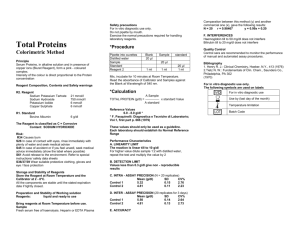

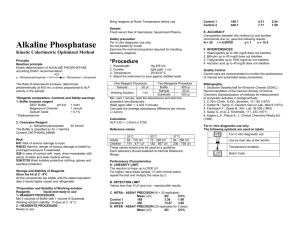

Reagents and Properties

advertisement

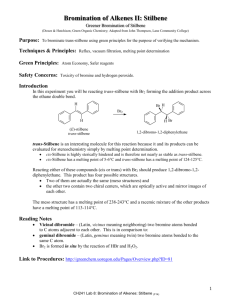

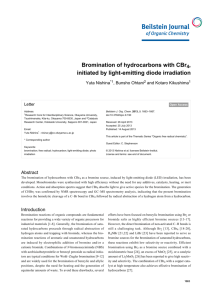

Greener Bromination of Alkenes Prepared by Joshua J. Pak, Idaho State University Modified from “The Evolution of a Green Chemistry Laboratory Experiment: Greener Brominations of Stilbene” Lallie C. McKenzie, Lauren M. Huffman, and James E. Hutchison, Journal of Chemical Education, 2005, 82(2), 306 PURPOSE OF THE Synthesis of vicinal dihalides by brominating alkenes. Introduction to EXPERIMENT Green Chemistry concepts. EXPERIMENTAL OPTIONS None BACKGROUD REQUIRED You should consult your textbook for the Cahn-Ingold-Prelog System for assigning the configuration of a chiral center. You should be familiar with techniques for reflux, vacuum filtration, and melting point measurement. The Twelve Principles of Modified from Anastas, P. T.; Warner, J. C. Green Chemistry: Theory Green Chemistry and Practice; Oxford University Press: New York, 1998. 1. Prevent Waste 2. Maximize Atom Economy 3. Design less Hazardous Chemical Synthesis 4. Design Safer Chemicals and Products 5. Use Safer Solvents/Reaction Conditions The ability of chemists to redesign chemical transformations to minimize the generation of hazardous waste is an important first step in pollution prevention. By preventing waste generation, we minimize hazards associated with waste storage, transportation and treatment. Atom Economy is a concept, developed by Barry Trost of Stanford University that evaluates the efficiency of a chemical transformation. Similar to a yield calculation, atom economy is a ratio of the total mass of atoms in the desired product to the total mass of atoms in the reactants. One way to minimize waste is to design chemical transformations that maximize the incorporation of all materials used in the process into the final product, resulting in few if any wasted atoms. Choosing transformations that incorporate most of the starting materials into the product is more efficient and minimizes waste. Wherever practicable, synthetic methodologies should be designed to use and generate substances that possess little or no toxicity to human health and the environment. The goal is to use less hazardous reagents whenever possible and design processes that do not produce hazardous by-products. Often, a range of reagent choices exists for a particular transformation. This principle focuses on choosing reagents that pose the least risk and generate only benign by-products. Chemical products should be designed to affect their desired function while minimizing their toxicity. Toxicity and ecotoxicity are properties of the product. New products can be designed that are inherently safer, while highly effective for the target application. In academic labs this principle should influence the design of synthetic targets and new products. The use of auxiliary substances (e.g., solvents, separation agents, etc.) should be made unnecessary wherever possible and innocuous when used. Solvent use leads to considerable waste. Reduction of solvent volume or complete elimination of the solvent is often possible. In cases where the solvent is needed, less hazardous replacements should be employed. Purification steps also generate large sums of solvent and other waste (chromatography supports, e.g.). Avoid purifications when possible and minimize the use of auxiliary substances when they are needed. 6. Increase Energy Efficiency Energy requirements of chemical processes should be recognized for their environmental and economic impacts and should be minimized. If possible, synthetic and purification methods should be designed for ambient temperature and pressure, so that energy costs associated with extremes in temperature and pressure are minimized. 