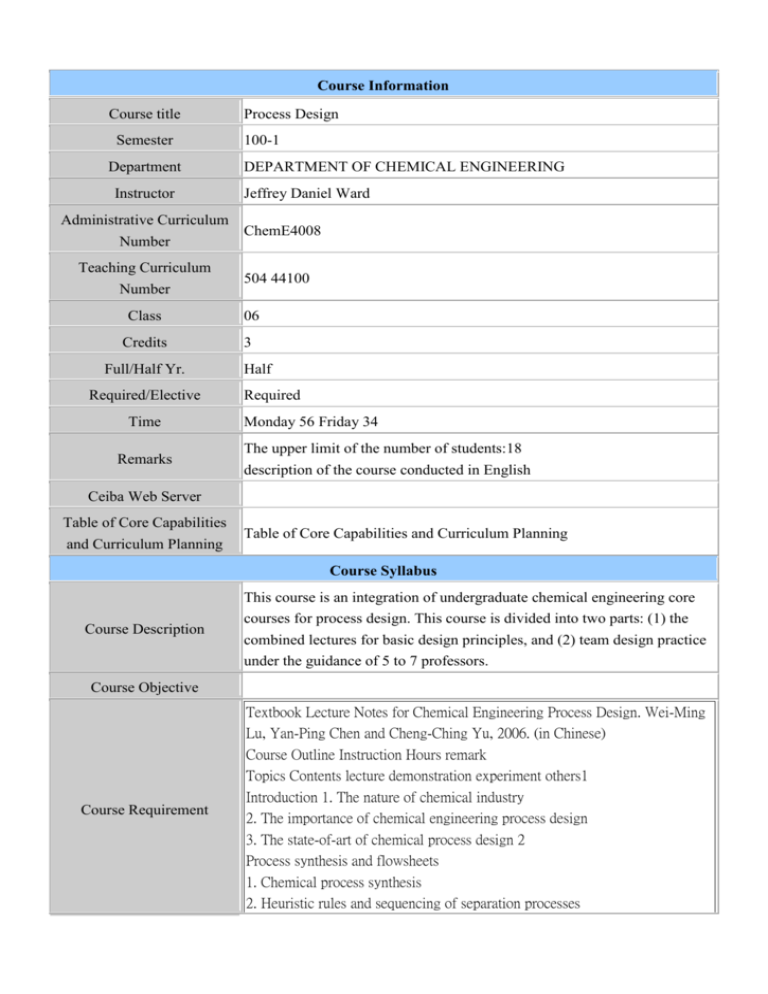

Course Information

advertisement

Course Information Course title Semester Department Instructor Process Design 100-1 DEPARTMENT OF CHEMICAL ENGINEERING Jeffrey Daniel Ward Administrative Curriculum ChemE4008 Number Teaching Curriculum Number 504 44100 Class 06 Credits 3 Full/Half Yr. Required/Elective Time Remarks Half Required Monday 56 Friday 34 The upper limit of the number of students:18 description of the course conducted in English Ceiba Web Server Table of Core Capabilities and Curriculum Planning Table of Core Capabilities and Curriculum Planning Course Syllabus Course Description This course is an integration of undergraduate chemical engineering core courses for process design. This course is divided into two parts: (1) the combined lectures for basic design principles, and (2) team design practice under the guidance of 5 to 7 professors. Course Objective Textbook Lecture Notes for Chemical Engineering Process Design. Wei-Ming Course Requirement Lu, Yan-Ping Chen and Cheng-Ching Yu, 2006. (in Chinese) Course Outline Instruction Hours remark Topics Contents lecture demonstration experiment others1 Introduction 1. The nature of chemical industry 2. The importance of chemical engineering process design 3. The state-of-art of chemical process design 2 Process synthesis and flowsheets 1. Chemical process synthesis 2. Heuristic rules and sequencing of separation processes 3. Chemical engineering process flowsheets 4. Hierarchy of process flowsheet 4 Computeraided process design 1. The principles of computer-aided process design 2. Process simulation using Aspen Plus software 3. Data base and data regression 2 Process integration and green chemical processes 1. The concept of pinch technology 2. Heat exchanger network design 3. Utility system and heat integration 4. Water minimization 5. Residual curves and distillation system design 4 Equipment selection and design 1. The basic principles of equipment selection 2. Heuristic rules for equipment design and selection 3. Selection and design of heat transfer equipments 4. Selection and design of separation equipments 4 Process control 1. Basic principles of control system 2. Advanced control systems 3. Design rules of control systems 4 Economic evaluation of chemical engineering processes 1. Principles of economic evaluation 2. Steps of economic evaluation 3. Estimations for capital and operation costs 4. Estimation of total product cost and profitability 4 Process optimization 1. Definitions of optimization problems 2. Methods for process optimization 3. Dominant design variables 4. Design example of a recycle plant 5. Flowsheet optimization 4 Conclusion 1. Future trend of process system engineering 2. Ethics and professionalism 3. Report writing 2 Evaluation and Assessment: Combined lectures (home assignments and final exam.) 50% ; Team design practice 50%. Course Website or Other remarks: http:// www.che.ntu.edu.tw/lab/therm/index.htm Office Hours References Designated reading