Asthma is a chronopharmacological disease

advertisement

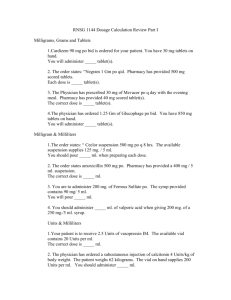

Vol-2/Issue-6/Nov-Dec 2013 PhTechMed ISSN: 2278-1099 Formulation and Evaluation of Pulsatile Drug Delivery System of Salbutamol Sulphate Using pH Dependent Systems Talasila Eswara Gopala Krishna Murthy*1, Kommineni Veditha2, Phanihassanth3 *1Bapatla College of Pharmacy, Bapatla, Guntur 2 Vignan Pharmacy College, Vadlamudi, Guntur 3 Dr.Reddy's Labs, Hyderabad Abstract Asthma is a chronopharmacological disease prone to occur during early morning hours that is around 4am to 6am. The objective of the present study is to formulate and evaluate a pH dependent pulsatile drug delivery system to achieve the onset of action between 4am to 6am. The core tablets were prepared by direct compression method using different diluents such as Flow lac 100, Tablet tose-70, DCL-21, Spray dried lactose, Avicel, Di calcium phosphate, Microlac 100. The pH dependent coating tablets were prepared by compressing the core tablet with pH in sensitive polymer HPMC and pH sensitive polymer Eudragit L 100 of different ratios. The duration of the lag phase during dissolution can be controlled by the thickness of the HPMC layer. The prepared tablets were evaluated for weight variation, hardness, friability, content of active ingredient and content of uniformity and in vitro drug release studies. The drug release from the core tablet is dependent on the diluent employed in the preparation of core tablet. The influence of pH dependent polymer was found to be more compared to pH independent polymer. A lag time of five hours is observed from compressed coated tablet containing Eudragit L 100 only. Key Words: Enteric coated tablets, pulsatile drug delivey system, core, film coated Introduction Asthma is a chronic disease of the respiratory system in which the airway occasionally constricts and lined with excessive amounts of mucus. These acute episodes may be due to exposure to cold air, emotional stress, environmental stimulant, exercise, viral respiratory tract infections, food additives and medications. During asthma attacks the smooth muscle cells in the bronchi constrict the airways become inflamed and swollen and breathing becomes difficult. This is often referred to as a tight chest and is a sign to immediately take medication. The treatment of asthma generally includes conventional oral dosage forms like tablet, capsules, oral liquids and inhalers, but oral administration is the most widely accepted route of delivery due to its ease of administration, convenience, compatibility and patient compliance [Bradley et. al., 2001; Peter et. al., 1995]. Salbutamol sulphate is a short acting β2 adrenergic receptor agonist has t1/2 of 2.8 hours used for the relief of bronchospasm in conditions such as asthma and it is well absorbed through out GIT. As Asthma is a chronopharmacological disease prone to occur during early morning hours that is around 4am to 6am [Martin et. al., 1998; Stroms et. al., 1994; Pincus et. al., 1995]. To show action at that time, patient has to administer the drug at 3am which may not be convenient to the patient. Hence to increase patient compliance pulsatile drug delivery system of Salbutamol sulphate is developed which delivers the right drug, at right time, right amount, to the right patient [Yoshida et. al., 1993; Lin et. al., 1996]. Hence the objective of present study was to formulate an enteric coated tablet to increase the onset of action of broncho dilator for the treatment of asthma. Materials and Methods Salbutamol sulphate, Flow Lac 100, Tablet Tose-70, DCL-21, Spray Dried Lactose, Avicel, Di Basic Calcium Phosphate, Microlac 100, Cross Caramullose Sodium, HPMC (3000-5600 Address for Correspondence Email ID: gopalakrishnatalasila@yahoo.com Tel No.: +918643-223202 Received: 12/08/2013 Accepted: 01/10/2013 www.pharmtechmedica.com cps) and Eudragit L 100 were obtained as gift samples from M/S Natco pharma Ltd. Hyderabad and other chemicals like Magnesium Stearate, Talc, and Ethanol were purchased locally. 