Recent Advances In High Resolution X

advertisement

Recent Advances In High Resolution X-Ray Diffraction Studies

Of Semiconductors For Technological Applications

Krishan Lal

National Physical Laboratory

Dr. K.S. Krishnan Road

New Delhi - 110012

ABSTRACT

Basic principles of high-resolution X-ray diffraction techniques and essential

features of a five-crystal X-ray diffractometer developed in author’s

laboratory have been described.

Illustrative examples include direct

observation of large strain fields around dislocations in nearly perfect

gallium arsenide single crystals and relationship between oxygen content

and perfection of silicon single crystals. It has been possible to characterize

thin epitaxial film of SiGe (40 nm thick) by using normal incidence highresolution x-ray diffractometry.

Introduction

Bulk crystals and thin films of semiconductor materials are widely being employed in a

wide variety of microelectronic and optoelectronic devices.

Also, for fundamental

understanding of semiconductors, it necessary to establish a relationship between properties

and traces of impurities and defects like dislocations and point defects. It is necessary to

have stringent control on elemental composition and real structure of crystals as these are

subject to processing steps for fabrication of devices. Advanced techniques are available

for diagnostic purposes. High-resolution X-ray diffraction (HRXRD) techniques have been

1

widely employed to evaluate the quality of raw single crystal wafers (crystallinity,

perfection, orientation and surface preparation) [1-3]. For epitaxial films one can in

addition determine lattice mismatch with respect to the substrate wafers and from it their

chemical composition. The nondestructive character of HRXRD techniques makes them

particularly effective in evaluation of crystals at different stages of processing. Practically

all types of defects including boundaries, dislocations, clusters of point defects and isolated

point defects can be investigated by employing these techniques. In addition, non-localized

defects like biaxial stress in thin film - single crystal substrate systems can be determined

[4-7]. This paper describes essential features of HRXRD techniques and some recent

experimental results.

High Resolution X-ray Diffraction

The following two theories of X-ray diffraction from crystals are widely used

[8-

11]: (i) the kinematical theory; and (ii) the dynamical theory. The first theory is rather

approximate but widely used for investigating problems connected with ideal structure of

crystals. The dynamical theory of X-ray diffraction is widely employed for study of nearly

perfect crystals [3, 8-11]. This is a rigorous theory and enables determination of the shape

of diffraction curves, understanding anomalous transmission of X-rays through crystals

during Laue diffraction and pendellosung phenomenon. According to the dynamical theory

the diffraction curves of an ideally perfect crystal should have half widths of a few arc sec.

The reflectivity at the diffraction maximum can be nearly 100%. To realize these features

in actual experiments it is necessary to improve the quality of X-ray beams employed in

normal X-ray diffraction experiments. The angular divergence and wave length spread (in

terms of angle) of the exploring X-ray beam should be less than 1 arc sec. X-ray diffraction

with such beams is termed as high resolution X–ray diffraction (HRXRD).

To produce nearly parallel and monochromatic X-ray beams one employs X-ray

diffraction from nearly perfect crystals like those of silicon.

The angular range of

diffraction for perfect crystals is limited to a few arc sec, as we had mentioned above.

Therefore, such crystals select only a narrow range of angles from the incident beam in a

diffraction experiment. By combining a few monochromators, it is possible to achieve high

2

quality X-ray beam with reasonable intensity.

A wide variety of multi-crystal X-ray

diffractometer have been developed to achieve high resolution in X-ray diffraction

experiments [1-3, 12]. In author’s laboratory a series of diffractometers have been

developed and fabricated for a variety of experiments. These include a five-crystal X-ray

diffractometer with state-of-the-art level resolution.

Fig. 1 shows a schematic line diagram of the five crystal X-ray diffractometer

designed, developed and fabricated in author’s laboratory [2,12]. The X-ray beam emerging

from a fine focus X-ray source is collimated with the help of a specially designed

collimator, which is positioned for a foreshortening of ~3°.

The collimator has two sets of

fine slits one of these is vertical and perpendicular to the plane of diffraction. This restricts

the divergence of the X-ray beam to ~80 arc sec in the plane of diffraction. The collimated

beam falls on a set of two plane silicon monochromator crystals of Bonse- Hart type [13].

