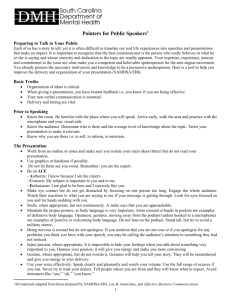

be309 final project

advertisement

BE309 FINAL PROJECT VIBRATION ANALYSIS OF A SINUSOIDALLY DRIVEN SYSTEM Group T1 Soe Y Ahn Bethany Gallagher Robert Pierson Zack Shinar Alexander Taich Abstract This experiment gave a thorough analysis of a system under a sinusoidal force. Using light plastic bars of various materials (Acrylic, Polystyrene, HMWPE) and sound waves, resonance phenomena was demonstrated. Two different transducers, piezoelectric accelerometer and electret condenser microphone, were used to record the vibration of materials. Initially, the impulse hammer was used to find the experimental fundamental frequencies of the materials, but due to low Young’s moduli of the bars, they vibrated in low frequencies in addition to their natural frequencies. This created excessive noise in the signal that interfered the determination of the fundamental frequencies. Expected fundamental natural frequency for each bar was calculated. For accelerometer the expected values for Acrylic, Polystyrene, HMWPE1, and HMWPE2 were 12.52, 3.79, 5.91, and 6.36 (HZ) respectively. With the microphone these values changed to 16.73, 6.52, 8.16, and 8.32 (Hz) as a result of lighter weight of the transducer. Resonant frequencies were determined through plotting power vs. input frequency. When the input frequency approached the resonant frequencies, the power of the vibration increased dramatically. The accelerometer graphs displayed sharp peaks at resonant frequencies, but with the microphone, continuous increase in power was observed. This is due to the fact that the omnidirectional microphone recorded the sound waves from the speaker as well as the vibration of the bars. Experimental resonant frequencies were found to be much greater than the expected values. Therefore, they were attributed to harmonics of the system. Due to low power in low frequency region, the transducers were not able to detect the fundamental frequencies. The experimental values correlated with harmonics of the expected fundamental frequencies. Deviations from the theoretical harmonics were greater for the accelerometer due to its heavy mass. The average percent deviation for the accelerometer ranged from 14.99 to 34.43% and for the microphone it ranged from 5.98 to 20.19 %. The HMWPE bars with different widths were expected to have increase in natural frequency with increase in width. However, the trend was unclear because of difficulty in determining which harmonics were recorded. Finally, a glass slide cover with an expected fundamental frequency of 1.697KHz was subjected to input frequency with high amplitude that was varied around the expected value in attempt to shatter the glass slide cover. However, not enough energy was transferred to break it. Background Every object constantly vibrates at a certain frequency. That frequency is called the natural frequency and depends on object’s composition and shape. The lowest such frequency is called the fundamental frequency. Integer multiples of the fundamental frequency are called harmonics. If a force is applied to an object with the same frequency as the object’s fundamental frequency, then constructive interference is observed and the amplitude of the object’s vibration increases. This increase in amplitude of vibration at natural frequency is called resonance. The natural frequency can be theoretically calculated for any object by knowing it’s physical properties. One way of generating a sinusoidal force is through a speaker. The force on the bar is a product of the pressure generated by the waves sent by the speaker and the contact area on the bar. The speaker creates regions of high and low pressure around the bar when generating the sound by either moving a speaker membrane that is attached to an electromagnet (Figure 1). When the membrane is pushed outwards pressure increases. The opposite is true when the membrane is pulled back. This force, striking the bar at a certain frequency, causes sinusoidal vibrations of the testing sample. An equation for such a wave is x(t)=sin(t) where is the circular frequency of the wave. Figure 1: Schematic representation of sound waves created by a speaker Motion of an oscillating system is governed by the following combination of forces: F(total) = F(spring)+F(damping)+F(driving) and can be described by a following second order linear differential equation: a2y’’+a1y’+a0y = b0*x(t), where a2 is the mass of the object, a1 is the expression for damping, a0 is the function of geometry and elastic properties and b0 is amplitude of the sinusoidal force. No physical object can vibrate at its theoretical natural frequency, but, instead, vibrates at a damped natural frequency which is related to the natural frequency by the relationship: d = n ( 1 – 2)1/2 where is the damping factor. Undamped natural frequency can be determined from the equation: 0=sqrt (a0/a2), where, assuming that the object is a bar, a0 = (6EI)/(3Lz2 – z3) and a2 = LWT. I=WT3/12 is the moment of inertia, is density, E is Young’s modulus of bar material and z is the distance from fixed end of the bar to vibrating point of interest, L length of the bar, and T and W are thickness and width, respectively. Based on the 2nd order differential equation of motion, the frequency response of a system with damping can be represented with the following equation that relates the vibration amplitude with the frequency of the input force. Amplitude F ( o 2 ) 2 4 2 2 2 F = amplitude of the input sinusoidal force 2 = damping constant/ mass = a1/a2 o = natural frequency = frequency of the input signal (note that = 2f where f is frequency in Hz) By analyzing the above equation the frequency at which the maximum oscillation occurs can be o 2 2 2 found to be If damping constant is 0, will equal to o. At this frequency, the amplitude of the vibration will maximum and the value