Introduction - Online Abstract Submission and Invitation System

#1387

BioDeNOx: novel process for NOx removal from flue gases based on chemically enhanced biological NO and iron reduction

Peter van der Maas, Bram Klapwijk and Piet Lens

Sub-Department of Environmental Technology, Wageningen University, Bomenweg 2,

P.O.Box 8129, 6700 EV Wageningen, The Netherlands.

ABSTRACT

The BioDeNOx process combines the principles of wet absorption of NO into a aqueous

Fe(II)EDTA

2-

solution (

20 mM) with biological reduction of NO in a bioreactor. Stable

NO removal with efficiencies of 70-80 % was demonstrated when treating flue gas containing 500 ppm NO and 3-4 % O

2

. Biological reduction of both NO and

Fe(III)EDTA

-

are the crucial conversions during the regeneration of Fe(II)EDTA

2-

. Not

NO reduction, but reduction of EDTA chelated Fe(III) turned out to be the rate limiting process. Redox cycling of FeEDTA plays an important role in the biological denitrification process. With respect to Fe-reduction, polysulfide is most likely involved in the electron transfer between the bacteria and Fe(III)EDTA

-

.

KEYWORDS

Flue gas treatment, Nitric oxide, iron EDTA, redox

INTRODUCTION

The emission of nitrogen oxides (NO x

) to the atmosphere causes serious environmental problems, e.g. acid rain and depletion of the ozone layer.

1

Selective catalytic reduction

(SCR) processes, which are generally applied for NO x

emission abatement, require high temperatures (> 300

C) and expensive catalysts.

2

Therefore, biological techniques using denitrification may represent promising alternatives for the conventional SCR techniques, because denitrification occurs at ambient temperatures with the use of cheap microbial inocula (e.g. soil or activated sludges). One major drawback of biological techniques like trickling filtration is a rather low treatment efficiency at economic retention times 3 because of the rather slow transfer of NO from the gas to the liquid phase. When using aqueous solutions of Fe(II)EDTA as scrubber liquor, the mass transfer can be accelerated.

These Fe(II)EDTA solutions have the ability to form stable complexes with NO, and therefore provides high absorption efficiencies for gaseous NO .

In an instantaneous reaction, the nitrosyl-complex is formed according to the reactions 1 and 2

4

:

1

NO (g)

NO (aq)

NO (aq) + Fe(II)EDTA

2

Fe(II)EDTA-NO

2-

(1)

(2)

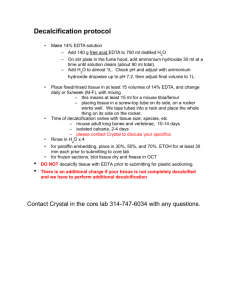

The principles of wet absorption of NO with biological reduction of NO in a bioreactor are combined in the so called BioDeNOx process 5 , as schematically represented in

Figure 1. In this process, the biological reduction of NO to di-nitrogen gas (N

2

) takes place under thermophilic conditions, at around 50-55

C, which is the adiabatic temperature of scrubber liquors. When ethanol is used as electron donor, the denitrification reaction occurs according to the overall reaction 3 5 :

6 Fe(II)EDTA-NO 2- + C

2

H

5

OH

6 Fe(II)EDTA 2 + 3 N

2

+ CO

2

+ 3 H

2

O (3)

Since industrial flue gasses generally contain 2-8 % oxygen, part of the Fe(II)EDTA is oxidized to Fe(III)EDTA according to:

4 Fe(II)EDTA 2 + O

2

(aq)

4 Fe(III)EDTA + 2 H

2

O (4)

To regenerate the absorption liquor, the Fe(III)EDTA

-

that is formed by reaction 4 has to be reduced back to Fe(II)EDTA

-

. Thus, besides NO reduction, reduction of EDTA chelated Fe(III) is a core reaction within the regeneration pathway of the BioDeNOx process.

To optimize the bioreactor performance, i.e. biological regeneration of Fe(II)EDTA

2-

, this research aims to elucidate the mechanisms and kinetics of NO reduction and

Fe(III)EDTA- reduction in BioDeNOx reactors.

