1403846

advertisement

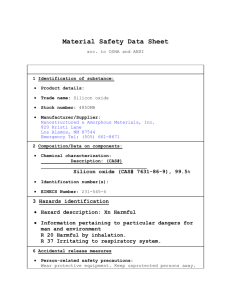

1 EFFECT OF GEL VOLUME IN AUTOCLAVE ON 2 HYDROTHERMAL SYNTHESIS OF MORDENITE 3 FROM RICE HUSK SILICA 4 5 Running head: Effect of gel volume on mordenite synthesis 6 7 Suriyan Rakmae and Jatuporn Wittayakun* 8 School of Chemistry, Institute of Science, Suranaree University of Technology, Nakhon 9 Ratchasima 30000, Thailand. Tel.: +66 44 224 256; Fax: +66 44 224 185. 10 Email: jatuporn@sut.ac.th 11 *Corresponding author 12 13 Abstract: 14 Silica prepared by refluxing rice husk with HCl acid followed by calcination 15 (refluxed RHS) and dissolution of rice husk ash followed by precipitation 16 (precipitated RHS) was used as a silica source for a synthesis of mordenite in 17 sodium form (NaMOR) by hydrothermal method. The gel volume in an 18 autoclave was 30, 50 and 70%. The NaMOR products from both silica 19 sources were analyzed by X-ray diffraction (XRD), X-ray fluorescence 20 (XRF), N2 adsorption-desorption, ammonia temperature programmed 21 desorption (NH3-TPD) and scanning electron microscopy (SEM). All samples 22 showed characteristic XRD peaks of NaMOR. The properties of the products 23 including Si/Al ratio, surface area, acidity and morphology were influenced 24 by gel volume in the autoclave and the silica source. 25 26 Keywords: Mordenite, hydrothermal synthesis, rice husk silica, reflux, 27 precipitation 28 29 Introduction 30 In several countries including Thailand, rice husk (RH) is produced in a large 31 quantity as a byproduct from rice milling. RH composes of about 20 wt% of 32 inorganic compound in which silica is a main component (about 85-98% wt%) 33 (Juliano et al., 1985). Several methods to obtain the silica from rice husk with 34 high purity are acid treatment of RH before cacination (Liou, 2004, Panpa and 35 Jinawath, 2009, Krishnarao et al., 2001) and dissolution RHA with alkali solution 36 before precipitation with acidic solution (Kalapathy et al., 2000). Silica from RH 37 is amorphous with a uniform dispersion by molecular unit, fine particle size, high 38 purity and surface area (Liou et al., 2011). Moreover, when RH is burned, rice 39 husk ash (RHA) with silica purity of 76-95 wt% was obtained depending on 40 conditions (Kordatos et al., 2008, Naskar et al., 2012, Tepamat et al., 2013). Silica 41 from leaching of RH and RHA can be used as a silica source for the synthesis of 42 silicon-based materials. 43 With high purity, RHS can be used as a silica source for the production of 44 porous inorganic materials such as zeolites LSX (Khemthong et al., 2007), NaY 45 (Wittayakun et al., 2008; Khabuanchalad et al., 2008) NaBEA (Loiha et al., 46 2009), NaZSM-5 (Pimsuta et al., 2013) and MCM-41 mesoporous silica (Artkla et 47 al., 2008). Moreover, rice husk charcoal was used as a silica source for the 48 synthesis of zeolite NaA (Tepamat et al., 2013) and silicon carbide (SiC) 49 (Makornpan et al., 2013). The interest of this work was to use silica from rice 50 husk for the synthesis of zeolite mordenite (MOR). 51 MOR is a zeolite with interconnected pore channels between 12- 52 membered ring and 8-membered ring (Baerlocher and McCusker, www). The unit 53 cell dimensions of NaMOR were first reported by Meier (1961). It has a pore 54 channel between 12-membered ring in the c-axis and 8-membered ring in the b- 55 axis. Si/Al ratio of MOR can be varied depending on composition of the synthetic 56 batch (Roland and Kleinschmit, 2003). MOR has been used as a solid catalyst for 57 various industrial chemical reactions (Pantu et al., 2007). 58 Kulawong et al. (2011) reported a synthesis of NaMOR in sodium form 59 (NaMOR) using rice husk silica (RHS). They crystallized the NaMOR in a 60 Teflon-lined autoclave with 150 mL capacity at various time and used the optimal 61 condition for a synthesis with another autoclave with 250 mL capacity. However, 62 the void volume was not reported for both vessels. Thus, it is an aim of this work 63 to understand the influence of gel volume in an autoclave on physicochemical 64 properties of MOR. Moreover, an effect of the silica source from acid leaching 65 and from precipitation was studied. 