mathematical modelling of cutting force as the most reliable

advertisement

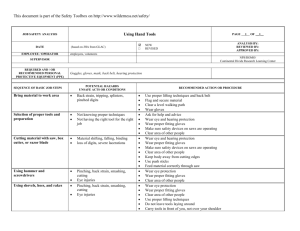

34th INTERNATIONAL CONFERENCE ON PRODUCTION ENGINEERING 28. - 30. September 2011, Niš, Serbia University of Niš, Faculty of Mechanical Engineering MATHEMATICAL MODELLING OF CUTTING FORCE AS THE MOST RELIABLE INFORMATION BEARER ON CUTTING TOOLS WEARING PHENOMENON Obrad SPAIĆ, Zdravko KRIVOKAPIĆ, Rade IVANKOVIĆ Production and Management Faculty in Trebinje, East Sarajevo University, Trg palih boraca 1, Trebinje, Republika Srpska, Bosna i Hercegovina sobrad1@teol.net, zdravkok@ac.me, rade.ivankovic@gmail.com Abstract: Being one of their prominent exploitative characteristics, cutting tools durability depends on the character, intensity and the speed of wearing. Identification of tool wearing is of great significance for the purpose of avoiding sooner or later replacement of tools. The parameters of tool wearing can be measured by out-process and in-process-measuring systems. Given the extremely limiting role of the former in modern production lines, development of the latter (the indirect measuring systems) has gained prominence. The basis of indirect measuring systems comprises a set of various signals originating from the units of the system under treatment which stand in certain correlations with the wearing parameters. The paper presents mathematical models of axial force designed on the basis of experimental research in drilling tempered steel by twist drills made of high-speed steel manufactured by powder metallurgy. Key words: tool, durability, wear, cutting force, mathematical model 1. INTRODUCTION 2. AXIAL CUTTING FORCE IN DRILLING Identification of cutting elements wear is of high practical importance because, apart from allowing for timely replacement of tools, it also allows for management of wearing processes as well as for automation of treatment and technological processes. Production lines, in particular those of mass and large scale automated production benefit from timely replacement of cutting tools as it eliminates the low quality of final products and reduces production costs arising from sooner and later replacement of tools. As in modern production lines the out-process methods of measuring tool wear have become a significantly limiting factor, development of online process measuring systems are gaining prominence. The process methods most frequently applied are the indirect ones whose basis comprises a set of various signals originating from the units of the system under treatment which stand in certain correlations with the wear parameters. The information bearers (signals) of tools wear in cutting process that are most often used by researchers are cutting force and resistance. Thus, J. Sheikh-Ahmad and R. Yadav [1] designed a force model at milling composite materials by applying regression analysis. B. Lotfi, Z. W. Zhong and L. P. Khoo [2] designed a model to predict cutting force at milling dependent on tool orbit. J. T. Lin, D. Bhattacharyya and V. Kecman [3] showed that measuring cutting force enables for tool wear to be monitored without interruption of cutting process. Based on the comparative analysis of the assessment of wear of a 8 mm diameter twist drill, C. Sanjay, M. L. Neema and C. W. Chin [4] showed that modified regression equations could be used to asses the value of tool wear. Axial cutting force in drilling (the auxiliary movement resistance), F3, along with other conditions unaltered, is in the function of cutting regime (the twist drill nominal diameter, the spindle speed and feed): F f (D, n,s) (1). By way of experimental-analytical method, i.e. the theory of experiment planning and the theory of regression analysis, the cutting force can be expressed in the form of a degree function: F CF Db1F n b2F sb3F (2), where: CF, b1F, b2F, b3F – are the constants dependent on the type of material, D [mm] – is the drill nominal diameter, n [rev/min] – is the spindle speed, and s [mm/rev] – is the feed. 3. EXPERIMENT PLANNING With the aim to design a mathematical model of axial force as the information bearer on the wear phenomenon, the paper contains experimental research on the basis of which the constants CF, b1F, b2F, b3F