Purified gas N

2

/ CO

2

SCRUBBER

NO absorption

Iron oxidation

Fe(II)EDTA

Fe(II)EDTA-NO

Fe(III)EDTA

BIOREACTOR

NO reduction

Iron reduction

Flue gas

NO / O

2

EtOH

Figure 1

Schematic principle of BioDeNOx

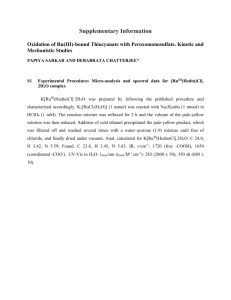

CONTINUOUS REACTOR PERFORMANCE

The technical feasibility of the BioDeNOx concept was demonstrated in a bench scale installation with a continuous flue gas flow of 650 l/h

6

. Ethanol was supplied as the

2

electron donor for the biological regeneration process. Fig. 2A shows that the NO removal efficiency was 70 - 80 % at an influent concentration of 500 ppm NO. Note that this removal efficiency is the result of the limited scrubber / absorption efficiency and that all scrubbed NO was fully converted to N

2

.

The ORP in the bioreactor, which indicates the ratio between Fe(III)EDTA and

Fe(II)EDTA, was found to be a proper signal for the control of the ethanol supply. The

NO removal efficiency declined at ORP values higher than –140 mV versus Ag/AgCl

(pH 7.0)

6

, which value approximates the standard redox potential (E

0

) of the system

Fe(III)EDTA/Fe(II)EDTA

9

. The supply of electron donor (ethanol) should be controlled at an ORP below that value.

Not the NO reduction capacity, but the iron reduction capacity was the limiting the load of the bioreactor

6

. Inoculation of the bioreactor with sludge with good properties for reduction of EDTA chelated Fe(III), resulted in a stable operation with a flue gas containing 3,3 % O

2

and 500 ppm NO. Under these conditions, app. 90 % of the electron flow is used for Fe(III)EDTA reduction and only 10 % for NO reduction (Fig. 2B).

A

600

500

400

300

200

100

0

196 198 200 202 time (d)

204 206 208

100

80

60

40

20

0

NO in

NO ef n NO

B

0,16

0,14

0,12

0,1

0,08

0,06

0,04

0,02

0

196

4

3,5

3

2,5

2

1,5

1

0,5

0

NO load

O2 load

O2 conc.

198 200 202 time (d)

204 206 208

Figure 2

NO removal efficiency (A) and bioreactor load (B).

The load is expressed as molar electron equivalents per liter per day (meq.l

-1

.d

-1

)

3

MECHANISMS AND KINETICS OF BIOREACTOR PROCESSES

Nitric oxide reduction

Various sludges from full scale denitrifying and anaerobic reactors, as well as several electron donors were screened on their capability to catalyze NO reduction under thermophilic conditions (55

C, pH 7.2). Reduction of NO to N

2

showed to be biologically catalyzed with nitrous oxide (N

2

O) as an intermediate 7 . BioDeNOx reactor mixed liquor showed a constant NO reduction rate of 0.67 mM.h

-1

(Fig. 4). Since the liquor contained

530 mg protein per liter, that volumetric rate is equivalent with a specific rate of 0.35 nmol.mgprot

-1 per second

8

.

Fig. 3 shows that NO reduction in aqueous Fe(II)EDTA

2-

medium was independent of the presence of ethanol. Also other external e-donors like ethanol, acetate or hydrogen did not affect the NO reduction rate 7 .

However, the NO reduction rate is affected by the

Fe(II)EDTA

2-

concentration: higher EDTA concentrations showed higher NO reduction rates (Fig. 4). The relation between the Fe(II)EDTA

2-

concentration and the NO reduction rate appeared to be first order, with rate constants of 438, 1419 and 4038 h -1 for the assays containing 5, 10 and 25 mM NaH

2

EDTA, respectively (4). K m

-values for NO were, respectively >30 nM, > 120 nM and > 200 nM

8

.

