[17] P.Stiuca, V.Chiroiu, CMNicolescu, ch.12, On the mechanical

advertisement

![[17] P.Stiuca, V.Chiroiu, CMNicolescu, ch.12, On the mechanical](http://s3.studylib.net/store/data/007616744_2-1887c0729fbaf3ba82043651e9efafea-768x994.png)

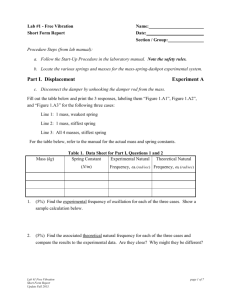

Proiect 106/2007, cod CNCSIS 247/2007 DIRECTOR PROEICT dr. Ligia Munteanu Title of the project KNOWLEDGE-BASED CHARACTERIZATION OF DAMPING CAPACITY OF NANOCOMPOSITES WITH AUXETIC MATERIALS AND CARBON NANOTUBES Abstract CONTROL. THE AUXETIC MATERIALS HAVE NEGATIVE POISSON’S RATIO (MOLECULAR CUBIC METALS AND FOAMS) ARE BIZARRE MATERIALS WHICH CAN BECOME FATTER WHEN STRETCHED. CARBON NANOTUBES HAVE THE ADVANTAGE OF INTERFACIAL SLIDING AT THE NANOTUBE-NANOTUBE AND NANOTUBE-POLYMER INTERFACES TO ENHANCE STRUCTURAL DAMPING WITHOUT SACRIFICING MECHANICAL PROPERTIES OR STRUCTURAL INTEGRITY. THE CHARACTERIZATION OF NANOCOMPOSITE FOILS IS ESSENTIAL TO ALLOW RESEARCHERS AND NANOMATERIAL PRODUCERS, IN PARTICULAR SMES, TO BE WELL AWARE OF THE STATEOF-THE-ART IN CHARACTERIZATION OF NANOMATERIALS. THE LIMITATIONS OF EXISTING INSTRUMENTATION AND METHODS SUCH NANOINDENTATION ARE: CALCULATION OF MODULUS OF ELASTICITY AND HARDNESS ARE LIMITED TO LINEAR, ISOTROPIC MATERIALS, NO INFORMATION IS OFFERED FOR VISCOELASTIC PROPERTIES AND DAMPING CAPABILITIES OF NANOSTRUCTURED MATERIALS. DAMPING CHARACTERIZATION OF MATERIALS IS AN OPEN PROBLEM, BEING LIMITED BY AN INCOMPLETE UNDERSTANDING OF MATERIAL PROPERTIES AT NANOSCALE. THE EXISTING METHODS FAIL IN NANOSCALE REGION AND CANNOT PREDICT DAMPING, BECAUSE MANY OF IMPORTANT PHENOMENA, SUCH AS DISCONTINUOUS ADHESIVE BINDING ENERGY, HYSTERESIS, DIFFUSION, CREEP, ATOMIC SHEAR, PLASTIC FLOW, RELAXATION, TEMPERATURE GRADIENTS, ARE NOT CONSIDERED. THE PROJECT IS ABLE TO OVERCOME THESE LIMITATIONS BY ADVANCING NEW IDEAS ON NANOINSTRUMENTATION AND MODELING OF DAMPING ACROSS THE LENGTH SCALES. THE PROJECT IS SET UP AS A 3-YEAR PROJECT WITH OBJECTIVES: 1) AUXETICITY WINDOW TO NANOCOMPOSITES; 2) CARBON NANOTUBES AS NOVEL HIGH PERFORMANCE DAMPING MATERIALS; 3) NANOCOMPOSITE FOILS WITH AUXETICS AND CARBON NANOTUBES INCLUSIONS; 4) A NEW CONCEPT FOR NANOINDENTATION, 5) CASE STUDY:ACOUSTIC NANOPANELS.. THE MANAGER OF THIS PROJECT PROPOSED TWO FP7 PROJECTS WITH PRACTICAL APPLICATIONS IN THIS DOMAIN. Research team: (without the project manager) Nr. crt. * Name Birth data Title Doctoral degree 1 Veturia Chiroiu 1942 Researcher I yes 2 Cristian Rugina 1969 Researcher I yes 3 Dan Dumitriu 1974 researcher yes 4 Daniel Baldovin 1978 researcher PhD student 5 Cornel Secara 1980 researcher PhD student 6 Ana Maria Mitu 1973 researcher PhD student 7 Valerica Mosnegutu 1973 researcher PhD student Signature Preamble The term auxetic is coming from the Greek word auxetos, meaning that which may be increase. Materials with a negative Poisson ratio are auxetic materials. Instead of getting thinner like an elongated elastic band, the auxetic material grows fatter, expanding laterally when stretched. An auxetic system is composed from different materials with different properties with a new mechanical architecture based on tailored properties. For example, the auxetic carbon-fibre reinforced composites or microporous polymers are auxetic systems with various enhancements in the strength and damping properties [1]. Since Iijima's original report [2], carbon nanotubes have been recognized as fascinating materials with nanometer dimensions promising exciting new areas of engineering. We refer to a new class of nanostructured damping materials that show dramatically improved acoustic properties compared to traditional viscoelastic damping polymers. With their nanoscale dimensions (high surface area to volume ratio), large aspect ratio, high stiffness, low density, excellent thermal stability and extremely high thermal conductivity, carbon nanotubes can provide very high damping and noise absorption with minimal weight penalty. Project Concept: Commercial need, technological project and research solution The ethical and practical reasons for making sure that materials and products are what they are supposed to be, are the heart of the commercial testing industry. Application with high reliability of any device that experiences damping ability can be successful only if the primary mechanisms of damping and mechanical properties are precisely known. Around the year of 2000 there were 5 nanoindenters in the world, and today there are at least 5 manufactures of nanoindenters, and about 180 labs in Europe in the field of instrumented nanoindentation testing. Up to 2006, over 1300 nanoindenters