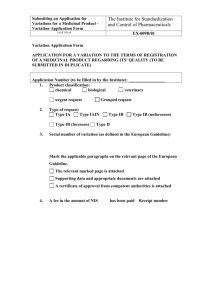

2.1. Minor variations of Type IA

advertisement