250

200

150

100

50

0

0 20 40 t (h)

60 80 100 ethanol present ethanol absent

Figure 3

NO reduction (monitored by the gaseous N accumulation in headspace) during batch experiments in presence and absence of ethanol (T = 55

C).

4

1,40E-04 y = 4015,2x - 3E-05

R

2

= 0,9839

1,20E-04

1,00E-04

8,00E-05

6,00E-05 y = 1419,4x - 0,0001

R

2

= 0,9882 y = 438,42x - 6E-05

R

2

= 0,9891

4,00E-05

2,00E-05

0,00E+00

0,00E+00 5,00E-08 1,00E-07 1,50E-07 2,00E-07 2,50E-07 3,00E-07

NO (aq) [M]

25 mM 15 mM 5 mM

Figure 4

NO reduction rate versus NO (aq) concentration in assays containing 25 mM, 15 mM and

5 mM Fe(II)EDTA 2. Ethanol was available as external electron donor (initial concentration 5 mM).

The observation that the specific rate of biological NO reduction to N

2

O in aqueous

Fe(II)EDTA

2-

medium is not dependent on the presence of ethanol (Fig. 3), but on the

Fe(II)EDTA

2-

concentration (Fig. 4) indicates that Fe(II)EDTA

2-

is a more direct electron donor for NO reduction than ethanol. is the preferred electron donor for NO reduction according to: .

2 Fe(II)EDTA-NO

2-

+ 2H

+

N

2

O + H

2

O + 2 Fe(III)EDTA

-

N

2

O + 2 Fe(II)EDTA 2 + 2 H +

N

2

+ H

2

O + 2 Fe(III)EDTA -

(5)

(6)

This is supported by the redox properties of FeEDTA and bacterial Nitric Oxide

Reductase (NOR), the denitrification enzyme that catlyzes NO reduction to N

2

O. The possible roles of Fe(II)EDTA

2-

as electron donor in NO reduction are schematically presented in Fig. 5.

5

EtOH

Various

Redox reactions

4

Cyt c

3

1

2

Fe(II)EDTA

2periplasm

Cyt BC1

complex

NOR cytoplasm

Figure 5

Possible electron transfer pathways for NOR reduction

8

:

1.

NOR reduction by reduced Cytochrome c

2.

Direct NOR reduction by Fe(II)EDTA

2-

3.

The conventional electron transfer chain: Cytochrome c reduction by the Cyt bc 1 complex

4.

Cytochrome c reduction by Fe(II)EDTA

2-

The system Fe(II)EDTA 2/Fe(III)EDTA is redox reversible and has a midpoint potential of + 96 mV

9

. This implicates that it easily accepts electrons from a system with a lower

E

0

and that it donates electrons to any redox sensitive system with a higher standard redox potential

10

. Bacterial NOR is a membrane bound enzyme that receives both its electron donor and acceptor (NO) from the periplasmic side

11

. The midpoint potentials of bacterial Nitric Oxide Reductase (NOR) are in the range of +280 until + 320 mV, meaning that, from thermodynamic point of view, Fe(II)EDTA

2-

is a suitable electron donor for bacterial NOR reduction (reaction 6, line 2 in Fig. 5). Based on the molecular weight (360 Da), it may be assumed that Fe(II)EDA

2-

and Fe(III)EDTA

-

can penetrate into the periplasmic space, where these compounds can be involved in various redox reactions (Fig. 5). Direct NOR reduction by Fe(II)EDTA 2 (reaction 7) is, to the best of our knowledge, not reported in literature yet. However, Fe(II)EDTA

2-

is an excellent electron donor for Cytochrome c reduction (reaction 8)

12

:

NOR ox

+ 2 Fe(II)EDTA

2-

↔ NOR red

+ 2 Fe(III)EDTA

-

Cytc ox

+ Fe(II)EDTA

2-

↔ Cytc red

+ Fe(III)EDTA

-

(7)

(8)

Cytochrome c is a physiological reductant of cNOR, the most abundant NOR-type reported

11

. Reduction by Cytochrome c, and the associated NO reduction by reduced bacterial NOR proceeds according to, subsequently, reaction 9 and 10:

6

NOR ox

+ 2 Cytc red

↔ NOR red

+ 2 Cyt ox

(9)

NOR red

+ 2 NO ↔ NOR ox

+ N

2

O (10)

In case of NOR reduction by Fe(II)EDTA

2-

, both the electron acceptor (NO) and donor

(Fe(II)EDTA

2-

) are coming from the periplasmic side. Therefore, the proposed electron transfer chain does not generate a proton motive force (PMF). However, energy production and cell growth can be maintained by the a PMF that is generated by an aspecific reduction of Fe(III)EDTA

-

by an enzyme-system that translocates protons. This alternative electron acceptor, Fe(III)EDTA , is produced by NO reduction (reactions 3 and 4) and also present in biodenox reactor liquors. Note that the more conventional electron supply chain via the Cytochrome BC1 complex and prior redox couples, i.e. oxidation of ethanol, cannot be excluded (Fig. 5).

Fe(III)EDTA

-

reduction

As mentioned above, not NO reduction but reduction of Fe(III)EDTA

-

was the limiting process of the bio-regeneration. To optimize this process, it is important to know the principle of the reduction of EDTA chelated Fe(III). Fe(III)EDTA

-

can be chemically reduced by a variety of electron donors, e.g. sulfide 13 , ascorbic acid 14 and thionine 15 .

This rises the question whether in the BioDeNOx concept, the reduction of Fe(III)EDTA

is a direct biological conversion by dissimilatory iron reducing bacteria, or a chemical reduction. The latter implicates the involvement of a compound to transfer the electrons from the bacteria to EDTA chelated Fe(III), as illustrated by Fig. 6.

CO

2

+ H

2

O Fe(II)EDTA CO

2

+ H

2

O EM red

Fe(II)EDTA

B B

EtOH Fe(III)EDTA EtOH EM ox

Fe(III)EDTA

Figure 6

Direct enzymatic versus indirect nonenzymatic Fe-reduction. EM = electron mediator,

B = bacterium

Fig. 7 presents the effect of the addition of electron mediating compounds (0.5 mM) on the Fe(III)EDTA

-

reduction rate in batch vials that were inoculated with BioDeNOx mixed reactor liquor in the presence of 5 mM ethanol as electron donor. Without the addition of any electron mediating compound, a Fe(III)EDTA

-

reduction rate of 0.9 mM/h was observed. Addition of sulfide or elemental sulphur resulted in a substantial acceleration of the Fe(III)EDTA

-

reduction rate to, respectively, 8.3 and 6.7 mM/h

16

.

Also L-cystein (5.3 mM/h) and vitamin B12 (3.0 mM/h) stimulated Fe(III)EDTA

reduction. Thionin inhibited Fe(III)EDTA reduction, while AQS, AQDS and riboflavin

7

had no significant effect. No Fe(III)EDTA

-

reduction occurred in the sterile controls (Fig.

7).

5

4

3

2

1

9

8

7

6

0 co nt ro l rib of la vi n su lfid e th io ni n

Lcy st ei n am in

B

12 vit

AQ

S

DS

AQ su lfu r p ow de r

Figure 7

The effect of various (possible) electron mediating compounds (0.5 mM) on the

Fe(III)EDTA reduction rate with ethanol as electron donor (initial concentration 5 mM).

Assays were inoculated with 1 % (v/v) BioDeNOx mixed reactor liquor.

The amount of sulphide added showed to be linearly related with the Fe(III)EDTA

reduction rate

16

(Fig. 8) according to: d[Fe(III)EDTA

-

]/dt = k

1

* [S

2-

injected] where the first order rate k

1

constant amounts

9 h

-1

(Fig. 8).

(eq. 1)

12

10 y = 9,1543x + 1,02

R

2

= 0,997

8

6

4

2

0

0 0,2 0,4 0,6 0,8 1 1,2 sulfide added (mM )

Figure 8

Effect of the sulfide addition on the Fe(III)EDTA

-

reduction by BioDeNOx mixed reactor liquor (inoculum 1 % v/v) with ethanol as electron donor (initial concentration 5 mM).