were determined within the assumed mathematical model (2). Given that the axial force is in the function of three parameters (D, n, s), the experiment was conducted in line with the complete three-factor orthogonal first-order plan, i.e. the Box-Wilson’s plan, repeating the experiment four times in the central plan point (n0=4) as illustrated in Table 1. Table 1. The three-factor plan matrix Experimental points 1 2 3 4 5 6 7 8 9 10 11 12 Coded values x0 x1 x2 x3 x1x2 x1x3 x2x3 x1x2x3 +1 +1 +1 +1 +1 +1 +1 +1 +1 +1 +1 +1 -1 +1 -1 +1 -1 +1 -1 +1 0 0 0 0 -1 -1 +1 +1 -1 -1 +1 +1 0 0 0 0 -1 -1 -1 -1 +1 +1 +1 +1 0 0 0 0 +1 -1 -1 +1 +1 -1 -1 +1 0 0 0 0 +1 -1 +1 -1 -1 +1 -1 +1 0 0 0 0 +1 +1 -1 -1 -1 -1 +1 +1 0 0 0 0 -1 +1 +1 -1 +1 -1 -1 +1 0 0 0 0 3.1. Experiment conditions The experiment was conducted by means of twist drills (TD) DIN 338, nominal diameter Ø6.0; Ø7.75 and Ø10.0 mm, made of high-speed steel with 8% of Co, manufactured by powder metallurgy, used for drilling blind hole in tubes made of chrome-molybdenum alloy steel for enhancement, Č.4732, thermally treated to 43-45 HRc hardness. The chemical composition, thermal treatment conditions and microstructure of the TD steel and test tubes are shown in References [5]. Construction of twist drills followed the recommendations in References pertaining to drilling hard treatable materials (tempered steel) as well as previous experience. The drills were manufactured by grinding technology. The geometrical elements of TD are shown in References [5]. The experiment was conducted using test tubes, Ø60 mm in diameter, with the thickness adjusted to the blind hole drilling depth 1=3xd. Test tubes’ hardness was evenly distributed along longitudinal and cross cut and within the prescribed limits. Cutting regimes were defined in line with the recommendations stated in References [5], adhering to the interval limits of variations of influential factors ( n sr2 n min n max , and s sr2 s min s max ) and are shown in the three-factor plan matrix (Table 1). The experiment was conducted in the laboratory of the Faculty of Mechanical Engineering in Podgorica, University of Montenegro, on the universal milling machine Typ: FGU-32. Integrated with the milling machine was the equipment for measuring axial force and torque manufactured by KISTLER. During the experiment, the 8% solution of Teolin H/VR in the quantity of 1 l/min was used for cooling and lubrication. 3.2. Axial force measuring Axial force measuring was conducted by means of a three-component dynamometer manufactured by “Kistler“, TYP 8152B2, with the measurement range Real values The output s vector d n [F] [mm] [rev/min] [mm/rev] [mm/min] 6.0 10.0 6.0 10.0 6.00 10.0 6.0 10.0 7.75 7.75 7.75 7.75 250 250 500 500 250 250 500 500 355 355 355 355 0.027 0.027 0.027 0.027 0.107 0.107 0.107 0.107 0.053 0.053 0.053 0.053 6.67 6.67 13.33 13.33 26.67 26.67 53.33 53.33 18.67 18.67 18.67 18.67 F1 F2 F3 F4 F5 F6 F7 F8 F9 F10 F11 F12 from 100 to 900 kHZ, integrated with the universal milling machine and Global Lab software. For the data acquisition during the experiment, the KISTLER high-frequency amplifier, type AE-Piezotron Coupler 5125B was used while a two-channel DAQ Scope PCI-5102 was used as an AD convertor. The acquired signals were processed by means of a virtual instrument, aided by Global Lab software. The data acquisition schema is illustrated in Figure 1. Figure 1. Data acquisition schema during the experiment 4. EXPERIMENT RESULTS Measurement of axial force was conducted in line with the stated Plan matrix in five measuring points. The first measurement was conducted during drilling of a blind hole, l=3d, with sharp twist drills while the fifth (the last) measurement was conducted subsequent to the achieved lengths of drilling (in mm) during which the twist drills wear reached the following maximally allowed (defined in advance) values: for TD Ø6.0 mm – 0.25 mm for TD Ø7.75 mm – 0.30 mm for TD Ø10.0 mm – 0.35 mm The mean value of the wear band width of the back surfaces was taken to represent the maximum wear value (B ≈ 0.04D), at the edge of regular area which is at 0.025mm distance from outer fibres (Figure 2). At different cutting regimes (the nominal diameter, the spindle speed