66 67 68 Materials and Methods 69 Preparation of rice husk silica by reflux and calcination (RRHS) 70 RH was obtained from a local mill near Suranaree University of 71 Technology, Thailand. It was washed several times with tap water, soaked in DI 72 water for 10 min and dried at 70 ºC overnight. Twenty five grams of the dried rice 73 husk was filled in a 250-mL round bottom flask, added with 180 mL of 3 M HCl 74 solution (prepared from 37% HCl, Merck) and refluxed at 100 ºC for 6 h. The 75 refluxed rice husk was washed several times with tap water until pH of the wash 76 solution equaled to that of the tap water, soaked in DI water for 10 min, dried at 77 70 ºC overnight and calcined at 600 ºC for 6 h in a muffle furnace (CABOLITE) 78 with a heating rate of 2 ºC/min. 79 80 Preparation of rice husk silica by dissolution-precipitation (PRHS) 81 First, rice husk ash (RHA) was prepared by calcination of the dried RH at 82 600ºC in a muffle furnace with heating rate of 2 ºC/min and cooled to room 83 temperature. Four grams of RHA was dissolved in 100 mL NaOH solution 84 (Prepared from NaOH pellet (Merck) with RHA: NaOH weight ratio of 1:1.9) in 85 polyethylene bottle under magnetic stirring with a speed of 300 rpm for 36 h at 86 room temperature. Then, the solution was filtered through a filter paper (Whatman 87 No.1) by an aspirator to a polyethylene beaker, added with a 6 N H2SO4 solution 88 (Sigma Aldrich) dropwise from a burette until the pH was about 11. Then, the 89 solution was heated to 90-95 ºC with continuous addition of sulfuric acid. 90 Precipitation of silica began when the pH was about 10.5-10.6. Then, DI water 91 (50 mL) was added and the gel was broken by magnetic stirring. The H2SO4 92 solution was further added until the pH was 7 and the mixture was kept under 93 stirring at this condition for 3 h. The precipitated silica was separated by 94 centrifugation and washed repeatedly with warm DI water until the pH of washed 95 water equal to that of DI water. Then, the precipitated silica powder was dried at 96 120 ºC for 24 h in a hot air oven. 97 98 Synthesis of mordenite (MOR) 99 The NaMOR was synthesized with a procedure adapted from Kim and 100 Ahn (1991). Silica (either RRHS or PRHS) was suspended in DI water to form 101 slurry in a polypropylene bottle. Then, sodium aluminate (Riedel-de Haën®, 102 41.383% Na2O, 58.604% Al2O3) in NaOH solution was added under a magnetic 103 stirring (250 rpm) at room temperature to produce a gel with the following molar 104 ratio: 6Na2O:Al2O3:29.2SiO2:780H2O. The mixture was transferred to a Teflon- 105 lined stainless steel autoclave and crystallized at 170 ºC (with heating rate 2.5 106 ºC/min) without agitation for 120 h. The autoclave volume was 245 cm3 and the 107 percent of gel/autoclave volume was 30, 50 and 70%. The sample was named 108 according to the silica type and gel volume. For example, R-MOR-30 was the 109 product from refluxed RHS with volume 30% of the autoclave volume; P-MOR- 110 70 was the product from precipitated RHS with volume 70% of the autoclave 111 volume. 112 washed thoroughly with DI water and dried at 100 ºC overnight. 113 After crystallization, the product was separated by centrifugation, 114 Characterization 115 Phase of NaMOR was studied by an X-ray diffraction (XRD, Bruker AXS 116 D5005) with nickel-filtered Cu Kα radiation (wavelength = 1.54 Å) scanning in 117 the 2θ range of 5–50º, at an increment of 0.02º and scan speed of 1 s/step). 118 Elemental analysis was determined by X-ray fluorescence (XRF, Horiba 119 Scientific XGT-5200). Morphologies of the silica were studied by scanning 120 electron microscopy (SEM, JOEL/JSM-6010LV). All samples were coated with 121 gold by sputtering (Neocoater/mp-19020NCTR). 