7. Use Renewable Feedstocks Whenever possible, chemical transformations should be designed to utilize raw materials and feedstocks that are renewable. Examples of renewable feedstocks include agricultural products or the wastes of other processes. Examples of depleting feedstocks include raw materials that are mined or generated from fossil fuels (petroleum, natural gas or coal). 8. Avoid Chemical Derivatives Unnecessary derivatization (use of blocking groups, protection/ deprotection, temporary modification of physical/chemical processes) should be minimized or avoided if possible, because such steps require additional reagents and can generate waste. Synthetic transformations that are more selective will eliminate or reduce the need for protecting groups. In addition, alternative synthetic sequences may eliminate the need to transform functional groups in the presence of other sensitive functionality. 9. Use Catalysts Catalytic reagents (as selective as possible) are superior to stoichiometric reagents. Catalysts can serve several roles during a transformation. They can enhance the selectivity of a reaction, reduce the temperature of a transformation, enhance the extent of conversion to products and reduce reagent-based waste (since they are not consumed during the reaction). By reducing the temperature, one can save energy and potentially avoid unwanted side reactions. 10. Design for Degradation Chemical products should be designed so that at the end of their function they break down into innocuous degradation products and do not persist in the environment. Efforts related to this principle focus on using molecular-level design to develop products that will degrade into hazardless substances when they are released into the environment. 11. Analyze in Real-Time to It is always important to monitor the progress of a reaction to know Prevent Pollution when the reaction is complete or to detect the emergence of any unwanted by-products. Whenever possible, analytical methodologies should be developed and used to allow for real-time, in process monitoring and control to minimize the formation of hazardous substances. 12. Minimize the Potential for One way to minimize the potential for chemical accidents is to choose Accidents reagents and solvents that minimize the potential for explosions, fires and accidental release. Risks associated with these types of accidents can sometimes be reduced by altering the form (solid, liquid or gas) or composition of the reagents. o r d e r t o o b t a i n BACKGROUND I n c o m p l e x m o l e c u l e s , i t INFORMATON i s o f t e n n e c e s s a r y t o i n t r o d u c e m o r e r e a c t i v e f u n c t i o n a l groups more reactive than s i m p l e h y d r o c a r b o n s . A l k e n e s ( o l e f i n s ) Figure 1: The bromination of h y d r o c a r b o n s trans-stilbene c o n t a i n i n g t h e c a r b o n c a r b o n d o u b l e b o n d f u n c t i o n a l g r o u p m a y b e h a l o g e n a t e d t o f o r m a l k y l h a l i d e s , w h i c h a r e t h e n c a p a b l e o f u n d e r g o i n g a v a r i e t y o f f u r t h e r c h e m i c a l t r a n s f o r m a t i o n s . I n t h e e x p e r i m e n t s d e s c r i b e d i n P a r t s A a n d B , y o u w i l l b r o m i n a t e a n a l k e n e , t r a n s - s t i l b e n e , a s s h o w n i n F i g u r e 1 . Br2 Br H Br H Figure 2: General mechanism of bromination across a double bond. The Br-Br bond becomes polarized, so the bromine attacks first as an electrophile and then as a nucleophile. B r o m i n a t i o n o f a n l k e n e i s a n e x a m p l e o f n a d d i t i o n r e a c t i o n : r o m i n e a d d s a c r o s s h e d o u b l e b o n d t o i e l d a v i c i n a l i b r o m i d e . A c o m m o n l y c c e p t e d p a t h w a y f o r