Carbonate Cracking - API Balloting System 3.0

advertisement

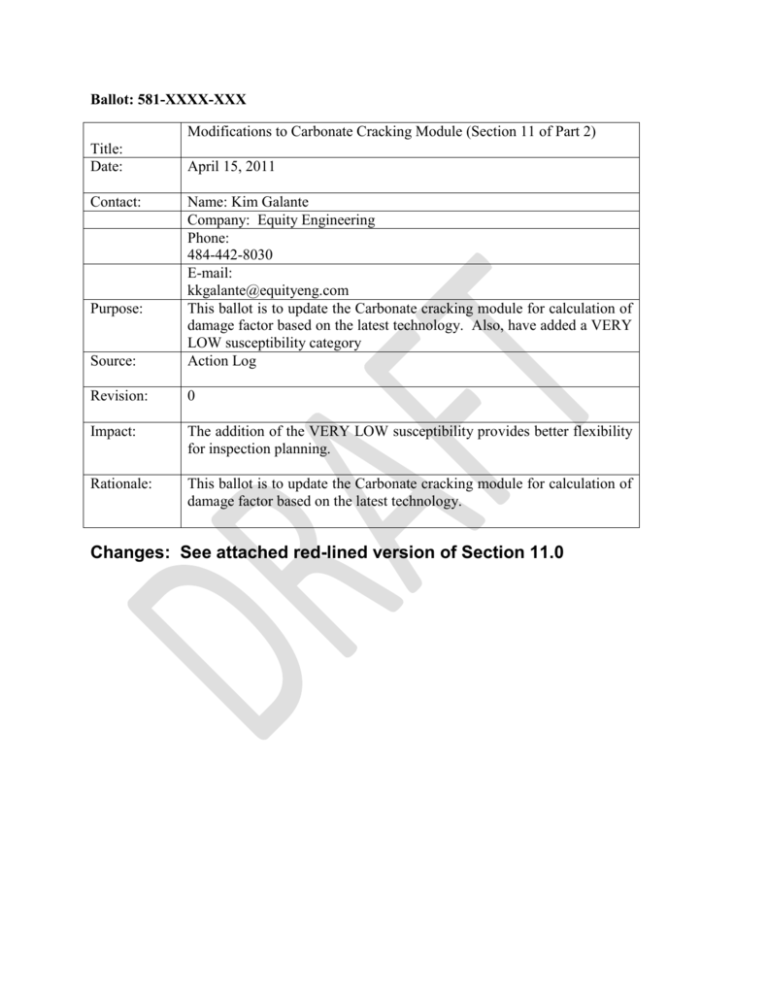

Ballot: 581-XXXX-XXX Modifications to Carbonate Cracking Module (Section 11 of Part 2) Title: Date: Contact: April 15, 2011 Source: Name: Kim Galante Company: Equity Engineering Phone: 484-442-8030 E-mail: kkgalante@equityeng.com This ballot is to update the Carbonate cracking module for calculation of damage factor based on the latest technology. Also, have added a VERY LOW susceptibility category Action Log Revision: 0 Impact: The addition of the VERY LOW susceptibility provides better flexibility for inspection planning. Rationale: This ballot is to update the Carbonate cracking module for calculation of damage factor based on the latest technology. Purpose: Changes: See attached red-lined version of Section 11.0 11 SCC DAMAGE FACTOR – CARBONATE CRACKING 11.1 Scope The damage factor calculation for components subject to alkaline carbonate stress corrosion cracking (ACSCC) is covered in this paragraph. 11.2 Description of Damage Carbonate cracking is the common term applied to surface-breaking cracks that occur at or near carbon steel welds under the combined action of tensile stress and in the presence of an alkaline sour water containing moderate to high concentrations of carbonate (CO 3). On a macroscopic level, carbonate cracking typically propagates parallel to the weld in the adjacent base metal, but can also occur in the weld deposit or heat-affected zones. At times, ACSCC may be mistaken for SSC or SOHIC, but further review will show that carbonate cracking is usually located further from the toe of the weld and contains multiple, parallel cracks. At times, the pattern of cracking observed on the steel surface is described as a “spider web” of small cracks, which initiate at or interconnect with weld-related flaws that serve as local stress risers. Finally, from the microscopic perspective the intergranular, oxide-filled cracks are similar in appearance to caustic stress corrosion cracking and amine cracking. Historically, carbonate cracking has been most prevalent in fluid catalytic cracking unit (FCCU) main fractionator overhead condensing and reflux systems, the downstream wet gas compression system, and the sour water systems emanating from these areas. Based upon recent survey results, sour water strippers with side-pumparound designs, Catacarb/CO2 removal facilities for hydrogen manufacturing units and delayed coker light ends units have been added to the list of affected units. In all instances, both piping and vessels are affected. Assuming the presence of a free water phase containing H2S, three key parameters are used to assess the susceptibility to carbonate cracking; pH of the water, carbonate concentration of the water, and the residual stress level of the exposed carbon steel. Typical pH’s are in the 8-10 range. Regarding contaminant/additive concentrations, no threshold for H2S has been identified; no evidence exists to indicate cyanides or polysulfides have any impact; and increased ammonia (NH3) concentrations will directionally increase ACSSS likelihood. As for residual stress levels, they typically emanate from welding, but can be associated with cold worked areas. Studies have concluded that the sour water’s corrosion electrochemical potential can be used to assess the likelihood of ACSCC. However, accurate measurement in a field environment is difficult. Therefore, further discussion of the electrochemical potential is outside the scope of this document. With regard to mitigation techniques, the application of a post fabrication stress-relieving heat treatment (e.g. postweld heat treatment) is the most commonly used method of preventing carbonate cracking. A heat treatment of about 649°C - 663°C [1200°F-1225°F] in accordance with WRC 452 is considered effective. The heat treatment requirements apply to all exposed welds as well as any external welds with heat affected zones (HAZ) in contact with the service environment. Other mitigation techniques include: process barriers (either organic or metallic), alloy upgrades (solid or clad 300SS, Alloy 400 or other CRA), effective water washing and inhibitor injection. 11.3 Screening Criteria If the component’s material of construction is carbon or low alloy steel and the process environment contains “free” sour water at pH > 8 in any concentration, then the component should be evaluated for susceptibility to carbonate cracking. 11.4 Required Data The basic component data required for analysis is given in Table 5.1 and the specific data required for determination of the carbonate cracking damage factor is provided in Table 11.1. 