The diffracting surfaces of these monochromators are along (1 1 1). When these are

oriented for diffraction one gets well resolved Kα1 and Kα2 X-ray beams. The Kα1 beam is

isolated with the help of another collimator, which stops the residual direct beam and the

Kα2 component. The Kα1 beam is further diffracted from a plane silicon monochromator

having its diffracting surface along (1 0 0). The third monochromator is oriented for

diffraction from (8 0 0) set of planes. This highly dispersive geometry leads to a substantial

reduction in the divergence and the wavelength spread of the X-ray beam. This beam is

generally employed as the exploring X-ray beam. The specimen is mostly the fourth

crystal of the diffractometer. It can be oriented in the Bragg or the Laue geometries. The

beam diffracted from the specimen is further diffracted from an analyzer crystal. The

analyzer crystal is very useful when changes in lattice parameter of the specimen due to

externally applied electric field are to be determined or mismatches between epitaxial films

and substrate crystals are to be determined precisely. The design of the diffractometer is

such that the specimen can occupy any position depending upon the requirements of the

experiments to be performed.

The five-crystal X-ray diffractometer can be employed for making the following

HRXRD experiments: (i) diffractometry; (ii) topography; (iii) diffuse X-ray scattering

measurements; (iv) measurements of curvature of wafer

3

- thin film systems for

determination of biaxial stress; (v) precise determination of lattice parameters of crystals

and thin films, (vi) determination of lattice and orientational mismatches between epitaxial

films and substrate single crystals; and (vii) determination of orientation of crystal surfaces

and flats on single crystal wafers.

It can also be used for accurate measurement of

absorption coefficient of crystals for X-rays including study of anomalous transmission of

X-rays during Laue diffraction. Experiments like diffractometry can be controlled with the

help of a PC.

Fig. 2 shows a typical diffraction curve of a nearly perfect silicon crystal recorded

with the five-crystal X-ray diffractometer [2]. This curve was recorded with (1 1 1) planes,

which are nearly parallel to the surface of the specimen. For comparison, we show in Fig.

3 a theoretical diffraction curve obtained by using the dynamical diffraction theory in the

plane wave approximation [2]. It can be seen that the half width of the experimental curve

is larger than that of the theoretical curve by only 0.3 arc sec. Also, the experimental curve

shows nearly 100% reflectivity at the peak (Fig.2).

Therefore, we can see that the

experimental curve is very close to the theoretical diffraction curve. These features are

indications of high resolution that can be achieved by employing such a system. The author

and his colleagues have carried out a variety of investigations by employing this and the

other multi-crystal diffractometers.

Some recent results will be summarized in the

following.

Characterization of Defects in Semiconductor Crystals

X-ray diffraction topography is widely used for direct observation and

characterization of dislocations in nearly perfect crystals.

Multi-crystal X-ray

diffractometers are well suited to image the large strain field around dislocations in nearly

perfect crystals. We shall describe a typical example of characterization of dislocations in

gallium arsenide crystals [6]. Fig. 4 shows a typical high-resolution traverse topograph of a

(1 0 0) GaAs crystal, which was grown by the horizontal Bridgman method. Three images

of dislocations are observed in the entire volume of the crystal. The size of each image is

very large, extending to ~ 1 mm. This shows that HRXRD techniques are very sensitive to

4

strain field covering a large region around the defects. Also, one can see that in the top

right-hand corner, a small region is not diffracting. A very small tilt of a few arc sec is

responsible for it. It may be mentioned that the half-width of diffraction curve of this

particular specimen was ~ 10 arc sec. The specimen was maintained at the peak of the

diffraction curve as it was traversed across the X-ray beam for recording the topographs.

Defects structure in a variety of crystals has been investigated in authors laboratory.

This includes silicon, gallium arsenide, CdTe, GaSb, lithium niobate, BGO, diamond,

saphire, garnets and others. In the case of silicon it is rather rare to find a dislocation.

However, characterization of point defect clusters and isolated point defects in dislocation

free crystals is an area of considerable importance. Further, interesting microstructure can

be observed on application of high electric fields to these crystals [2].

It is well known that X-ray diffractometery and topography techniques can not be

directly employed for study of point defects and their clusters. The author and his coworkers have employed high-resolution diffuse X-ray scattering (DXS) measurements for

study of these defects in nearly perfect crystal [14-23]. It has been shown that silicon

crystals grown by the two widely employed techniques, namely the Czochralski (CZ) and

the floatzone (FZ) methods contain different types of point defects [15,19]. It has been

shown that in the crystals grown by the CZ method the dominant contribution to DXS is

from defects of interstitial type. In the FZ grown crystals on the other hand the dominant

defects were of vacancy type. A phenomenological model has been successfully employed

to analyze the DXS data for obtaining essential parameters of the defects [24].

