Advanced Manufacturing Engineering and Management

advertisement

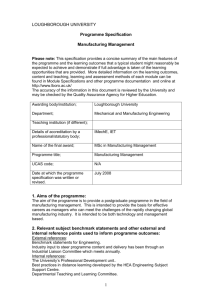

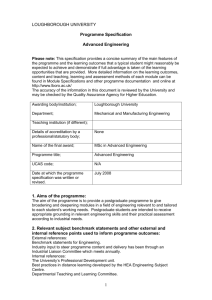

LOUGHBOROUGH UNIVERSITY Programme Specification Advanced Manufacturing Engineering and Management Please note: This specification provides a concise summary of the main features of the programme and the learning outcomes that students are expected to achieve if full advantage is taken of the learning opportunities that are provided. More detailed information on the learning outcomes, content and teaching, and learning and assessment methods of each module can be found in Module Specifications and other programme documentation and online at http://www.lboro.ac.uk/admin/ar The accuracy of the information in this document is reviewed by the University and may be checked by the Quality Assurance Agency for Higher Education. Awarding body/institution; Loughborough University Department; Mechanical and Manufacturing Engineering Teaching institution (if different); Details of accreditation by a professional/statutory body; IMechE, IET Award; MSc Being sought Provisional Established (e.g .BA, MSc etc) Programme title Length of programme Advanced Manufacturing Engineering and Management 1 year full-time, up to 8 years part-time UCAS code; N/A Date at which the programme specification was written or revised. March 2011 1. Programme Aims: The aim of the programme is to provide a postgraduate programme in the field of manufacturing management. This is intended to provide the basis for effective careers as managers who can meet the challenges of the rapidly changing global manufacturing industry. It is intended to be both technology and management based. 2. Relevant subject benchmark statements and other external and internal reference points used to inform programme outcomes: External references: Benchmark statements for Engineering. Industry input to steer programme content and delivery has been through an Industrial Liaison Committee which meets annually. 1 Internal references: Teaching Centre. Best practices in distance learning developed by the HEA Engineering Subject Support Centre. Departmental Teaching and Learning Committee. 3. Programme Learning Outcomes 3.1 Knowledge and Understanding: On successful completion of this programme, students should be able to demonstrate knowledge and understanding of: The generic nature of design and the phases and activities within the overall design process. The role of human mental processes in design. The relationships between design manufacturing and commerce and the principles of new product development. Management and business practices (including finance, design management and quality). Basic company accounting. Sustainable development, environmental legislation, resource conservation and design for the environment in a company context. Design and programming of CNC machine tools. Manufacturing system layouts. Manufacturing control systems. The modern global enterprise and its organisation. The effect of national culture upon business performance. IT infrastructure for global operation and the virtual enterprise. The principles of Rapid Prototyping, Rapid Tooling, and Rapid Manufacture; their applications and limitations. The role and limitations of integrated software support systems for product design. The capabilities of Product Data Technology. Lean and agile operations’ philosophies. Six sigma systems. Modern distribution systems. Demand management. Specify the requirements of a manufacturing enterprise and business process. Team management techniques and practices. Understand the capabilities and limitations of modern computer aided design technology as applied to concurrent engineering. Understand project management skills and team working practices. Learning, teaching and assessment methods to enable outcomes to be achieved and demonstrated: All modules are delivered as block taught one-week modules to provide access to both full-time and part-time students. Each module is taught by a mixture of lectures, seminars and practical work. Assessment is in the form of examinations and/or written coursework and/or oral presentation of in-class assignments as described in the module specifications. A full-time programme administrator provides support to the programme. A module timetable provides structure to the programme. A coursework hand-in timetable system is provided to control student working across the year. Research skills are developed through coursework assignments and in particular through an industrial project 2 that includes an exhibition of work, oral presentation, a research paper, in addition to the conventional thesis. 3.2 Skills and other attributes: a. Subject-specific cognitive skills: On successful completion of this programme, students should be able to: Appreciate the broad range of influences and activities within the design process and explain their significance. Evaluate technical and commercial risk and make decisions based on available information. Identify solutions to engineering problems from a sustainability/environmental standpoint. Evaluate machine tool designs. Design manufacturing cells/systems for new/existing products. Specify and implement a manufacturing system. Create an appropriate organisation for global business. Select on the basis of application and limitations, the most appropriate “rapid” technology. Evaluate the most appropriate software to support concurrent engineering activity. Specify and design an appropriate lean/agile business or distribution system. Evaluate mass-customisation systems. Develop a complex manufacturing enterprise, evaluating and justifying the chosen route. Learning, teaching and assessment methods to enable outcomes to be achieved and demonstrated: All modules are delivered as block taught one-week modules to provide access to both full-time and part-time students. Each module is taught by a mixture of lectures, seminars and practical work. Assessment is in the form of examinations and/or written coursework and/or oral presentation of in-class assignments as described in the module specifications. A full-time programme administrator provides support to the programme. A module timetable provides structure to the programme. A coursework hand-in timetable system is provided to control student working across the year. Research skills are developed through coursework assignments and in particular through an industrial project that includes an exhibition of work, oral presentation, a research paper, in addition to the conventional thesis. b. Subject-specific practical skills: On successful completion of the programme, students should be able to: Use the design process to plan and carry out projects. Plan and implement reorganisation of a company for increased effectiveness. Select and conduct experimental procedures to support analysis. Generate new ideas and develop and evaluate a range of solutions. Programme an NC machine tool. Perform and analyse results for both static and dynamic accuracy of a machine tool. Use a CAD/CAM system to facilitate NC programming. Use some of the various rapid prototyping systems and processes. Use appropriate CAE techniques to generate tooling. Use modern information modelling techniques for decision support systems. 