122 The surface area of obtained NaMOR was determined by N2 adsorption- 123 desorption analysis (Micromeritics ASAP 2010) from the Brunauer-Emmet-Teller 124 (BET) method in a relative pressure range of 0.01–0.2. Each sample was first 125 degassed at 300 ºC and the analysis was carried out at liquid nitrogen temperature. 126 The acidity of obtained NaMOR was determined by temperature- 127 programmed desorption of ammonia (NH3-TPD) in a Belcat-B equipped with a 128 thermal conductivity detector. A sample amount of 250 mg was packed in a 129 tubular U-shaped quartz cell, preheated at 500 ºC with a heating rate of 10 ºC/min 130 in a He flow (50 mL/min) for 110 min to eliminate physisorbed species and 131 cooled to 70 ºC. Then a constant flow of 30 mL/min of 5 vol. % NH3/Ar gas 132 mixture was introduced over the samples for 30 min to achieve saturation. After 133 purging with He for 5 min to remove physisorbed NH3, then, the sample was 134 heated to 130 ºC with a heating rate of 10 ºC/min and held for 3 h to remove 135 physisorbed species. The NH3-TPD measurement was performed from 130 to 850 136 ºC with a heating rate of 10 ºC/min with He as a carrier gas. The number of acid 137 sites was calculated from the peak area compared to a reference material with a 138 known number of acid sites (ZSM-5) that was analyzed with the same conditions. 139 140 Results and discussion 141 The XRD pattern of the obtained products from refluxed rice husk silica 142 including R-MOR-30, R-MOR-50 and R-MOR-70 are illustrated in Figure 1. The 143 pattern of all samples contained peaks with similar positions to those of NaMOR 144 reported in literatures (Kulawong et al., 2011; Zhang et al., 2009, Mignoni et al., 145 2008). The order of relative peak intensity changed when the gel volume. From R- 146 MOR-30 the strongest peak was 9.8º followed by 25.7º corresponding to the plane 147 200 and 202, respectively. From R-MOR-50 the order of relative intensity was 148 similar but the second peak became stronger. From R-MOR-70 a switch in the 149 intensity order was observed. The growth of zeolite crystal depends on solubility 150 of the starting material and equilibrium within the autoclave during 151 crystallization. The larger volume of the gel led to the higher autogeneous 152 pressure in the autoclave and resulted in higher solubility of the starting material. 153 The crystal growth in the 202 plane for from reflux RHS increased with the gel 154 volume. Kulawong et al. (2011) reported that NaMOR synthesized with a 150 mL 155 capacity autoclave showed the strongest XRD peak at 25.6º. When the synthesis 156 was done with a 150 mL capacity autoclave, the peak at 9.8º became a dominant 157 one. 158 The XRD pattern of the obtained products from precipitated rice husk 159 silica including P-MOR-30, P-MOR-50 and P-MOR-70 are illustrated in Figure 2. 160 The patterns of all samples also contain characteristic peaks of NaMOR 161 (Kulawong et al., 2011; Zhang et al., 2009, M. L. Mignoni et al., 2008) with the 162 strongest peak from the plan 202. The intensity of the plan 200 increased with the 163 gel volume. From P-MOR-50 and P-MOR-70, the intensity of the peak at 6.5º 164 (corresponding to the plane 110) was significantly higher than that from P-MOR- 165 50. The XRD pattern depends on the synthesis conditions. For example, it was 166 reported by Structure Commission of the International Zeolite Association that 167 intensity of the plan 200 was the highest in NaMOR with Si/Al ration of 5 168 (Baerlocher and McCusker, www). 169 The Si/Al ratios of all samples determined by XRF are listed in Table 1. 170 The ratio in the product from both silica sources was higher than that in the gel. 171 The Si/Al ratio of NaMOR from refluxed RHS increased with the gel volume. 