8 Stage Dissolution test apparatus (DISSO-2000)-Labinda instrument Pvt Ltd, Weighing machine-Essae-Teraoka Ltd, Digital pH meter-Systronics Pvt Ltd, UV- Vis SpectrometerElico Ltd, Digital balance(AX-200)-Schimazu corporation, Disintegration Apparatus-Campbell Electronics, CMD 3-16 Station Rotary Tableting Machine-CMC Machinery, Cadmach Single Stroke Tablet Machine (Hoko-25Type)-CMC Machinery, Friability Apparatus-Campbell Electronics, Monsanto Hardness Tester Shreeji Chemicals were also employed in this investigation. Pre Formulation Studies The following Micromeritics properties of the selected diluents were conducted. Evaluation of Micromeritics Properties of Direct Compression Diluents Bulk density 5gms of blend was weighed and it was transferred to a measuring cylinder. It was subjected to 3 tappings, the bulk volume was noted8. The bulk density was calculated by the formula: Bulk weight Bulk Density = Bulk volume Carr’s index (%) 5gms of blend was weighed and it was transferred to a measuring cylinder and then it was subjected to 100 tappings. The tapped density and poured density were noted8. Carr's index was calculated by the following formula: Carr’s Index (%) = Tapped Density-Poured Density Tapped Density X100 403 Vol-2/Issue-6/Nov-Dec 2013 Hausner’s ratio 5gms of blend was weighed and it was transferred to a measuring cylinder and then it was subjected to 100 tappings. The tapped density and poured density were noted 8. Hauser's ratio was calculated by the following formulae: Tapped Density Hausner’s Ratio = Poured Density Murthy et al., formed were noted down [Indian pharmacopeia, 2007].The angle of repose (θ) was calculated by the formulae: h Angle of repose = Tan-1 r Preparation of Core Tablet The core tablets were prepared by direct compression technique. The composition of the tablets was showed in the table I. All the excipients were passed through sieve No. 60. The required ingredients were weighed accurately and mixed Angle of repose 5gms of blend was taken and it was poured into a hollow thoroughly for 5 min. Then the resulting mixture was cylinder which was placed on a graph sheet. Then the cylinder compressed to form a tablet using 5mm compression tool with was slowly lifted. Then height and diameter of the heap Cadmach single stroke tablet machine (Hoko-25 Type). Table I: Composition of Core Tablet Quantity(mg per tablet) Ingredient F1 F2 F3 F4 F5 F6 F7 Salbutamol sulphate 4 4 4 4 4 4 4 Flow lac 100 65 - - - - - - Tablet tose-70 - 65 - - - - - DCL-21 - - 65 - - - - Spray dried lactose - - - 65 - - - Avicel - - - - 65 - - Di calcium phosphate - - - - - 65 - Microlac 100 - - - - - - 65 Cross caramallose sodium 5 5 5 5 5 5 5 Magnesium stearate 1 1 1 1 1 1 1 Total Weight 75 75 75 75 75 75 75 Evaluation of core tablets Weight variation Twenty tablets were collected at random and were weighed collectively and individually. From the collective weight, average weight was calculated9. The percent weight variation was calculated using the formula: Average weight – Individual weight %Weight Variation= Average weight Hardness Hardness of the tablet was determined using the Monsanto hardness tester. The lower plunger was placed in contact with the tablet and a zero reading was taken. The plunger was then forced against a spring by tuning threaded bolts until the tablet fractured. Then the final reading was recorded [Leon et. al., 1987]. The