[ CLICK HERE & TYPE TITLE OF PAPER ]

![[ CLICK HERE & TYPE TITLE OF PAPER ]](http://s3.studylib.net/store/data/007624866_2-1211a6c7352fe296cb179f924b58b1b1-768x994.png)

STORMWATER QUALITY IMPROVEMENT DEVICES

ISSUES FOR CONSIDERATION

Geoffrey John Hunter, watershed@bigpond.com

Engineering Coordinator: Stormwater, Penrith City Council, Penrith NSW Australia

Abstract

Stormwater runoff is responsible for transporting many of the pollutants, which are degrading our waterways. The control of stormwater pollution is an integral part of the Stormwater Management

Plans that Councils in NSW have prepared in response to a Direction issued under Section 12 of the Protection of the Environment Administration Act, 1991 . Structural stormwater quality controls play an important role in meeting the pollution control objectives established in these plans. This presentation will examine many of the proprietary stormwater quality improvement devices

(SQIDS) available on the market and investigate the issues that should be considered when selecting a particular proprietary device to control stormwater pollution. Particular attention will be given to issues regarding the location of the devices within the catchment, their operation and maintenance. Three case studies in western Sydney and one from the Central Coast of NSW, will be used as examples of the real costs associated with stormwater pollution control.

Key Words: stormwater quality control, at source, in line, end of line, wet vaults, first flush, treatable flow rate, maintenance, confined spaces.

Introduction

“Urban runoff pollution results from numerous sources. It is the result of rainfall and snow melt that becomes contaminated as it travels through the atmosphere, along the land surface, and makes its way to a water body.

Urban runoff can enter a water body from an identifiable point source, such as a separate storm sewer outfall or a combined sewer overflow. It can also flow directly into a water body without an easily identifiable point of entry. Regardless of the point of entry, urban runoff has diffuse origins and, therefore, is difficult to manage and control.” (USEPA

1993)

Urban runoff management in its broadest and most comprehensive form involves controlling both the quantity and quality of the runoff.

Discussion

Effects of Urbanisation on Stormwater

Quantity

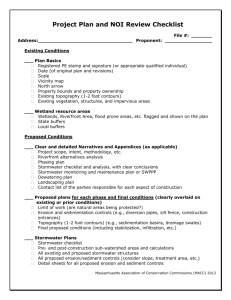

As a catchment urbanises, components of its natural drainage system (depression storage, infiltration capacity, wetlands, floodplains, etc) may be removed or altered. Urban assets and infrastructure eliminate vegetation and compact the soil. The catchment becomes more impervious and rainfall does not infiltrate as readily, resulting in increased runoff, runoff velocities and peak flows. See

Figure 1 for the relationship between runoff percentage and imperviousness. Traditional drainage practices have focused on removing the water from the urban areas as quickly as possible to prevent flooding. This approach does not take into account:

off-site damage from accelerated flow;

increased downstream flooding;

water pollution;

deposition of sediments;

floodplain and channel erosion;

wildlife habitat and natural vegetation; and

loss of a freshwater resource.

Figure 1 Changes in Runoff Flows

Resulting from Paved Surfaces

(Source: Livingston and McCarron, 1992)

To combat the increased runoff, velocities and more frequent flood events, stormwater management now has to accommodate both water quantity and quality controls. Many of these incorporate permanent at source controls (on-site detention, grass swales, pocket wetlands, infiltration basins, bioretention, minimisation of impervious surfaces) and/or regional control facilities

(large retardation basins and wetlands). In combination these practices have the effect of slowing the runoff, creating more site storage, enhancing infiltration potential, reducing the flood peaks and mitigating the impacts of the smaller recurrence interval storms. The result is a runoff hydrograph from an urbanised catchment that more closely resembles the hydrograph from the undisturbed catchment.

Effects of Urbanisation on Stormwater

Quality

"

Land use directly affects water quality. In an undeveloped area, the natural physical, chemical, and biological processes interact to recycle most of the materials found in stormwater. As human land use intensifies, these natural processes are disrupted and our everyday activities add materials to the land surface. Leaves, animal wastes, oil, greases, heavy metals, fertilizers, pesticides and other materials are washed off by rainfall and are carried by stormwater to our wetlands, lakes, rivers and bays."

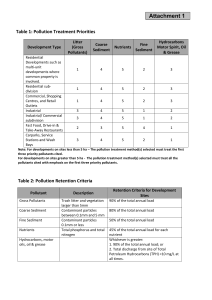

(FDEP 1993) The relationship between pollutant concentrations and Imperviousness are shown in Table 1.

No matter how appropriate the Best

Management Practice (BMP) they can only accomplish significant levels of non-point source pollutant load reductions if they are properly designed and maintained.

Practices to mitigate the impacts of stormwater pollutants aim to prevent their entrainment and/or to remove them from the runoff as soon as possible.

