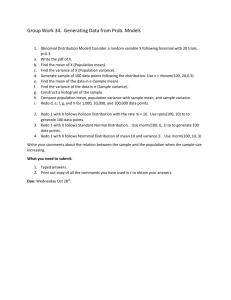

Exercise

Split Plot Analysis

Case Study

This case study on factors affecting the lifetimes of electronic components is used to introduce the basic ideas of split-plot analysis.

It starts with an inappropriate analysis that ignores the plot structure, notes why the structure makes that analysis inappropriate and proceeds towards an appropriate analysis.

The first step is to recognise the distinction between analysis of factors that vary at the whole plot level and analysis of factors that vary at split plot level, within the whole plots. The former may be implemented by a straightforward randomised blocks analysis. The latter is facilitated by designating the block effect to be a random effect, which produces separate levels of chance variation, one appropriate to the whole plot analysis and a second appropriate to the split plot analysis.

Understanding the distinctions between different levels of chance variation and their implications for interpretation of the analysis of variance tables, specifically, the definition of the F-ratios calculated in the table, requires some knowledge of the expected values of the mean squares in the table. Minitab provides formulas for these expected means squares which, when suitably interpreted, shed light on the matter. They also provide a basis for calculating the components of variance corresponding to the various sources of variation.

The basic interpretations of the analysis of variance table indicate the relevant summary graphs and tables that summarise the conclusions of the experiment in a format suitable for client reports.

Standard diagnostics are available for assessing the validity of the standard assumptions. In this case, all seems well.

However, there appears to be evidence of departure from assumptions usually associated with split plot designs. These are examined and commented on.

The study

Electronic components are baked in an oven at a set temperature for a set time. Two factors thought to influence the life times of the components were the oven temperature and the bake time. Trial settings for these factors were chosen as follows:

Oven Temperature (T), °F, 580, 600, 620, 640,

Baking time (B), min, 5, 10, 15.

To save on costly runs, three components were baked together at each temperature, with one withdrawn at each of the set times. This plan was replicated 3 times. The results are shown in

Table 1.

Sources of variation

The response variable

Lifetime, is affected by variation in 2 treatment factors,

Temperature of Oven (T), with 4 levels, 580, 600, 620, 640, and

Baking Time (B), with 3 levels, 5, 10, 15,

Replicate

3

2

1

Table 1 Results of accelerated life time tests for electronic components

Temperature of Oven (°F)

580

600

620

640

580

600

620

640

580

5

217

158

229

223

188

126

160

201

162

Baking Time (min.)

10

233

138

186

227

201

130

170

181

170

15

600

620

122

167

185

181

180

182

as well as variation between

Replicates (R),

640 182 201 and chance variation.

A possible analysis

If this was a standard fully randomised experiment, with each of the 4×3 = 12 treatment

199 combinations being run in random order, independently within each replication, then it would constitute a straightforward randomised blocks experiment, with replicates, presumably run at different times, acting as blocks.

A suitable model for this analysis would include all main effects and 2-factor interactions, including replicates as blocks, with the three way interaction of Temperature, Baking Time and

Replication used to estimate random error, that is,

T + B + R + T*B + T*R + B*R +

.

Using Minitab to fit this model (entered in the Model window as above, without the

, which

Minitab includes automatically) leads to

Analysis of Variance for Lifetime, using Adjusted SS for Tests

Source DF Seq SS Adj SS Adj MS F P

T 3 12494.3 12494.3 4164.8 17.16 0.000

B 2 566.2 566.2 283.1 1.17 0.344

R 2 1962.7 1962.7 981.4 4.04 0.045

T*B 6 2600.4 2600.4 433.4 1.79 0.185

T*R 6 1773.9 1773.9 295.7 1.22 0.362

B*R 4 7021.3 7021.3 1755.3 7.23 0.003

Error 12 2912.1 2912.1 242.7

Total 35 29331.0

175

152

155

156

195

147

161

172

213 page 2

The principal conclusions from these (partial) results are that the main effects of changing Temperature are highly statistically significant, the main effects of changing Baking Time are not statistically significant, there is no statistically significant interaction between the two factors.

Supplementary conclusions are that blocking appears to have been effective, although not necessary to arrive at the principal conclusions, there is a highly statistically significant interaction between Baking Time and Blocks

(Replications).

The latter conclusion, if confirmed, is unexpected and needs explanation. (This issue will be returned to below).

An appropriate analysis for Temperature effects

The analysis shown above is inappropriate because, at each level of Temperature, the same oven set-up was used for the three Baking time levels. Thus, in the case where the 12 treatment combinations are run in random order, as per the above analysis, the oven temperature must be re-set between each run (unless, by chance, 2 successive runs are at the same Temperature), while in the case of the actual experiment described at the outset, the oven temperature is set up once at each Temperature level, and 3 runs at different Baking times are completed before the oven is re-set.