h i s a d d i t i o n i n v o l v e s n i o n i c m e c h a n i s m i n h i c h t h e e l e c t r o n - r i c h l k e n e a c t s a s a u c l e o p h i l e a n d t h e r o m i n e i s t h e l e c t r o p h i l e . A s r o m i n e a n d t h e a l k e n e a p p r o a c h o n e a n o t h e r , t h e B r-B r b o n d b e c o m e s p o l a r i z e d ( b e c o m i n g m o r e p o s i t i v e n e a r t h e a l k e n e a n d m o r e n e g a t i v e a t t h e o t h e r e n d ) . T h e m o r e p o s i t i v e l y c h a r g e d B r a t o m i s t r a n s f e r r e d t o t h e a l k e n e t o y i e l d a b r o m o n i u m i o n a n d a b r o m i d e a n i o n . I n a a a b t y d a t a w a n b e b s e c o n d s t e p , b r o m i d e a t t a c k s o n e o f t h e c a r b o n a t o m s o f t h e c y c l i c b r o m o n i u m i o n t o o p e n t h e t h r e e m e m b e r e d r i n g a n d y i e l d t h e v i c i n a l d i b r o m i d e . T h e s e c o n d s t e p i s a b i m o l e c u l a r n u c l e o p h i l i c s u b s t i t u t i o n r e a c t i o n ( S N 2 ) . T h e n e t r e s u l t o f t h i s r e a c t i o n i s a n t i a d d i t i o n o f b r o m i n e across the double bond. Br Br bromonium ion Br Br Br Br– T r a d i t i o n a l l y , t h i s r e a c t i o n i s p e r f o r m e d i n a s o l v e n t , l i k e m e t h y l e n e c h l o r i d e o r c a r b o n t e t r a c h l o r i d e ( b o t h s u s p e c t e d c a r c i n o g e n s ) , t h a t w i l l n o t p a r t i c i p a t e i n t h e r e a c t i o n b u t w i l l d i s s o l v e t h e a l k e n e . S o m e b r o m i n a t i o n s m a y a l s o b e c a r r i e d o u t i n g l a c i a l a c e t i c a c i d , a v o l a t i l e a n d c o r r o s i v e l i q u i d . T h e t r a d i t i o n a l r e a g e n t , e l e m e n t a l b r o m i n e , i s a l s o d a n g e r o u s t o h a n d l e , b e c a u s e i t i s h i g h l y c o r r o s i v e a n d c a u s e s s e v e r e b u r n s u p o n c o n t a c t w i t h t h e s k i n . W h i l e t h i s r e a c t i o n w o r k s v e r y w e l l o n m o s t s u b s t r a t e s , i t c a n b e d a n g e r o u s t o perform i n a n i n s t r u c t i o n a l l a b o r a t o r y s e t t i n g . F o r t h e s e r e a s o n s , t w o g r e e n e r a l t e r n a t i v e s t o t h i s r e a c t i o n a r e p r e s e n t e d . An alternative to traditional bromination is presented below. The Bromination of trans-stilbene largest modification is that instead of using liquid bromine, an with pyridinium tribromide alternative reagent, pyridinium tribromide, popularized by Djerassi and Scholz (1), is used. This reagent provides for gradual release of bromine into the reaction medium because it is in rapid equilibrium with pyridinium hydrobromide and molecular bromine (see Figure 3). As the bromine is consumed in the reaction, more is produced by the pyridinium tribromide. Because the dangerous reagent is produced in situ, it no longer needs to be handled directly (2). An additional advantage of pyridinium tribromide is that it is an easily weighed solid, in contrast to liquid bromine. Another benefit of this reaction is that a more benign solvent, ethanol, can be used in the place of a chlorinated solvent. Figure 3: Equilibrium between + Br2 N H Br3– N H Br2– pyridinium tribromide and The biggest drawback to this reaction is the lower atom economy pyridinium hydrobromide and bromine (many atoms from reagents are wasted) as compared to the traditional bromination procedure. Aside from the desired product, pyridinium hydrobromide is also produced as waste. Pyridinium tribromide also is corrosive and can cause significant damage to metal equipment, especially balances. Bromination of trans-stilbene The bromination with pyridinium tribromide is an example of a with hydrogen peroxide and reaction that