and the feed), TD reached the maximally Assessment of the significance of the first-order model was done by means of application of F-criteria, for the adopted level of significance q=0.05, according to the pattern: Frj N Figure 2. Twist drill wear allowed wear value at different drilling lengths. The measured axial force value at maximal wear is shown in Table 2. Table 2. Axial force values at maximal TD wear Exp. points 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. b 2j S2E , j 1, 2,3 (7). Dispersion of experiment results in the multi-factor space is as follows: S2E 1 fE n0 å y0i y0 2 (8). i 0 S2E = 0.007 , D n s lmax Fmax [mm] [rev/min] [mm/rev] [mm] [N] 6.0 250 0.027 1265.40 956.50 10.0 250 0.027 2700.00 594.50 6.0 500 0.027 1533.00 1090.50 10.0 500 0.027 2340.00 1139.00 6.0 250 0.107 999.00 955.50 10.0 250 0.107 4800.00 638.50 6.0 500 0.107 1800.00 1925.50 10.0 500 0.107 756.00 1579.70 7.75 355 0.053 2569.13 783.30 7.75 355 0.053 2336.63 682.90 7.75 355 0.053 2569.13 655.50 7.75 355 0.053 2801.63 754.80 where: fE = n0-1 = 3 – is the degree of freedom of experimental error. The degrees of freedom of parameters bj, (j = 0, 1, 2, 3) are: fbj = 1, which results in the tabled value of the dispersion relation Fri,1-q/1, 3 = 10.10 [7]. The parameters of the model and assesments of significance are listed in Table 3, which shows that all parameters of the first-order model (b0, b1, b2 i b3) are significant. Table 3. Model parameters Model parameters Disper. relations (Fri) Assesments 5. MATHEMATICAL AXIAL FORCE MODELLING OF The pattern of axial cutting force (2) subsequent to linearisation can be expressed in the following form: y b0 b1x1 b2 x 2 b3 x3 (3), where: y = lnF, b0 = lnCF, x1 =ln(D), x2 =ln(n) and x3 =ln(s). The orthogonal first-order plan with constant members can be applied to the above pattern with coding performed by means of the equations of transformation: X1 2 X2 2 X3 2 ln D ln Dmax ln Dmax ln Dmin ln n ln n max ln n max ln n min ln s ln s max ln s max ln s min 1, 1 76831.617 16.813 19.112 102.457 0.575 12.214 9.484 1.724 sign. sign. sign. sign. not sign. sign. not sign. not sign. ŷ 6.820 0.1215x1 0.121x 2 0612x 3 (9). 5.358 D0.822 s0.433 (5), N (6). (10). n 0.372 (4). while parameters bj are determined on the basis of results of N = 2k points arranged along the vertexes of hypercube according to the pattern: 1 å x ji yi , j 1, 2,3 N i 0 Fb0 Fb1 Fb2 Fb3 Fb12 Fb13 Fb23 Fb123 On the basis of listed parameters the empirical model was deduced of axial force at maximal TD wear: F By applying regression analysis, the parameter of the model b0 is determined on the basis of results of all N = 2k + n0 plan points, in line with the pattern [6]: bj 6.820 0.121 -0.129 0.298 -0.021 0.103 0.091 -0.039 Revisiting the original coordinates by means of the equations of transformation (4) provided for deduction of a concrete empirical axial force model: 1 , and 1 N b0 å x 0i yi N i 0 b0 b1 b2 b3 b12 b13 b23 b123 Testing of adequacy of the defined model was done according to Fisher’s criterium [6]: FrLF S2LF (11). S2E FrLF 15.061. Dispersion of experiment results in the multi-factor space is as follows: S2LF n0 k 1 N 2 2 y N b u i y0u y0 f LF u 1 i 0 u 1 2 (12). S2LF 0.1048 . 6. CONCLUSION The degree of freedom of model adequacy is: fLF=N-k-1-(n0-1)=5, thus entailing the tabled value of dispersion relation of Ft(5%;5;3) = 9.0 [7]. Given the FrLF > Ft(5%;5;3) the mathematical model fails to describe the correctly observed function of response, which implies existence of effects of mutual action among the model parameters. Three-factor orthogonal first-order plans allow for assessment of basic effects as well as the effects of mutual action of the first and second order on the empirical model of the response function. Should the complete three-factor first-order model be applied, the pattern to describe the (axial force) response function becomes nonlinear and can be expressed in the form of the equation: The mathematical models designed by means of orthogonal first-order plan and regression analysis fail to properly describe the response function, i.e., axial cutting force within the boundaries of the covered multi-factor space due to mutual action of the model parameters, the