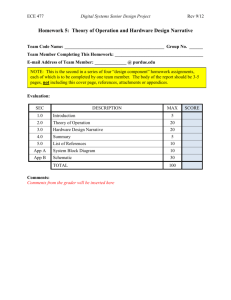

EE 477 Final Report

advertisement