11.5 Basic Assumptions The main assumption in determining the damage factor for carbonate cracking is that the damage can be characterized by a susceptibility parameter that is designated as high, medium, or low based on process environment, material of construction, and component fabrication variables (i.e. heat treatment). Based on a susceptibility, a Severity Index can be determined that a measure of the susceptibility of the component cracking (or the probability of initiating cracks) and the probability of a crack resulting in a leak. If cracks are detected in the component during an inspection, the susceptibility is designated as High, and this will result in the maximum value for the Severity Index. Cracks that are found during an inspection should be evaluated using Fitness-For-Service methods in API 579 [10]. 11.6 Determination of the Damage Factor 11.6.1 Overview A flow chart of the steps required to determine the damage factor for carbonate cracking is shown in Figure 11.1. The following paragraphs provide additional information and the calculation procedure. 11.6.2 Inspection Effectiveness Inspections are ranked according to their expected effectiveness at detecting carbonate cracking and correctly predicting the rate of damage. Examples of inspection activities for carbonate cracking that are both intrusive (requires entry into the equipment) and non-intrusive (can be performed externally), are provided in Table 11.2. The effectiveness of each inspection performed within the designated time period must be characterized in accordance with Table 11.2. The number and category of the highest effective inspection will be used to determine the damage factor. If multiple inspections of a lower effectiveness have been conducted during the designated time period, they can be equated to an equivalent higher effectiveness inspection in accordance with paragraph 4.4.3. 11.6.3 Calculation of the Damage Factor The following procedure may be used to determine the damage factor for carbonate cracking, see Figure 11.1 a) STEP 1 – Determine the number of inspections, and the corresponding inspection effectiveness category using paragraph 11.6.2 for all past inspections. Combine the inspections to the highest effectiveness performed using paragraph 4.4.3. b) STEP 2 – Determine the time in-service, age , since the last Level A, B, C or D inspection was performed. c) STEP 3 – Determine the susceptibility for cracking using Figure 11.1 and Table 11.3 based on the pH of the water and CO3 concentration, and knowledge of whether the component was subject to PWHT. Note that a HIGH susceptibility should be used if cracking is known to be present. d) STEP 4 – Based on the susceptibility in STEP 3, determine the severity index, e) STEP 5 – Determine the base damage factor for carbonate cracking, SVI , from Table 11.4. Dcarbonate , using Table 7.4 fB based on the number of, and the highest inspection effectiveness determined in STEP 1, and the severity index, SVI , from STEP 4. STEP 6 – Calculate the escalation in the damage factor based on the time in-service since the last inspection using the age from STEP 2 and Equation (2.21). In this equation, it is assumed that the probability for cracking will increase with time since the last inspection as a result of increased exposure to upset conditions and other non-normal conditions. f) D carbonate D carbonate age f fB 1.1 (2.1) 11.7 Nomenclature is the in-service time since the last Level A, B, C or D inspection was performed age Dcarbonate f D carbonate fB SVI is the damage factor for carbonate cracking is the base value of the damage factor for carbonate cracking is the severity index 11.8 References 1. R. D. Merrick, “Refinery Experiences with Cracking in Wet H 2S Environments,” Materials Performance 27, 1 (1988), pp. 30–36. 2. J. H. Kmetz and D. J. Truax, “Carbonate Stress Corrosion Cracking of Carbon Steel in Refinery FCC Main Fractionator Overhead Systems,” NACE Paper #206, CORROSION/90. 3. H. U. Schutt, “Intergranular Wet Hydrogen Sulfide Cracking,” NACE Paper #454, Corrosion/92 (see also “Stress Corrosion Cracking of Carbon Steel in Amine Systems,” NACE paper #187, Corrosion/87) (see also Materials Performance 32, 11 (1993), pp. 55-60). 4. E. Mirabel et al, “Carbonate-type Cracking in a FCC Wet Gas Compressor Station”, Materials Performance, July, 1991, pp.41-45. 5. NACE Publication 34108, “Review and Survey of Alkaline Carbonate Stress Corrosion Cracking in Refinery Sour Water”, NACE International, Houston, TX, 2008. 