Anolyte

TSS

Phosphate

TKN

BOD

5

COD

F.coliform

Iron

Lead

Zinc

5% Imp 50% Imp 90% Imp

80

0.04

0.52

9

26

9

0.36

0.004

0.0008

212

0.20

1.10

14

65

28

0.48

0.03

0.09

123

0.20

1.40

19

69

31

0.58

0.06

0.17

Table 1 Pollutant Concentrations as a

Function of Imperviousness (mean

concentrations in mg/L) (Adapted from

Chang et al, 1990)

Filtration practices (sand filters, bio-filtration, porous pavements) have proved efficient in the USA, especially when used high in the catchment eg. carparks, commercial and industrial sites. Infiltration systems have proved successful where soils are permeable and groundwater contamination and/or its proximity to the infiltration system is not an issue. Strict adherence to soil erosion and sediment control plans, during construction, has greatly reduced the amount of sediment entering the receiving waters. These practices have been well documented in the literature but their consistent enforcement throughout the catchment is necessary if they are to be effective.

Stormwater Quality Improvement

Devices (SQIDs)

Pollutants commonly found in urban stormwater are described in Table 2, which has been adapted from the Victorian

Stormwater Committee, 1999. Source control should be the central theme of stormwater management. BMPs refer to those practices that are used for a given set of conditions to achieve satisfactory water quantity and quality enhancement at a minimum cost (Livingston and McCarron,

1992). They can be physical, structural, or management practices that, when used singly or in combination, prevent or reduce pollution of water

.

For stormwater management to be effective,

BMPs must be applied throughout the watershed. Nonetheless, the increase in pollutant loads from urban areas is typically so large that, even with the use of BMPs, it is unlikely that pollutant loads will be reduced to pre-development conditions. "Results suggest, that appropriately designed and properly sited BMPs can provide some mitigation of stormwater impacts on stream communities. However, the resulting communities differ greatly from those in undeveloped watersheds and reflect a fundamental alteration in stream biotic diversity." (Jones et al, 1996).

Pollutant

Sediment

Urban Source

Soil erosion & car washing

Pavement and vehicle wear

Atmospheric deposition

Spillage/illegal discharges

Organic matter (leaves, grass)

Weathering of bldgs/structures

Nutrients

O

2

Demanding

Substances

Organic matter decay

Atmospheric deposition

Sewer overflows/septic tanks

Animal/bird faeces

Spillage/illegal discharges pH (acidity)

Organic matter (leaves, grass)

Fertilisers

Sewer overflows/septic tanks

Animal/bird faeces

Detergents (car washing)

Atmospheric deposition

Spillage/illegal discharges

Microorganisms

Atmospheric deposition

Spillage/illegal discharges

Organic matter decay

Erosion of roofing material

Animal/bird faeces

Sewer overflows/septic tanks

Organic matter decay

Toxic Organics Pesticides and herbicides

Spillage/illegal discharges

Sewer overflows/septic tanks

Heavy Metals

Gross

Pollutants

(litter & debris)

Atmospheric deposition

Vehicle wear

Sewer overflows/septic tanks

Weathering of bldgs/structures

Spillage/illegal discharges

Pedestrians and vehicles

Waste collection systems

Leaf-fall and lawn clippings

Spills and accidents

Oils and

Surfactants

Increased

Water Temp.

Asphalt pavements

Spillage/illegal discharges

Leaks from motor vehicles

Car washing & organic matter

Runoff from impervious areas

Removal of riparian vegetation

Table 2 Pollutants in Urban Stormwater

Before a particular BMP or series of BMPs can be determined, the land take, catchment area, objectives for the receiving waters, soil and groundwater requirements all have to be considered and investigated, and the preferred practice adopted that best fits with these constraints.

For the purposes of this paper, structural

SQIDs will be classified as:

At Source Control — located as close to the source of pollution as possible;

In-Line Control — constructed as a structural member and an integral part of the drainage system;

End of Line Control — situated as the last structural component of the formal drainage system.

Costs for each device can be derived from

DPWS, 2001 (supply only) or by contacting the supplier directly. Installation costs are site specific and dependent on the nature of the soil (rock, shale, clay, sand etc) as well as access to the site, and can result in the installation costs being 2 to 3 times the supply cost. Contact details for each manufacturer are contained in DPWS, 2001.

At Source Controls

Pit Inserts – are installed as an integral component of the gully pit (not within the pipeline) and screen the pollutants out of the runoff as it enters the pit. They are generally located directly beneath the grate and/or the lintel.

Contacts:

Dencal: (03) 9801 3057

Enviropod: (02) 9807 7477

Ecosol RSF100: (02) 9560 2802

Pit Bull: (02) 4975 3012

Pratten Insert: 0419 419 478

Prime Composites: (02) 9525 6515

Lintel and Grate Covers (Excerpts) – are external to the grate and/or lintel of the pit and filter the runoff before it enters the pit. They are intentionally placed across the pit opening and can be used to prevent the runoff entering the pit

(especially good for construction sites).

Durham: (02) 4587 7011

Pit Bull: (02) 4975 3012

Filtration Media – can be used as an effective treatment for fine particulates and dissolved pollutants. Bio-retention and sand filters can be incorporated into the landscaping on small impervious sites such as carparks. The StormFilter™ utilises cartridges containing media within a gully pit to filter the runoff.

Beresford Concrete Products:(02) 4392 3300

Ingal Civil Products: (02) 9710 5555

In Line Controls

Ecosol RSF 4000 & RSF 6000 GPTs – are underground wet vault traps that rely on a hydraulic weir to divert the runoff into a deep separation chamber where it is filtered through a 3 mm mesh screen before flowing into a parallel by-pass flume. Water diverted into the separation chamber is forced into the bypass flume through a vertical riser, which creates a slight backwater situation and forms the hydraulic weir. Intended to trap gross pollutants and coarse sediment.