This model

is based on the assumption that he defects are loosely clustered point defects. Typical

values of radii of vacancy clusters in FZ crystals were 0.6 μm [18]. For CZ crystals, the

cluster size was obtained as 0.8 m [19]. It has been shown that the DXS distribution is

very sensitive to the thermal history of the specimen and the nature of treatment it has

undergone during various processing steps for device fabrication. Control of oxygen level

in FZ grown silicon crystals can produce remarkable changes in the point defects. The

essential results of a recent study are described in the following.

A comparative study of defects in silicon crystals grown by the FZ as well as the

CZ methods had yielded interesting results [21,22]. It was found that the FZ crystals, which

5

contain lower concentration of oxygen than the CZ crystals have slightly lower degree of

perfection than the CZ crystals [15,21].

It may be mentioned that somewhat similar

relation is to known in the case of type I and type II natural diamond crystals [26]. The

perfection of type I diamond crystals, which contain appreciable concentration of nitrogen

is higher than that of the type II diamonds which are relatively free of nitrogen. We have

investigated the effect of oxygen content on the degree of perfection of FZ grown silicon

crystals [21,22].

For study of effect of oxygen concentration on crystalline perfection of FZ crystals

we had selected high purity silicon crystals characterized by electrical resistivity of 10

kcm [20]. Oxygen was introduced by heating this specimen under oxygen at different

temperatures (from room temperature 1100C.). The concentration of oxygen was

monitored by using infrared absorption measurement around 1105 cm-1 by employing a

FTIR spectrophotometer [27]. It was found that a marginal increase in oxygen content

starts taking place after annealing the specimen at 873 K and higher temperature.

Annealing at 1073 K produced an increase in oxygen concentration from 1.3 × 1017 cm-3

(no heat treatment) to

3.6 × 1017cm-3. It may be mentioned that good quality CZ grown

crystals have about this concentration of oxygen. Annealing at higher temperatures led to

further increase in the oxygen concentration. For example, those specimen which were

annealed at 1373 K the oxygen concentration reached 1.7 × 1018 cm-3 However, a shift in

the wavelength of the infrared absorption band was observed which, suggested

agglomeration of oxygen. This was confirmed by diffuse X-ray scattering measurements

described below.

High resolution X-ray diffractometery and high resolution diffuse X-ray scattering

(DXS) measurements were made after each annealing step described above. The half

widths of the diffraction curves of (111) lattice planes of these specimen crystals were 11

arc sec to begin with. The absolute value of the integrated intensity

10-5 rad.

The DXS intensity distribution was typical of FZ grown silicon crystals indicating

dominant contribution of vacancy type defects. The change in real structure was negligible

up to annealing temperature of 873 K. Remarkable changes were observed for annealing

6

temperatures lying between 873 K and 1073 K. Fig. 5 shows a set of three diffraction

curves recorded before annealing, after annealing at 1073 K and after annealing at 1373 K.

The half widths of diffraction curve decreased from 11 arc sec, to 7 arc sec after annealing

at 1073 K. Further annealing at 1373 K led to the broadening of the diffraction curve and

the half width increased to 10.5 arc sec, showing a deterioration in the perfection of the

crystals. The results of absolut

10-5 rad. after

10-5

-5

rad. Further, the v

rad after annealing at 1373 K. This

experiment indicates a direct co-relation between the concentration of oxygen in silicon and

its crystalline perfection. The perfection is maximum when the oxygen level is about 4 x

1017 cm-3 (obtained after annealing at 1073 K), which is typical of high quality CZ crystals.

Fig. 6 shows a typical set of four DXS intensity vs. K* plots. These were recorded

at the following stages: before annealing, after annealing at 873 K, after annealing at 1073

K and after annealing at 1373 K. Here K* is a vector, which joins the elemental volume of

the reciprocal space under investigation to the nearest reciprocal lattice point. In this

figure, we show only those plots in which K* is along the reciprocal lattice vector R*. The

point defect cluster in this crystal could be modelled as platelets lying of (1 1 1) plane.