This restricted set-up of the actual experimental means that the chance variation between the three runs within each Temperature set-up is likely to be less than the chance variation between runs at different Temperatures. In particular, for comparing variation between Temperature settings, variation within Temperature settings does not provide an appropriate measure of chance variation.

For the purpose of finding an appropriate measure of chance variation to use as a basis for assessing Temperature effect (a denominator for F), one solution is, first, to average the

Lifetimes within each Temperature level and, second, to analyse the summarised data appropriately. Averaging the Lifetimes within each Temperature level ignores both the Bake

Time effects and the chance variation around each within-Temperature mean, that is, the within-

Temperature chance variation. Variation between runs at different temperatures, replicated, remains and is available as a basis for calculating an estimate of variance appropriate to serve as a reference for a measure of variation between Treatment levels, that is, a denominator for the corresponding F-ratio.

The original data table with the within-Temperature averages (means) added follows. page 3

Replicate

1

2

Temperature of Oven (°F)

580

600

620

640

580

600

620

640

A more conventional display is

3

2

1

5

Baking Time (min.)

620

640

580

600

620

640

580

600

620

640

580

600

217

158

229

223

188

126

160

201

10

233

138

186

227

201

130

170

181

194.7

134.3

163.7

184.7

181.7

162.3

176.7

194.0

15

175

152

155

156

195

147

161

172

Mean

208.3

149.3

190.0

202.0

194.7

134.3

163.7

184.7

3 580

600

620

162

122

167

170

185

181

213

180

182

181.7

162.3

176.7

640 182 201 199 194.0

As the individual measurements are irrelevant to the analysis of Temperature effects, this may be reduced to

Replicate

Temperature of Oven (°F)

Mean

208.3

149.3

190.0

202.0

Temperature of Oven (°F)

580

600

620

1

208.3

149.3

190.0

Replicate

2

194.7

134.3

163.7

3

181.7

162.3

176.7

640 202.0 184.7 194.0

If we regard Replicates as Blocks, this may be regarded as a randomised blocks layout. The formal analysis of variance for randomised blocks was introduced in Lecture 1.2. For these data, the results from Minitab are as follows. page 4

General Linear Model: Life versus R, T

Factor Type Levels Values

R fixed 3 1, 2, 3

T fixed 4 580, 600, 620, 640

Analysis of Variance for Life, using Adjusted SS for Tests

Source DF Seq SS Adj SS Adj MS F P

R 2 654.24 654.24 327.12 3.32 0.107

T 3 4164.77 4164.77 1388.26 14.09 0.004

Error 6 591.31 591.31 98.55

Total 11 5410.32

S = 9.92736

The conclusions to be drawn from this analysis are broadly the same as the corresponding conclusions from the earlier, inappropriate, analysis, i.e., the effect of changing Temperature is highly statistically significant, blocking appears to have been effective.

The corresponding F-ratios are somewhat smaller, and that corresponding to Replication

(blocking) is not statistically significant at the conventional 5% level. The explanation for this will emerge shortly.

There is a much closer numerical correspondence between corresponding sums of squares and mean squares in the two analysis of variance tables; those in the first table are 3 times those in the second. For this purpose, note that the Error sum of squares in the second table corresponds to the R*T interaction in the first.

The factor of 3 arises because the within-Temperature means are means of 3 individual measurements. Recall that the variance of a mean of n measurements (square of the standard error), is 1/3 the variance of an individual measurement. The mean squares in the analysis of variance table are all "sample" variances based on the means.

Exercise: Confirm this numerical correspondence.

Note that the averages used in the second Minitab analysis must not be rounded, as in the summary data table above, to ensure exact correspondence. For the purposes of producing the second analysis of variance above, the means were calculated in Excel and copied with full accuracy into Minitab. Using the rounded means in the data table will not give an accurate correspondence.

Interpreting R*T interaction as Error

The correspondence between the R*T interaction sum of squares in the first analysis of variance table with the error sum of squares in the second recalls the assumption that the Block by

Treatment interaction amounted to chance variation when analysing randomised blocks in

Lecture 1.2 and Laboratory 1. Unfortunately, in both of those examples, there was graphical evidence to the contrary, a fact that was not evident to the original analysts.