can be represented with the following equation. Amplitude(max) F 2 o 2 2 When damping constant approaches 0, will also approach 0 and in turn, the amplitude will approach infinity. Figure 2. Relationship of amplitude vs. frequency with varying In this experiment, the samples are various types of polymers. Polymers today are often incorporated in several bioapplications and implants. For example, PVC, acrylic, and polyethylene are often utilized for ear parts, facial prosthesis, lung, kidney, and liver parts, and bones and joints. Often, plastics are used in situations where corrosion is an extreme problem. The physical characteristics of the polymers are of great importance when deciding the material for the implant. Polymers are composed of long-chained molecules that are capable of assuming many conformations through rotation of valence bonds. Plastics are found in an either amorphous or semicrystalline state. They are never completely crystalline due to the lattice defects that form disordered, amorphous regions. Primarily, plastics have lower elastic moduli as compared to materials such as metals and ceramics. This low elastic modulus effects such properties as the fracture strength of the material, the tensile strength, and the resonance frequency of the material. The lower elastic modulus is directly related to the natural frequency of the material and therefore plastics have significantly lower natural frequencies. Within the lattice, the freedom of motion of the polymer chains is retained at the local level while the chain interaction prevents large scale movement or flow. The testing of the resonance frequency of materials is of vital importance in the field of implants and bioengineering. For example, in the ear implant, the material is vulnerable to all the frequencies of sound in the surrounding environment. If the sounds approached the natural frequency of the implant material, deformation and damage could occur due to the dramatic increase in the amplitude of the vibrations of the molecules. In addition, these vibrations could cause injury to the delicate bones of the inner ear. Picture 1: Middle ear implant Also, implant materials would be subject to possible vibrations caused by such innocent actions as riding in a car or airplane, possibly even the high impact of running. The vibrations sent through the implants such as joint or bone could cause such violent increase in amplitude that extensive deformation and possible cracking could occur. Therefore, the resonance frequency of the material must be great enough to ensure that the activities the implant will be subject to will not generate vibrations significant enough to equal it. Accelerometer and Microphone Vibrations of the bars are measured by a transducer which converts the amplitude of motion into a proportional voltage or electrical output. Two transducers were used for each bar. The first transducer was a piezoelectric accelerometer. The mechanism contains a piezoelectric crystal that gives off a charge when pressure is applied. The accelerometer is equipped with a piezoelectric crystal, a mass (to apply pressure in relation to the relative movement of the accelerometer) and an FET circuit. The FET circuit converts the charge amplitude of the crystal into a relative voltage or electrical signal. The other transducer was an omnidirectional condenser microphone. A microphone is a voltage generator that has an optimum load impedance. The microphone used in our experiment had an impedance of 1 k, which is not considered “low impedance” but is significantly lower than a “high impedance” microphone. The lower the level of impedance allows longer distance transmission of the signal. The condenser microphone acts as a capacitor that changes its capacitance in respect to pressure variations. The condenser, or electret, is an insulator that has a quasi-permanent static charge trapped on it. (Schetgen) The DC power supply acts as an FET impedance converter. The schematics of the microphone and the power supply are near identical. A voltage is sent to the microphone and to an output via a capacitor. The voltage sent to the microphone is then sent to the ground. The change in capacitance of the condenser is accompanied by a change in voltage from the power supply of the output signal. Materials 1. Impulse Hammer 2. Speaker 3. Piezoelectric Accelerometer 4. Panasonic Electret Condenser Microphone 5. Function Generator 6. 100 Watt amplifier 7. Power supply 8. Bar support with clamp and clamping plate 9. Pyrex Glass Slide Cover 10. Bars of plastic cut from sheets: HMWPE, Acrylic, Polystyrene Table 1: Physical Properties of Plastic Bars Bar Material E, Mpa Length, z, cm cm Width, Thickness, cm cm 1 Acrylic 3450 53 32.8 5.9 0.35 2 Polystyrene 3200 52 32.8 4.8 0.15 3 HMWPE 690 52 32.8 5.9 0.35 4 HMWPE 690 52 32.8 7.8 0.35 Procedure: 1) Expected values: Before starting testing the bars expected fundamental frequencies were calculated using the equations given in background section. This values will be compared to the experimental values. 2) Impluse Hammer: This part of our lab was done using an experiment nearly identical to the previous vibration lab. An impulse hammer was used to find the resonant frequency of the bars. Plastic bars were clamped to the table and accelerometer and microphone were used as transducers. Attachment of the accelerometer was done similar to the vibration lab done earlier this semester. Attachment of the accelerometer was also be done similar to the previous vibration lab and the microphone was also be attached directly on the bar. The fundamental frequency of each bar will be determined using power spectra. 