Contact: (02) 9560 2802

Rocla Downstream Defender – oil and grit separator consisting of three concentric cylinders with a separation chamber beneath. Stormwater enters the system through the outer cylinder, which has a sloping base opening into the separation chamber. The heavier particles separate out and are retained as the stormwater and remaining suspended solids are diverted into the central cylinder where they slowly rise and overflow into the second cylinder, which is connected to the outlet pipe. Cleaning

is by eduction and must be carried out before the captured material packs down hard. Generally supplied as a pre-cast unit

Contact: 131 004 (Toll Free)

Rocla CleansAll® - an underground gross pollutant and sediment trap that utilises a screened basket to separate the gross pollutants followed by a deeper sump for silt retention. Baskets must be cleaned at 50% full to prevent an unacceptable increase in energy levels upstream of the device. Generally supplied as a pre-cast unit. Cleaned by lifting the baskets out and emptying them into a waiting truck. Stored water and fine sediments need to be pumped or sucked into an appropriate containment vessel for disposal.

Contact: 131 004 (Toll Free)

Stormwater Rubbish Trap – a gross pollutant and coarse sediment trap, which can be modified to incorporate an Atlantis

Drainage Cell to provide fine particulate separation. This device incorporates a series of cages across an underground rectangular chamber to capture positively buoyant pollutants and drop out coarse sediment. Once through the cages the runoff is detained by, and filtered through the Atlantis Drainage Cell before discharging to the outlet pipe. Access into the underground chambers is required for cleaning, which entails removal of the cages and evacuation of the sediment.

Contact: (02) 9389 0580

Continuous Deflective Separation – better known b y its acronym CDS™

Technologies. Gross pollutants and sediments are separated from stormwater by centrifugal forces, which also prevents the screen from becoming blocked by debris and other items such as plastic bags. The mesh screen is made of expanded metal and can be supplied in stainless steel if required. The circular motion of the water cleans the screen and helps maintain the design treatable flow rate throughout the storm. Pollutants are stored wet, in a sediment sump that may be up to 7 m deep depending on the size of the catchment being treated.

Baskets can be fitted to smaller units to facilitate cleaning. Smaller units can be supplied as fibreglass pre-cast units whereas the larger devices are generally cast in-situ. Captured material should not be allowed to build up to the level of the screen. Cleaning is best carried out with a HIAB “grab bucket”, but this does not provide for decanting of the stored water, which requires additional equipment to educt or pump it into an appropriately sealed storage unit for disposal.

Contact: (02) 9807 7477

Humegard ™ - a gross pollutant and coarse sediment trap designed to be installed within stormwater drainage systems constrained by flat grades and low head. They remove gross pollutants from the flow by means of a boom and a holding chamber. The boom creates only a marginal increase in the head loss across the structure (k

0.2). Trapped debris is stored wet in a separation chamber and sump that are located offline from the pipeline. High velocities

(>1.5 m/s) can cause a reduction in the efficiency of the device. Restricted access into the holding chamber can be an issue during cleaning and maintenance but this can be overcome with the installation of additional access lids. Can be cast in situ or supplied in modular pre-cast units to be assembled on site.

Contact: (02) 9832 5555

Humeceptor™ – developed in Canada where it is known as a Stormceptor, it is a pre-cast device designed to specifically remove oil and fine sediment out of stormwater runoff from small industrial catchments and carparks. It is divided into two components, a fibreglass bypass chamber, and a concrete treatment chamber. Stormwater flows into a circular by-pass chamber where the low flows are diverted down and into a treatment chamber by a low weir and

vertical pipe. The downstream section of the by-pass chamber is connected to the outlet stormwater pipe, ensuring that once the material is captured it is not rereleased. Must be cleaned at 15% full to ensure trapped oil is not re-mobilised and fine particulates are not re-suspended by turbulence. Access into the device is restricted and it must be cleaned by eduction.

Contact: (02) 9832 5555

SPEL Stormceptor™ – developed in the

U.K. for oil and fine sediment control, it is designed as an easily transportable onepiece fibreglass unit. It is specifically designed to separate oil and other light liquids out of stormwater runoff from supermarkets, carparks and industrial areas. The unit is divided into two (2) chambers with interconnecting vertical ducts. The first chamber (Primary Zone) provides grit separation while the second chamber (Quiescent Zone) provides fine particulate separation and traps oil behind a weir, which does not have direct access to the overflow by-pass pipe. Gross pollutant separation is required before the runoff enters the device. There is provision within the device to mount monitoring equipment and sensors, as well as a coalescing plate separator. To increase the structural integrity of the fibreglass units it may be necessary to encase the unit in concrete. Access into the device is limited and cleaning is by eduction, there are specially designed inspection openings to determine the amount of material captured.

Contact: (02) 9683 5555

Stormfilter® – a product developed by

Stormwater Management of Oregon

U.S.A. It is an underground concrete vault designed as a series of interconnected cells to firstly separate the gross pollutants and sediment, and secondly the free floating oil and fine particulates. The final chamber incorporates a series of cartridges that filter the water through various media

(activated carbon, perlite, zeolite, compost, geotextile fabric), selected on the basis of the pollutants of concern in the catchment. Pipe full by-pass can be accommodated through the device or with the use of a Storm Gate diversion weir.