has been made safer, yet has considerable opportunities hydrobromic acid for continued improvement. Although the solvent and bromination reagent are less hazardous, pyridinium tribromide is corrosive and can cause significant damage to metal equipment. While molecular bromine has been removed from the teaching lab, the hazard is not eliminated entirely because the reagent is synthesized from pyridine and bromine. Another drawback to this reaction is the relatively poor atom economy; while the desired product is obtained, a quantitative amount of pyridinium bromide is produced as waste. Recent literature reports have described a greener method of bromination that has a high atom economy, uses less corrosive materials, and eliminate liquid bromine and chlorinated solvents (5,6). In this reaction (see Figure 4), hydrobromic acid and hydrogen peroxide are used to generate molecular bromine, and in an ethanol solvent. The only byproduct of this reaction is water. Figure 4: Molecular bromine is 2 HBr + H2O2 Br2 + 2 H2O produced in situ by the oxidation of hydrobromic acid by EtOH hydrogen peroxide. Equipment Magnetic stir bar 100 mL round-bottom flask Water-jacketed condenser with tubing Sand bath in crystallizing dish or hot water bath Thermometer (-10 to 260 C) 25 mL graduated cylinder Disposable syringe (1 - 3 mL) 250 mL or 400 mL beaker for ice bath Hirsch funnel with adapter 50 mL filter flask Filter circles (Whatman Grade 4 - 1.5cm dia.) 50 mL beaker or watch glass for end product crystals Reagents and Properties Item trans-stilbene (transdiphenylethylene) hydrobromic acid hydrogen peroxide sodium bicarbonate, saturated aqueous solution stilbene dibromide (1,2dibromo-1,2diphenylethane) CAS # 103-30-0 Hazards Quantity/Student 2.0 g 10035-10-6 7722-84-1 144-55-8 Corrosive, causes burns Corrosive, causes burns 1.3 ml 0.8 ml Up to 5 ml 5789-30-0 Irritant Small amount for comparing melting points PROCEDUE SAFETY PRECAUTIONS: Care must be taken when using concentrated acid and/or 30% hydrogen peroxide. Both are corrosive, can cause eye and skin burns, and are harmful if inhaled. Be careful to avoid contact with skin and refrain from inhaling these compounds. Neutralize all excess acid in the provided containers, and clean up all spills immediately. Acid will damage in your clothes and your skin, so try not to spill any. Ethanol is flammable so use caution. Assembling the Apparatus Connect the 100mL round-bottom flask to a water-jacketed condenser (don’t forget to grease the joints). Connect the tubing such that water comes in the bottom opening on the side of the condenser and leaves through the opening above. Clamp the apparatus to a support stand, and lower it into the sand or water bath. a 1 0 0 m l r o u n d Bromination of Alkene 1. P r e p a r e b o t t o m f l a s k w i t h a s t i r b a r , a n d p r e p a r e a 9 0 - 1 0 0 ° C w a t e r b a t h in a 125-250 ml beaker. 2. M e a s u r e o u t 0 . 5 g s t i l b e n e , a n d a d d i t t o t h e f l a s k w i t h 1 5 m L o f e t h a n o l . Affix a r e f l u x c o n d e n s e r a n d h e a t t h e r e a c t i o n w i t h s t i r r i n g . A l l o w t h e s o l i d s t o d i s s o l v e . A d d a l i t t l e m o r e e t h a n o l i f solid remains undissolved. 3. O n c e all solids are d i s s o l v e d , s l o w l y a d d 0 . 8 m L o f H B r ( a b o u t 2 . 5 e q u i v a l e n t s ) , a n d l e t t h e s o l u t i o n h e a t a n d 4. 5. Collecting, Washing, and 6. Drying the Crystal 7. s t i r . T h e p r e c i p i t a t e c a u s e d b y t h e a d d i t i o n o f a c i d s h o u l d g o b a c k i n t o s o l u t i o n , b u t i t m a y n o t . C o n t i n u e e v e n i f i t d o e s n o t a l l g o b a c k i n . M e a s u r e o u t 0 . 8 m L o f 3 0 % h y d r o g e n p e r o x i d e ( a b o u t 2 . 