of the G.P zones in Al-Ag and Al-Ag-Sn alloys by a method based on the microhardness. The presence of Sn results in a retarding effect on the G.P zones formation. Keywords: G.P zone, precipitation. 1. Introduction A supersaturated solid solution Al-Ag evolves towards the balance characterized by the precipitation of the equilibrium phase δ(Ag2Al) according to the sequence 3. Results and discussion DSC scans recorded at 2°C min-1 for two samples Al-39wt%Ag, Al-39wt%Ag-0.05%Sn alloys wish have been homogenized 72h at 540°C and quenched (fig.1) showed the following: * G.Pzones ' phase phase [1, 2] 0,06 Where α* is the supersaturated solid solution, G.P Guinier – Preston zones is heap of atoms of silver. These zones are coherent with the matrix network, δ’ is a metastable phase semi-coherent and δ is the Ag2Al equilibrium precipitate, incoherent with the matrix network, is soothing. The precipitation of zones G.P governed by the diffusion of atoms of solution, is favored by the presence of gaps and the rise of the temperature. In this paper, we are propose to study the effect of Sn in the state of tracks on the kinetics of formation of the G.P zones for different temperature of ageing at [90-150]°C by method based on the microhardness. 2. Experimental Our Al-39wt.%Ag, Al-39wt.%Ag-0.05%Sn alloys were prepared by fusion of Aluminum and Silver are pure 99,99 at temperature 1000°C. The samples are homogenizing at 540°C however 72 hours, and quenched in water. The samples obtained were analyzed by EDAX. Samples for calorimetric measurements were of 1.5 mm thickness. The calorimetric measurements were performed with a METLER TA 400 DSC. A protective atmosphere of pure argon was used. The Vickers microhardness were determined on the samples under a load of 100g, by using microhardness measurements [SHIMADZU]. DSC 0,04 0,02 Al39% Ag0.05Sn Al39% Ag dQ/dT 0,00 -0,02 -0,04 -0,06 -0,08 -0,10 -0,12 -0,14 T(°C) -0,16 0 50 100 150 200 250 300 350 400 Fig.1. DSC scans of Al-39wt.%Ag and Al-39wt.%Ag-0.05%Sn alloys homogenized for 72h at 540°C. A) Case of Al39wt.%Ag alloy: 1. an endothermic effect in the temperature range [170200]°C due certainly to the dissolution of GP zones. 2. an exothermic peak between [240-300]°C due to the precipitation of phases δ’and δ. B) Case of Al39wt.%Ag-0.05Sn alloy: 1. An endothermic between [150-194]°C thing that Al39%Ag alloy to the dissolution of GP zones. An exothermic peak between [230-310]°C due to the precipitation of phases δ’and δ. 2. 185 T=125°C Al39% Ag Al39% Ag0.05Sn 180 220 210 HV 200 175 T=200°C Al39% Ag Al39% Ag 0.05Sn HV 170 165 190 160 180 155 150 170 145 160 140 t(h) 150 0,01 0,1 1 10 100 140 t(h) 130 0,01 0,1 1 10 100 Fig.2.Vickers microhardness curves for Al-39wt.%Ag and Al-39wt.%Ag0.015wt.%Sn alloys at 200°C. The isotherms of hardness, in the temperature T=200°C (Fig.2) in first time, show a softening due to the dissolution of G.P zones. Fig.3.b. Vickers microhardness curves for Al-39wt.%Ag and Al39wt.%Ag-0.015wt.%Sn alloys at 125°C. 185 180 The isotherms of hardness, established for samples Al-39wt.%Ag, Al-39wt. %Ag-0.05Sn alloys, for different ageing at [90-150]°C (Fig.3.(a).(b).