Personal Protective Equipment (PPE) Program for MIOSHA Personnel

advertisement

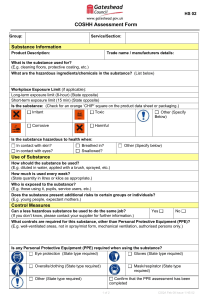

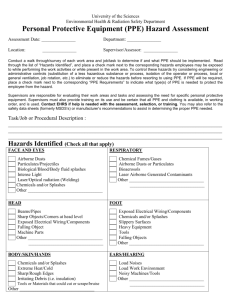

MIOSHA AGENCY INSTRUCTION Michigan Occupational Safety and Health Administration Michigan Department of Energy, Labor and Economic Growth DOCUMENT IDENTIFIER: DATE: MIOSHA-ADM-06-4R2 December 18, 2009 SUBJECT: Personal Protective Equipment (PPE) Program for MIOSHA Personnel ABSTRACT I. Purpose: The PPE Program for MIOSHA Personnel provides employees with the necessary information to understand the agency’s PPE requirements and provides MIOSHA PPE users with the means to obtain proper PPE from the agency. II. Scope: This procedure applies to all MIOSHA employees who utilize personal protective equipment. III. References: A. Agency Instruction ADM. #04-5, MIOSHA Safety and Health Management System B. MIOSHA Construction Safety Part 6, Personal Protective Equipment C. MIOSHA General Industry Part 33, Personal Protective Equipment D. MIOSHA Occupational Health Part 433, Personal Protective Equipment E. OSHA 29 CFR 1910.132, Personal Protective Equipment F. OSHA 29 CFR 1926.28, Personal Protective Equipment IV. Distribution: MIOSHA Staff; General; S drive and Internet accessible. V. Cancellations: This PPE procedure for MIOSHA employees cancels any MIOSHA agency-level document, policy, or procedure where there is a conflict. VI. Contact: Denise Thelen, Safety and Health Coordinator VII. Originator: __ Douglas Kalinowski, Director Michigan Occupational Safety and Health Administration MIOSHA-ADM-06-4R2 December 18, 2009 Personal Protective Equipment (PPE) Program for MIOSHA Personnel I. Purpose. The PPE Program for MIOSHA Personnel provides employees with the necessary information to understand the agency’s PPE requirements and provides MIOSHA PPE users with the means to obtain proper PPE from the agency. II. Scope. This procedure applies to all MIOSHA employees who utilize PPE, and includes employees who use their own PPE. This procedure does not cover respiratory protection, hearing protection, and job tasks that involve exposure to blood or other potentially infectious materials, because other procedures or instructions already cover these subjects. III. References. This procedure incorporates the requirements of: A. Agency Instruction ADM. #04-5, MIOSHA Safety and Health Management System B. MIOSHA Construction Safety Part 6, “Personal Protective Equipment” C. MIOSHA General Industry Part 33, “Personal Protective Equipment” D. MIOSHA Occupational Health Part 433, “Personal Protective Equipment” E. OSHA 29 CFR 1910.132, “Personal Protective Equipment” F. OSHA 29 CFR 1926.28, “Personal Protective Equipment” IV. Cancellation. This PPE procedure cancels any MIOSHA agency-level document, policy, or procedure where there is a conflict. V. Document Originator. This procedure was written by Michael T. Mason, reviewed by the Safety and Health Advisory Committee, and approved by the MIOSHA Director. VI. Expiration Date. This procedure is effective immediately and will remain in effect until canceled or superseded. VII. Personal Protective Equipment Program. A. Responsibilities. 1. It is the responsibility of the agency director or designee to: a) Establish PPE policies and procedures. b) Review and approve all changes to the MIOSHA PPE Program. c) Grant permission to MIOSHA employees to use their own PPE. d) Ensure that PPE and training are provided at no cost to PPE users. 1 MIOSHA-ADM-06-4R2 December 18, 2009 Personal Protective Equipment (PPE) Program for MIOSHA Personnel e) 2. 3. Arbitrate in any situation of disagreement regarding the adequacy of the program, PPE, etc. (this does not affect the union grievance procedures). Responsibilities of the MIOSHA Equipment Committee: a) Interface with MIOSHA staff and vendor personnel to determine which general and specialized equipment and materials to purchase based on efficiency and cost. b) Perform or obtain cost/price analysis, as appropriate. c) Write specification for product and solicit bids from potential vendors. Each division director and the Disaster Response Team Administrator may appoint a PPE Coordinator to coordinate their PPE program or divide the duties as appropriate. It is the responsibility of each division director and the Disaster Response Team Administrator to ensure that: a) Hazard assessments are conducted. b) Appropriate PPE is assigned. c) Affected employees receive training. d) Invoices for PPE, such as prescription safety glasses and safety footwear, are forwarded to the Finance Division of the Department of Energy, Labor and Economic Growth for payment. e) An evaluation of effectiveness of their current program is periodically conducted and any problems identified during the evaluation are corrected. f) Documentation of the program is maintained. Examples of information to document include, but are not limited to, the following: (1) Certifications of hazard assessment. (2) Certifications of training. (3) A list of items of PPE that the division or unit will provide and maintain. (4) A list of items of PPE that employees, with supervisory approval, may use and maintain at their own expense. 