6. M. Rivera et al, “Carbonate Cracking Risk Assessment for an FCCU Gas Plant”, Paper #04639, NACE International, Houston, TX, 2004. 7. D. Milton et al, “FCCU Light Ends Plant Carbonate Cracking Experience”, Paper #07564, NACE International, Houston, TX 2007. 8. WRC Bulletin 452, “Recommended Practices for Local Heating of Welds in Pressure Vessels”, Welding Research Council (WRC), Shaker Heights, OH. 11.9 Tables Table 11.1 – Data Required for Determination of the Damage Factor – Carbonate Cracking Required Data Comments Susceptibility (Low, Medium, High) The susceptibility is determined by expert advice or using the procedures in this paragraph. This type of cracking may be sporadic and may grow rapidly depending on subtle changes in the process conditions. Periodic monitoring of process pH and CO3-2 in FCC sour waters should be done to determine cracking susceptibility. Presence of Water (Yes or No) Determine whether free water is present in the component. Consider not only normal operating conditions, but also startup, shutdown, process upsets, etc. Presence of H2S in the Water (Yes or No) Determine whether H2S is present in the water phase in this component. If analytical results are not readily available, it should be estimated by a knowledgeable process engineer. pH of Water Determine the pH of the water phase. If analytical results are not readily available, it should be estimated by a knowledgeable process engineer. CO3 Concentration in Water Determine the carbonate concentration of the water phase present in this component. If analytical results are not readily available, it should be estimated by a knowledgeable process engineer. Age (years) Use inspection history to determine the time since the last SCC inspection. Inspection Effectiveness Category The effectiveness category that has been performed on the component. Number of Inspections The number of inspections in each effectiveness category that have been performed. Table 11.2 – Guidelines for Assigning Inspection Effectiveness – Carbonate Cracking Inspection Effectiveness Category Intrusive Inspection Example None A Highly Effective Wet fluorescent magnetic particle testing (WFMT) of 100% of repair welds and 50-100% of other welds/cold bends. Alternating Current Field Measurement (ACFM) can also be used to detect and size surface breaking cracks. See Notes below. B Usually Effective WFMT or ACFM of 20-49% of welds/cold bends. See Notes below. Shear wave ultrasonic testing of 50100% of welds/cold bends; or Acoustic Emission testing with follow-up shear wave UT. WFMT or ACFM of less than 20% of welds/cold bends; or Dry magnetic particle testing of 50100% of welds/cold bends; or Shear wave ultrasonic testing of 20-49% of welds/cold bends. Dry magnetic particle testing of less than 50% of welds/cold bends. Shear wave ultrasonic testing of less than 20% of welds/cold bends; or Radiographic testing; or Visual inspection for leaks. Visual inspection. Although cracks may be seen visually in more progressed damage, WFMT or ACFM is best for crack detection. No inspection Inspection Category C Fairly Effective D Poorly Effective E Ineffective Non-intrusive Inspection Example NOTES: 1. When cracking is identified, it is suggested that metallographic techniques, in-situ or destructive, be used to confirm the cracking mechanism. Table 11.3 – Susceptibility to Cracking – Carbonate Cracking Susceptibility to Cracking as a Function Residual Stress and of CO3 Concentration in Water Effective PWHT, possible cold working pH of Water CO3 < 100 ppm < 8.0 Very Low ≥ 8.0 Very Low Unknown or Ineffective PWHT, possible cold working CO3 ≥ 100 ppm CO3 < 100 ppm CO3 ≥ 100 ppm Very Low Low Medium Low Medium High Table 11.4 – Determination of Severity Index – Carbonate Cracking Susceptibility Severity Index – High 1000 Medium 100 Low 10 Very Low 1 SVI 11.10 Figures STEP 1: Determine the number of inspections and the corresponding inspection effectiveness category for all past inspections. For all past inspections, combine inspections to the highest effectiveness performed. STEP 2: Determine the time in-service, age, since the last inspection. Cracks present? Yes No pH of Water STEP 3: Determine the susceptibility for cracking using Table 11.3 High Susceptibility CO3 Residual Stress STEP 4: Determine the severity index from Table 11.4. STEP 5: Determine the base damage factor for carbonate cracking using Table 7.4. STEP 6: Calculate the escalation in the damage factor using Equation 2.21. Figure 11.1 – Determination of the Carbonate Cracking Damage Factor