172 This result could be from the higher solubility of RHS for the sample with the 173 higher gel volume. In case of NaMOR from precipitated RHS, the change in Si/Al 174 ration could not be related to the gel volume. The lowest Si/Al ratio was from P- 175 MOR-50. From observation the silica from precipitation could be dissolved more 176 easily than the refluxed RHS. 177 The N2 adsorption-desorption isotherm of the NaMOR are presented in 178 Figure 3. The isotherm of all samples was type I which is the characteristic of 179 microporous materials. The adsorption increased rapidly at low relative pressure 180 corresponding to the adsorption in micropores and became nearly constant 181 afterward. The BET surface areas are included in Table 1. The surface area of 182 NaMOR synthesized with refluxed RHS increased with the gel volume. The 183 surface area of R-MOR-30 was significantly lower than R-MOR-50 and R-MOR- 184 70 implying that R-MOR-30 had lower crystallinity. This could be the effect from 185 lower pressure in the autoclave which resulted in the lower solubility of RHS. In 186 contrast, the surface areas of NaMOR prepared from precipitated RHS were 187 similar. This result may due to the higher solubility of RRHS. 188 The NH3-TPD profiles of the NaMOR synthesized with different volumes 189 are shown in Figure 4. Normally, NaMOR exhibited only one peak at low 190 temperature (Katada et al., 2007). All NaMOR from this work also exhibited an 191 additional small peak at high temperature. Similar observation was reported by 192 Kulawong et al. (2011). The peak at low and high temperature corresponded to 193 ammonia desorbed from Brønsted and Lewis acid sites, respectively (Karge and 194 Dondud, 1989; Ma et al., 2000). The intensity of desorption of NaMOR from both 195 silica sources increased with the gel volume. The desorption temperature of R- 196 MOR-70 and P-MOR-70 was lower than that of other samples corresponding to 197 the weaker acid sites. Ma et al. (2000) proposed that the ammonia desorption from 198 ZSM-5 at low temperature associated with the ammonia adsorbed either on Si– 199 OH or from non-zeolitic impurity. The peak desorbed at high temperature was 200 related with the ammonia adsorbed on Si–OH–Al. 201 SEM micrographs of the NaMOR synthesized from refluxed and 202 precipitated RHS are illustrated in Figure 5 and 6, respectively. Particles of 203 NaMOR synthesized from refluxed RHS (Figure 5) were not uniform in size and 204 shape. Aggregated plate-like sheets and amorphous-like matter were observed. 205 Particles of NaMOR synthesized from precipitated RHS (Figure 6) were more 206 uniform with less amorphous-like matter. The particle size decreased with the gel 207 volume in the autoclave. The larger crystal size related to small number of nuclei 208 formation in the synthesis gel (Cubillas and Anderson, 2010; Cundy and Cox, 209 2005). Moreover, the uniform of the zeolite crystal synthesized by using 210 hydrothermal method crucially related to homogeneous distribution of the starting 211 nuclei in the system (Mintova and Valtchev, 2002). 212 213 Conclusions 214 NaMOR was synthesized by hydrothermal method using refluxed and precipitated 215 rice husk silica (RHS). All products gave characteristic XRD peaks of NaMOR 216 with differences in relative intensity. 217 refluxed RHS changed from plane 200 to 202 with the increase of starting gel in 218 the autoclave. On the other hand, the strongest peak in NaMOR from precipitated 219 RHS was from the plan 202. In NaMOR from refluxed RHS the Si/Al ratio, 220 surface area and Brønsted acidity increased with the gel volume. In NaMOR from 221 precipitated RHS the connection between either Si/Al ratio or surface area and the 222 gel volume could not be made, however, the Brønsted acidity increased with the 223 gel volume. The NaMOR from precipitated RHS had higher surface area and 224 uniformity in particle shape and size more than that from refluxed RHS. 225 The strongest peak in NaMOR from 226 Acknowledgements 227 Scholarship for S. Rakmae was from Royal Golden Jubilee Ph.D. program from 228 Thailand Research Fund (TRF) and Suranaree University of Technology (Grant 229 No. PHD/0173/2553). 