However the cartridges have a very low

(1 L/s) treatable flow rate each. Ingal

Civil Products have converted the cartridges to fit within the Buffa Tank onsite detention system and can supply the system in modular fibreglass units. A specialised attachment for a HIAB is available to remove the cartridges for cleaning and oils and fine sediment can be removed by hand or eduction. The drainage system within the base slab allows the device to drain dry through the cartridges.

Contact: (02) 9710 5555

CI&D

– designed as an oil and fine sediment separator. This device utilises a Diversion Chamber to divert flows into a Storage Chamber where the sediments are separated from the runoff by centrifugal action and low water velocities. The use of internal baffles within the Storage Chamber retain the oil in the top of the Stormwater Silt & Oil

Arrestor. It can be supplied as a precast unit but must be cleaned by eduction.

Contact: (02) 9602 9022

End of Line Controls

Net Tech – gross pollutant traps consisting of a fabricated stainless steel pipe extension and a heavy duty UV stabilised polyethylene net. The extension is fitted to the end of the pipe at its point of discharge. It incorporates a release mechanism that allows the net to detach and choke off, trapping the rubbish inside, while still being attached to the end of the pipe. This ensures a pipe full bypass, but any additional material mobilised later in the storm will by-pass. The device is visible and the stainless steel fittings appear to be highly prized, and as a consequence vandalism can be a problem. Care must be taken to ensure the release mechanism is properly set and does not stick in the locked

position. Cleaning involves undoing the clamp on the net and emptying it into the back of a small truck.

Contact: 0414 574 300

Pratten Trap – utilise a galvanised steel cylinder attached to the end of the pipe or headwall with a net attached to the outlet end of the cylinder. The net is not automatically released and is held in place by a bolted clamp, and by-pass occurs as a result of increased head, which trips a trap door upstream of the material stored in the net. When incorporated into a concrete hob downstream of the headwall, with an integral trash rack this device can effectively trap gross pollutants and coarse sediment. A variation with a vertical drop is available for sites such as sea walls and retaining walls. Captured material is stored in a drained condition but the device is highly visible, which can be a concern for vandalism.

Contact: 0419 419 478

Ecosol RSF 1000 – can be provided as a complete mesh cage at the end of the pipe or can be incorporated as an integral component of an existing headwall. The object is to provide an enclosed chamber, within which a basket filters out gross pollutants, without compromising the hydraulic characteristics of the upstream pipe system. A drop is required to allow installation of the baskets below the pipe outlet. Surcharge is by overtopping the basket, which can re-suspend positively buoyant material.

Contact: (02) 9560 2802

The Stormwater Boom – consists of a floating boom, with an attached skirt that can be anchored to the invert of the creek or estuary or weighted to stay vertical in mid-water. It is not essential that the boom be installed in a constantly flowing creek or be continually buoyant, however it is preferable that it be installed in areas of permanent water. The skirted boom is designed to bow out in the direction of the flow entrapping the rubbish within it. As the water level rises the boom commences to float and the rubbish is retained upstream of the boom. The skirt is manufactured from a permeable fabric that allows filtered water to pass through, yet retains positively and neutrally buoyant solids. The height of the boom can be set to allow overtopping in extreme floods. If desired a sacrificial section (shackle) can be incorporated that breaks under extreme pressure.

Specialist equipment (water lift dredge or hand collection) is required for maintenance as these devices work best in areas of permanent inundation.

Contact: 0419 419 478

Bandalong Boom and Litter Trap – the boom is designed to collect or deflect floating debris into the litter trap. It is manufactured from polyethylene pipe in segment lengths of 3 or 6 metres. An aluminium mesh skirt is fixed to the underside of the boom to prevent material, floating mid-water, bypassing the boom. The litter trap is connected to the mid-sections of the polyethylene pipe and acts as the permanent collection chamber. The stainless steel fittings are highly prized by the boating community and vandalism is common. If the unit becomes grounded during low water situations the rigid aluminium skirt and rigid floats can be damaged. A recent modification provides vandal proof connections between the polyethylene floats.

Contact: (03) 9437 0021

Gross Pollutant Trap (Baffled Box) -

This is one of the most common and probably the oldest technology currently in use. It consists of a coarse sediment trap/sump, with a trash rack on the downstream end to remove litter and debris. They are generally poured in situ and require regular maintenance based on the storage capacity of the sediment sump. Captured material is generally stored wet. The trash rack should be cleaned after every major storm and/or when the open area of the rack is reduced by about 20%. Vehicular access

is a major consideration and the device needs to be drained before entry. In the

Baffled Box modification internal weirs provide energy dissipation and need to be removed to allow front-end loader access.

Contact: requires detailed designs by a civil and hydraulic engineer. Sedimentation calculations are generally based on Stoke’s

Law or physical models.

Baramy® Gross Pollutant Trap – supplied as a pre-cast concrete treatment system by Beresford Concrete Products.

