Supplementary Information (doc 1183K)

advertisement

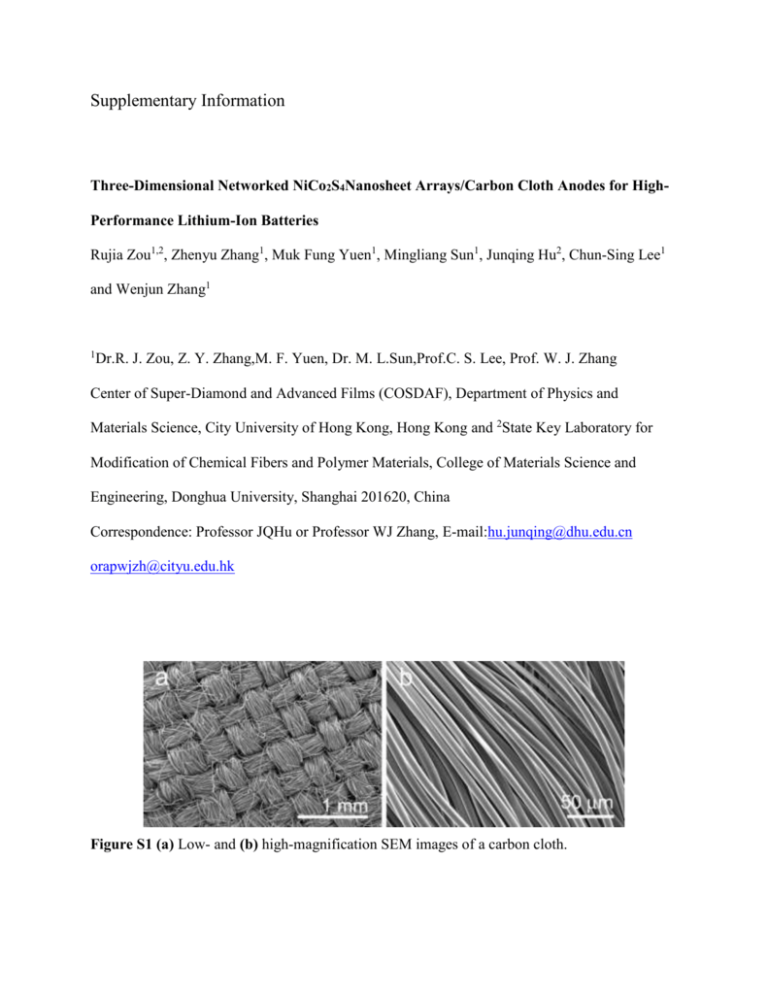

Supplementary Information Three-Dimensional Networked NiCo2S4Nanosheet Arrays/Carbon Cloth Anodes for HighPerformance Lithium-Ion Batteries Rujia Zou1,2, Zhenyu Zhang1, Muk Fung Yuen1, Mingliang Sun1, Junqing Hu2, Chun-Sing Lee1 and Wenjun Zhang1 1 Dr.R. J. Zou, Z. Y. Zhang,M. F. Yuen, Dr. M. L.Sun,Prof.C. S. Lee, Prof. W. J. Zhang Center of Super-Diamond and Advanced Films (COSDAF), Department of Physics and Materials Science, City University of Hong Kong, Hong Kong and 2State Key Laboratory for Modification of Chemical Fibers and Polymer Materials, College of Materials Science and Engineering, Donghua University, Shanghai 201620, China Correspondence: Professor JQHu or Professor WJ Zhang, E-mail:hu.junqing@dhu.edu.cn orapwjzh@cityu.edu.hk Figure S1 (a) Low- and (b) high-magnification SEM images of a carbon cloth. Figure S2 (a) Low- and (b) high-magnification SEM images of the NiCo-precursor NSAs synthesized on carbon cloth. Figure S3 (a) N2 adsorption/desorption isotherms and (b) the corresponding pore size distribution of NiCo2S4 NSAs scratched from carbon cloth using the BJH method. Figure S4 TEM images showing the lithiation process of NiCo2S4 nanosheet at different time of (a) 1 min, (b) 5 min, (c) 10 min, and (d) 15 min. Figure S5 CV curves of carbon cloth at a scan rate of 0.1 mVs-1 between 0.01 and 3 V. Figure S6 Cycling performance and corresponding Coulombic efficiency of NiCo2S4 NSAs/carbon cloth electrode at 2000 mA g-1. Figure S7 Cycling performance of carbon cloth electrode at 1000 mA g-1. Figure S8 (a) Low- and (b) high-magnification SEM images of the NiCo2S4 flowers. Figure S9 Coulombic efficiency of NiCo2S4 flowers electrodes at 1000 mA g-1. I. Methods Synthesis: In a typical synthesis, 0.29g of Co(NO3)2·6H2O, 0.145g of Ni(NO3)2·6H2O and 0.56g methenamine were dissolved into a solution of 35 mL of methanol to form a clear pink solution. The carbon cloth substrates were cleaned by sonication sequentially in acetone for 24 h, deionized (DI) water and ethanol for 30 min, and then transferred into autoclave in an electric oven at 180 ˚C for 12 h. The carbon cloth was taken out from Teflon autoclave at room temperature and was then cleaned by ultrasonication to remove the loosely attached products on the surface. Then, the 3D networked NiCo2S4 NSAs/carbon cloth were obtained by placing NiCo2O4-precursor NSAs/carbon cloth in a 50 mL autoclave with a solution containing Na2S·9H2O (0.30 g)in an electric oven at 90 ˚C for 24 h. The as-obtained product was washed successively with deionized water and ethanol to remove any residual ionic species, and finally dried in vacuum for 24 h. Besides, NiCo2S4 flowers were also synthesized using hydrothermal reaction. 0.58g of Ni(NO3)2·6H2O, 0.29g of Ni(NO3)2·6H2O and 4.0 g methenamine were dissolved into a solution of 35 mL of methanol to form a clear pink solution, and the resulting solution was placed in a 50 mL Teflon-lined autoclave. The autoclave is heated to 180 ˚C for 12 h to obtain NiCo2O4-precursor flowers. After wards, the NiCo2O4-precursor flowers were converted into NiCo2S4 flowers under the same ion exchange procedure as above. The NiCo2S4 flowers products were washed successively with deionized water and ethanol to remove any residual ionic species, and finally dried in vacuum for 24 h. The mass of the active material (NiCo2S4 NSAs) was estimated to be in the range from 1.02 to 1.36 mg for samples synthesized in different batches. To measure the mass of active materials, 6 pieces of carbon cloth of the same size were weighted by using an electronic balance (Sartorius BP 211D) with the resolution of 0.01mg, and their average mass was 20.05 ± 0.04 mg. After the synthesis process, the 3D networked NiCo2S4 NSAs/carbon cloth was weighted. By subtracting the average mass of carbon cloth, the masses of NiCo2S4 NSAs (active material) synthesized in different batches were obtained. The uncertainty of the average mass of carbon cloth will lead to an error of about ± 4% in estimating the mass of NiCo2S4 NSAs.