(c)), show hardness due to the G.P zones formed just after quenching. The landing (plateau) correspond of equilibrium metastable to the precipitation G.P zones, where the volume fraction is maximal. The precipitation of phase metasteble δ’ hardness alloy, the decline in hardness was thus probably associated with formation of equilibrium phase δ. HV T=150°C Al39% Ag Al39% Ag 0.05Sn 175 170 165 160 155 150 145 t(h) 140 0,01 0,1 1 10 200 190 180 Fig.3.c. Vickers microhardness curves for Al-39wt.%Ag and Al39wt.%Ag-0.015wt.%Sn alloys at 150°C. T=90°C Al39% Ag Al39% Ag0.05Sn HV The transformed fraction, F, representing the volume occupied by the G.P zones during the heat treatment of ageing reported to the volume which they occupy to the equilibrium metastable, based on MERLE relation: 170 160 HV (t) =F.HV (equilibrium metastable) + (1-F). HV (0) [3]. 150 140 0,01 t(h) 0,1 1 10 100 Where HV (t) is the hardness each treatment time t, HV (equilibrium metastable) is the maximum hardness obtained in which the G.P zones occupy a maximum volume and HV(0) is the hardness of T=90°C the as-quenched solid solution. Al39% Ag The 1,0 kinetics isothermal are kept of ageing at [90-150]°C give the F Fig.3.a. Vickers microhardness curves for Al-39wt.%Ag and Al39wt.%Ag-0.015wt.%Sn alloys at 90°C. Al39% Ag0.05Sn phases of the germinate, growth and coalescence. The 0,8 τ incubation time of G.P zones (Fig.4. (a).(b).(c)), establish by extrapolation, they are characteristic of germinate fast on reason oversaturation of vacancies just after quenching. 0,6 The phases of growth and coalescence are slower on reason of elimination of a party of the vacancies in excess obtained in the 0,4 quenching. HV(t) this isotherms fig(3) show, when Sn is in the solid solution a decrease of the life of the G.P zones. 0,2 t(h) 1E-3 0,01 0,1 1 10 210 1,1 1,0 F T=90°C Al39% Ag Al39% Ag0.05Sn T=150°C Al39% Ag Al39% Ag0.05Sn 1,0 0,9 F 0,8 0,8 0,7 0,6 0,6 0,5 0,4 0,4 0,3 0,2 t(h) 1E-3 0,01 0,1 1 0,2 t(h) 10 0,1 1E-3 0,01 0,1 1 10 Fig.4.a Kinetics isotherms of precipitation of the G.P zones in the Al39wt.%Ag and Al-39wt.%Ag-0.015wt.%Sn alloy s at T=90°C. Fig.4.c Kinetics isotherms of precipitation of the G.P zones in the Al39wt.%Ag and Al-39wt .%Ag-0.015wt.%Sn alloy s at T=150°C. 0,8 Time of incubation obtained allow to determine from the relation of Arrhenius; activation energy to the diffusion during the transformation, defined by [4]. t= B exp (Q/RT) Where Q is the activation energy of the transformation, R is the constant of perfect gaze; T is the temperature and B the constant T=125°C Al39% Ag Al39% Ag0.05Sn 1,0 F 0,6 -3,0 Al39% Ag Al39% Ag 0.02Sn -3,2 0,4 -3,4 -3,6 Lnti (h) 0,2 -3,8 -4,0 t(h) 0,0 1E-3 0,01 0,1 1 10 -4,2 -4,4 -4,6 -1 1/T(K ) Fig.4.b Kinetics isotherms of precipitation of the G.P zones in the Al39wt.%Ag and Al-39wt.%Ag-0.015wt.%Sn alloys at T=125°C . -4,8 0,0023 0,0024 0,0025 0,0026 0,0027 0,0028 Fig.4.d Determination of the energies of activation to the diffusion during germinates of the G.P zones. Al-39wt.%Ag Q= 8 KJ Al-39wt.%Ag-0.015wt.%Sn Q= 31 KJ This low energy to compared that of diffusion silver in the aluminum pure Q=100KJ/mol is characteristic of germinate fast on reason oversaturation of vacancies just after quenching. 