squared elements action effects, as well as the action of a series of parameters whose source, nature and span of action are unknown. This points to the fact that highly complex processes that take place in the zone of drilling tempered steel and which are conditioned by actions of numerous influential and mutually collinear factors, cause difficulties for mathematical models to be applied so as to describe the behaviour of mechanical, thermo-dynamical, tribological, chemical and other phenomena in the cutting zone. y = b0 +b1x1+b2x2+b3x3+b12x1x2+b13x1x3+ b23 x2x3+b123 x1x2x3 (13). On the basis of values of the model parameters corresponding to mutual action effects (see Table 4) and taking into account the assessment of significance, while also revisting the original coordinates by means of the equations of transformation (4), the following non-linear empirical model of axial force is deduced: lnF = 6.82+2.187∙ln(D)+0737∙ln(n)-2.994∙ln(s)+ 0.586ln(D)∙ln(s)+0.38∙ln(n)∙ln(s)-7.536 (14). Given that the dispersion relation value of the parameter b13 (9.484) is approximate to the tabled value (10.10), its influence has been included in the model. The modelled values of axial force, as well as the relative error in relation to the experimental results are shown in Table 4. Table 4. Modelled values of axial force Exp. Modelled Error Exp. Modelled Error points values % points values % 1 830.47 -13.19 5 1024.26 -6.07 2 860.2 -9.97 6 1602.63 -16.75 3 535.15 -9.98 7 948.21 -16.75 4 554.3 -13.19 8 1483.64 -6.08 9-12 907.81 26.24 If we compare the modelled and experimental values of axial force in the experimental points, we can see that maximal deviation of experimental points from modulled surface is 16.75%, thus providing for the model (14) to be considered a mathematical interpretation of the goal function. However, in the central plan point the deviation of modulled results from the experimental ones is 26.24%, which means that mathematical model fails to properly descibe the response function within the boundaries of the covered multi-factor space. Therefore, the null hypothesis that the effects of squared elements in the model equal zero must be jettisoned. For the purpose of designing a mathematical model in order to properly decribe axial force within the boundaries of the covered multi-factor space it is necessary to apply the second-order polynomial model which necessitates additional amount of information on the diffusion system, i.e. additional number of experiments. REFERENCES [1] Sheikh-Ahmad J., Yadav R. (2008) Model for predicting cutting forces in machining CFRP, International Journal of Materials and Product Technology, Vol. 32, Number 2-3, 152 – 167 [2] Lotfi B., Zhong Z. W., Khoo L. P. (2009) Prediction of cutting forces along Pythagorean-hodograph curves, The International Journal of Advanced Manufacturing Technology, Vol. 43, Numbers 9-10, 872-882 [3] Lin J. T., Bhattacharyya D., Kecman V. (2003) Multiple regression and neural networks analyses in composites machining, Composites Science and Technology, Vol. 63, 539–548 [4] Sanjay C., Neema M. L., Chin C. W. (2005) Modelingof tool wear in drilling by statistical analysis and artificial neural network, Journal of Materials Processing Technology, Vol. 170, 494–500 [5] Spaić O. (2006) Uporedna analiza habanja zavojnih burgija od brzoreznog čelika proizvedenog konvencionalnom metalurgijom i metalurgijom praha, MSc thesis, University of East Sarajevo, Faculty of Production and Management Trebinje [6] Stanić J. (1986) Metod inženjerskih mjerenja, Faculty of Mechanical Engineering Beograd [7] Laković R., Nikolić B. (1999) Primijenjena statistika 2. dio – eksperiment, University of Montenegro, Faculty of Electrical Engineering, Podgorica CORRESPONDENCE Obrad SPAIĆ, PhD, Assoc. prof., University of East Sarajevo, Faculty of Production and Management, Trebinje, Trg palih boraca br. 1, Trebinje, sobrad1@teol.net Zdravko KRIVOKAPIĆ, PhD, Prof., University of Montenegro, Faculty of Mechanical Engineering, Podgorica, Džordža Vašingtona bb, Podgorica, zdravkok@ac.me Rade IVANKOVIĆ, PhD., Prof., University of East Sarajevo, Faculty of Production and Management Trebinje, Trg palih boraca br. 1, Trebinje, rade.ivankovic@gmail.com