3) Sinusoidal force: the goal of this section was determine the natural frequency of the bar under the sinusoidal force. A speaker was used to provided a sinusoidally varying force. The speaker was mounted to a stool and fixated with clamps and tapes. And the speaker was placed about 1~2cm away from the plastic bars. The input frequency was generated with the virtual bench and ranged from 1Hz and included two resonant frequencies. The geometry(lengths, width, and thickness) of the bars were varied also. Compare the results to that of the impulse hammer and expected values. 4) Application: The final part of our experiment consisted of using a glass cover slide. The resonant frequency of this slide was be determined by the equations mentioned above. To subject the slide to maximum energy, the glass was fixed firmly directly in front of the speaker. The method of fixation with a clamp reduced any possible energy loss because vibrations were limited to the glass only. After determination was complete, the amplitude of the input frequency was increased around the vicinity of the expected natural frequency. Figure 3. Setup for Sinusoidal Experimentation RESULTS A theoretical natural frequency of each bar with the accelerometer or microphone attached was calculated. Then each bar was subjected to a sinusoidal input force of equal amplitude. The input frequency ranged from 1Hz to the second harmonic frequency of each bar. The FFT data for each test frequency were recorded. The power of the peak in the FFT plot corresponding to each input frequency was then determined. The power vs. input frequency was plotted to find the experimental natural frequency (see graph 1 and 2). Each peak in the graph represents natural frequency of the bar. The lowest natural frequency is the fundamental frequency. Table 3 shows the experimental natural frequencies that we found through plotting graphs. Table 2: Theoretical fundamental natural frequencies of the bars Bar Theoretical natural frequency Theoretical natural frequency with with accelerometer (Hz) microphone (Hz) 1 12.52 16.73 2 3.79 6.52 3 5.91 8.16 4 6.36 8.32 Table 3: Experimental natural frequencies of the bars Bar Experimental natural frequencies Experimental natural frequencies with accelerometer (Hz) with microphone(Hz) 1 16.5, 51 34, 50 2 16.5, 65.5 64.5, 100.5 3 19.5, 41.5 65.5, 82.5 4 14.5, 40 80, 100 Graph1: Power vs. input frequency of bar 3 with the accelerometer attached Graph 2: Power vs. input frequency of bar 3 with the microphone attached Since the experimental resonant frequencies were much higher than the expected fundamental natural frequencies, we calculated harmonics of the expected values and compared them with our results for both the accelerometer and microphone. Table 4 presents the calculated harmonics of natural frequencies. Only the harmonics that correlate to our experimental values are included in the table. The deviations from the expected harmonics were determined and the percent deviation for each bar is shown in Table 5. Table 4: Theoretical harmonics of natural frequency Bar Expected harmonics with Expected harmonics with accelerometer (Hz) microphone(Hz) 1 12.52, 50.09 33.46, 52.54 2 15.88, 67.49 63.92, 102.08 3 17.73, 41.37 65.28, 81.6 4 12.72, 38.16 83.2, 99.84 Table 5: Average percentage deviation from the theoretical natural frequencies Bar Avr % deviation from theoretical harmonics with accelerometer 19.52 34.43 14.99 28.46 1 2 3 4 Avr deviation from theoretical harmonics with microphone 5.98 7.67 7.48 20.19 Table 6. Natural Frequency variance with width of bar. Bar Width Accelerometer (Hz) Microphone 0.059 0.078 5.91 6.36 8.16 8.32 0.059 0.078 19.5,41.5 14.5, 40 65.5,82.5 80, 100 Calculated HMWPE HMWPE Experimental HMWPE HMWPE Discussion: First we used the impulse hammer to determine the fundamental frequency of each bar. However, peaks that correspond to natural frequencies could not be determined from power spectra data. Low Young moduli of the plastic bars created unwanted multiple vibrations. These vibrations made determination of the resonant frequency difficult by creating “noise” all along the spectrum of frequencies. To circumvent this problem, it would be necessary to increase the relativity resistivity to motion. This could be done through a) using a material of higher modulus of elasticisty or b)increasing the thickness of the bar. For the sinusoidally driven system, the theoretical fundamental natural frequencies were first calculated as shown in Table 2. The theoretical fundamental natural frequencies are lower for the bars with the accelerometer attached due to its heavier mass (90 grams). By increasing the mass of the object, the resonant frequency will decrease. This can be shown through the equation: = (a0/a2) Since a2 is equal to the mass of the object, then as the mass increases from the addition of the accelerometer the resonant frequency will decrease. To determine the natural frequency for each bar, power vs. input frequency graphs were plotted. With the microphone, we were able to obtain data that corresponded to expected harmonics. Sharp peaks representing resonance phenomena were clearly visible. However, extra “noise” made the entire graph appear less than ideal. Unlike with the accelerometer, we saw a continuous increase in power with an increase in frequency with the microphone. We believe this is due to the microphone’s detection of the speaker sound in addition to the vibration of the bar. This coincides with the increased amplitude with increased frequency and could possibly show much b better with some sort of filter to eliminate this affect. With added power from the speaker sound, the peaks for resonant frequencies were more difficult to distinguish. The microphone has an omni-directional pick up pattern, which means it detects sound from all directions. This type of microphone is applicable to our experiment, because omnidirectional microphones are extremely effective at relatively close ranges. At close ranges only pressure waves directly in front of the microphone are detected. The method of attaching