2 MIOSHA-ADM-06-4R2 December 18, 2009 Personal Protective Equipment (PPE) Program for MIOSHA Personnel (5) 4. 5. 6. B. A list that shows what PPE has been provided to whom and when it needs to be replaced. The Management and Technical Services Division, Laboratory and Equipment Services Section (LESS), has the following responsibilities: a) Process purchase orders for PPE, replacement parts, accessories, and cleaning supplies. b) As instructed by the division or unit purchasing the PPE, stock inventories of PPE in various sizes and styles and ensure that spare parts are available. c) Service, return to the manufacturer, or contract with a trained technician for the repair or servicing of PPE. The Safety and Health Coordinator has the following responsibilities: a) Keep a master copy of the PPE program on file. b) Make the written PPE program, certifications of hazard assessment and training available upon request to affected employees and other authorized individuals for examination and copying. MIOSHA PPE users have the following responsibilities: a) Follow the requirements of the PPE program of their particular division or area, or abide by an employer’s PPE policy, whichever requires the greater protection. b) Use PPE as necessary. c) Attend required training sessions. d) Care for, clean, and maintain PPE as necessary. e) Inform supervision of the need to repair or replace PPE. f) Stay alert to surroundings to avoid unnecessary exposure to hazards while performing their job assignments. g) Inform supervision when a special situation arises that may require additional or other PPE. Hazard Assessment. 3 MIOSHA-ADM-06-4R2 December 18, 2009 Personal Protective Equipment (PPE) Program for MIOSHA Personnel C. 1. Based on a general assessment of all work sites, it is the policy of MIOSHA that all MIOSHA employees on construction sites utilize safety glasses, safety footwear, and hard hats, and employees on all general industrial sites use safety glasses and safety footwear. 2. At the start of any inspection/investigation/audit or other field activity, the MIOSHA employee will assess the need for PPE, which would include the employers’ PPE assessment. 3. If in the course of an inspection/investigation/audit or other field activity, the MIOSHA employee encounters a hazardous condition that requires the use of PPE that was not addressed by the employer’s PPE hazard assessment, the MIOSHA employee will promptly address the hazardous condition with the employer, and don the appropriate PPE before proceeding, unless other appropriate action has eliminated the hazard. 4. For each work site the additional, required PPE will be documented in the case file, if the required PPE is more than what is required by VII.B.1. of this procedure. Eye and Face Protection. 1. Eye protection will be worn during all inspections/investigations/audits or other field activity where eye hazards exist. 2. Wherever special hazards exist that may require additional eye protection, goggles or face shields will be worn. 3. Equipment fitted with appropriate filter lenses will be used to protect against light radiation. Tinted and shaded lenses are not filter lenses unless they are marked or identified as such. Refer to Appendix A for a chart of filter lenses for protection against radiant energy. 4. For employees who wear prescription lenses, eye protectors will either incorporate the prescription in the design or fit properly over the prescription lens. D. Head Protection. Head protection will be furnished to, and used by, all MIOSHA employees while on construction sites, and on other sites where a hazard exists from falling or flying objects or from other harmful contacts or exposures, such as electric shock, hair entanglement, chemicals, or temperature extremes. E. Foot Protection. 1. MIOSHA employees are required to wear approved safety footwear at all times during inspections/investigations/audits or other field activity. 4 MIOSHA-ADM-06-4R2 December 18, 2009 Personal Protective Equipment (PPE) Program for MIOSHA Personnel 2. F. Safety footwear with metatarsal protection is required to be worn in work areas where heavy materials could be dropped on the foot (e.g., foundries), and where the employer requires such protection be worn. Hand Protection. 1. Hand protection will be worn to protect against specific hazards such as chemical and electrical hazards, heat, cuts, bruises, or abrasions. 