8

These results strongly indicates that Fe(III)EDTA reduction is not a direct biological conversion, but an indirect reduction with the involvement of a sulfur compound as an extracellular electron shuttle, most likely polysulfide. The electron mediator is formed by the injection of sulphide in aquous Fe(III)EDTA , since the specific Fe(III)EDTA reduction rate is linearly related with the concentration of the amount of sulfide injected

(Fig. 8). Injection of sulphide into the aqueous Fe(III)EDTA

-

solution leads to the formation of elemental sulfur and Fe(II)EDTA

2-

according to reaction 11

13

. As a result of that reaction, monosulfides polymerize to polysulfdides , S n

2-

, with n = 2 – 7. (reaction 12), but it a ferric chelate, e.g. Fe(III)EDTA

-

, was found to be required for sulfur polymerization

17

(overall reaction 13).

2 Fe(III)EDTA

-

+ S

2-

→ 2 Fe(II)EDTA + S

0

(s)

S

0

+ n S

2-

→ S n+1

2n Fe(III)EDTA + n S 2 → S n

2 + n Fe(II)EDTA 2-

(11)

(12

(13)

Also elemental sulfur and cysteine accelerated the Fe(III)EDTA- reduction rate substantially (Fig. 7). Since sulfides are produced during S

0

and cysteine reduction, it is assumable that polysulfides also play a catalytic role during Fe(III)EDTA- reduction in presence of S

0

and cysteine.

In literature, only limited information is available on biological Fe(III) reduction when chelated to EDTA. Lovley and co-workers suggested that chelation to NTA or EDTA stimulates bacterial Fe(III) reduction because then Fe(III) stays soluble under neutral pH

18

.

However, others

19

postulated that EDTA chelated Fe(III) is not bio-available for the dissimilatory Fe-reducing bacterium Shewanella putrefaciens because of the strong binding properties of EDTA. Also it is reported that Fe(III)EDTA is a rather poor eacceptor for dissimilatory Fe-reducing bacteria when applied at high concentrations, e.g.

25 mM 20 . These high FeEDTA concentrations are typical for BioDeNOx.

Contrary to Fe(III)EDTA-, polysulfides are a suitable electron acceptor for many bacteria and archae

21

. Therefore it is assumable that not dissimalatory iron reducing bacteria but reducers of elemental sulfur or polysulfides play a key role in the reduction of EDTA chelated Fe(III) within the BioDeNOx concept.via biological reduction and chemical oxidation of polysulfides according to, respectively, reaction 14 and 15:

S n+1

2-

+ 2 e- → S n

2-

+ S

2-

S n

2-

+ 2 Fe(III)EDTA- + HS

-

→ S n+1

2-

+ 2 Fe(II)EDTA

2-

+ H+ (overall)

(14)

(15)

Since NOx contaminated flue gasses generally also contain some SO

2

22 , reduced sulfur compounds are expected to be available in the mixed reactor liquor of BioDeNOx reactors under practical conditions.

9

CONCLUSION

NO x

removal by chemical absorption to aqueous Fe(II)EDTA solutions, combined with the biological regeneration of that scrubber liquor, is a promising alternative for conventional chemical and biological treatment techniques. Biological reduction of both

NO and Fe(III)EDTA are the crucial conversions during the regeneration of Fe(II)EDTA.

Redox cycling of FeEDTA plays an important role in both NO and Fe(III)EDTA- reduction. The proposed pathway for regeneration of the NO and O

2

loaded scrubber liquor is schematically presented in Fig. 9 (Van der Maas et al. 2004).

O

2

3

C

2

H

5

OH

CH

3

COOH

6

N

2

4

Fe(III)EDTA

-

H

2

S

4a

5

S

0

H

2

CO

2

Fe(II)EDTA

2-

NO

1

Fe(II)EDTA-NO

2-

2

2

N

2

O

Figure 9

Proposed pathway of the BioDeNOx regeneration process. 1. Absorption of NO to aqueous Fe(II)EDTA

2-

. 2. Denitrification of the sorbed NO with Fe(II)EDTA

2-

as electron donor. 3. Oxidation of chelated Fe(II) by the oxygen present in the flue gas. 4.

