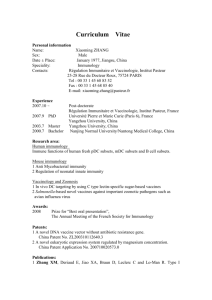

Jixi Zhang

advertisement

Research Activities: My research activities focus on the integrated study of mechanical behavior and materials science, including strength and fracture of metal matrix composites (MMCs), experimental investigations on cyclic plastic deformation, fatigue, and associated substructures of structural materials, multi-scale constitutive modeling, characterization and rendering of 3D realistic complex microstructures, and optimization of microstructure and mechanical properties based on computational mechanics. The overall goal of my research is to understand the deformation and failure mechanisms of structural materials and develop multi-scale mechanism-based models to predict material behavior under various loading conditions. 1. Strength and fracture mechanisms of metal matrix composites (MMCs): (1) manufacturing of short-fiber reinforced aluminum alloy matrix composites by squeeze casting technique; (2) strength and fractographs of aluminum matrix composites at room temperature and elevated temperatures, (3) in situ observation of fracture process of MMCs by SEM and TEM; (5) prediction of the mechanical properties of MMCs considering fracture mechanisms. Fig. 1 Distribution of short fibers in -Al2O3/Al-5.5Mg composite [14] Fig. 2 In-situ tensile process of -Al2O3/Al-5.5Mg composite [14] Fig. 3 Tensile fracture surface of -Al2O3/Al-5.5Mg composite, indicating many heads of broken fibers and dimples [14]. 2. Cyclic plastic deformation and mechanism: (1) cyclic plastic deformation of typical metallic materials under various cyclical loading conditions; (2) evolution of slip patterns; (3) evolution of dislocation substructures; (4) the relationship between macroscopic mechanical properties and microscopic substructure parameters; (5) the mechanisms of the formation of typical dislocation substructures in metallic materials. Fig. 4 Slip pattern of OFHC copper under 90 degree of out-of-phase [10] Fig. 5 Dislocation substructure under fully reversed tension-compression at an axial strain amplitude of 0.15% [6]. Equivalent Stress Magnitude (MPa) CTM/TO CTM/TC CTM/NPP CTM/ Transient Stage CRM/TC CTS/TC CTS/TO Fitting Line 200 150 100 50 0.5 1.0 1.5 2.0 2.5 -1 Reciprocal of Cell Size, 1/d, (m) Fig. 6 Relationship between equivalent stress magnitude and reciprocal of dislocation cell size [6] 3. Inhomogeneous plastic deformation of annealed mild steel under multiaxial stress state: (1) Lüders band formation and propagation under multiaxial stress state; (2) inhomogeneous cyclic plastic deformation phenomenon and the associated evolution of dislocations of mild steels under fully reversed stress-controlled cyclic loading with the stress amplitude much lower than the yield stress. 7 Small bonded strain gages on tubular specimen [12] Biaxial Tension-Torsion Axial Stress (MPa) 400 Work Hardening Propagation of Lüders Bands t2 300 • t1 • 200 100 0 0.000 0.005 0.010 0.015 0.020 Extensometer Axial Strain 8 Axial stress-strain curve and formation of Luders band under biaxial tension-torsion Shear Stress (MPa) 200 150 100 Propagation of Lüders Bands • Work Hardening t1 • 50 t2 Biaxial Tension-Torsion 0 0.000 0.005 0.010 0.015 Midsection Shear Strain 9 Shear stress-strain curve under biaxial tension-torsion 0.020 0.025 0.014 Biaxial Tension-Torsion Axial Strain 0.012 Work Hardening Propagation of Lüders Bands 0.010 0.008 0.006 Gage 7 5 0.004 9 11 1 3 Elastic 0.002 Strain Gage Extensometer Avg Strain Gage 0.000 100 200 250 300 350 Time (s) 10 Variation of local axial strain with time under biaxial tension-torsion 0.016 150 Biaxial Tension-Torsion Surface Shear Strain Work Hardening Propagation of Lüders Bands 0.012 0.008 Gage 6 8 4 10 0.004 2 12 Elastic Strain Gage Extensometer Avg Strain Gage 0.000 100 150 200 250 300 350 Time (s) 11 Variation of local shear strain with time under biaxial tension-torsion [12] (4) Computational mechanics: (1) constitutive model of cyclic plastic deformation; (2) constitutive model of crystal plasticity; (3) multiaxial fatigue criterion based on the critical plane approach Axial Stress (MPa) 200 Experiment Simulation 100 0 -100 OFHC Copper Tension-compression -200 -0.010 0.000 0.005 0.010 Axial Strain 12 Comparison of stabilized hysteresis loops of OFHC copper under tension-compression [1]. 