Electronic Supplementary Material CuO nanoleaf electrode: Facile

advertisement

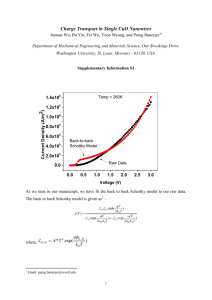

Electronic Supplementary Material CuO nanoleaf electrode: Facile preparation and nonenzymatic sensor applications Shaohuang Weng, Yanjie Zheng, Chengfei Zhao, Jianzhang Zhou, Liqing Lin, Zongfu Zheng, Xinhua Lin1 XRD and TEM characterization of CuO nanoleaf electrode The XRD pattern of the resulting CuO nanoleaf electrode with a reaction time of 10 min is shown in Figure S3. Three broad diffraction peaks located at 2θ=32.5°, 35.5°, and 38.7° indexed as [110], [002], and [111], respectively, were consistent with the main CuO phase (JCPDS No. 01-080-0076) with monoclinic phase. Except for the peaks attributed to the Cu substrate, no additional peaks were found in the Cu2O phase, indicating that copper was oxidized to CuO thoroughly during the short preparation process. The TEM image in Figure S4A illustrates the leaf-life morphology of the as-prepared CuO. An HR-TEM image of the CuO edge is shown in Figure S4B, further confirming the structure of the nanoleaf. The interplanar spacings were approximately 0.25 and 0.23 nm, which were in good agreement with the d-spacings of the (002) and (111) planes of the monoclinic CuO. Electrochemical properties and surface area of CuO nanoleaf electrode Ferricyanide solution was used as an electrochemical probe to estimate the electroactive surface area to evaluate the electrocatalytic property of the CuO nanoleaf electrode. Figure S6 displays the cyclic voltammetry (CV) of the CuO electrode at a series of different scan rates in 10 mM K3Fe(CN)6 with 1 M KCl solution. The CuO nanostructure showed a quasi-reversible redox behavior in the S. Weng · Y. Zheng · C. Zhao · L. Lin · X. Lin() Department of Pharmaceutical Analysis, Faculty of Pharmacy, Fujian Medical University, Fuzhou 350004, China E-mail: xhl1963@sina.com J. Zhou State Key Laboratory of Physical Chemistry of the Solid Surface and Department of Chemistry, College of Chemistry and Chemical Engineering, Xiamen University, Xiamen, 361005, China Z. Zheng() The 476 Hospital of PLA, Fuzhou 350002, China Fuzong Clinical College of Fujian Medical University, Fuzhou 350025, China E-mail: fuhos@163.com 1 K3Fe(CN)6 solution, confirming that the CuO nanoleaf electrode exhibit good electrochemical response current. Furthermore, the inset a of Figure S6 demonstrates that the anodic and cathodic peak currents (Ip) of the CuO nanoleaf electrode linearly increased as a function of the square root of the scan rate, suggesting that the mass transfer phenomenon of the CuO nanoleaf electrode was mainly diffusion-controlled [S1]. Considering the relation between the oxidation current peak and scan rate, the real surface area for the CuO nanoleaves was calculated according to the Randles–Sevcik equation [30]. The inset a of Figure S6 shows that the electroactive surface area of the CuO nanoleaf electrode was 0.268 cm2.Furthermore, the electroactive surface area of the different reaction time were compared, as shown in the inset b of Figure S6. The 10-min reaction time CuO showed the largest electroactive surface area compared to others no matter how long reaction time. It shows that the current synthesis route of CuO nanoleaf electrode has the notable advantage of short time, easy-control and large surface area. Figure S1 XRD pattern of the growth of CuO on Cu sheet with different reaction time, from a to g: 1 h, 30 min, 20 min, 300 s, 60 s, 20 s and 10 s. Inset shows the amplified pattern of 2θ from 35 to 45 degree. 2 Figure S2 SEM image of the growth of CuO on Cu sheet with different reaction time. (a) 300 s; (b): 20 min; (c) 30 min; (d) 1 h . Figure S3 XRD pattern of the prepared CuO nanoleaf electrode. The peaks marked with asterisks denote the copper substrate. 3 Figure S4 TEM (a) and HRTEM (b) images of the CuO nanoleaves. Figure S5 The mechanism of CuO nanoleaf electrode for the detection of H2O2 at 0.1 V. 4 1.0 Peak current (mA) 1.5 1.5 0.5 0.4 0.3 0.2 0.15 0.1 0.08 0.05 0.02 0.01 a 1.0 0.5 0.0 0.5 -1.0 -1.5 0.1 0.0 0.2 0.3 0.4 1/2 scan rate 0.5 1/2 0.6 0.7 0.8 (v/s ) 0.30 -0.5 2 Area (cm ) Current (mA) -0.5 -1.0 b 0.25 0.20 0.15 0.10 0.05 -1.5 0.00 0 10 20 30 40 Time (min) 50 60 -0.2 -0.1 0.0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 Potential (V, Vs Ag/AgCl) Figure S6 Cyclic voltammograms of the CuO nanoleaf electrode in a 10 mmol·L-1 K3Fe(CN)6/1 mol·L-1 KCl solution at different scan rates. Insets: anodic and cathodic currents as functions of the square root of the scan rate (a), surface areas of different CuO nanoleaf electrode prepared from different reaction-time (b). 1.5 a Current (mA) 1.0 0.5 c 0.0 -0.5 -0.4 -0.2 0.0 0.2 0.4 0.6 0.8 Potential (V, Vs Ag/AgCl) Figure S7 Cyclic voltammograms of the CuO nanoleaf electrode in 0.1 mol·L-1 NaOH solution with (a: 0.5 mmol·L-1 glucose + 0.48 mmol·L-1 H2O2+0.5 mmol·L-1 AA, b: 0.5 mmol·L-1 glucose + 0.48 mmol·L-1 H2O2+0.05 mmol·L-1 AA and c: 0.5 mmol·L-1 glucose + 0.48 mmol·L-1 H2O2) at a scan rate of 100 mV·s-1. 5 Reference: S1: Bard AJ, Faulkner LR(Ed.), Shao YH, Zhu GY, Dong XD, Zhang BL(Tr.) (2005) Electrochemical Methods Fundamentals and Applications, 2nd ed. Chemical Industry Press, Beijing 6