In this case, there is some slight suggestion of Block*Treatment interaction, as shown in the following Interaction Plot. page 5

Block*Treatment Interaction

210

200

190

180

170

160

150

140

Replicate

1

2

3

130

580 600 620

Temperature

640

The pattern of parallel replicate profiles evident at the higher temperatures for all three replicates is broken by Replicate 3 at the lower temperatures, with mean lifetime for Replicate 3 low at temperature 580 and high at 600.

These exceptions correspond to the deleted residuals at

2.8, approximately, in the Diagnostic

Plot below.

Diagnostic Plot

3

2

-1

-2

1

0

-3

140 150 160 170 180 190 200 210

Fitted Value

These residual values are probably not sufficiently exceptional to warrant exclusion. While including them may give a somewhat conservative estimate of standard deviation, excluding them would probably result in two small a standard deviation. Thus, it seems sensible to regard the variation in the diagnostic plot as due to chance. Equivalently, we accept the assumption of no Block*Treatment interaction.

Split Plot Analysis

The randomised block analysis provided us with information on the main effect of one treatment factor, Temperature. For this purpose, we focussed on experimental units which were page 6

combinations of smaller units. Within each of the combined units, Temperature did not vary between these smaller units, so that variation at that level was irrelevant for comparing

Temperature levels and, therefore, for assessing Temperature effects.

However, the second treatment factor, Baking time, did vary between these smaller units. To get information on the second treatment factor, we need to make comparisons between such units. To do this, we need to make use of the split unit structure in the experiment.

The combined units are referred to as Whole units (or Whole plots in an agricultural setting).

The smaller units are referred to as Split units (or split plots). A split plot design is essentially hierarchical, with part of the design, here the randomised blocks design for assessing

Temperature, implemented at the whole plot level and the rest implemented at the split plot level.

Correspondingly, there are two basic Components of Variance, one at the Whole plot level and a second, typically smaller, at the split plot level. When interactions come into play, there will be other corresponding components of variance.

Replication (Blocking) as a Random Effects Factor

Minitab facilitates a split plot analysis by designating the blocking factor at the higher level to be a random effects factor.

In agricultural field trials, this is easily envisaged, where the variation in fertility from one physical block of experimental plots to another physical block may be substantial, but unpredictable, and so may be regarded as the outcome of a selection from a Normal

"population" of fertility levels, with an appropriate standard deviation,

B

, where B stands for

Blocking.

In the experiment being analysed here, the set up conditions from one replication of this experiment to another may be considerable, with environmental factors, staff factors, and timing of critical tasks, temperature gauge settings and more, varying more or less unpredictably.

Thus, the overall effect for any particular replicate may be regarded as the outcome of a selection from a Normal "population" of replication effects, with an appropriate standard deviation,

R

, where R stands for Replication.

Implementing the analysis.

The first step is to list the response variable and experimental factors. Here we have

Lifetime, Response:

Treatment Factors: Temperature (T)

Baking time (B)

Blocking Factor: Replication (R)

Next, list the terms in the model involving these factors:

T + R + T*R + B + T*B + R*B.

Note the gap between the top and bottom of the hierarchy; B is not involved at the top level and is involved in everything at the bottom level.

The 3-factor interaction T*R*B is not included; it is taken to reflect chance variation (Error) at the lower level, with standard deviation

E

, just as the T*R interaction represents chance variation at the top (randomised block) level. Note that some authorities make a further assumption that the page 7

R*B interaction is also negligible and so may be omitted or, equivalently, subsumed into chance variation at the lower level of the hierarchy. As this is not necessary, and as there is evidence from other experiments that blocks may well interact with treatment factors, it seems sensible to include it.

To understand the basis for the analysis of variance, we need information on the expected values of the various mean squares. This will tell us which mean squares to compare via an F ratio so that we can assess the statistical significance of the various factor effects. These

"Expected Mean Squares" will also show us how to calculate the individual variance components, like

2

R

,

2

E

, etc., although these are of less interest here.

Suitable factor plots and tables will help us interpret the results

Minitab output

A split plot analysis using Minitab General Linear Model gave the following analysis of variance table.

Analysis of Variance for Lifetime, using Adjusted SS for Tests

Source DF Seq SS Adj SS Adj MS F P

R 2 1962.7 1962.7 981.4 0.54 0.618 x

T 3 12494.3 12494.3 4164.8 14.09 0.004

R*T 6 1773.9 1773.9 295.7 1.22 0.362

B 2 566.2 566.2 283.1 0.16 0.856

T*B 6 2600.4 2600.4 433.4 1.79 0.185

R*B 4 7021.3 7021.3 1755.3 7.23 0.003

Error 12 2912.1 2912.1 242.7

Total 35 29331.0 x Not an exact F-test.