hardness was computed by deducting the initial pressure from the final pressure. Content of active ingredient Ten tablets of Salbutamol Sulphate containing the equivalent of 40mg of Salbutamol were collected randomly, powdered and shaken with 60ml of water for 1hr. The resulting solution was diluted to 100ml and then filtered. The filtrate was suitably diluted and analyzed for Salbutamol at 276nm9. Content uniformity Ten tablets, each containing equivalent to 4mg Salbutamol were collected randomly and analyzed for the content of www.pharmtechmedica.com Salbutamol separately in each case according to the procedure described in content of active ingredient [Michael, 2006]. Friability The Roche friability test apparatus was used to determine the friability of the tablets. 10 tablets were selected, dedusted and weighed. Then they were placed in a drum and rotated for 100 times. Then tablets were dedusted to remove loose dust and were reweighed9. The percentage friability was calculated by formula: Initial weight – Final Weight %Friability= Initial Weight Disintegration Six tablets were collected randomly and introduced one tablet into each tube separately, added a disc to each tube. Suspended the assembly in the beaker containing water and operated the apparatus for 15min [Michael, 2006]. Dissolution studies on core tablet Dissolution studies were performed for different core tablets which were formulated using different diluents are by employing paddle method. The temperature was maintained at 37±0.5ºc and paddle was set at 50 rpm. The dissolution medium used was 7.4 pH phosphate buffer and about 5ml of sample was withdrawn at a sample interval of 5min up to 30min and sample was replenished with fresh dissolution 404 Vol-2/Issue-6/Nov-Dec 2013 medium. The collected samples were analyzed at 276nm. The dissolution studies were carried out in triplicate [United States pharmacopeia, 2004]. Formulation of Compression Coated Tablets Pulsatile drug delivery systems for Salbutamol sulphate were prepared with compression coating technique by employing the core tablet prepared with the diluents DCP and combination of pH sensitive polymer Eudragit L 100 and hydrophilic polymer HPMC as matrix forming material. The composition of the prepared compression coated tablets was showed in Table II. Accurately weighed (150mg) amount of the polymer mixture was placed in 12mm die. The selected core tablet F6 was placed at the centre with the help of forceps. Then another portion of Eudragit L 100: HPMC mixture equivalent to 150mg was accurately transferred into the die cavity. The resulting blend was subjected to compression by employing CMD 3-16 Station Rotary Tableting Machine. Evaluation of compression coated tablets The prepared compression coated tablets were evaluated for the weight variation, hardness, friability, content of active ingredient and content of uniformity as per the procedures mentioned earlier. Dissolution Studies The dissolution studies on the coated tablets were performed up to 7 hrs with different dissolution media viz 0.1N HCl (0-2 hrs), 6.8 pH Phosphate buffer (2-5 hrs) and 7.4 pH Phosphate buffer (5-7 hrs).The dissolution studies were conducted at 37.0 ± 0.5°c using paddle type apparatus (50 rpm).5ml of aliquot were withdrawn at 30min time interval and replenished with fresh dissolution media. The samples were analyzed at 276nm for the estimation of Salbutamol sulphate. Results and Discussion Pulsatile drug delivery systems for Salbutamol sulphate were prepared with a view to release the Salbutamol at 4am from the administered dosage form for effective treatment of noctural asthma. Pulsatile drug delivery systems were designed with compression coating technique and the results