the microphone pick up face directly to the bar allows a thin space of air to couple the condenser to the bar. When the microphone is air-coupled to the bar, the bar acts as a speaker when it begins to vibrate. The vibrating bar creates pressure waves in the air-couple. Consequently, these pressure waves are detected by the microphone. The noisy data suggests the microphone responded to more than just the vibration of the bar. The continued increase in output amplitude with respect to increase in frequency input suggests the graphs contain the frequency response of the microphone. The microphone was manufacture tested to contain a relatively constant response for the frequency range, 40Hz-4kHz, with a minimum response to 20Hz. The increase of amplitude on the microphone graphs suggests this increase in power. Energy increases for constant amplitude as frequency increases. This phenomenon might have attributed to the continual increase in amplitude as frequency increased. Also, the ability for the microphone to detect sound in multiple directions may have cause noise from other sources (i.e., the speaker). The nature of the air-couple is also questionable. The motion of the bar might have possessed a horizontal motion in addition to the visually observable translational vibration. The piezoelectric accelerometer only deciphers translational movement. This inherent filtering mechanism may have been the reason why the data acquired from the accelerometer contained distinct peaks and relatively no noise. The data from the microphone did possess reproducible characteristics that are relevant to the calculated data suggesting that the bars did influence the response of the microphone. Had we had better foresight, a noise trial or an equivalent over-damped trial would have been performed. This noise data could be used to create a filter for our experimental data. The theoretical fundamental natural frequencies ranged from 5.91-16.73 Hz. However, the experimental resonant frequencies determined from the graphs of power vs. input frequency range from 14.5 – 80 Hz. An explanation for this deviation is that high frequency sound carries higher energy than lower frequency sound of the same amplitude. Therefore, due the sensitivity of the transducers, only the higher energy signals were detected. This coincides with the published sensitivities of the accelerometer (lowest detectable frequency = 3 Hz) and microphone(lowest detectable frequency = 20 Hz). Between the accelerometer and the microphone, the setup using the microphone produced higher frequency results. This is due to the microphone’s low sensitivity, which results in a higher frequency threshold for picking up vibrations in the bar. The smaller magnitude of peaks in power spectrum of microphone data compared to that of the accelerometer also shows that the microphone has lower sensitivity than the accelerometer. We calculated the theoretical harmonic frequencies for each bar and found the ones closest to the experimental values (Table 4). Then we compared these harmonics to the experimental results. The average percent deviation was determined (see Table 5) and the bars with the microphone attached showed smaller deviation from the theoretical harmonics of the natural frequency. The average percent deviation of the accelerometer ranged from 14.99 to 34.43% and that of the microphone ranged from 5.98 to 20.19 %. The smaller deviation for the microphone is due to the microphone’s small mass and small physical dimensions. Attachment of the microphone does not affect the natural frequency of the bar as much as the accelerometer does. This would make it an advantageous instrument for performing that measurement; however the decreased sensitivity of the microphone are a detriment. The microphone should be adequate for measuring the natural frequencies of objects that posses higher natural frequency such as a wine glass. Although the accelerometer has better sensitivity compared to the microphone, the addition of the accelerometer will affect the resonant frequency by changing the mass of the object and the geometry of the object. The geometry of the object will also change from the addition of the accelerometer. First of all, the moment of inertia will change. A second effect will be the Young’s Modulus. The accelerometer has a significantly different Young’s Modulus than the bar, and therefore the section of bar surrounded by the accelerometer will be affected. All of these affect the resonant frequency of the combination bar/accelerometer. The accelerometer is very accurate and precise in measurement due to its high sensitivity. However, its relatively high mass (even greater than some of the plastic bars) alters the natural frequency of the bars from the theoretical values. Therefore the accelerometer will be ideal for a system with heavier mass and high Young’s modulus. The microphone is less accurate and less precise because of its low sensitivity, but due to its small mass, the measured natural frequency does not deviate much from the theoretical value. So the microphone is more ideal to measure undamped natural frequency of a system with a light mass, low Young’s modulus and high natural frequency. A transducer with a high sensitivity and a light mass will be an ideal apparatus to measure the natural frequency of our system with high precision and accuracy. Part of our hypothesis was the positive relationship between width of the bar and its natural frequency. We tested two HMWPE bars with identical length and thickness and different widths. The results of that test are presented in Table 6. Since, as discussed earlier, we could not measure the fundamental natural frequency but only the harmonics it is impossible at this point to correlate width and frequency data. It is apparent that there is a possibility from the table that different harmonics were