S = 15.5779

Preliminary analysis indicates that the Temperature effect is very highly statistically with an Fvalue of 14.09 and a p-value of 0.004, the B main effect is not at all statistically significant, there is no statistically significant T*B interaction, but the R*B interaction is highly significant. As noted earlier, this latter finding is remarkable.

Note that the first 3 lines of the analysis of variance table echo the randomised blocks analysis exactly (with the factor of 3 incorporated, see Exercise above).

Expected Mean Squares

Minitab gives the following coded information on expected mean squares, needed to understand the analysis of variance table

Expected Mean Squares, using Adjusted SS

Source Expected Mean Square for Each Term

1 R (7) + 4.0000 (6) + 3.0000 (3) + 12.0000 (1)

2 T (7) + 3.0000 (3) + Q[2, 5]

3 R*T (7) + 3.0000 (3)

4 B (7) + 4.0000 (6) + Q[4, 5]

5 T*B (7) + Q[5]

6 R*B (7) + 4.0000 (6)

7 Error (7) page 8

The key to decoding this table is that integers in parentheses represent variance components of the corresponding sources of variation. Thus,

(1)

↔ 2

R

,

(3)

↔ 2

RT

,

(6)

↔ 2

RB

,

(7)

↔ 2

E

The bigger is the value of a variance component, the bigger is the corresponding factor effect.

Also, the Q[ ... ] terms measure the effects of the corresponding fixed-effects factors. The formulas for these involve sums of squares of effects of the factor levels, hence the Q, meaning

Quadratic.

Integers in the form 4.0000 represent numbers of factor levels, or their product.

The Expected Mean Square formulas thus may be rewritten as

Mean Square Expected Mean Square

1 MS(R)

2

E

+ 4

2

RB

+ 3

2

RT

+ 12

2

R

2 MS(T)

2

E

+ 3

2

RT

+ Q[2]

3 MS(R*T)

2

E

+ 3

2

RT

4 MS(B)

2

E

+ 4

2

RB

+ Q[4]

5 MS(T*B)

2

E

+ Q[5]

6 MS(R*B)

2

E

+ 4

2

RB

7 MS(E)

2

E

Note that Q[2, 5] and Q[2, 5] have been simplified to Q[2] and Q[4] . These Q's really measure main effects; the "5" refers to a related interaction term.

Rationale for calculating F-ratios

Skipping the first line, note that the second and third lines differ by a measure of the T main effect. If that is 0, the ratio of expected mean squares is 1 and the corresponding F-ratio of actual mean squares will be close to 1. On the other hand, if the T main effect is not zero, the ratio of mean squares will exceed 1. Thus, if the actual F-ratio is considerably bigger than 1, it indicates that the T main effect is non zero.

The actual F-ratio in this case is MS(T)/MS(R*T) = 4164.8 / 295.7 = 14.08, differing by rounding error from the 14.09 shown in the analysis of variance table.

Similar arguments apply to the comparisons of lines 3 and 7, lines 4 and 6 and lines 6 and 7.

Exercise: Confirm the values of the F ratios in the Analysis of Variance table (other than that for R).

Line 1 does not correspond meaningfully to any other single line. It does correspond to

Line 3 + Line 6 – Line 7, page 9

differing by 12

2

R

. This provides a formal comparison for testing the R main effect. However, because of the minus sign in the comparison quantity, the F distribution does not apply exactly.

Since this tests the Blocking effect, an issue of secondary interest, the lack of an exact test is of no great consequence. The F-ratio may be used informally to assess whether blocking was effective.

Consequences of using the "right" error mean squares

Recall from the discussion of the randomised blocks analysis of the Temperature effect (p. 5) that the F-ratio for testing the Temperature effect, reproduced exactly in the split plot analysis, was somewhat smaller than the corresponding F-ratio in the original inappropriate analysis on pages 2-3. It now emerges that the "right" error mean square incorporates an additional component of variance, 3

2

RT

, in addition to the basic error variance,

2

E

. In the inappropriate analysis, the expected error mean square was simply

2

E

. This explains why the F-ratio for

Treatment effects was smaller in the split plot analysis (and in the appropriate randomised blocks analysis of p. 5) than in the inappropriate randomised blocks analysis of pp. 2-3.

For this reason, the effects of the factor(s) that vary between the whole plots only are determined with less precision than those that vary at the within plots level. Another reason is that there are more degrees of freedom associated with the within plots error mean square.

This is sometimes offered as a virtue of the split plot design, namely, that it offers the opportunity of examining some factors with more precision and others with less precision. In practice, particularly in industrial applications, split plot designs are used because of the cost or difficulty of changing the levels of one or more factors, which are then restricted to vary just between whole units.