It utilises horizontal and vertical screens to filter the gross pollutants out of the runoff. They require a drop at the outlet of the piped drainage system and the entrained litter and debris is separated as the stormwater passes through the screens. The separated material is stored dry, which reduces the opportunity for the organic material to decompose and release nutrients. The grade of the access ramp is a major consideration when designing the unit and should be suitable for a wheelbarrow or have sufficient turning circle to accommodate a bobcat. A sediment sump can be incorporated downstream for coarse sediment control. Care must be taken to ensure adequate surcharge capacity without scouring out of the backfilled material surrounding the device.

Contact: (02) 4392 3300

Nicholas Ski-Jump - This device uses expanded metal mesh to screen out rubbish from stormwater flows at the outlet headwall of stormwater drainage systems. Sediment is captured in a chamber located beneath the litter and debris separation screens. All material is retained in a dry state to reduce the opportunity for nutrients to be released into the water column as the organic material decays. The stored material is removed by accessing the rear separation chamber and raking the material into a wheelie bin, which requires the access to the unit to be suitable for dragging a full wheelie bin by hand. Bypass occurs when the head level upstream forces the side trap doors

(wings) to open and the stormwater is surcharged around the stored material.

The coarse sediment separation chamber is provided below the gross pollutant screens and the device can be modified to fit within open channels.

Contact: (02) 9427 4910

Pollutant Removal Considerations

Pollutant Removal Mechanisms

Horner et al (1994) listed “all the principal mechanisms that can capture, hold, and transform various classes of contaminants in urban runoff and the factors that promote the operation of each mechanism to improve water quality.” The effectiveness of the mechanism to remove pollutants is a function of time. Consequently Hydraulic

Residence Time is the most basic variable to consider when applying effective treatment practices.

Features that help achieve any objective:

Increasing hydraulic residence time;

Low turbulence;

Fine, dense herbaceous plants;

Medium-fine textured soils.

Features that help achieve specific objectives:

Phosphorus control – high soil exchangeable aluminium and/or iron content; addition of precipitating agents;

Nitrogen control – alternating aerobic and anaerobic conditions; low toxicants; circumneutral pH;

Metal control:

High soil organic content;

High soil cation exchange capacity;

Circumneutral pH.

Organic matter control:

Aerobic conditions;

High light;

High soil organic content;

Low toxicants;

Circumneutral pH.

NOTE: Other considerations include the pollutant load running off the catchment and the ability of the device to store that load between rainfall events without by-passing.

Many devices, in particular In-Line devices are intended to be charged by a low-flow weir. Where this is the case, care should be taken when calculating the pollutant load, as most of the heavier pollutants are contained within the lower portion of the pipeline. Bypass weirs and flumes should have sufficient capacity to by-pass the pipe full flow without surcharge, and without compromising the upstream hydraulic grade line .

Wet Vaults as Gross Pollutant Traps

Abood and Riley (1997) found that in the

Lane Cove Valley, gross pollutants had a deleterious effect on water quality, and the decomposition of the gross pollutants increased with time while ever the gross pollutants were kept within a wet anaerobic environment. They concluded that the pool of water “would be a major source of low water quality which would be flushed downstream in the early stages of a flood event. Programs of gross pollutant removal should be on a one month cycle, and possibly more frequent.”

Strynchuk, Royal and England (1999) reached a similar conclusion in their analysis of the effect of grass clippings and leaves on water quality when stored in a wet anaerobic condition. “The results of this study show that the majority of organic-based pollutants, which leach from grass clippings and leaves into water, will be released within 1 to 22 days, depending on the pollutant.” They concluded “that in order to avoid significant leaching of most ‘pollutants’, it is desirable to quickly remove organic debris from collection devices that retain water.”

Strynchuk, Royal and England (1999) also found that for leaves and grass clippings,

BOD

5

concentrations peaked at 9 days; colour was continuously released between 1 and 22 days; and phosphorus was released within the first day of immersion. Abood and

Riley (1997) found significant increases in

Phosphorus, Nitrogen, COD and Suspended

Solids, in non-aerated pools during the first

100 days after collection. Cigarette butts were found to increase phosphorus, suspended sediment, conductivity and COD loads within the samples within about 10 days of being immersed.

Wet vaults provide an environment conducive to the conversion of solid gross pollution into soluble pollutants. Anaerobic decomposition, low pH and low light conditions are all features of underground wet vaults. In combination they make it possible for pollutants bound to small particulates or stored in a solid form to be broken down and released back into the water column. The presence of anaerobic bacteria, within the vault, has the potential for significant gas production (hydrogen sulfide, methane) and this may occur within 7 days of collection.

Separation of the waste stream into individual pollutants, combined with regular cleaning and removal can alleviate problems associated with pollutant re-mobilisation in wet vaults. From the research quoted above, it would appear that wet vaults should be cleaned out as soon after a rainfall event as possible and at intervals not exceeding 30 days. Inspection of the device, to determine the need for cleaning, should occur after 10 mm of rainfall or every 2 weeks, whichever comes first.

Conclusion

This paper is meant to provide some guidance on the proprietary devices available and the location within the catchment that

best suits their individual design characteristics eg at-source, in-line, end of line etc. The in-line wet vault type of GPTs have proved very popular in western Sydney and some characteristics common to each device are emerging, especially with regard to installation costs. These characteristics can provide guidance to Local Government staff to allow them to plan and budget for gross pollution control throughout their developed catchments.