were sold in the EU and over 150000 in US. Almost all universities in Europe have bought at least one indenter, capable of 1200 mN maximum force with 0.1 N resolutions and 200 m maximum displacement with 0.02 nm resolution (a nanoindenter cost is about 250000 euro). The growth of nano-instrumentation industry revenue for the years of its history is presented in the diagram The indenters markets in Europe are loosing sales and market share to cheaper competition from US, where the nanoindenters market is highly developed, exploding into real money. The Minnesota Hysitron company (founded by Wyrobek in 1993) get the first grant to develop a nanoindenter from federal government of $70,000 in 1993, then the company grew - from less than $700,000 in 1995 revenue to more than $6 million in 2000 to $14 million in 2005, and more than $45 million in sales in 2006. But the current technologies cannot do damping characterization of the materials because conventional nanoindenters are used to characterize the elastic properties of material [3]. Damping characterization of materials is an open problem, being limited by the incomplete understanding of material properties on the nanoscale. The existing methods fail in the nanoscale region and cannot predict damping, because many of important phenomena are not taken into account. The project is set up as a 3-year project targeted to SMEs. The innovation consists in the design of new nanoinstrument able to measure the elastic and viscoelastic properties of nanomaterials, especially the damping capabilities. This innovation is suited to nanotechnology being addressed to nano-manufacturing as intelligent system of interest in input materials for nanotechnology industries. The innovative steps of the project are: ▪development of a new method to lay as a basis to enhanced nanoindentation technique ▪development of novel instrumentation to measure elastic and viscoelastic properties, with the emphasis on the damping on the the nanoscale and novel software. The expected result is designing a nanoindenter targeted at SMEs to mark the second generation of instrumented nanoindentation systems, operating in nanoand microhardness regimes and extending the testing capabilities of the first generation. Why is the damping important? Damping is the phenomenon by which mechanical energy is dissipated in dynamic systems. Knowledge of damping is important in utilization and testing of innovative materials, devices and processes and enhances quality control systems [4]. Why do we need new equipment for damping characterization? Recent results in improving and optimization of damping in nanomaterials on the nanoscale level, report novel structures which are widely used in aerospace and marine applications due to their specific stiffness and strength with respect to weight. The concept of this proposal is a new vision about the nanomaterials with high acoustic properties that allow better absorbion of noise. This vision is resulting from the very recent scientific results in the field of smart acoustic nanopanels. This proposal is focusing on the advancing of new concepts on nanoinstrumentation for characterizing the elastic and visco-elastic properties of nanomaterials, with applications to characterization of smart acoustic nanopanels for providing the local noise control of manned spaces and quiet zone generation in aircraft, vehicles and in high noise manufacturing areas. The nanopanels employ advanced nanocomposite foils (NF) and embedded micromechanical systems (MEMs) based acoustic and vibration sensors. The NF are nanocomposites with highly integrated inclusions of auxetic materials and carbon nanotubes. The auxetic materials with negative Poisson’s ratio (such as molecular auxetic cubic metals and foams) are bizarre materials which can become fatter when stretched, a phenomenon which is attracting the practical interest in the noise supression. Carbon nanotubes have a direct advantage of interfacial sliding at the nanotube-nanotube and nanotube-polymer interfaces to enhance structural damping without sacrificing mechanical properties or structural integrity. The characterization of NF is essential to allow researchers and nanomaterial producers, in particular SMEs, to be well aware of the state-of-the-art in characterization tools for nanostructured materials. The project is based on a new vision of the needs for understanding damping based on new theoretical and computational methods, useful tools to understand the relation between damping, nanocontacts and indentation. Indentation is accompanied by a series of phenomena