200 Experiment -0.005 Cycles 64~128 200 Cycles 1~10 Simulation Cycles 64, 128 Cycles 1~10 Cycle 16 Cycle 16 Cycle 32 Cycle 32 100 Axial Stress, MPa Axial Stress, MPa 100 0 0 -100 -100 -200 -200 -100 -50 0 50 Shear Stress, MPa 100 -100 -50 0 50 Shear Stress, MPa 100 13 Comparison of stress response of OFHC copper under 90 degree out-of-phase nonproportional loading [1]. 1500 Stress, MPa 1000 500 0 -500 Simulation Experiment -1000 0.00 0.02 0.04 Strain 0.06 0.08 14 Fit for stress-strain curve of tested Ti-6Al-4V for the room temperature uniaxial strain history with multiple strain rates and strain hold periods [7]. Observed Life (Cycles) 10 10 10 10 10 6 Multiaxial fatigue life of OFHC copper with different grain size and texture (TO: cyclic torsion; TC: Tension-compression NPP: Nonproportional loading) 5 4 CRTM_TO CRM_TC CRTM_NPP CTM_TO CTM_TC CTM_NPP CTS_TO CTS_TC Sequence Loading Ratchetting Loading 3 2 10 2 10 3 4 5 6 10 10 10 Predicted Life (Cycles) 15 Comparison of experimental data and predicted fatigue lives of OFHC copper [9] (5) Rendering of 3D complex microstructures in computational modeling: (1) 3D Voronoi tessellation; (2) efficient simulated annealing algorithms to specify the grain-size distribution, phase distribution and texture; (3) meshing of 3D complex microstructures; (4) microstructurebased finite element analysis 16 Simulation of a dual phase microstructure: grains and lamellate (+) grains 125 Grains 512 Grains Target 17 Comparison of simulated and target grain orientation distributions [7]. 18 Meshing of 3D non-periodic polycrystalline microstructure with C3D4 elements 19 Meshing of 3D periodic polycrystalline microstructure with C3D4 elements 20 Simulation of microstructure sampled on failure plane and the corresponding 3D FE models (cut views on the midsection planes) [4]. 21 Contours of fatigue indicator parameter (FIP) [4]. PUBLICATIONS Journal Publications 1. Zhang, J. and Jiang, Y., “Constitutive modeling of cyclic plasticity deformation of a pure polycrystalline copper,” International Journal of Plasticity 24, (2008), pp. 1890-1915. J22 2. Jiang, Y. and Zhang, J., “Benchmark experiments and characteristic cyclic plasticity deformation,” International Journal of Plasticity 24, (2008), pp. 1481-1515. J21 3. Zhao, T., Zhang, J., and Jiang, Y., “A study of fatigue crack growth of 7075-T651 aluminum alloy,” International Journal of Fatigue 30, (2008), pp. 1169-1180. J20 4. Zhang, J., Prasanna, R., Shenoy, M. M., and McDowell, D. L., “Modeling fatigue crack nucleation at primary inclusions in carburized and shot-peened martensitic steel,” Engineering Fracture Mechanics, 2008, doi: 10.1016/j.engfracmech.2008.10.011. J19 5. Prasanna, R., Zhang, J., and McDowell, D. L., “Subsurface fatigue crack nucleation at primary inclusions in carburized and shot peened high strength steels: 3D finite element modeling strategy,” Accepted by International Journal of Fatigue, 2008. J18 6. Zhang, J. and Jiang, Y., “An experimental study of the formation of typical dislocation patterns in polycrystalline copper under cyclic shear,” Acta Materialia 55, (2007), pp. 1831-1842. J17 7. Zhang, M., Zhang, J., and McDowell, D. L., “Microstructure-based crystal-plasticity modeling of cyclic deformation of Ti-6Al-4V,” International Journal of Plasticity 23, (2007), pp. 1328-1348. J16 8. Shenoy, M., Zhang, J., and McDowell, D. L., “Estimating fatigue sensitivity to polycrystalline Ni-base superalloy microstructures using a computational approach,” Fatigue & Fracture of Engineering Materials & Structures 30, (2007), pp. 889-904. J15 9. Zhang, J. and Jiang, Y., “Fatigue of polycrystalline copper with different grain sizes and texture,” International Journal of plasticity 22, (2006), pp. 536-556. J14 10. Zhang, J. and Jiang, Y., “An experimental investigation on cyclic