Aastrom Biosciences, Inc

advertisement

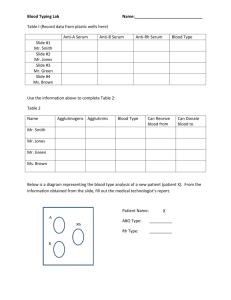

Cell culture procedures and release criteria TRC Cell Production After assessing cell concentration using the Coulter Z2 (Beckman Coulter, Fullerton, CA, http://www.beckmancoulter.com), BM MNC are inoculated into the cell cassette (includes bioreactor and medium reservoir). Prior to inoculation, bioreactors are primed with long-term bone marrow culture (LTBMC) medium consisting of IMDM, 10% fetal bovine serum, 10% horse serum, 5 _M hydrocortisone, gentamicin sulfate, and vancomycin. The bioreactor is designed such that medium flow rate can be adjusted at any time during the culture process within an operating range of 10%–500% volume medium exchange per day depending on the needs of the culture. The entire volume of the culture area is approximately 280 ml. For TRC production, LTBMC is passed through the bioreactor at a controlled ramped perfusion schedule starting at 0% volume medium exchange from day 1 to day 3, 25% exchange per day from days 3 to 8, and 75% exchange per day from day 8 until harvest on day 12. The cultures are maintained at 37°C with 5% CO2 and 20% O2 in the incubator for the duration of the culture. Cells are harvested by trypsinization (0.025% trypsin-EDTA in 0.9% sodium chloride). Cell Culture Reagents and Conditions The culture medium (Base Medium, Aastrom Biosciences, Inc., Ann Arbor, MI, USA) consists of Iscove’s Modified Dulbecco’s Media (IMDM), 10% fetal bovine serum, 10% horse serum, 5 μM hydrocortisone, gentamycin sulfate, and vancomycin. Once inoculated, the cell cassette is placed in a custom incubator constructed in a modular manner which controls all environmental conditions. After cultivation for 12 days at 37°C, 5% CO2, with a ramped continuous medium perfusion schedule, the cell product, including both nonadherent and adherent cells, is harvested by trypsinization and collected into a harvest bag. Sampling of the culture medium via a sample port is carried out 48 hours prior to harvest, to allow testing for bacterial and fungal contaminants and endotoxins. All recorded data are saved on these individual memory devices to comply with GMP-compliant documentation of relevant data. Base Medium The Base Medium is a sterile and endotoxin free growth medium used in the processing of the bone marrow aspirate. The Base Medium is used from the start of the manufacturing process through to the harvest of the cellular product from the Cell Cassette. Base Medium is a solution composed of 80% (v/v) IMDM, 10% (v/v) fetal bovine serum, 10% (v/v) horse serum, hydrocortisone and gentamicin. It is stored as a refrigerated liquid (2 to 8º C) and packaged in a flexible bag. The Base Medium is specially produced for Aastrom and it is manufactured in compliance with GMP Quality System Requirements and certified to ISO 9001:2000 or ISO 13485. Country of Origin: New Zealand or Australia only. It should be noted that virus contamination is controlled separately on the fetal bovine serum and horse serum, which are two of the main ingredients of Base Medium (Iscove’s Modified Dulbecco Medium plus 10% FBS and 10% HS). To minimize risks, Base Medium only includes fetal bovine and horse sera from approved suppliers (that hold EDQM certificates) and provided with a certificate of analysis confirming that the serum lot has been tested and complies with the established specifications. These components are properly controlled so that the viral and BSE safety in the Base Medium is completely assured. The Base Medium is available from two approved suppliers: Name of producer: Cambrex Bio Sciences Walkersville, Inc. and Invitrogen Corporation (Gibco, Life Technologies) Fetal bovine serum (FBS) Fetal bovine serum (FBS) is commonly used as an essential supplement to cell culture media. FBS is a cocktail of most of the factors required for cell attachment, growth, and proliferation in vitro and is thus used as an almost universal growth supplement effective with most types of human and animal cells. The fetal bovine serum is procured from suppliers that have been inspected and issued a TSE Certificate of Suitability by the European Directorate for the Quality of Medicines (EDQM). The herds that supply the fetal bovine serum are all isolated herds of New Zealand or Australia, which are countries free of TSE/BSE. Additionally, Aastrom has submitted to its Notified Body BSI appropriate documentation supporting the fulfillment of the requirements established in the Directive 2003/32/EC of 23 April 2003 introducing detailed specifications regarding the requirements laid down in Council Directive 93/42/EEC with respect to medical devices manufactured utilizing tissues of animal origin. Fetal bovine