reported by experiments but not explained by existent theories. The core of the project is to clarify these phenomena (DISCONTINUOUS ADHESIVE BINDING ENERGY, HYSTERESIS, DIFFUSION, CREEP, ATOMIC SHEAR, PLASTIC FLOW, RELAXATION, TEMPERATURE GRADIENTS). The progress of material science is intimately related to achievements of powerful modelling methods that make possible the examination of atomic and electronic structures on the nanometer level. The proposed equipment is able to control processes over a wide range of length scales, from atomic to macroscopic, being designed to have high resolution and increased sensitivity, and capable of working accurately. In new materials design and discovery, the proposed nanoinstrument is capable of manipulating and controlling the damping of materials on the atomic and nanolevels. Current State of the Art The history of nanoscale instrumentation is rather short, barely twenty years. That history dates back to the day in 1981 when Heinrich Rohrer and Gerd Binnig (IBM Research in Zurich), invented the scanning tunnelling microscope (STM). In the subsequent decades a wide range of machines and tools emerged, including especially the atomic force microscope (AFM).The motivation of the project consists in a future size of nanoinstrumentation market in Europe. While full range of competitors is global, most of the markets are dominated by US companies. This proposal offers a means of understanding the strategic importance of nanoinstrumentation in the nanotechnology landscape and suggests some key avenues for investment. The nanoindentation is a powerful set of tools for investigating the mechanical properties of materials in small dimensions. It refers to depthsensing indentation testing in the nanometer range by using machines that can make such tiny indentations while recording load and displacement with very high accuracy and precision, and analysis models by which the data can be interpreted to obtain hardness, modulus, and other mechanical properties [5]. The classical indentation tests by Brinell, Vickers, Knoop, and Rockwell [6] are primarily used to measure Young modulus and hardness of a material [7] but not the viscoelastic properties and damping capabilities. The Limitations of Existing Technologies The limitations of the current nanoindentation methods are: ▪ calculations of the modulus of elasticity (based on the unloading curve) and hardness are limited to linear, isotropic materials ▪ problems associated with the pile-up or sink-in of the material on the edges of the indent during the indentation process remain a question that is still under discussion ▪ no information is offered for the elastic and viscoelastic properties of nonlinear anisotropic, nonhomogeneous nanostructured materials ▪ no damping information for materials is offered [8], [9] ▪ the existing theories are falling outside the field of linear classical theories. The properties of materials of small dimensions are very different from those of comparable bulk materials [10], [11], [12]. The principal limit is given by the fact that the effects of intimate phenomena interacting on different scales are not taken into account (avalanche of discontinuities of adhesive binding energy, hysteresis, local diffusional flow, creep, generation and multiplication of dislocations, homogeneous shear of atomic planes, plastic flow, relaxation, temperature gradients [13]). Due to these lacks, the existing theories are not capable to achieve accuracy and high consistency in damping evaluation. This requirement is important in the area of material synthesis, where damping can serve to manipulate and control structures in situ on the atomic and nano-levels. The efficiency and accuracy of testing nanostructured materials and other materials to existing ASTM standards must be improved or replaced to meet new standards. More lab and SMEs managers want to purchase new testing instruments to reduce testing times and to improve the accuracy and reliability of testing machines. What new theories and concepts this project is advancing ? This project is focusing on: (1) development of a new method based on the novel approaches of nonlocal continuum theory and soliton theory [14], [15], [16], [17] applied to nanoindentation technique [18] in analysis and characterization of damping [19]; (2) development of adequate instrumentation for measurement the damping at nanoscale, including novel software. The project is based on previous results of the director of this project and of the research team in analyzing the nanoindentation tests for diamondlike carbon thin