Armstrong, A - Oxidative rearrangement - Spiral

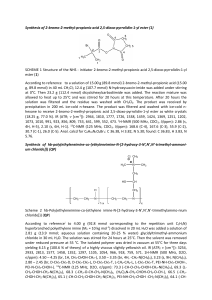

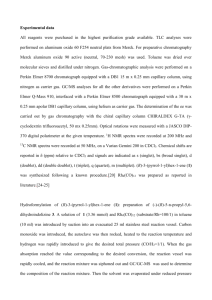

advertisement