Therefore, for the sake of clarity, plots with K* along [1 11 ] {curve (a)} and [1 1 1]

{curve (b), and (d)} are shown in this figure. The experimental data is shown as discrete

points. The phenomenological model was used to analyze the experimental data [24]. The

lines in Fig 6 were obtained by employing the model proposed by Dederichs. The fit

between the experimental points and the theoretical curves is quite good. In the as grown

state, the DXS data showed the dominance of the isolated vacancies and their clusters. The

cluster size was ~ 0.2 m. A comparison of curves (a) and (b) shows that there is an over

all decrease in the DXS intensity on annealing, showing an improvement in the degree of

perfection. Also, a small decrease in cluster size has taken place (from 0.24 m to 0.22

m). The most remarkable change is observed in curve (c). The entire curve is a single

straight line with a slope of – 2. The sign of the anisotropy in DXS distribution has

7

changed to positive, from the negative sign observed in the as grown specimen. The

change in the sign of the anisotropy indicates the dominance of interstitial point defects,

which may be oxygen impurity atoms.

It may be noted that after annealing at this

temperature the crystals had shown remarkable improvement in the degree of perfection. In

curve (d) we can see two well defined regions in DXS plots with slopes of –2 (at low values

of K*) and –4 (at higher values of K*). This indicates clustering of interstitial defects after

annealing 1373 K.

The size of the interstitial clusters was found to be ~ 0.8 m.

urements and

analysis of DXS distribution has clearly shown that the enhancement in the degree of

perfection of silicon crystals is linked with the oxygen concentration in silicon crystals. An

oxygen concentration of ~ 4 x 1017 cm-3 without segregation is optimum for achieving high

degree of crystalline perfection.

Structural Characterization of Thin Epitaxial Films

Thin films of a wide of variety of materials are extensively employed in all most all

devices. It is a challenge to unravel the real structure of these films when one or more of

their dimensions are restricted to very smaller values, in nanometer range. X-ray

diffractometery, particularly, in grazing incident mode has been quite widely used [28].

Even the normal high resolution X-ray diffractometery can give valuable of information

about epitaxial films regarding crystallinity, structural quality, lattice and orientational

mismatches between films and substrates and the biaxial stress in such system. A wide

variety of films have been investigated in the author’s laboratory. These include MBE

grown structures of InAlAs, InGaAs, SiGe, CdTe, GaSb and films grown by other

techniques like those of silicon oxide, silicon nitride, polysilicon, silicon oxinitride and Mosilicide on silicon [6, 7, 29-35]. Biaxial stress in multi-level metallizations on GaAs

substrates had been investigated in details. One typical result of structural characterization

of MBE grown SiGe films is reported in this following [30].

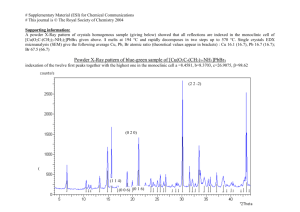

Fig. 7 shows a typical high resolution X-ray diffraction curve of a 40 nm thick MBE

grown SiGe film. It can be seen that a very well defined diffraction peak could be obtained

8

by employing normal incidence diffraction, even though the thickness of this film is very

small. From the observed angular separation between the diffraction peaks of the film and

the substrate the value of the lattice mismatch

composition was deduced as Si82.4Ge17.6. It needs to be emphasized that if one obtains the

erved angular separation between the diffraction

The lattice mismatch is not the only mismatch between the lattice planes of the epitaxial

film and those of the substrate. In general, the lattice planes of the film and substrate are

not parallel to each other. There is a finite angle between the two. Therefore, the observed

angular separation between the diffraction peaks of the film and the substrate crystal is a

function of both

is ignored, the values of chemical composition of the films may be in serious error. By

employing the analyzer crystal of the diffractometer the value of both the mismatches can

be determined precisely. In some of the highly mismatched thin films, like MBE grown

GaSb films on GaAs, the mismatch is very large [31]. The angular separation between the

film and the substrate peaks is ~ 1 arc deg. In such situations, it is not feasible to use the

analyzer crystal for determination of mismatches. One studies the variations in angular

separation between the two peaks as a function of the azimuthal rotation of the specimen in

its own plane. The angular separation shows periodic variation with azimuthal rotation. By

analyzing this data one can determine the values of both the mismatches.

Conclusions

In this paper we have briefly described the fundamental principles of high resolution Xray diffraction techniques, a five-crystal X-ray diffractometer developed in author’s

laboratory and their application in study of bulk crystals and thin films. The following

typical experimental results have been described as illustrative examples:

(i)

characterization of dislocations in nearly perfect GaAs crystals;

9

(ii)

study of influence of oxygen on crystalline perfection of silicon single crystals;

and

(iii)

structural characterization of silicon germanium films.