serum is heat-inactivated at 56ºC for 30 minutes before being used for the formulation of the Base Medium and it must be stored from –5ºC to – 20ºC. The supplier tests FBS for bacterial, fungi, mycoplasma and virus contamination in order to assure the biological safety of fetal bovine serum produced. Fetal bovine serum used to prepare Base Medium is available from these qualified vendors: Invitrogen Corp and JHR Biosciences Horse serum (HS) All horses used to manufacture the horse serum come from New Zealand or Australia. Horse serum is heat-inactivated at 56ºC for 30 minutes before being used for the formulation of the Base Medium. The storage temperature is from – 5ºC to –20ºC. The supplier tests HS for bacterial, fungus, mycoplasma and virus contamination (including equine infectious anemia (EIA)) in order to assure the biological safety of the horse serum produced. Horse serum used to prepare Base Medium is available from the following qualified vendors: Invitrogen Corp, JHR Biosciences Control of the Harvest Reagent The sterile Harvest Reagent is used to prepare the Harvest Solution, which is used in the final processing steps of the ARS TRC production. The harvest solution is prepared from 500 ml of a solution of 0.9% Sodium Chloride for Injection and 60 ml of Harvest Reagent, following aseptic techniques. The Harvest Reagent, supplied by Aastrom, is basically composed of a concentrated solution of trypsin, EDTA and phosphate buffer contained in a vial with a needle septum stopper, frozen during shipping and stored from –5º C to – 20ºC. The expiration date is 18 months from date of manufacture. The porcine derived trypsin is supplied from animals with origins in USA, Canada and New Zealand. Harvest Reagent is tested by the supplier (GIBCO) according to standard specifications. Porcine parvovirus, PERV, other virus (those detailed in 9 CFR – US Code Federal Regulations - 113) and mycoplasma are also controlled on the raw material trypsin prior to be used in the Harvest Reagent manufacture. The trypsin is gamma irradiated and has been validated to be free of viruses. Future trends Highlighting the advances being made in regenerative medicine and the use of tissue engineering to grow replacement organs, may clinicians and scientists describe the emerging need for large quantities of serum-free, animal component-free, and well-defined media and the chemicals supplements needed to replace the function of serum proteins and help advance this work into human trials and clinical applications. The trend is to take serum out of industrial processes. That trend continues to push further up the pipeline, with a growing emphasis on serum-free, animal byproduct-free culture conditions in the cell line generation phase. As a consequence, a number of strategies have been developed to reduce or replace the requirement for FBS in cell culture media. It is a well known fact, that natural clot serum rather than plasma promotes the growth and proliferation of cultured cells. This appears to be due to the release of VEGF and various mitogenic growth factors (GR) like EGF, IGF-1, PDGF, FGF, and TGF from activated platelets. Researchers are exploring the growth promoting and mitogenic potential of human platelet lysates (PL) on cultured mammalian cells, and they have seen that PL can serve as valuable alternatives to the use of FBS in cell and tissue culture in the future. Composition and viability of the final product: release criteria 48 hour prior to harvest a sample is retrieved and analyzed for standard quality control. • Expansion under Single pass perfusion SPP conditions results in a high viability cell product, determined by 7-aminoactinomycin D (7AAD) (Beckman Coulter, Fullerton, CA). Viability readings should be beyond the range of 75% in order to comply with healthcare regulations. Flow cytometry is used to determine the phenotypes found in the final product, • Mesenchymal components (CD105+/166+ and CD90+), along with macrophage CD14auto+ populations are significantly expanded during SPP culture. • A dual positive CXCR4 and VEGFR1 positive cell, believed to be critical for neovascularization, is increased in TRCs.6 • Cells expressing endothelial cell markers (VEGFR1+, VEGFR2+, and CD144+/146+) are increased up to 6-fold in TRCs. • Many hematopoietic components are reduced although still present in TRCs, including T-cells (CD3+), B-cells (CD19+, not shown), mature myeloid cells (CD11b+, CD45+), and primitive hematopoietic cells (CD34+). The ability of cells within TRCs to form clonogenic colonies is also measured. Both hematopoietic (CFU-GM) and mesenchymal (CFU-F) colonies were monitored and, while CFU-F are substantially increased , CFU-GM are slightly decreased by culturing.