measured. Since we do not know exactly which harmonics it was that we were able to detect, no width-based comparison can be performed. Finally, a glass slide cover of expected natural frequency of 1.697 kHz was subjected to input frequencies with large amplitude. This range of the input signal varied around the fundamental frequency of the glass in an attempt to generate resonance. This resonance would increase the molecular vibrations to the point of shattering the glass in the ideal case. Unfortunately, significant energy was unable to be generated by the speaker to create resonance in the glass. Appendix Here we wish to present a proposal for a modified version of the vibration analysis laboratory that builds upon the data and skills acquired through our project. In addition to the proposed lab, there are several additions that could make the experiment better. The first addition that would definitely benefit the results of the lab is a light-weight transducer with a sensitivity on the order of magnitude of the current accelerometer. The proposed cost of this would be around $350 and is susceptible to damage. These are the two biggest disadvantages to using this for the lab. A second addition would be a high mass, high resonant frequency material. This, of course, is counter-intuitive, because mass and resonant frequency are commonly inversely proportional. However, such a material would greatly increase the results of the lab using the following experiment. The high natural frequency would allow the microphone and accelerometer to measure that frequency more accurately. The high mass would counter-act the affects of heavy accelerometer. A third addition that may improve the results is to increase the width of the bar. Increasing the width will allow for the pressure generated by the speaker to affect the bar along a greater surface area. This would increase the mass and may prove to be detrimental through the decreased resonant frequency and greater force needed to move that mass. A fourth addition is decreasing the microphone detection of the speaker. This could be done through several deviations of the method we employed. First, the affix of the microphone needs to seal the microphone to the bar. This will decrease transient air from entering the microphone. Second, the surrounded noise (from speaker and lab) needs to be decreased. This can be done by damping the microphone with light weight foam. Affix the microphone properly to the bar will also help. A final improvement would to use a unidirectional microphone. This would decrease unwanted noise and increase detection of the air pressure caused by the bar. There are benefits and drawbacks of the new vibration lab. The trade-off is steering the students to gain a maximum amount of knowledge in an allowable amount of time. These two ideas are in direct conflict. Therefore, judgements must be made of which concept is most beneficial to one’s education. In the new lab, the concepts of damping factor and geometry are de-emphasized in favor of learning the use of an accelerometer versus a microphone, the utilization of sinusoidal driven waves, and bars of materials more suitable to bioengineering purposes. Modified Experiment for BE309 Fall 1999 Vibration Analysis OBJECTIVES A. Experimental Goals 1. To measure the vibration response of metal bars to an impulsive load and determine the sensitivity, damping factor, damped and undamped natural frequency of the bars; 2. To measure the response of a sinusoidal force on plastic bars and plot a frequency versus relative power. 3. To measure the amplitude variance using a microphone versus an accelerometer as the transducer. B. Educational Goals 1. To understand the relationship between harmonics and fundamental frequency. 2. To understand the impulse response of structures in both the time and frequency domains. 3. To gain a tangible representation of FFT graphs and utility in engineering purposes. BACKGROUND A. Biomedical Relevance and Importance When subjected to appropriate mechanical forces, objects can vibrate at specific resonant frequencies. Under appropriate conditions, sufficiently high amplitudes of the vibrating wave can damage an object, even to the point of destruction. We are all familiar with the example of a wineglass shattered by a soprano’s high frequency note. Resonant vibrations can also adversely affect the mechanical integrity of the human body. A very significant example today is the damage done to the inner ear by today’s widespread fad to listen to music at extreme sound volumes. Since the cochlea of the inner ear is sensitive to a very wide frequency range from about 20 Hz to at least 15 kHz, high amplitude sound vibrations anywhere in that range can irreversibly damage the delicate hair cells, particularly those having resonances at high frequencies. Vibration considerations are also very important in ergonomics, the design of systems in which humans interact with their environment, in applications ranging from office furniture design to vehicular suspensions to wild amusement park rides. B. Scientific Background 1. Wave Motion Given a sinusoidal wave x(t), the wavelength of the wave is defined as the distance, and the period T as the time, between two successive identical points on the wave. The velocity of the wave is defined as v = f, where v is velocity and f is frequency. A good model for understanding wave motion is a vibrating string, such as a violin string. If a string of given length is fixed at one end and started vibrating at the other, a continuous wave will travel down the string to the fixed end and be reflected back. As the string continues to vibrate, waves will travel in both directions; the waves traveling down the string will tend to destructively interfere with the reflected waves producing waves of relatively low amplitude. However, if the string can be vibrated