Acknowledgements

The author had the privilege and pleasure of collaborating with a number of

colleagues and students in his laboratory and with a number of distinguished scientists from

India and abroad. Collaborative research with the following colleagues is particularly

acknowledged: Drs. Niranjana Goswami, G. Bhagavannarayana, R.R. Ramanan and Prof.

H.L. Hartnagel. A part of this work was supported under an Indo-US project coordinated

by the Department of Science and Technology, New Delhi and a part of the work was

carried out under an Indo-German project coordinated by Council of Scientific and

Industrial Research, New Delhi.

References

1. D. Keith Bowen and B.K. Tanner, High Resolution X-ray Diffractometry and

Topography, Taylor and Francis Ltd., London EC4A 3DE (1998).

2. Krishan Lal, Proc. Ind. Nat. Sci. Acad. 64A, (1998) 609-635.

3. Z. G. Pinsker, Dynamical Scattering of X-rays in Crystals, Springer-Verlag, Berlin,

(1978).

4. G.A. Rozgonyi and T.J. Ciesielka, Rev. Sci. Instrum. 44 (1973) 1053-1057.

5. A. Segmuller, I.C. Noyan and V.S. Speriosu, Prog. Crystal Growth Charact. 18

(1989) 21

6. Krishan Lal, S. Niranjana N. Goswami J. Wurfl and H.L. Hartnagel, J. Appl. Phys.

67, (1990) 4105-4113.

7. Krishan Lal,

Reshmi

Mitra, G. Srinivas and V. D. Vankar, J. Appl. Cryst. 29

(1996) 2-10.

10

8. W.H. Zachariasen, Theory of X-ray Diffraction in Crystals, Wiley, New York

(1945).

9. M. Von Laue,

Rontegenstrahlininterferennzen, Acad. Verlagsgescllschaft,

Frankfurt, (1960).

10. B.W. Batterman and H. Cole, Rev. Mod. Phys. 36 (1964) 681-717.

11. Andre Authier, Dynamical Theory of X-ray Diffraction, Oxford University Press,

Oxford (2001)

12. Krishan Lal, Bull. Mater. Sci. 16 (1993) 617-642.

13. U. Bonse and M. Hart, Appl. Phys. Lett. 7 (1965) 238-239.

14. Krishan Lal, Prog. in Crystal Growth Charac. 18 (1989) 227-266

15. Krishan Lal and G. Bhagavannarayana, J. Appl. Cryst. 2 (1989) 209-215.

16. Krishan Lal, G. Bhagvannarayana and G. S. Virdi, J. Appl. Physics 69 (1991) 80928095.

17. Krishan Lal, G. Bhagavannarayana and G. S. Virdi, Solid State Phenomena 47-48

(1996) 377-382.

18. G. Bhagavannarayana, Ph. D. Thesis, University of Delhi, Delhi, (1994).

19. R.R. Ramanan, G. Bhagavannarayana and Krishan Lal, J. Crystal Growth 156 (1995)

377-382

20. R.R. Ramanan, S. Niranjana N. Goswami and Krishan Lal, Acta Cryst. A54 (1998)

163-171.

21. Krishan Lal, R.R. Ramanan and G. Bhagavannarayana, J. Appl. Cryst., 33 (2000)

2-9.

22. R. R. Ramanan, Ph. D. Thesis, University of Delhi, Delhi, (1998).

23. R.V. Anantha Murthy, M. Ravikumar, A. Choubey, Krishan Lal, Lyudmila

Kharachenko, V. Shleguel, V. Guerasimov, J. Crystal Growth, 197 (1999) 865-873.

24. P. H. Dederichs, J. Phys. F 3 (1973) 471; Phys. Rev. B4 (1971) 1041.

25. G. Bhagavannarayana, A. Choubey, Yu. V. Shubin, and Krishan Lal, Acta Cryst. (to

be published).

26. G. Davies , Diamond, London: Adam Hilger (1984).

11

27. ASTM, Annual Book of the American Society for Testing Materials Standards,

F1221-80, (1980) 538-540.

28. S.A. Stepanov, E.A. Kondrashkina, M. Schmidbauer, R. Koehler, J. –U. Pfeiffer, T.

Jach, and A. Yu. Souvorov, Phys. Rev. B, 54 (1996) 8150-8162.

29. Krishan Lal in Semiconductor Devices, Krishan Lal (Ed.), Narosa Publishers, New

Delhi, (1995), 243-252.

30. M. Mukhopadhyay, L.K. Bera, S.K. Ray, S.N. Sahu, B.R. Mehra, N. Goswami,

Krishan Lal and C.K. Maiti, IETE Journal of Research, 43 (1997) 155-163.