In general a GPT should not be installed on catchments in excess of 20 ha (TFR <

1.5 m³/s), and an underground, in-line wet vault suitable for this size catchment in western Sydney generally costs between

$80,000 and $150,000. Cleaning and maintenance costs vary depending on the number and proximity of devices and the tipping fees, but generally each device requires cleaning every month at a cost of between $500 and $1,500. If soluble pollutants are an issue and need to be removed then the capital works costs should be doubled i.e. approximately $20,000 per hectare of development. However Holroyd

City Council found that the incorporation of a flood attenuation system with a high level of water quality control, significantly increased the capital costs per catchment hectare.

Sydney Smith Park has a 26 ha residential catchment, and the stormwater management strategy for the catchment cost approximately $40,000 per hectare including attenuation of the 1:100 yr peak flows to 1:2 yr, design flows with gross pollutant control, sand filters and water re-use. (Peterson and

Ritchie, 2000)

A similar system at Blue Haven on the

Central Coast of NSW cost approximately

$15,000 per hectare of a 20 ha residential catchment, and the stormwater pollution controls in Plumpton Park, Blacktown cost approximately $12,500 per hectare for a 100 ha residential catchment. At Scope Creek in

Penrith, treatment of the dry weather flows from a 200 ha rural/residential catchment has cost $3,000 per hectare of its contributing catchment.

No one product provides the solution to all the pollution problems associated with stormwater runoff. However, source and at source controls can provide the opportunity to reduce costs by keeping structural controls small, unobtrusive and maintainable.

Pointless Personal Pollution is responsible for much of the pollution in stormwater. The most cost effective source control is preventing pollution from occurring in the first place. This can be achieved by making the polluters aware of the impact of their actions and effecting a behaviour change. Structural controls should endeavour to separate the waste stream and store the pollutants in a dry condition prior to collection.

Comprehensive stormwater management incorporates:

Surface drainage and flood protection;

Protection of aquatic habitat and biota;

Reduction of stormwater pollutants;

Erosion and sediment control;

Aesthetic & recreational opportunities;

Reuse of stormwater;

Values assigned to ecosystems;

A community education program.

When used in a series or “treatment train” a combination of BMPs can provide cost effective solutions. Structural BMPs are necessary to remove gross pollutants from runoff that would, if left untreated, reduce the effectiveness of natural treatment systems such as wetlands and bio-retention facilities.

To be successful any Stormwater

Management Program requires a comprehensive, continuous team approach incorporating federal, state and local governments and must be based on communication, cooperation, creativity and, most importantly, commitment.

Acknowledgments

The author acknowledges the assistance of the following companies and organisations in the preparation of this paper:

All Pumps Sales and Services, Bandalong

Engineering, Baramy, Boyden and Partners,

CDS Technologies, CSR-Humes, Ecosol,

Ingal Civil Products, Net Tech, Nicholas Civil,

Rocla Pipeline Products, Sinclair Knight

Merz, Stormwater Management, Stormwater

Systems, Brisbane City Council, Blacktown

City Council, Hornsby Shire Council, Holroyd

City Council, Penrith City Council, Wyong

Shire Council, Melbourne Water, CRC for

Catchment Hydrology, University of South

Australia, Swinbourne University, NSW EPA and various Government agencies throughout the U.S.A.

References

Abood M. and Riley S.J. (1997) “Impact on

Water Quality of Gross Pollutants”.

Research Report No. 121 Urban Water

Research Association of Australia, June

1997. (72 pages)

Allison R., Chiew F. and McMahon T. (1997)

“Stormwater Gross Pollutants”. Industry

Report 97/11 by the Cooperative Research

Centre for Catchment Hydrology, Department of Civil Engineering, Monash University,

December 1997. (17 pages)

Brown S., Shrestha S. and Riley S.J. (1999)

“The allocation of Resources to Stormwater

Pollution Control”. In Impacts of Urban

Growth on Surface water and Groundwater

Quality, proceedings of International Union of

Geodesy and Geophysics, at Birmingham,

UK, 18-30 July 1999. IAHS Publication no.

259 ISBN 1-901502-06-6. (pp.381-389)

Chang G., Parrish J. and Souer C. (1990)

“The First Flush of Runoff and its effect on

Control Structure Design”. Environmental

Resource Management Division, Department of Environmental and Conservation Services,

City of Austin, Texas. Summary in

Watershed Protection Techniques Center for

Watershed Protection, Vol.1, No.2, Summer

1994, Technical Note 28. (pp.88-90)

Chiew F., Mudgway L.B., Duncan H.P. and

McMahon T.A. (1997) “Urban Stormwater

Pollution”. Industry Report 97/5 by the

Cooperative Research Centre for Catchment

Hydrology, Department of Civil Engineering,

Monash University, July 1997. (18 pages).

CRC-CH (1999) “Removal of Solids and

Associated Pollutants by a CDS Gross

Pollutant Trap”. Prepared by the Cooperative

Research Centre for Catchment Hydrology,

Report 99/2 February 1999. (38 pages)

DPWS (2001) “Contract 019 – Stormwater

Treatment Devices User Guide: 1/6/98 to

31/5/2002”. NSW Department of Public

Works and Services. McKell Building, 2-24

Rawson Place Sydney. (54 pages)

Strynchuk J., Royal J. and England G. (1999)

“Grass and Leaf Decomposition and Nutrient

Release Study Under Wet Conditions”.