films and thin modulated foils [13]. The objectives of the project contribute towards a great technological vision based on the idea of using atomistic-scale simulation in future to point to new types of experiments, for example study of the ceramic-carbon nanotubes, nanocontacts, acoustic nanopanels with auxetic materials and carbon nanotubes. We will understand how the nanoindentation measurements can be used by coupled atomistic-mesoscopic-macroscopic theories to do a plausible explanation for the complex phenomena that accompany the indentation, and can be a precious tool for data interpretation and for the design of new experimental setups. The current knowledge and instrumentation fails in damping properties analysis when the feature sizes approach the 10 nm range or beyond. For example, damping of vibration has become an important requirement in the design of automotive and aerospace structures. Design considerations involve minimization of resonance amplitudes and extending the fatique life of structures subjected to near resonant vibrations under suddenly applied forces. For the present, some limited information on the materials with reduced damping can be obtained from displacement oscillations, but for materials with high damping, like natural rubber, the results are not accurate at all. An incorrect measure of damping, can cause design changes that can also cause undesirable reduction in stiffness and strength. The new concept consists in pushing the material by a line of indenters moving with velocity v, some of them acting on each surface of material in opposite directions, or acting on a single surface with the opposite surface clamped, as in the fig.1. In this way, it is possible to evaluate not only the elastic properties, but also the damping properties, free of substrate effect. The director of this project has studied the honeycomb structures and hexagonal chiral (noncentosymmetric) with negativ Poisson’s ratio (fig.1), composite plates (figs.2 and 3) and carbon nanotubes (figs.4 and 5) [20], [21], [22]. Details in [23] and [24]. Also, the team has studied with FEM the indentation problem with a plan indenter (fig.7). Fig.1. A honeycomb structure and a chiral (noncentrosymmetic) hexagonal structure with negative Poisson’s ratio [20], [21]. Fig. 2. The composite plate [20], [21]. Fig. 3. The homogenized Young’s modulus variation with respect to Poisson’s ratio of the auxetic material [20], [21]. Fig. 4. A cross section of a zigzag single-walled nanotube of carbon [22]. Fig. 5. The generation of solitonic deformations at the carbon nanotube bending [22]. Fig.6. Schematic representation of the concept of two indenters moving with the same velocity in the same direction on the specimen surface. Fig. 7. Indentation of a surface with a plan indenter. [1] Lakes, R. S., Experimental micro mechanics methods for conventional and negative Poisson's ratio cellular solids as Cosserat continua, J. Engineering Materials and Technology, 113, 148–155, 1991. [2] Iijima, S., Helical microtubules of graphitic carbon, Nature, London, 354, 56–58, 1991. [3] J.L.Hay, G.M. Pharr, Instrumentated indentation testing, ASM Handbook vol. 6 Mechanical testing and evaluation 2000, pp.231-242. [4] De Silva, Clarence W., Vibration: Fundamentals and Practice, Boca Raton: CRC Press LLC, 2000. [5] K.L. Johnson, Contact Mechanics, Cambridge University Press, Cambridge, MA, 1985. [6] W.D., Calliste. Jr., Materials science and engineering - An introduction, New York: John Wiley & Sons, Inc., 1996. [7] W.C. Oliver, G.M. Pharr, An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments, J. Mater. Res., vol 7, no. 6, 1992, pp 1564–1583. [8] J.L.Loubet, B.N. Lucas, W.C. Oliver, Some measurements of viscoelastic properties with the help of nanoindentation, NIST Special Publication 896: International Workshop on Instrumented Indentation, 1995, p 31–34. [9]V.Chiroiu, M.Mihailescu, L.Munteanu, ch.3, Applications of smart materials in engineering, in Advanced Engineering in Applied Mechanics (eds. L.Vladareanu, T.Sireteanu), 2006. [10] A.C. Eringen, Continuum mechanics at the atomic scale, Crystal Lattice Defects, 7, 1977, pp.109–130. [11] A.C. Eringen, On nonlocal continuum thermodynamics, Modern developments in thermodynamics, (ed. B. Gal-Or), John Wiley and Sons, New York, 1974, pp.121–142. [12] D. Dumitriu, V. Chiroiu, On the modelling of nanocontacts, Rev. Roum. Sci. Tech. - Méc. Appl.., 2006. [13] V.Chiroiu, D.Dumitriu, Post-doctoral program for devepment of new coupled atomistic-continuu theories with applications to modeling of nanocontacts and indentation, CEEX 1531/ report, 2006. [14] L.Munteanu, St. Donescu, Introduction to Soliton Theory: Applications to Mechanics, Book Series Fundamental Theories of Physics, vol.143, Kluwer Academic Publishers, 2004. [15] M.Mihailescu, V.Chiroiu, Advanced mechanics on shells and intelligent structures, Ed. Academiei, Bucuresti, 2004 [16]St.Donescu, L.Munteanu, ch.4, The effect of damping on the stability of dynamical systems, in Topics in Applied Mechanics, vol.2, Ed. Academiei, pp.85-117, 2004 (eds. V.Chiroiu , T.Sireteanu). [17] P.Stiuca, V.Chiroiu, C.M.Nicolescu, ch.12, On the mechanical behavior of nanostructured materials, in Topics in Applied Mechanics, vol.2, Ed. Academiei, pp. 355-391, 2004 (eds. V. Chiroiu, T.Sireteanu). [18]V.Chiroiu, C.Chiroiu, Probleme inverse in mecanica, Ed. Academiei, 2003 [19] D.Dumitriu, L.Munteanu, V.Chiroiu, L.Solomon, On the nonlocal theory of nanoindentation, Al 4lea Simpozion Mecatronica, Microtehnologii si Materiale Noi, Univ. Valahia din Targoviste, 7-8 dec. 2006, Revista Romana Mecanica Fina, Optica si Mecatronica, nr. 31 / 2006, pp.219-224. [20] L.Munteanu, St.Donescu, On the complexity and analysis of auxetic systems, Trends and Challenges in Applied Mathematics ICTCAM 2007, Bucharest 20-23 June 2007. [21] St. Donescu, V.Chiroiu, L.Munteanu, On the evaluation of the Young’s modulus for a laminated periodic composite structure based on auxetic materials, Rev. Roum. Sci,. Techn. serie Mecanique Appl., 2007. [22] N.-D. Stanescu, L. Munteanu, V. Chiroiu, N. Pandrea, Sisteme dinamice. Teorie si aplicatii, vol.1, Editura Academiei, 2007. [23] V. Chiroiu, C. Chiroiu, Inverse problems in mechanics, Springer, Series of Solid Mechanics and Its Applications (ed. Gladwell, G.M.L) [24]V.Chiroiu, P.Stiuca, L.Munteanu, St.Donescu, Introducere in nanomecanica, Editura Academiei, 2005. Scientific & Technological Objectives The overall aim of the project is to develop the concepts for a new equipment & method for measurement of the elastic and viscoelastic properties (with damping capabilities) of materials on the nanoscale, based on novel approaches (case study acoustic nanopanels with auxetic materials and carbon nanotubes). The research is based on the top recent results in the world in the area of smart acoustic nanopanels with high acoustic properties: auxetic materials and carbon nanotubes. The smart acoustic panel will reduce radiating noise by employing these advanced materials and actuation embedded MEMs based acoustic and vibration sensors. No Objectives 1 3 New scientific knowledge of the correlation between the properties and nanostructure of materials in detail by a combination of synthesis, mechanical property measurements, nanostructural examination and modeling. Development of technological capability of new non-local method PreisachTzitzeica as a basis for nanoindentation and damping characterization. A new idea of an auxeticity window to nanocomposites 4 Carbon nanotubes as novel high performance damping materials 5 Nanocomposite foils with auxetic materials and carbon nanotubes 6 A new concept for nanoindentation 7 Technology integration & design of a responsive instrumentation to measure the elastic and viscoelastic properties of materials, including novel software Case study: acoustic nanopanels with auxetic materials and carbon nanotubes 2 8 9 10 11 Technology analytical validation of virtual nanoinstrument (case study results experimental virtual setups, data interpretation, comparisons) Dissemination of knowledge Workflow scheduling and work plan for project management .. Quantification Reports and publications Reports and Publications Reports and Publications Reports and Publications Reports and Publications Reports and Publications Virtual Nanoinstrument Reports and Publications Reports. Data base Reports Reports The innovative character of DAMSYS is able to overcome the limitations of the current nanoindenation by: ▪ modeling of the damping mechanisms ▪ design of new machinery able to measure elastic and viscoelastic properties of materials on the nanoscale. The technology steps to be made to achieve that are: ▪ significant enhancing of the state of art in the domain by modeling of damping mechanisms over a wide range of length scales, from the atomic to the macroscopic ▪ novel nonlocal method Preisach-Tzitzeica originating from the well understanding of competition and interplay of several atomic scale damping mechanisms, in order to exploit size dependent damping phenomena, when the feature sizes approach the 10 nm range or beyond [1] ▪ creation of new equipment in the instrumented nanoindentation testing and