31. S. Niranjana N. Goswami, Krishan Lal, A. Vogt and H. L. Hartnagel, (to be

published).

32. S.K. Halder, Vijay Kumar, Krishan Lal, P. Suryanarayana, B.B. Dixit and P.D.

Vyas in Physics of Semiconductor Devices, Krishan Lal (Ed.), Narosa Publishers,

New Delhi (1994) 337-339.

33. S.K. Halder, Vijay Kumar, Krishan Lal, Vipan Kumar and O.P. Agnihotri in

Physics of Semiconductor Devices, Krishan Lal (Ed.), Narosa Publishers, New

Delhi (1994) 340-342.

34. S. Niranjana N. Goswami, Krishan Lal, R. Kothari and Y. K. Bhatnagar in

Semiconductor Devices, Krishan Lal (Ed.), Narosa Publishers, New Delhi (1996)

382-384

35. S. Niranjana N. Goswami, Krishan Lal, J. Wurfl and H.L. Hartnagel in Physics of

Semiconductor Devices, Krishan Lal (Ed.), Narosa Publishers, New Delhi, (1994)

337-339.

12

MonochromatorCollimator 1

X-ray Source

MonochromatorCollimator 3

K2

K1

K1

Slit 1

Analyser

Crystal

MonochromatorCollimator 2

Slit 2

Specimen

Detector

Fig. 1

A schematic line diagram of the Five Crystal X-ray Diffractometer designed,

developed and fabricated at author’s laboratory.

13

(111) Silicon Crystal Specimen;

(111) Diffracting Planes;

Mo K Radiation;

(+,-,+,-,(+)) Configuration.

Half Width: 3.7 arc sec

Fig. 2 A high resolution X-ray diffraction curve of a (111) silicon single crystal

recorded on the Five Crystal X-ray Diffractometer. Symmetrical Bragg

geometry, (+, -, +, -, +) configuration of the diffractometer, and Mo K1

exploring beam were employed. The points represent the as measured data

without any corrections being applied.

14

0.9

Reflectivity EH2 / E02

20

/E

2H

Re

fle

ctiv

ity

E

0.8

0.7

0.6

0.5

Half Width: 3.43

arc sec

0.4

0.3

0.2

0.1

0

10

5

0

-5

-10

-15

Deviation From Bragg Angle , arc sec

Fig. 3 A theoretical diffraction curve calculated on the basis of plane

wave dynamical theory for an ideally perfect silicon crystal for

experimental conditions of Fig 2.

15

g [220]

2mm

Fig. 4 A HRXRD traverse topograph of a nearly perfect gallium

arsenide crystal recorded in symmetrical Laue geometry

with Mo K1 radiation. Only three dislocations are

observed in the entire volume of the wafer.

16

35

b Annealing Temperature, A T

o

600 C

o

800 C

2

Diffracted X-ray Intensity, 10 c/s

30

o

25

1100 C

20

7 arc sec

10.5 arc sec

15

11 arc sec

10

5

c

a

0

-60

-40

-20

0

20

40

60

Glancing Angle , arc sec

Lal, Ram anan, and Bhagavannarayana, J. Appl. Cryst. (1999), in press

Fig. 5 Typical diffraction curves of a nearly perfect single crystal

of silicon. Mo K1 radiation, symmetrical Bragg geometry

and (+, -, +, -) configuration of the diffractometer were

employed. (a), (b) and (c) were recorded after annealing the

specimen at 873 K, 1073 K and 1373 K, respectively.

17

Fig. 6 A set of typical log [DXS intensity I/I0] vs. log K* plots

for a silicon crystal grown by the FZ method. (a), (b), (c)

and (d) are respectively for as grown state and after

annealing at 873 K, 1073 K and 1373 K. Other

experimental conditions were the same as in Fig. 6.

18

MBE Grown SiGe Epitaxial Film

25

400 Relp; Mo K1

Film thickness: 40 nm

20

Film Composition: Si

82.4

Ge

17.6

15

10

5

0

-900

-800

-700

-500

-600

Glancing Angle , arc sec

-400

Fig. 7 A typical high resolution X-ray diffraction curve of a 40 nm thick

silicon-germanium film grown by molecular beam epitaxy on a (100)

silicon substrate. Mo K1 radiation, (+, -, +, -) configuration of the

diffractometer and symmetrical Bragg geometry were employed.

19