Report for Brevard County Surface Water

Improvement, Viera Florida. (6 pages)

Florida Department of Environmental

Protection (FDEP ) (1993) "Model Local

Government Stormwater Management

Program". Prepared by the

Stormwater/Nonpoint Source Management

Section, Tallahassee, Florida. (54 pages)

Hunter G.J. and Claus E. (1995) “Preliminary

Water Quality Results from a Constructed

Wetland at Plumpton Park, Blacktown,

NSW.” Conference proceedings Wetlands for Water Quality Control. September 1995,

James Cook University, Townsville. (pp.265-

274)

Hunter G.J. and Constandopoulos J. (1997)

“Development of Pollutant Load Retention

Curves for a Stormwater Treatment Wetland at Plumpton Park, Blacktown, Sydney”.

Conference proceedings Science &

Technology in the Environmental

Management of the Hawkesbury-Nepean

Catchment.

10-11 July 1997, University of

Western Sydney-Nepean. (pp.79-86)

Hunter G. (1999) “Stormwater Treatment

Devices”. Workshop Proceedings

Stormwater Treatment Devices, for the

Stormwater Industry Association, 8 th

International Conference on Urban Storm

Drainage, the Hilton Hotel Sydney, 1 st

September, 1999. (48 pages)

Horner R.R., Skupien J.J., Livingston E.H. and Shaver H.E. (1994) "Fundamentals of

Urban Watershed Management - Technical and Institutional Issues". Terrene Institute,

Washington D.C. and the U.S. Environmental

Protection Agency. (302 pages)

Jones R.C., Via-Norton A. and Morgan D.R.

(1996) “Bioassessment of the BMP

Effectiveness in Mitigating Stormwater

Impacts on Aquatic Biota.” Conference proceedings Effects of Watershed

Development & Management on Aquatic

Ecosystems.

August 1996, Snowbird Utah.

Engineering Foundation 345 East 47 th Street

New York. (pp.402-417)

Leif W.T. (1998) “Sediment Removal in

Catch Basins and Catch Basin Inserts”.

Snohomish County Public Works, Everett,

Washington USA, March 1998. (33 pages)

Livingston E.H. and McCarron

M.E. (1991) "Stormwater Management: A

Guide for Floridians." Florida Department of

Environmental Regulation, Tallahassee,

Florida. (72 pages)

NSW EPA (19 97) “Managing Urban

Stormwater – Treatment Techniques.”

Prepared by the NSW Environment

Protection Authority for the State Stormwater

Coordinating Committee. (104 pages)

Peterson R. and Ritchie P. (2000) “Domain

Creek Comparative Technologies –

Approaches to Stormwater Management in

Urban Catchments”. Institute of Public

Works Engineering Australia conference in

Penrith NSW, May 2000. (7 pages)

Phillips D.I. (1997) “A New Gross Pollutant

Trap for Urban Drainage Systems ‘The In-

Line Litter Separator’”. School of Civil

Engineering, Swinburne University of

Technology Melbourne, Victoria. (9 pages)

Stenstrom M.K. and Lau S. (1999) “Catch

Basin Inserts to reduce Pollution from

Stormwater”. Proceedings of Conference on

Comprehensive Stormwater & Aquatic

Ecosystem Management . Auckland New

Zealand, 22-26 February, 1999. (12 pages)

Stormwater Committee (1999) “Urban

Stormwater - Best Practice Environmental

Management Guidelines.” CSIRO Publishing,

Collingwood Vic Australia. ISBN 0 643 06453

2. (268 pages)

Shaver E., Maxted J., Curtis G. and Carter

D. (1995) "Watershed Protection Using an

Integrated Approach", in Stormwater NPDES

Related Monitoring Needs. H.C. Torno, ed.,

American Society of Civil Engineers, New

York, NY. (pp.435-459)

University of South Australia (1998)

“Performance Assessment of the Rocla

CleansAll™”. Prepared for Rocla Pipeline

Products by The Urban Water Resources

Centre, February 1998. (12 pages)

University of South Australia (1998) “Testing of the Ecosol RSF 4000 for Hydraulic

Headloss”. Prepared for Ecosol Pty Ltd by

The urban Water Resources Centre, 23 rd

January 1998. (37 pages)

USEPA (1993) "Handbook - Urban Runoff

Pollution Prevention and Control Planning".

United States Environmental Protection

Agency EPA625-R-93-004. (175 pages)

USEPA (1999) “Storm Water Technology

Fact Sheet – Sand Filters”. United States

Environment Protection Agency EPA 832-F-

99-007. (7 pages)

Williamson R.B. (1991) “Urban Runoff Data

Book”. Water Quality Centre Publication

No.20, National Institute of Water and

Atmospheric Research, Hamilton, NZ. (51 pages)

Appendix A

For the purposes of this paper, the following terms (taken from the Draft Stormwater Quality

Control Policy for Penrith City Council) have been defined as:

“Approval”/ “Approved” a consent, licence or permission or any form of authorisation issued by Council.

“Debris” accumulated material that is not necessarily of anthropogenic origin e.g leaf litter, branches, garden refuse, etc.