3 Design in detail a lean and/or agile business system. Use enterprise modelling architectures, methods and simulation tools. Learning, teaching and assessment methods to enable outcomes to be achieved and demonstrated: All modules are delivered as block taught one-week modules to provide access to both full-time and part-time students. Each module is taught by a mixture of lectures, seminars and practical work. Assessment is in the form of examinations and/or written coursework and/or oral presentation of in-class assignments as described in the module specifications. A full-time programme administrator provides support to the programme. A module timetable provides structure to the programme. A coursework hand-in timetable system is provided to control student working across the year. Research skills are developed through coursework assignments and in particular through an industrial project that includes an exhibition of work, oral presentation, a research paper, in addition to the conventional thesis. c. Generic skills: On successful completion of this programme, students should be able to: Plan and monitor multi-disciplinary projects. Appreciate the central role of design within engineering. Communicate effectively and make presentations of a technical/business nature to achieve maximum impact. Identify methods to assist in innovation, teamworking and engineering communication. Demonstrate competence in using computer based engineering techniques. Analyse and understand complex engineering problems. Use teamworking skills. Explain the integration of lean/agile systems. Learning, teaching and assessment methods to enable outcomes to be achieved and demonstrated: All modules are delivered as block taught one-week modules to provide access to both full-time and part-time students. Each module is taught by a mixture of lectures, seminars and practical work. Assessment is in the form of examinations and/or written coursework and/or oral presentation of in-class assignments as described in the module specifications. A full-time programme administrator provides support to the programme. A module timetable provides structure to the programme. A coursework hand-in timetable system is provided to control student working across the year. Research skills are developed through coursework assignments and in particular through an industrial project that includes an exhibition of work, oral presentation, a research paper, in addition to the conventional thesis. 4. Programme structures and requirements, levels, modules, credits and awards: The programme is the responsibility of the Wolfson School of Mechanical and Manufacturing Engineering. It is studied on a full-time or part-time basis and leads to one of the following awards: MSc – 180 credits Postgraduate Diploma (PGDip) – 120 credits Postgraduate Certificate (PGCert) – 60 credits 4 The programme is made up of taught modules and a substantial project. All modules have a credit weight. The credit weight for a module is awarded to a candidate who gains a module mark of not less than 50%. The lowest acceptable mark for a module is 40% (the minimum performance level). Full-time candidates may be awarded an MSc after accumulating 60 credits for their project, 90 credits from taught modules and being assessed at the minimum performance level or better in further modules with a total credit weight of 30. Full details can be found in the Programme Regulations at: http://www.lboro.ac.uk/admin/ar/lps/progreg/year/1112/index.htm 5. Criteria for admission to the programme: Admission is normally by an honours degree in engineering or physical sciences. Other academic or professional qualifications such as a chartered professional qualification are considered on their merits. Industrial or other appropriate experience may also be used as part qualification for admission to the programme. 6. Information about the programme assessment strategy: Students are assessed on each module using coursework and/or examination. Assessment of a module normally takes place at the end of the semester the module is taught in. The individual project is assessed at the end of the programme. Reassessment may take place during the University’s special assessment period. The pass mark to achieve credit for a module is 50%. There is also a minimum performance pass-level, which is set at not less than 40% in the module assessment. In order to pass the MSc students must: take modules with a total credit weight of 180, including the project module; obtain 150 credits; pass modules with a further credit weight of 30 at the minimum 40% performance pass-level. In terms of marks in the module assessments, this means that students must obtain: 50% or more in their project module (yielding 60 credits); 50% or more in modules with a credit weight of 90; 40% or more in further modules with a credit weight of 30. In order to obtain distinction in the MSc, students must obtain 180 credits and have a weighted average assessment score over all offered modules of at least 70%. 7. What makes the programme distinctive? The programme offers a combination of manufacturing management and technical manufacturing skills which is now becoming rare in the UK education sector. It offers training in state-of-the-art manufacturing techniques which are highly applicable to modern-day manufacturing industry both in the UK and abroad. 8. Particular support for learning: Information on all the University’s support services can be found at: http://www.lboro.ac.uk/admin/ar/templateshop/notes/lps/index.htm Additional Wolfson School services include: Computing Facilities: The School has installed many computers to enhance the extensive central facilities provided by Computing Services. There are four networked computer suites within the Wolfson School building that are used for both teaching and private study with access 24 hours, 7 days per week. 9. Methods for evaluating and improving the quality and standards of learning: http://www.lboro.ac.uk/admin/ar/templateshop/notes/lps/index.htm 5