5 e q u i v a l e n t s ) a n d a d d i t d r o pw i s e t o t h e r e a c t i o n . T h e c o l o r s h o u l d c h a n g e f r o m c l e a r a n d c o l o r l e s s t o d a r k g o l d e n y e l l o w . R e f l u x t h e r e a c t i o n a n d s t i r f o r a b o u t 2 0 m i n u t e s , o r u n t i l t h e yellow c o l o r d i s a p p e a r s a n d t h e m i x t u r e b e c o m e s a c l o u d y w h i t e . R e m o v e t h e r e a c t i o n f r o m t h e h e a t a n d l e t i t c o o l . O n c e a t r o o m t e m p e r a t u r e , n e u t r a l i z e t h e s o l u t i o n ( p H 5 t o 7 ) w i t h a c o n c e n t r a t e d N a H C O 3 s o l u t i o n . I t m a y o n l y t a k e a l i t t l e , d e p e n d i n g o n h o w m u c h e x c e s s a c i d y o u h a v e . C h e c k p H w i t h p H p a p e r . O n c e n e u t r a l i z e d , p u t t h e f l a s k o n i c e t o f u r t h e r c o o l i t a n d c a u s e m o r e c r y s t a l s t o p r e c i p i t a t e . C o l l e c t t h e c r y s t a l s b y v a c u u m f i l t r a t i o n , r i n s i n g w i t h v e r y c o l d w a t e r a n d a l i t t l e b i t o f v e r y c o l d e t h a n o l . L e t a i r f l o w o v e r t h e p r o d u c t t o h e l p d r y i t . R e c o r d y o u r y i e l d a n d p r o d u c t m e l t i n g p o i n t ( l i t e r a t u r e m . p . 8. 2 R s f 4 e t r 1 °C d e c . ) . c r y s t a l l i z e t h e i l b e n e d i b r o m i d e o m xylene (or ethyl acetate). I R s p e c t r o s c o p y and melting Identifying the Product 9. Obtain point . Cleaning Up 10. Place recovered materials in the appropriate labeled collection containers as directed by your laboratory instructor. Clean your glassware with soap. Post-Laboratory Questions 1. Calculate the percent yield of your bromination reaction. 2. Compare the melting point of your product(s) to the data provided. (+)-1,2-dibromo-1,2-diphenylethane meso-1,2-dibromo-1,2-diphenylethane 110 °C 238 °C 3. Draw your product in its correct stereochemical configuration and compare your result with your prediction from Pre-Laboratory Assignment. 4. Draw the mechanism for the bromination of trans-2-butene. Be sure to draw all intermediates clearly. References: 1. Djerassi, C.; Scholz, C. R. J. Am. Chem. Soc. 1948, 70, 417-418. 2. When a reagent is generated in (rather than added to) the reaction medium it is said that the reagent is prepared in situ. 3. The purpose of the clamp is to allow you to remove the flask from the hot plate without burning yourself in the event that the solution starts to boil vigorously. 4. Be careful not to turn the hot plate up too far – the hot plate will be slow to heat at first, and then heat extremely fast. Once hot, it will take a very long time to cool down again! 5. Ho, T. L.; Gupta, B. G. B.; Olah, G. A. Synthesis 1977, 676-677. 6. Barhate, N. B.; Gajare, A. S.; Wakharkar, R. D.; Bedekar, A. V. Tetrahedron 1999, 55, 1112711142. 7. Totten, L. A.; Jans, U.; Roberts, A. L. Environ. Sci. Technol. 2001, 35, 2268-2274. 8. Durst, H. D.; Gokel, G. W. Experimental Organic Chemistry; McGraw-Hill: San Francisco, 1987; pp 240-241. 9. Trost, B. M. Science 1991, 254, 1471-1477. 10. Trost, B. M. Acc. Chem. Res. 2002; 35(9), 695-705. 11. Hudlicky, T.; Frey, D. A.; Koroniak, L.; Claeboe, C. D.; Brammer, L. E. Green Chemistry 1999, 1, 57-59. ________________________________________ Name ___________ Section ___________ Date Bromination of Alkenes Pre-Laboratory Assignment 1. What safety issues should be considered when using HBr and H2O2? 2. Calculate theoretical yield for the bromination reaction. 3. Provide all applicable principles of Green Chemistry in this experiment. 5. (a) Look up and draw the structure of trans-cinnamic acid, cis-stilbene, and trans-stilbene. (b) Predict the relative stereochemistry of each products and draw the predicted structures.