are reported here. Salbutamol sulphate core tablets were formulated with direct compression technique by employing different commercially available direct compressible diluents. The blends containing the Salbutamol and the direct compressible diluents were subjected to micromeritics Murthy et al., evaluation and the results are shown in table III. These blends exhibited good flow property and hence compressed to form tablet. The prepared tablets were evaluated for various quality control tests and the results were depicted in table IV. All the tablets complied weight variation, friability, content of active ingredient and content uniformity test. The tablets formulated with the diluents DCL failed to disintegrate within the specified 15 min disintegration time, however the remaining tablets passed the disintegration test. The formulations were further subjected to dissolution studies in 7.4 pH phosphate buffer. The dissolution profiles were showed in fig 1. The dissolution rate followed first order kinetics. The dissolution kinetics parameters were presented in table V. The dissolution rate was found to be influenced by the diluents employed in the formulation of tablets. Based on the release rate of Salbutamol sulphate, the diluents can be ranked as DCP>Microlac 100>Tablet Tose 70>Avicel>Spray dried lactose>Flow Lac 100> DCL-21. The formulations containing DCP showed relatively better dissolution rate, hence the core tablet containing DCP (F6) was selected for further studies. Studies on compression coated tablets Compression coated tablets of Salbutamol sulphate were formulated with compression coating technique by employing different proportions of pH sensitive polymer Eudragit L 100 and the hydrophilic swellable polymer HPMC as coating material and the tablet formulated with DCP(F6) as core material. All the formulated tablets were subjected to various quality control tests and the obtained data was showed in table VI. All the formulations complied the pharmacopoeial requirements. The dissolution studies on these formulations were conducted in 0.1N HCl for 0-2hours, 6.8 pH phosphate buffer (2-5) and 7.4 pH phosphate buffer (5-7 hours). The dissolution data was showed fig 2. The formulation containing only Eudragit maintained a lag time of 5 hours and the drug was released after 5 hours. The lag time was found to be increased with the concentration of Eudragit L 100 and the release rate was found to be increased with the reduction of HPMC content. Thus pulsatile drug delivery systems formulated with only Eudragit L 100 is more suitable for pulsatile drug delivery systems to maintain a lag time of 5 hours. Table II: Composition of Compression Coated Tablets Containing Salbutamol Sulphate Core Tablet Quantity(mg per tablet) Ingredients CCT1 CCT2 CCT3 CCT4 CCT5 UPPER LAYER HPMC 150 100 75 50 EUDRAGIT L 1OO 50 75 100 150 CENTRAL CORE(F5) LOWER LAYER HPMC 150 100 75 50 EUDRAGIT L 100 50 75 100 150 375 375 375 375 375 Total Weight www.pharmtechmedica.com 405 Vol-2/Issue-6/Nov-Dec 2013 Murthy et al., Table III: Micromeritics Properties of Blends Containing Salbutamol Sulphate and Direct Compressible Diluents S. No Diluents Bulk density (g/ml) Angle of repose(ϴ) Carr’s Index (%) Hausner's ratio 1. Spray dried lactose 0.595 25.64 14.26 1.166 2. Micro lac-100 0.465 18.72 18.56 1.22 3. Avicel 0.333 30.96 24.48 1.324 4. Flow lac-100 0.543 28.76 19.5 1.243 5. DCL-21 0.531 37.66 25.63 1.344 6. Di Calcium phosphate 0.416 47.46 15.75 1.37 7. Tablet tose-100 29.50 16.2 1.194 0.510 Table IV: Quality Control Test Report of Salbutamol Sulphate Core Tablets Formulation Average weight Hardness (kg/meter) Friability %Drug Content Content uniformity Disintegration time (min) F1 74.5±1.7 4.2 0.53 