“Development” means: a) the use of land, and

“Free Oil”

“First Flush” b) c) d) e) the subdivision of land, and the erection of a building, and the carrying out of works, and the demolition of a building or work, and f) any other act, matter or thing referred to in section 26

(Environmental Planning and Assessment Act, 1979) that is controlled by an environmental planning instrument. free floating viscous liquids that do not emulsify in aqueous solution e.g. cooking oil, motor oil etc. treatment strategy shall meet the following criteria where: a) Cat chments ≤ 5 ha i) Gross Pollutants – a Treatable Flow Rate = 60 L/s/ha, with sufficient storage volume to retain the pollutants generated by the 1 st 30 mm of runoff; ii) Fine Particulates – a Treatable Flow Rate = 10 L/s/ha, with sufficient storage volume to retain the pollutants generated by the 1 st 13 mm of runoff; b) Catchments > 5 ha

Compliance with the modelling techniques in Appendix F Managing

Urban Stormwater: Council Handbook (Draft) NSW EPA (1997);

Minimum Treatable Flow Rate equivalent to the 6-month ARI critical storm for the catchment (maximum duration of 15 minutes for urbanised catchments

≤20 ha.);

“Gross Pollutants”

“Litter” term used to collectively describe litter and debris transported by urban runoff, of a size that may be retained by a 5 mm mesh screen. all material of human (anthropogenic) origin that is capable of being mobilised by stormwater runoff.

“Nutrients” a substance that provides nourishment to another organism. For the purposes of stormwater runoff it may be defined as Total

Nitrogen(TN) consisting of nitrate nitrogen (NO

3

-N), nitrite nitrogen

(NO

2

-N), ammonium nitrogen (NH

4

+ -N) and organic nitrogen, and

Total Phosphorus (TP) consisting of; filterable phosphorus

(orthophosphate PO

4

-3 -P, condensed phosphates, organic phosphorus and colloidal phosphorus); and particulate phosphorus

(organic particles and inorganic particles that may or may not be adsorbed to fine particulates).

“Pollutant”

“Sediment” a contaminant that adversely alters the physical, chemical, or biological properties of the environment. solid material of varying size, both mineral and organic, that is in suspension, is being transported, or has been moved from its site of origin by air, wind, water or gravity, and comes to rest on the earth’s surface either above or below sea level. Coarse Sediment is defined as soil partic les ≥0.5 mm in diameter. Fine Particulates are defined as all material ≥0.02 mm but <0.5 mm in diameter.

Fine

Sediment is the fraction of soil consisting of silt (0.002 mm to 0.02 mm in diameter) and clay (<0.002 mm in diameter).

“Soil” 1.(Agronomy) the unconsolidated mineral and organic matter on the immediate surface of the earth that serves as a natural medium for the growth of land plants.

2.(Engineering) earth and rock particles resulting from the physical and chemical disintegration of rocks, which may or may not contain organic matter. It includes fine materials (silts and clays), sand and gravel.

“Total Suspended Solids”

include a range of inorganic and organic particles suspended in the water column, which can be defined as the filterable residue retained on a 2.0 μm pore size filter dried at 105˚C.

“Treatable Flow Rate” the minimum flow that a pollution control device must be capable of treating, without bypass, to achieve the desired gross pollution retention criteria for the particular Development Style and Catchment

Area. For the Cities of Blacktown and Penrith in western Sydney, the Treatable Flow Rate (TFR), for sites equal to or less than 5 ha in area, shall be 60 L/s for every hectare of catchment for gross pollutants and 10 L/s for every hectare of catchment for fine particulates. The goal of establishing a TFR is to capture and retain gross pollutants generated by the first 30 mm of runoff, and to capture and retain fine particulates generated by the first 13 mm of runoff.

Appendix B

Simplistic Format for Selecting a Particular Device

Before comparing individual devices it is necessary to first identify all the site constraints e.g. pollutant type, hydraulics, flooding, access, available infrastructure etc. and ensure that each of the devices can meet the specific needs of those constraints.

Appendix C

Author Biography

Geoff Hunter is the Engineering Coordinator: Stormwater at Penrith

City Council and has 30 years experience in Stormwater

Management, 17 years in Local Government and 13 years with private Consultants and Contractors. Penrith is located 60 kms west of Sydney on the Hawkesbury-Nepean River, at the foot of the Blue

Mountains

Geoff holds qualifications in Surveying, Soil and Water Management,

Stormwater Wetland Management and Environmental Management.

He was awarded a Churchill Fellowship to investigate “ The Use of

Wetlands for Soil and Water Management ” in the USA (1996) and a

Bursary from the IMEA to research “Comprehensive Stormwater

Manag ement” in NZ and the USA (1998). His areas of interest include Constructed Wetlands, Bio-filtration, sand filters, stormwater pollution control, natural resource management and stream rehabilitation. In the last 5 years, Geoff has presented numerous papers on Environmentally Sensitive Stormwater Management, structural stormwater controls and the impacts of urbanisation on aquatic ecosystems.

He is the Local Government representative to the Stormwater

Industry Association (NSW), provides technical assistance to the

State Stormwater Advisory Committee and is a member of the

Environment Panel of the Institute of Public Works Engineering

Australia (NSW)

Postal Address : Geoffrey Hunter, PO Box 63, Penrith NSW

Australia 2751

E-mail : watershed@bigpond.com