plastic deformation and substructures of polycrystalline copper,” International Journal of Plasticity 21, (2005), pp. 2191-2211. J13 11. Zhang, J. and Jiang, Y., “An experimental study of inhomogeneous cyclic plastic deformation of 1045 steel under multiaxial cyclic loading,” International Journal of Plasticity 21, (2005), pp. 2174-2190. J12 12. Zhang, J. and Jiang, Y., “Luders bands propagation of 1045 steel under multiaxial stress state,” International Journal of Plasticity 21, (2005), pp. 651-670. J11 13. Zhang, J. and Jiang, Y., “A study of inhomogeneous plastic deformation of 1045 Steel,” ASME Journal of Engineering Materials and Technology 126, (2004), pp. 164-171. J10 14. Kang, G., Yang, C., and Zhang, J., “Tensile properties of randomly oriented short Al2O3 fiber reinforced aluminum alloy composites. I. microstructure characteristics, fracture mechanisms and strength prediction,” Composites Part A: Applied Science and Manufacturing, 33A, (5), (2002), pp. 647-656. J9 15. Kang, G., Yang, C., and Zhang, J., “Strengths and fracture mechanisms of Al2O3 short fiber reinforced Al-Mg alloy matrix composite at elevated temperatures,” Journal of Materials Science and Technology, 18, (3), (2002), pp. 257-260. J8 16. Kang, G., Gao, Q., and Zhang, J., “Tensile elastic modulus, strength and fracture of Al2O3/Al alloy composites,” Journal of Materials Science and Technology, 16, (5), (2000), pp. 475-480. J7 17. Kang, G., Gao, Q., and Zhang, J., “Analysis and modeling of tensile behavior of Al2O3/Al alloy composites,” Engineering Mechanics (Chinese), 17, (5), (2000), pp. 4451. J6 18. Yang, C., Liu, S., Zhang, J., and Lei, T., “Tensile fracture process and interfacial strength on -Alumina short fiber reinforced aluminum alloys,” Chinese Journal of Materials Research, 13, (3), (1999), pp. 334-336. J5 19. Zhang, J., Yang, C., Liu, S., Zhang, X., and Kang, G., “Tensile strength and fracture mode of -Alumina short fiber reinforced aluminum alloys,” Chinese Journal of Material Research, 12, (3), (1998), pp. 282-286. J4 20. Yang, C., Liu, S., and Zhang, J., “Research on fracture process and strength mechanism of Al matrix composites reinforced by two kinds of Al2O3 short fibers,” Acta Materiae Compositae Sinica, 14, (1), (1997), pp. 27-32. J3 21. Zhang, X., Liu, S., Gao, Q., Zhang, J., and Qin, S., “TEM investigation on cracking in Al2O3 short fiber /Al-5.5Zn composite,” Acta Materiae Compositae Sinica, 14, (2), (1997), pp. 45-49. J2 22. Zhang, J., Yang, C., and Liu, S., “Tensile strength and fracture mechanism of short alumina fiber/aluminum alloy metal matrix composites,” Acta Materiae Compositae Sinica, 14, (1), (1997), pp. 33-37. J1 Conference Publications 1. Jiang, Y., and Zhang, J., “Constitutive modeling of cyclic hardening, nonproportional hardening, and stain ratcheting in cyclic plasticity,” Plasticity, 2008. 2. Jiang, Y., and Zhang, J., “Constitutive modeling of cyclic hardening and nonproportional hardening of polycrystalline copper,” Fifth International Conference on Nonlinear Mechanics, 2007. 3. Zhang, M., Zhang, J., McDowell, D. L., and Neu, R. W., “Investigation of complex polycrystalline grain structures on fretting of duplex Ti-64 using 3D Voronoi tessellation,” The 9th International Fatigue Congress 2006, Atlanta, USA. 4. Jiang, Y., and Zhang, J., 2005, “Influence of grain size and texture on cyclic plastic deformation of polycrystalline copper,” Plasticity, 2005. 5. Jiang, Y. and Zhang, J., 2004, “Inhomogeneous cyclic plastic deformation of 1045 Steel,” Proceedings of International Conference of Heterogeneous Materials Mechanics, Chongqing, China, June 21-26, 2004, pp. 185-188. 6. Zhang, J. and Jiang, Y., 2004, “An investigation of nonproportional hardening of polycrystalline copper,” Proceedings of International Conference of Heterogeneous Materials Mechanics, Chongqing, China, June 21-26, 2004, pp. 193-196. 7. Zhang, J., and Jiang, Y., 2002, “Mechanisms of inhomogeneous cyclic plastic deformation of 1045 steel,” 14TH US National Congress of Theoretical and Applied Mechanics, Blacksburg, VA, June 23-28, 2002.