230 231 References 232 Artkla, S., Grisdanurak, N., Neramittagapong, S., and Wittayakun, J. (2008). 233 Characterization and catalytic performance on transesterification of palm olein 234 of potassium oxide supported on RH-MCM-41 from rice husk silica, Suranaree 235 J. Sci. Technol. 15(2):133-138. 236 237 Baerlocher, Ch. and McCusker, L.B., Database of Zeolite Structures: http://www.iza-structure.org/databases/ 238 Cubillas, P., and Anderson, M.W. (2010). Pore structure, diffusion and activity at 239 the subcrystal level. In: Zeolites and catalysis. Cejka, J., Corma, A., and Zones, 240 S., (eds). Wiley-VCH, Weinheim, p. 375-379. 241 Cundy, C.S. and Cox, P.A. (2005). The hydrothermal synthesis of zeolites: 242 Precursors, intermediates and reaction mechanism. Micropor. Mesopor. Mater. 243 82(1-2):1-78. 244 245 246 247 Juliano, B.O., Maniñgat, C.C., and Pascual, C.G. (1987). Properties of fraction of rice hull. Phytochemistry. 26(12):3261-3263. Kalapathy, U., Proctor, A., and Shultz, J. (2000). A simple method for production of pure silica from rice hull ash. Biores. Technol. 73(3):257-262. 248 Karge , H.G. and Dondur, V. (1990). Investigation of the distribution of acidity in 249 zeolites by temperature-programmed desorption of probe molecules. I. 250 Dealuminated. J. Phys. Chem. 94 (2):765-772. 251 Katada, N., Kanai, T., and Niwa, M. (2004). Dealumination of proton form 252 mordenite with high aluminum content in atmosphere. Micropor. Mesopor. 253 Mater.75(1-2): 61-67. 254 Khabuanchalad, S. Khemthong, P., Prayoonpokarach, S., and Wittayakun, J. 255 (2008). Transformation of zeolite NaY synthesized from rice husk silica to NaP 256 during hydrothermal synthesis, Suranaree J. Sci. Technol. 15(3):225-231. 257 Khemthong, P., Prayoonpokarach, S., and Wittayakun, J. (2007). Synthesis and 258 characterization of zeolite LSX from rice husk silica, Suranaree J. Sci. 259 Technol. 14(4):367-379. 260 261 Kim, G.J. and Ahn, W.S. (1991) Direct synthesis and characterization of highSiO2-content mordenites, Zeolites, 11(7):745-750. 262 Kordatos, K., Gavela, S., Ntziouni, A., Pistiolas, K.N., Kyritsi, A., and 263 Kasselouri-Rigopoulou V. (2008). Synthesis of highly siliceous ZSM-5 zeolite 264 using silica from rice husk ash. Micropor. Mesopor. Mater.115(1-2):189-196. 265 Krishnarao, R.V., Subrahmanyam, J., and Kumar, T.J. (2001). Studies on the 266 formation of black particles in rice husk silica ash. J. Eur. Ceram. Soc. 267 21(1):99-104. 268 Kulawong, S., Prayoonpokaracha, S., Neramittagapong, A., and Wittayakun, J. 269 (2011). Mordenite modification and utililization as supports for iron catalyst 270 for phenol hydroxylation Journal of Industrial and Engineering Chemistry, 271 17(2): 346-351. 272 273 Liou, T.H. (2004). Preparation and characterization of nano-structured silica from rice husk. Mater. Sci. Eng. A. 364(1-2):313-323. 274 Liou, T.H. and Yang, C.C. (2011). Synthesis and surface characteristics of 275 nanosilica produced from alkali-extracted rice husk ash. Mater. Sci. Eng. B. 276 176(7):521-529. 277 Loiha, S., Föttinger, K., Zorn, K., Klysubun, W., Rupprechter, G., and 278 Wittayakun, J. (2009). Catalytic enhancement of platinum supported on zeolite 279 beta for toluene hydrogenation by addition of palladium, J. Ind. Eng. Chem., 15 280 (6):819-823. 281 Ma, D., Zhang, W., Shu, Y., Liu, X., Xu, Y., and Bao, X. (2000). MAS NMR, 282 ESR and TPD studies of Mo/HZSM-5 catalysts: evidence for the migration of 283 molybdenum species into the zeolitic channels. Catal. Lett. 66(3):155-160. 284 Makornpan, M., Mongkolkachit, C., and Wasanapiarnpong, T. (2013). Fabrication 285 of silicon carbide ceramics from rice husks, Suranaree J. Sci. Technol. 286 21(2):79-86. 