vibration nanodamping. This task is based on a concept consisting in pushing the material by a line of indenters moving with velocity v, some of them acting on each surface of material in opposite directions, or acting on a single surface with the opposite surface clamped. In this way, it is possible to evaluate not only the elastic properties, but also the viscoelastic properties and damping properties, free of substrate effect. The concept of two indenters moving with the same velocity in the same direction of the surface of the specimen is represented in fig.6. More indenters may be used and a line of experiments for different problems (actuation and sensing, continuous dynamic analysis and quasi-static measurement of thin modulated multilayer foils, of ceramics reinforced with carbon nanotubes, modulated foils (fig.8) etc. Fig. 7. Modulated thin foils analysed by the research team of this project. Verification of the Novelty of the Concept & Specific Innovations No patent exists that covers the DAMSYS new method and designed equipment, we intend to create. The novel Preisach-Tzitzeica method applied to nanoindentatation improves existing methods and has a collection of results and techniques available in- house, developed by this team : V. Chiroiu, P. Stiuca, L. Munteanu, St. Donescu, Introduction to nanomechanics, Editura Academiei, Bucharest 2005. D. Dumitriu, V. Chiroiu, V., On the dual equations in contact elasticity, Rev. Roum. Sci. Tech. - Méc. Appl., 2006. D. Dumitriu, V. Chiroiu, J. Onisoru, J., On the elastic contact problem for a flat punch, 4th International Colloquium Mathematics in Engineering and Numerical Physics, 6-8 Oct. 2006, Bucharest, 2006. D.Dumitriu, L. Munteanu, V. Chiroiu, L. Solomon, On the nonlocal theory of nanoindentation, The 4th Simposium Mecatronics, Microtechnologies and New Materials, Revista Romana Mecanica Fina, Optica si Mecatronica, nr. 31, 2006, pp.219–224. M.Scalerandi, P.P.Delsanto, V.Agostini, K.Van Den Abeele, P.A.Johnson. Local interaction simulation approach to modeling nonclassical, nonlinear behavior in solids, Journ.Ac.Soc.Am.113, 3049-3059, 2003. The characterization of storage and loss modulus (anelastic and viscoelastic materials) may partially be analyzed by using a DMA nanoindenter (MTS). This recent capability will be used in this project to compare the DAMSYS results to the DMA results. We will prove by this, that DAMSYS solution is able to characterize each individual material from the damping capacity point of view. For example, it is able to distinguish between the ceramic grain and metal matrix in a metal matrix composite powder with a ceramic reinforcement. The results can be used further to change damping properties of metal matrix composites with applications to aerospace engineering, and so on. Also, we will prove that the damping properties of auxetic systems, composed from different materials with a new architecture based on tailored properties, cannot be evaluated by using DMA. This is because the materials with a negative Poisson ratio (auxetics, polymers, composites, metals, ceramics, honeycomb structures, reticulated metal foams) cannot be modelled by the theory which stays on the base of DMA or other testing machines. The to-day testing of damping characteristics is still done with old machines at large loads and according to ASTM specifications. The damping testing requirements for advanced analytical instruments on the nanolevel for R&D, and the need to improve productivity in the quality testing lab are two distinct requirements, i.e. testing on the nanolevel and nanoindentation testing. Overall Work Plan Strategy Acquisition of a deeper scientific understanding of damping capacities of nanostructured materials and new methods towards employing technological capabilities in instrumented nanoindentation testing are the base for all WPs. The key of WPs is to develop methods and instrumentation for investigating the elastic and viscoelastic properties of nanostructured materials. For example, nanocomposites are polymer-based materials that have significantly enhanced mechanical performance. The mechanically significant multiphase and multilayer structures cannot be adequately reproduced ex situ in large specimens. This restricts conventional characterization approaches as uniaxial tension or compression tests. Nanoindentation provides a means for measurement of the mechanical properties of each phase or layer as a whole. This is a critical requirement of multiscale mechanical modeling that would predict mechanical and damping performance for given composition and microstructure.