Reduction of Fe(III)EDTA

-

with sulfide / elemental sulfur as electron shuttle (4a). 5.

Biological sulfur reduction with electrons provided by the syntrophic converion of ethanol (6).

ACKOWLEDGMENT

This research was financially supported by the Dutch Foundation for Applied Sciences

(STW-NWO), grant STW WMK 4963, and Biostar Development CV.

10

REFERENCES

1.

Harding, A.W., Brown, S.D. and Thomas, K.M. (1996) Combustion and Flame.

107: 336-350.

2.

Davis, W.T., Pakrasi, A. and Buonicore, A.J. (1992) Air Pollution Engineering

Manual. Air and Waste Management Association, Van Nostrand Reinhold, New

York. pp 207-262.

3.

Du Plessis, C.A., Kinney, K.A., Schroeder, E.D., Chang, D.P.Y. and Scow, K.M.

(1998). Biotechnol. Bioeng.

58: 408-415.

4.

Demmink, J.F., Van Gils, I.C.F. and Beenackers, A.A.C.M. (1997) Ind. Eng.

Chem Res.

36: 4914-4927.

5.

Buisman, C. Dijkman, H., Verbraak, P.L. and Den Hartog, A.J. (1999) United

States Patent US5891408.

6.

Van der Maas, P.; Van den Bosch, P.; Klapwijk, B.; Lens, P. Biotechnol. Bioeng . 2004, In

Press.

7.

Van der Maas, P., Van de Sandt, T., Klapwijk, B. and Lens, P. (2003). Biotechnol.

Prog.

19: 1323-1328.

8.

Van der Maas, P., Manconi, I., Klapwijk B. and Lens P. (2005a) In prep.

9.

Kolthoff, I.M. and Auerbach, C. (1952) J. Am. Chem. Soc.

74: 1452-1456.

10.

Straub, K.L.; Benz; M.; Schink, B. FEMS Microbiol. Ecol.

2001, 34 , 181-186.

11.

Wasser, I.M., De Vries, S., Moënne-Loccoz, P., Schröder, I. and Karlin, K.D.

(2002) Chem. Rev. 102: 1201-1234.

12.

Hodges, H.L., Holwerda, R.A. and Gray, H.B. (1974) J. Am. Chem. Soc . 96:

3132-3137.

13.

Wubs, H.J. and Beenackers, A.A.C.M. (1994).

AIChE Journal. 40: 433-444.

14.

Mauricio, A.Q., Lopes, G.K.B., Gomes, C.S., Oliveira, R.G., Alonso, A. and

Hermes-Lima, M. (2003). Biochimica et Biophysica Acta 1620:15-24.

15.

Tanaka, K., Vega, C.A. and Tamamushi, R. (1983). Bioelectrochemistry and

Bioenergetics 11:289-297.

16.

Van der Maas, P., Van den Brink, P., Klapwijk B. and Lens P. (2005b) In prep.

11

17.

Clarke, E.T.; Solouki, T.; Russell, D.H.; Martell, A.E.; McManus, D. Anal. Chim.

Acta . 1994, 299, 97-111

18.

Lovley, D.R., Woodward, J.C. and Chapelle, F.H. (1996) Appl. Environ.

Microbiol . 62, 288-291.

19.

Haas, J.R. and Dichristina, T.J. (2002). Environ. Sci. Technol .36, 373-380.

20.

Finneran, K.T., Forbush, H.M., VanPraagh, C.G. and Lovley, D.R. (2002). J . Syst .

Evol . Microbiol ., 2002, 52, 1929-1935.

21.

Hedderich, R.; Klimmek, O.; Kröger, A.; Dirmeier, R.; Keller, M.; Stetter, K.O.

FEMS Microbiol. Rev . 1999 , 22 , 358-381.

22.

Philip, L.; Deshusses, M.A. Environ. Sci. Technol.

2003 , 37 , 1978-82

12