2. Glove selection will be based on performance characteristics of the gloves, conditions, duration of use, and hazards present. See Appendix B for examples of some performance characteristics. G. Protective Clothing. Protective clothing will be worn to protect against injury from flash fire hazards, contact with hot or molten metal, chemical exposure, and weather conditions. H. Cleaning and Maintenance. I. 1. PPE will be inspected, cleaned, and maintained as necessary, so that the PPE continues to provide the required protection. PPE will not be shared between staff until it has been properly cleaned and sanitized. PPE will be distributed for individual use whenever possible. 2. PPE that cannot be decontaminated will be disposed of in compliance with applicable regulations. Training. 1. 2. PPE training will include the following elements: a) When and why PPE is necessary. b) What PPE is necessary. c) How to properly don, doff, adjust, and wear the PPE. d) The limitations of the PPE. e) The proper care, maintenance, useful life, and disposal of the PPE. Retraining is required when: a) There are indications that PPE is not being used properly. b) There are changes in the PPE policy or equipment. 5 MIOSHA-ADM-06-4R2 December 18, 2009 Personal Protective Equipment (PPE) Program for MIOSHA Personnel 3. Recordkeeping. a) Written records will be kept of the names of employees trained, the type of training provided, and the dates when training occurred. b) Each division or area will maintain all training records for at least three years. 6 MIOSHA-ADM-06-4R2 December 18, 2009 Personal Protective Equipment (PPE) Program for MIOSHA Personnel Operations Shielded metal arc welding Appendix A Filter Lenses for Protection Against Radiant Energy Electrode size in 1/32” Arc current Minimum* protective (0.8mm) shade Less than 3 3-5 5-8 More than 8 Gas metal-arc welding and flux-cored arc welding Gas tungsten-arc welding Air carbon arc cutting (light) (heavy) Plasma arc welding Plasma arc cutting (light)** (medium)** (heavy)** Torch blazing Torch soldering Carbon arc welding Gas welding: Light Under 1/8 Medium 1/8-1/2 Heavy Over 1/2 Oxygen cutting: Light Under 1 Medium 1-6 Heavy Over 6 Source: 29 CFR 1910.133(a)(5). 7 Less than 60 60-160 160-250 250-550 Less than 60 60-160 160-250 250-500 Less than 50 50-150 150-500 Less than 500 500-1,000 Less than 20 20-100 100-400 400-800 Less than 300 300-400 400-800 7 8 10 11 7 10 10 10 8 8 10 10 11 6 8 10 11 8 9 10 3 2 14 Under 3.2 3.2-12.7 Over 12.7 4 5 6 Under 25 25-150 Over 150 3 4 5 MIOSHA-ADM-06-4R2 December 18, 2009 Personal Protective Equipment (PPE) Program for MIOSHA Personnel Appendix A *As a rule of thumb, start with a shade that is too dark to see the weld zone. Then go to a lighter shade which gives sufficient view of the weld zone without going below the minimum. In oxy-fuel gas welding or cutting where the torch produces a high yellow light, it is desirable to use a filter lens that absorbs the yellow or sodium line in the visible light of the (spectrum) operation. ** These values apply where the actual arc is clearly seen. Experience has shown that lighter filters may be used when the arc is hidden by the work piece. 8 MIOSHA-ADM-06-4R2 December 18, 2009 Personal Protective Equipment (PPE) Program for MIOSHA Personnel Appendix B Glove Chart Type Advantages Disadvantages Use Against 1. Natural rubber Low cost, good physical properties, dexterity Poor vs. oils, greases, organics. Bases, alcohols, dilute water solutions, fair vs. aldehydes, ketones 2. Natural rubber blends Low cost, dexterity, better chemical resistance than natural rubber vs. some chemicals Physical properties frequently inferior to natural rubber Same as natural rubber 3. Polyvinyl chloride (PVC) Low cost, very good physical properties, medium cost, medium chemical resistance Plasticizers can be stripped Strong acids and bases, salts, other water solutions, alcohols 4. Neoprene Medium cost, medium chemical resistance, medium physical properties NA Oxidizing acids, anilines, phenol, glycol ethers 5. Nitrile Low cost, excellent physical properties, dexterity Poor vs. benzene, methylene chloride, trichloroethylene, many ketones Oils, greases, aliphatic chemicals, xylene, perchloroethylene, trichloroethane; fair vs. toluene 6. Butyl Specialty glove, polar organics Expensive, poor vs. hydrocarbons, chlorinated solvents Glycol ethers, ketones, esters 7. Polyvinyl alcohol (PVA) Specialty glove, organic solvents Very expensive, water sensitive, poor vs. light alcohols Aliphatics, aromatics, chlorinated solvents, ketones (except acetone), esters, ethers 8. Fluoro-elastomer (Viton) Specialty glove, organic solvent Extremely expensive, poor physical properties, poor vs. some ketones, esters, amines Aromatics, chlorinated solvents, also aliphatics and alcohols 9. Norfoil (Silver Shield) Excellent chemical resistance Poor fit, easily punctures, poor grip, stiff Use for HAZMAT work 9