0,4 0,2 0,0 -0,2 -0,4 -0,6 0,6 -0,8 0,4 T=90°C Al39% Ag Al39% Ag0.05Sn Data1D Data1B 1,0 0,5 0,0 -1,0 0,0 -1,2 -0,2 -1,4 -0,4 -1,6 ln(ln(1/1-F)) -0,5 -1,0 0,2 -0,6 -0,8 T=150°C Al39% Ag Al39 % Ag0.05Sn Data1B Data1D ln(ln(1/1-F)) 0,6 T=150°C Al39% Ag Al39 % Ag0.05Sn Data1B Data1D ln(ln(1/1-F)) The kinetics isothermal are kept of ageing at [90-150]°C, (Fig. 5.(a);(b);(c))show the effect to addition as trace of the tin on the precipitation the G.P zones. It traps some present vacancies in alloys, the atoms of tin are responsible a retarding effect of the G.P zones formation. The curves log(log(1/1-F)) are characteristic of growth is defined by JMAK equation[5,6,7]. The growth check by the diffusion F(t)=1-exp(-kt)n Where n and k are the parameters of growth. lnt(h) -4,0 -3,8 -3,6 -3,4 -3,2 -3,0 -2,8 -2,6 -2,4 -2,2 -2,0 -1,8 -1,6 -1,0 -1,2 Fig.5.cDetermination of the parameters of growths in the Al-39wt.%Ag and -1,4 Al-39wt.%Ag-0.015wt.%Sn at T=150°C. -1,5 lnt(h) -1,6 -2,0 -4,0 -3,8 -3,6 -3,4 -3,2 -3,0 -2,8 -2,6 -2,4 -2,2 -2,0 -1,8 -1,6 lnt(h) -2,5 -4,0 -3,5 -3,0 -2,5 -2,0 -1,5 -1,0 -0,5 0,0 Al-39wt.%Ag Fig.5.a Determination of the parameters of growths in the Al-39wt.%Ag and Al-39wt.%Ag-0.015wt.%Sn at T=90°C. 90°C 125°C 150°C n 0.80 0.82 1.08 k 8.47 11.47 16.42 Al-39wt.%Ag-0.05Sn n 0.84 1.0 0.94 k 4.87 9.29 11.24 Table-1-Parameters of growth 1,5 0,5 0,0 ln(ln(1/1-F)) 1,0 T=125°C Al39% Ag Al39% Ag0.05Sn Data1B Data1D The parameters n are characteristic of heterogeneous the G.P zones The parameter k, characteristic the transformation speed, defined by k=A exp(-Q/KT). 4. Conclusions -0,5 -1,0 -1,5 -2,0 lnt(h) -4,0 -3,5 -3,0 -2,5 -2,0 -1,5 -1,0 -0,5 Fig.5.bDetermination of the parameters of growths in the Al-39wt.%Ag and Al-39wt.%Ag-0.015wt.%Sn at T=125°C. The isotherms of hardness, established in various temperatures, highlighted the precipitation of G.P zones, the metastable phase δ’ and the equilibrium precipitate δ. The establishment of the isothermal kinetics allowed to determine the visible energies of activation of the diffusion during the germinating and during the growth of G.P zones. The parameters of growth were determined during the growth of G.P zones. The isothermal kinetics showed that the addition of tin results a retarding effect on the G.P zones formation. References [I] Guinier (A).-solid state p h y s i c s , 9 , A c a d e m i c P r e s s , 1 9 5 9 . P . 2 9 4 [2]G.Gra iss,M.A.Ma hmoud,C ryst.Res.Tec hnol.35(2000 )95. [3]Meta llographic, Structures a nd phase Dia gra ms. America n Soc iety for Meta ls.M .8 th Edition, (1973)P175. [4 ]A. A.El-Da ly, A. Z.Moha med, M.M.Mosta fa,M.S.Sakr, Ain S ha ms Sc i. B u ll. 2 8 ( A ), ( 1 9 9 0 ) 2 5 9 . [5]Ka yaca n, Oz ha n, Haka n. A none xte ns ive sta tistica l approac h to the kinet ics of pha se tra ns for mation. Phys ica A vol.348,2005.P.223 -235. [6]A.Porter, K. E.Eas terling, pha se tra ns for mation in me ta ls and a lloys,2 edition c hap, Ha ll, (1992). [7]P. Ze iba,phase tra ns for mation controlled by diffus ion of moving bounda ries ,Polis h A cade my of sc ie nce, committee of meta llurgy, 1991,P 655 -662. 210 .