287 Mao, R.L.V., Al-Yassir, N., Lu, L., Vu, N.T., and Fortier, A. (2006). New 288 method for the study of surface acidity of zeolites by NH3-TPD, using a pH- 289 meter equipped with an ion selective electrode. Catal. Lett. 112(1–2):13-18. 290 Meier, W. M. (1961). The crystal structure of mordenite (ptilolite), Z. Kristallogr. 291 115:439-450. 292 Mignoni, M.L., Petkowicz, D.I., Machado, N.R.C.F., and Pergher, S.B.C. (2008). 293 Synthesis of mordenite using kaolin as Si and Al source. Appl. Clay Sci. 41(1- 294 2):99-104. 295 Mintova, S., and Valtchev, V. (2002). Effect of the silica source on the formation 296 of nanosized silicalite-1: an in situ dynamic light scattering study. Micropor. 297 Mesopor. Mater. 55(2):171-179. 298 Naskar, M.K., Kundu, D., and Chatterjee, M. (2012). A Facile Hydrothermal 299 Conversion of Rice Husk Ash to ZSM-5 Zeolite Powders. J. Am. Ceram. Soc. 300 95(3):925-930. 301 302 303 Panpa, W. and Jinawath, S. (2009). Synthesis of ZSM-5 zeolite and silicalite from rice husk ash. Applied Catal. B: Environ., 90(3-4):389-394. Pimsuta, M., Neramittagapong, A., Prayoonpokarach, S. and Wittayakun, J. 304 (2012) Desilication of NaZSM-5 and Utilization as Support of Fe for Phenol 305 Hydroxylation. Inter. J. Chem. Eng. Appl., 3(2):86-91. 306 Pantu, P., Boekfa, B., and Limtrakul, J. (2007). The adsorption of saturated and 307 unsaturated hydrocarbons on nanostructured zeolites (H-MOR and H-FAU): 308 An ONIOM study, J. Mol. Catal. A-Chem. 277(1-2): 171-179. 309 Roland, E. and Kleinschmit, P., Zeolites; in Bohnet, M; Brinker, C. J., eds.; 310 Ullmann’s Encyclopedia of Industrial Chemistry, 6th ed., Wiley: Weinheim, 311 2003. 312 Tepamat, T., Mongkolkachit, C., and Wasanapiarnpong, T. (2013). Synthesis of 313 zeolite NaA and activated carbon composite from rice husk. Suranaree J. Sci. 314 Technol. 21(2):119-123. 315 Wittayakun, J., Khemthong, P., and Prayoonpokarach, S. (2008). Synthesis and 316 characterization of zeolite NaY from rice husk silica. Korean J. Chem. Eng., 25 317 (4):861-864. 318 Zhang, L., Laak, A.N.C., Jongh, P.E., and Jong, K.P. (2009). Synthesis of large 319 mordenite crystals with different aspect ratios. Micropor. Mesopor. Mater. 320 126(1-2):115-124. 321 322 Table 1: Si/Al ratio and surface area of the synthesized MOR 323 % Gel volume in autoclave 30 Gel Si/Al Product Si/Al BET surface area (m2/g) R-MOR-30 Method to obtain rice husk silica Reflux 14.6 57.6 215 R-MOR-50 Reflux 50 14.6 62.2 357 R-MOR-70 Reflux 70 14.6 65.2 347 P-MOR-30 Precipitation 30 14.6 56.1 435 P-MOR-50 Precipitation 50 14.6 48.1 432 P-MOR-70 Precipitation 70 14.6 49.3 418 Sample 324 325 326 327 328 Figure 1 XRD patterns of NaMOR synthesized from rice husk silica from reflux 329 with volume 30, 50 and 70% of the autoclave 330 331 332 333 Figure 2 XRD patterns of NaMOR synthesized from precipitated rice husk silica 334 with volume 30, 50 and 70% of the autoclave 335 336 337 338 339 Figure 3. N2 adsorption–desorption isotherm of NaMOR synthesized with various volumes by using (a) RRHS and (b) PRHS. 340 341 342 343 344 345 346 347 348 349 350 351 352 353 354 355 356 357 358 359 360 Figure 4 NH3-TPD spectra of NaMOR with different starting material volume; 361 (a) synthesized from R-RHS and (b) synthesized from P-RHS 362 363 364 365 366 367 368 369 370 371 372 373 374 375 376 377 378 379 380 Figure 5 SEM images of NaMOR zeolites synthesized from R-RHS (a) R-MOR- 381 30 (low magnification) (b) R-MOR-30 (high magnification) (c) R- 382 MOR-50 (low magnification) (d) R-MOR-50 (high magnification) (e) 383 R-MOR-70 (low magnification) (f) R-MOR-70 (high magnification) 384 385 386 387 388 389 390 391 392 393 394 395 396 397 398 399 400 401 402 403 Figure 6 SEM images of NaMOR zeolites synthesized from PRHS (a) P-MOR- 404 30 (low magnification) (b) P-MOR-30 (high magnification) (c) P- 405 MOR-50 (low magnification) (d) P-MOR-50 (high magnification) (e) 406 P-MOR-70 (low magnification) (f) P-MOR-70 (high magnification)