Ct 109 notes: Separation efficiency, Smelter Contracts, and simple

advertisement

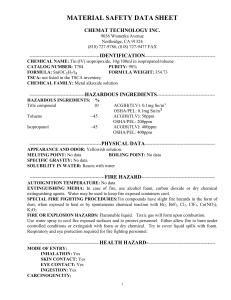

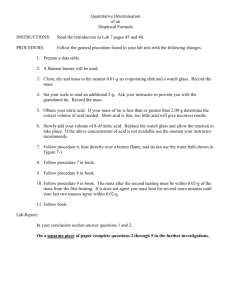

Ct 109 notes: Separation efficiency, Smelter Contracts, and simple calculations High price Low price N.S.R . Concentrate grade Fig 5:Effect of metal Price on NSR Changes in metal price, smelter terms etc affect NSR. If metal price increases, then optimum grade will be lower allowing high recoveries to be attained.. Smelter contracts Concentrates are sold under contract to “custom smelters” at prices based on metal markets such as the London Metal Exchange. Smelter are like ZimAlloys, Zisco, ZimPlat etc. The smelter, having processed the concentrate disposes it to the consumers. Assays are performed to determine the value of concentrates. Example: Simplified Smelter Contract: Material Tin concentrates assaying to less that 15% Sn to be free from deleterious impurities not stated and to contain sufficient moisture as to evolve dust when unloaded at our works Quantity Total production of concentrates. Valuation Tin less than 1 unit per dry tonne of concentrates at the lowest official London Metal Exchange prices. On the 7th market day after completion of arrival of each sampling lot into our works. Treatment Charge ₤385 per dry tonne of concentrate Moisture ₤24 per tonne os moisture Penalties Arsenic ₤40 per unit tonne Lot Charge: ₤175 per lot sampled of less tha 17 tonnes Pricing Delivery Free to our works in regular quantities, loose in tipping lorry, or in any other manner acceptable to both parties. Worked example: A tin concentrator treats a feed containing 1% tin and three possible combinations of concentrate and recovery are: High grade 63% tin at 62% recovery Medium grade 42% tin at 72% recovery Low grade 21% tin at 78% recovery Determine which of these combinations of grade and recovery produce the highest separation efficiency Assume: that tin is totally contained in the Cassirite (SnO2) which when pure contains 78.6% tin. Recovery = 100Cc/f, = 100 x C x concentrate grade/feed grade For high grade 62 = C x 63 x 100/1 therefore C =9.841 x10-3 S.E. = 100Cm(c-f)/(m-f)f = 0.984 x 78.6 x (63-1)/(78.6-1) x 1 = 61.8% Similarly for medium grade, 72 = 100 x C 42/1 C = 1.714 x 10-2 S.E. = 1.714 x 78.6 x (42-1)/(78.6-1) x 1 = 71.2% Low Grade concentrate: 78 = C x 21/1; C = 3.714 X10-2 S.E = 75.2% Highest Separation efficiency is achieved by production of a low grade (21% tin) concentrate and at high recovery(78%). NSR = Payment for contained metal –(Smelter charges + Transport costs) Assuming that we work with the same tin ore above, and that the ore is free of arsenic, And that the cost of transportation to the smelter is ₤20 per tonne of dry concentrate and Tin price per tonne = ₤8500 (LME) NSR can be calculated from the smelter contract: For the medium grade tin ore, Smelter payment is ₤8500 x 17,14 x (42-1)/100 000, = ₤59.73 Weight of 1 tonne medium grade ore is 17.14 kg Smelter treatment charge = ₤ 385 x 1.714 x10-2 = ₤6.59 Transport cost = ₤20 x 1.714 x10-2 = ₤0.34 NSR for processing 1 tonne = ₤ 59.73 - ( 6.59 - 0.34) = ₤52.80 Production of lower grade concentrate incurs higher smelter and freight charges but increases the payment of the contained metal due to higher recovery Breakdown of costs and revenue for treatment of cost and revenues for treatment 1 ton of mined ore (1%tin) Contained value = ₤ 85 mining processing Concentrate (72% recovery) Contained value ₤61.20 Transport and smelting Cost ₤40 cost₤8 Tailing Contained value ₤23.80 Effective cost ₤(61.20-52.80) = ₤8.40 Payment of ₤ 52.80 This balance between milling costs and metallurgical efficiency is critical to a concentrator treating ore of low contained value where it is critical that milling costs be as low as possible. Reagent costs are typically around 10% on a large copper mine but energy costs may contribute over 25%. Grinding is b7y far the greatest energy consumer and has the greatest effect on metallurgical efficiency. Grinding is essential for liberation of the minerals both it should not be carried out any finer than is justified economically. The effect of fineness of grind on NSR and grinding costs can be shown: Net Smelter return ₤/tonne NSR - grinding costs Grinding costs Grind size, microns (80% passing) Economic efficiency Economic efficiency compares the actual NSR per tones milled with the theoretical NSR Example; Calculate the economic efficiency of a tin concentrator treating an ore grading 1% tin producing a concentrate grading 42% at 72% recovery under the given smelter contract., tin price ₤8500 per tonne. As calculated before, NSR = ₤52.80 Assuming perfect milling, 100% recovery of tin would be achieved into a concentrate grading of 78.6%(ie pure cassiterite). Weight produced from 1 tonne concentrate = 12.72 kg. Transport cost = ₤12.71 x 20/10000 = ₤0.25 Treatment charge = ₤385 x 12.72/1000 = ₤4.90 Valuation = ₤17.72 x ( 78.6-1) x 85000 /100 000 = ₤83.90 NSR = ₤(83.90 - 0.25- 4.90) = ₤ 78.75 Economic efficiency = 52.80 x 100/78.75 = 67.0%