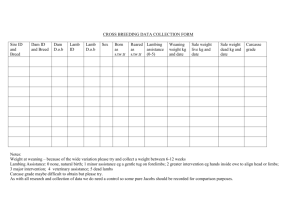

Economic evaluation of lamb production RD&E investment 1990/91

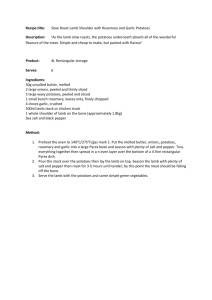

advertisement