in such a fashion as to assure that forward and reflected waves interfere constructively (the peaks and troughs of both forward and reflected waves occur at the same time) one will observe large steady peaks and troughs. These waves are called standing waves because they appear to be standing still relative to the string. Areas of destructive interference (areas of no string motion.) are called nodes, while areas of constructive interference (the peaks and trough areas) are called antinodes. A string can have different frequencies of vibration that will set up standing waves; such frequencies at which standing waves are produced are the resonant frequencies of the string. The lowest frequency that causes a standing wave on the string is known as the fundamental. Higher resonant frequencies are called harmonics. For example, when the A string above middle C on a piano is correctly tuned to the proper length and tension, the fundamental frequency will be 440 Hz when the key is struck. Some of the energy will go into higher harmonics or overtones, for instance, at 880 Hz, or A above high C (one octave higher). Each higher harmonic above the first (or fundamental) is an integral multiple of the fundamental. Thus when the string vibrates its energy is distributed among a specified set of resonant frequencies. Every material object behaves this way when given the appropriate energy.1 The specific vibration or motion observed depends on the properties and geometry of the system, as well as the means of excitation. 2. Second Order Systems The type of vibrating system we shall consider, which is of great importance in modeling many systems of bioengineering interest, is the second order system, so-called because it can be described in terms of a second order ordinary differential equation. To appreciate the significance of this model, we consider the various forces of importance in doing work on the system and distributing the system energy: 1 Such phenomena can be best understood by considering their behavior in both the time and frequency domains. If you have not yet done experiment #1, read the section about frequency domain in the background section of that write-up. 1. To a system initially at rest, an external applied force does work on the system, accelerates it and gives it a displacement y(t) from the rest position In mechanical terms, the system experiences an inertial force which depends on its mass and acceleration which in turn depends on the second derivative of y. 2. The system can lose energy as a result of dissipation due to frictional forces, also called resistive or damping forces. Such forces tend to lower the displacement or amplitude of vibration. Damping forces are 90o of phase with the displacement, which means they depend on the velocity or first derivative of y. If there were no damping forces, an object would continue to vibrate forever at constant amplitude and at a frequency called the undamped natural frequency; of course, all real systems must have some damping. However, the concept of an undamped system as an idealized model is very useful. 3. In order to oscillate, a system must have the ability to store energy, or exchange the energy form between kinetic and potential. Mechanical systems can store energy by virtue of their elasticity, characterized by a spring constant or elastic modulus such as Young’s modulus. The force applied to do the work for storing energy is directly proportional to the displacement y itself. To set a system into motion, some type of external force must be applied. Engineers use three idealized models to characterize the input force applied. The response of all real motions can be represented through combinations of these models, which can be generally expressed in terms of a forcing function b0x(t). The models are: (a) Impulse Response: In an ideal impulse, the time function x(t) is given by a delta function (t), defined as (t) = 0, t<0; (t) = 1, t=0 ; (t) = 0, t>0 This means the system is excited with an instantaneous force b0, and then left alone. Whether it continuous to vibrate depends only on the properties of the system itself. (b) Step Response: The ideal step is given by x(t) = 0, t<0 ; x(t) = 1, t0 At time zero, a force is applied and maintained. The step and impulse are related, since the derivative of the step function is obviously the impulse function. (c) Sinusoidal or frequency response: The time dependent function is given by x(t) = sin(2ft) That is, a force that varies sinusoidally with frequency f is applied and maintained. Such inputs are useful for studying system resonances, since if the forcing frequency f matches one of the system’s natural undamped frequencies, the system will resonate. To understand the motion of 2cd order systems quantitatively, we must analyze the forces involved. Applying Newton’s second law of motion to the system, we get a2 d 2 y (t ) dy (t ) a1 a 0 y (t ) b0 x (t ) 2 dt dt (1) The various coefficients in equation 1 reflect the force relationships discussed above. The first term is the inertial force, so that a2 is equal to the mass. The second term is the damping force; a1 will depend on the type of damping- e.g., for viscous damping it will be proportional to the viscosity of the fluid surrounding the system. The third term is the energy storage or elastic term; a0 is a function of the geometry and elastic properties; the term on the right is the forcing function that starts and may contribute to maintaining the motion. We can rewrite this equation in the form: D 2 2D 1 y (t ) Kx(t ) 2 n n (2) where D is a shorthand notation for the nth order derivative of y with respect to t. The parameters of this relation are defined by: K n b0 a0 a0 a2 a1 2 a0a2 the sensitivity of the system the undamped natural frequency the damping factor. The damping factor is the primary parameter for understanding second order