Graphical and numerical summaries

The main effect plot and numerical summary for Temperature follow.

Temperature Main Effects

200

190

180

170

160

150

580 600

Temperature

620 640

Temperature

Mean Lifetime

580

195

600

149

620

177

640

194 page 10

Using Temperature 600 leads to very low lifetime, around 150, whereas close to 200 is achievable. Either something unusual happened when temperature was at 600 or there is a strong non-linear effect. If the latter proves correct, further exploration is recommended with a view to further improving the lifetime.

The interaction of Baking time and Replication is also highly statistically significant, which is not expected. The corresponding interaction plots and data table follow.

Interaction of Baking Time and Replication

210

200

R

1

2

3

190

180

170

160

5 10

Baking Time

15

Baking Time 1

Replicate

2 3

5

10

15

207

196

160

169

171

169

158

184

194

The effect of increasing baking time was approximately linear in all three replicates, but with negative slope in Replicate 1, positive slope on Replicate 3 and no effect in Replicate 2.

Clearly, further investigation is needed to explain such unexpected behaviour. The circumstances which caused a complete turn-around in the effect of increasing baking time between Replicate 1 and Replicate 3 need elucidation if any informed decision is to be made about the ideal baking time.

Components of Variance

Components of variance are not usually of such great interest in applications such as this, where the key issue is to assess the factor effects with a view to determining optimum operating conditions, as they are in assessing a measurement system, where the key issues involve reducing variation in the system. However, the same calculation methods apply and, in this case, there is an unusual aspect.

The Analysis of Variance table and the Expected Mean Square formulas are reproduced 0n the next page.

Substituting 242.7 from the analysis of variance table for MS(E) in the Expected Mean Squares table gives

ˆ 2

E

= 242.7 page 11

Analysis of Variance for Lifetime, using Adjusted SS for Tests

Source DF Seq SS Adj SS Adj MS F P

R 2 1962.7 1962.7 981.4 0.54 0.618 x

T 3 12494.3 12494.3 4164.8 14.09 0.004

R*T 6 1773.9 1773.9 295.7 1.22 0.362

B 2 566.2 566.2 283.1 0.16 0.856

T*B 6 2600.4 2600.4 433.4 1.79 0.185

R*B 4 7021.3 7021.3 1755.3 7.23 0.003

Error 12 2912.1 2912.1 242.7

Total 35 29331.0

The Expected Mean Square formulas

Mean Square Expected Mean Square

1 MS(R)

2

E

+ 4

2

RB

+ 3

2

RT

+ 12

2

R

2 MS(T)

2

E

+ 3

2

RT

+ Q[2]

3 MS(R*T)

2

E

+ 3

2

RT

4 MS(B)

2

E

+ 4

2

RB

+ Q[4]

5 MS(T*B)

2

E

+ Q[5]

6 MS(R*B)

2

E

+ 4

2

RB

7 MS(E)

2

E

In Line 6, substituting

ˆ 2

E

for

2

E

and 1755.3 for MS(R*B) leads to

ˆ 2

RB

= ¼(1755.3 – 242.7) = 378.2.

Repeating this calculation for Lines 3 leads to

ˆ 2

RT

= 1/3(295.7 – 242.7) = 17.7.

Finally, substituting

ˆ 2

E

for

2

E

,

2

RB

for

2

RB

,

ˆ 2

RT

for

2

RT

and 981.4 for MS(R) leads to

ˆ 2

R

= –68.91.

Comments

The first comment relates to the counterintuitive negative estimate of the variance

2

R

. This occasionally happens because all the contributions to this estimate, are individually subject to chance variation. When the actual value of

ˆ 2

E

,

ˆ 2

RB

,

ˆ 2

RT

and MS(R),

2

R

is close to 0, but still positive, the negative contributions to its estimate may outweigh the positive contributions and thus lead to a negative estimate.

The usual resolution of this problem is to replace the negative estimate by 0.

The very small value of

ˆ 2

RT

also deserves some comment. This implies that the set-up variation in changing oven temperature within each replicate is very small relative to other sources of variation. Given that the reason for running the experiment in split plot format is page 12

because of difficulty and / or expense in such set-up, the small value of

ˆ 2

RT

is surprising.

Closer study of the process is needed to try to understand this.

Diagnostics

Diagnostic analysis at the within plot level leads to the following plots.

Residuals Versus Fittted Values

3

2

1

0

-1

-2

-3

120 140 160 180

Fitted Value

200 220 240

Normal Diagnostic Plot

3

2

1

0

-1

-2

-3

-2 -1 0

Normal Score

1

As there is nothing remarkable about these plots, no action is required.

2 page 13