98.56 97.54±1.7 6 F2 74.7±1.8 4.3 0.55 98.34 98.35±1.9 5 F3 75.2±1.9 4.0 0.57 98.86 99.36±2.0 >15 F4 75.1±2.1 4.1 0.62 99.34 98.48±2.1 6 F5 74.9±2.0 4.7 0.66 98.29 99.23±1.8 5 F6 74.7±1.7 4.4 0.62 98.44 98.79±1.5 3 F7 74.8±2.2 4.8 0.59 99.67 97.86±1.6 4 Table V: Dissolution Kinetic Data of Salbutamol Sulphate Core Tablet S. No Formulation T50 (F) (min) T90 (F) (min) DE20 (%) K (Min-1) 1. F1 4.442 14.762 58.9 0.156 2. F2 2.21 7.35 73.6 0.313 3. F3 55.8 185.0 11.4 0.0124 4. F4 3.22 10.71 43.04 0.215 5. F5 2.47 8.22 79.6 0.280 6. F6 1.711 5.688 82.9 0.405 7. F7 1.828 6.076 82.8 0.379 120 120 100 100 80 F1 F2 F3 60 F4 F5 F6 F7 40 20 %DRUG DISSOLVED %DRUG DISSOLVED Table VI: Quality Control Test Report of Compression Coated Tablets Containing Salbutamol Sulphate Formulation Average Weight (mg) Hardness (Kg/Meter) Friability %Drug Content Content Uniformity 374.5±2.1 6.7 0.33 97.58 96.64±1.6 CCT1 374.6±2.3 6.2 0.35 98.54 97.45±1.8 CCT2 374.8±2.0 6.4 0.37 98.23 99.46±1.9 CCT3 374.3±1.9 6.5 0.46 99.68 98.58±1.9 CCT3 374.7±2.4 6.6 0.37 99.43 99.33±2.0 CCT4 80 CCT1 CCT2 60 CCT3 CCT4 CCT5 40 20 0 0 0 5 10 15 20 25 30 35 TIM E(M in) Fig 1: Dissolution Profile of Salbutamol Sulphate Tablets Formulated With Different Diluents www.pharmtechmedica.com 0 1 2 3 4 5 6 7 8 TIM E(Hrs ) Fig 2: Dissolution Profile of Compression Coated Salbutamol Sulphate Tablets 406 Vol-2/Issue-6/Nov-Dec 2013 Conclusion All the selected diluents exhibited the required flow and compressibility. All the formulated core tablets satisfied weight variation, friability, drug content and content uniformity requirements. The disintegration time and dissolution rate was found to be influenced by the diluents employed in the preparation. The dissolution rate from all the core tablets followed first order kinetics. The lag time from the compression coated tablets was found to be influenced by the concentration of pH sensitive polymer. The lag time up to 5 hours can be achieved with compression coating technique by employing Eudragit L 100 as coating polymer. References Bradley JU, Lawrence ML, Drugs used in treatment of asthma. In: Hardman JG, Lee E., editors. Goodman and Gillman’s (2001): The pharmacological basis of therapeutics, 10th edition The Mc Graw-Hill Companies, New York, p. 735. Peter JB, Robert AM, George RB, (1995): Principles of pharmacology, Basic concepts and clinical applications, Thomson Publishing Company, New York, p.589. Martin RJ, Banks-Schlegal S, (1998): Chronobiology of asthma, Am J Resp Crit Care Med. 151: 1002–1007. Stroms WW, Bodman SF, Nathan RA, Byer P, (1994): Nocturnal asthma symptoms may be more prevalent than we think, J Asthm.3: 313–318. Pincus DJ, Beam WR, Martin RJ, (1995): Chronobiology and chronotherapy of asthma, Clin Chest Med. 6, 699–713. Yoshida R, Sakai K, Okano T, Sakurai Y, (1993): Pulsatile drug delivery system using hydrogels, Adv Drug Del Rev.11, 85–108. Lin SY, Lin YY, Chen KS, (1996): Permeation behavior of salbutamol sulphate through hydrophilic and hydrophobic membranes embedded by thermoresponsive cholestryl oleyl carbonate, Pharm Res.13, 914–919. Indian pharmacopeia (2007): Government of India Ministry of Health and Family Welfare, Vol-1, Published by The Indian Pharmacopeia Commission, Ghaziabad, p.177-183. Michael E Aulton, (2006): Pharmaceutics, The science of Dosage Form Design, 2nd Edition, Churchill Livingstone, p.133-134, 205-206. Leon Lachman, Herbert A. Lieberman, Joseph L. Kanig, (1987): The Theory and Practice of Industrial Pharmacy, 3rd Edition, Varghese Publication House, Bombay, p.297. United States pharmacopeia - 27 (2004): National formulary22, Asian edition, United States pharmacopoeial convention, Inc; p. 56. www.pharmtechmedica.com Murthy et al., 407