response. There are four values or ranges of , each with different significance, which can be understood mathematically by examining the roots of the term in brackets in equation 2. Since in this experiment we will only measure the system response to an impulse function, we will only discuss the solution to these equations for an impulse.2 The ranges of are: 2 The behavior of a vibrating system to a sinusoidal input force is much different than to an impulse, since oscillations may be sustained even in highly damped systems because of the continuous input of energy. However, we will not carry out such tests in this experiment. A further discussion of such phenomena is given in the appended notes on “Basics of Vibration.” (a) If =0, the roots are imaginary, and the system is undamped. The system response is given by a sinusoidal function A= Ao sin(nt) The system will oscillate forever at constant amplitude A0 with a frequency equal to the undamped natural frequency. Ideally the amplitude A0 is related to the impulse b0. (b) If 0< > 1, the roots are complex, and the system is underdamped. This is the situation of greatest interest in bioengineering. In response to an impulse, an underdamped system will vibrate with amplitude given by: A(t) = A0 e-nt sin (dt) (3) This very important relation states that the system will be observed to oscillate with a frequency d, called the damped natural frequency, which is related to the undamped natural frequency by the relation: d = n ( 1 – 2)1/2 (4) However, the amplitude of the oscillation decreases exponentially with time. If one joined each oscillation peak (at which sin dt = 1) together to give a continuous curve, it would be an exponential decay called an envelope. If one plotted the logarithm of the envelope curve vs time, the slope would be negative and equal to n, and the intercept would be equal to A0. In this case, A0 is the amplitude of the output at t=0. It is dependent on the impulse strength b0, the damped natural frequency d, and the efficiency of applying the impulse. (c) If =1, the roots are real and both equal to –1. The system is said to be critically damped. For this situation, the system does not oscillate. It responds to the impulse by moving from the rest position, and then returns to the rest position asymptotically. Critical damping can be useful in designing a system for moving people. Ergonomically, one might wish to critically damp systems such as elevators and cars to avoid possible injury from jerky motions. However, it would take some time to come to rest. (d ) If >1, the roots are real and unequal. The system is overdamped. In this case there are also no vibrations, and the system will come to rest more rapidly than when critically damped. An overdamped car suspension system might produce a bouncy ride. C. Equipment and Experimental Background 1. Accelerometers An accelerometer is a transducer that detects the components of acceleration of an object (or force if you know the mass). They can be placed on different parts of a moving object and by suitable calibration and knowledge of their properties the vibration response of‘ the object is studied.. In this experiment we use a piezoelectric accelerometer to measure the vibrations. In such transducers, a piezoelectric crystal is used to transducer motion into an electrical potential.3 Because the accelerometer has mass, it will distort the natural frequency of the bars being studied. Also the cables are delicate and particular attention must be paid to avoid breaking them- we only have one unit on hand. 2. Microphone A microphone is a voltage generator that has an optimum load impedance. The microphone used in our experiment had an impedance of 1kohm, which is not considered “low impedance”, but is significantly lower than a “high impedance” microphone. Lower the level of impedance allows longer distance transmission of the signal. The condenser microphone acts as a capacitor that changes its capacitance in respect to pressure variations. The condenser, or electret, is an insulator that has a quasi-permanent static charge trapped on it. (Schetgen) The DC power supply acts as an FET impedance converter. The schematics of the microphone and the power supply are near identical. A voltage is sent to the microphone and to an output via a capacitor. The voltage sent to the microphone is then sent to ground. The change in capacitance of the condenser is accompanied by a change in voltage from the power supply of the output signal. 3. Underdamped Impulse Response of Metal Bars In this experiment, we will study the underdamped vibrations of metal bars that have been given an impulse by striking with an impulse hammer, a fancy hammer equipped with a transducer that can give an output proportional to the magnitude of the impulse. For a bar of length L, width W, and thickness T vibrating either in air (air damped) or in liquid (liquid damped), relationships can be derived between the various coefficients such as: I moment of inertia = WT3/12 mass density of bar material E Young’s modulus of bar material viscosity of damping liquid z distance from fixed end of the bar to vibrating point of interest; 0 z L a0 = (6EI)/(3Lz2 – z3) a1 = C where C is a constant 3 A good introduction to such accelerometers, as well as related transducers which measure pressure and force, is appended. Read this carefully, paying particular attention to the cautions given. a2 = LWT or the mass of the bar (plus accelerometer!) B0 measured amplitude of impulse actually applied S measured sensitivity = A0/B0 Using these relationships, one can calculate the undamped natural frequency n, and parameters proportional to the damping factor . By observing the output of the impulse hammer in the frequency domain, one gets a measured estimate of the impulse magnitude B0. From the frequency domain output of the accelerometer, the damped natural frequency can be taken as the value of frequency (in the neighborhood of the estimated undamped natural frequency) with the highest energy. From the time domain output of the accelerometer, a semilogarithmic regression of the amplitude peaks vs. time will give an estimate of , n, and A0. By doing regression, you also get estimates of precision from the confidence intervals. Use the experimental measure of sensitivity S, defined above, rather than the theoretical value K given earlier. PRELABORATORY WORK- must be completed prior to lab A. Individual Work 1. Read the addendum on accelerometers; 2. If you have not yet done Exp. # 2, read the background about signal analysis and FFT and the frequency domain analysis of signals; B. Group Work 1. Become familiar with the Labview VI to be used and become familiar with those features you will need to analyze your data. 2. Estimate the expected sensitivity and undamped natural frequency expected for the various bars for the different setup conditions to be used. 3. Using the relations given in the scientific background for impulse response of an underdamped second order system, plot the expected time domain response curve of Bar#1 for damping factors of 0.05, 0.1, 0.2, and 0.5. APPARATUS and EQUIPMENT 1. Accelerometer 2. Impulse Piston (Hammer) 3. 2 Accelerometer Power Supplies 4. Bar support (attached to lab bench) with clamp and clamping plate 5. Three test metal Bars with following dimensions and materials: BAR 1 2 3 METAL Al Stainless Al L, mm 915 915 915 W, mm 38 38 51 T, mm 3 3 5 6. Cables 7. Large graduated cylinder 8. Damping solutions: water, 20 weight% sucrose, and carboxymethylcellulose solution(same viscosity as sucrose solution and same density as water) 9. 40 Watt Speaker 10. Panasonic Electret Condenser Microphone 11. Labview Data Acquisition program BE shared\309\vib.VI SPECIFIC PROCEDURES A. Impulse Bar Tests Mount each bar in turn in a vertical position in air using the bar mount clamping apparatus. We suggest a 50 mm distance from the end of the bar to the floor as the default position. Be consistent between bars to make comparison easier since all bars have the accelerometer mount hole the same distance, 480 mm, from the bottom. Start with Bar#1 and designate it as the control bar, used for comparisons with the others. To appreciate some of the unexpected problems with measuring vibrations, while carrying out the trial below, we suggest that each group member try placing his/her hand on the table top near the bar mount, and see if you can detect the table vibrating. 1. Remove the accelerometer from its storage box. Gently attach one end of the recording/power cable to the accelerometer and the other end to the power supply/amplifier. Connect the output of the power supply/amplifier to channel one of Labview, and the impulse hammer to channel 2. Check that the power supply/amplifier battery is good using the battery tester on the supply. Set the Lab View acquisition program to sample 3000 samples a second for 2 seconds. 2. Securely fasten Bar#1 to the support bracket using the clamp and clamping plate supplied. The effective vibrating length L of the bar is from the bottom of the clamping plate to the lower end. Measure it accurately. The distance z is from the same point to the accelerometer hole. Attach the accelerometer to the central hole of the bar with the ¼ inch fine thread screws provided. Tap the bar lightly with your hand to check that everything is working properly. Holding the impulse hammer at right angles to the bar strike the bar lightly to set it into vibration. Practice hitting the bar until you can get reasonable amplitude each time. It is not necessary to get the same amplitude each time since amplitude can normalized to a selected value, and all others tabulated as a percentage of that value. Do not hit too hard! The impulse hammer transducer may be damaged (value $1000)! Repeat for 5 trials. 3. Repeat with the bar length reduced to 2/3 of its initial length. 4. Remove the accelerometer from the bar and mount it in the hole provided on top of the clamping apparatus. Carry out a few trials measuring the vibrations picked up in the table. 5. Repeat steps 2-3 with bars # 2 and 3 respectively. 6. Hang Bar#1 with string from the clamp instead of clamping. Try a few trials. B. Sinusoidal Driven Force 1. Affix the plastic bars (acryllic, polysterene, and HMWPE) similar to the metal bar section. 2. Adjust the speaker to a maximum of 2 inches from the bars. Record this distance for use with all bars. 3. Record amplitude peaks using intervals of 10 Hz for frequencies. When you see the amplitude begin to rise lower the interval to 1 Hz. 4. Repeat this for each of the three bars. WORKUP OF RESULTS 1. For each trial determine the damped natural frequency, undamped natural frequency, damping ratio, and sensitivity. Average the values for the multiple trials. 2. Tabulate the results for the various bars and air damping conditions. Quantitatively explore the effect of bar geometry and material. Compare to expected values both in absolute terms and as ratios to the control bar. What differences are significant? 3. Tabulate the results of using the sinusoidal force as the generator of motion. Pay particular attention to how your data compares with the data calculated using the given equations. 4. Report the values found for the table vibration and compare with the bar results. 5. Compare impulse response of clamped bar with hanging bar. REFERENCE Biriukov, S.V. Surface Acoustic Waves in Inhomogeneous Media. Berlin, New York: Springer – Verlag, 1995. Kleppner, Daniel, Robert J. Kolenkow. An Introduction to Mechanics. New York: McGraw-Hill, Inc., 1973. Fall 1998 Bioengineering 309 Lab manual Febella, B., Fernandes, S. James, A., Musikabhunna, A.P. “ Study of Bivration Response of a Sinusoidal Oscillating Driving Function” : BE309, 1997