DEPARTMENT OF CHEMISTRY TEACHING LAB EXPERIMENT

advertisement

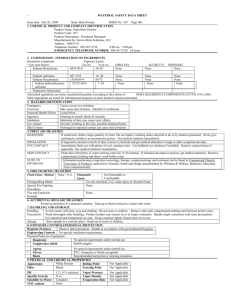

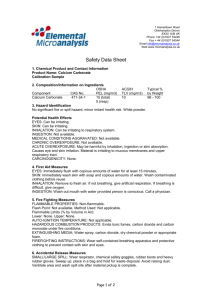

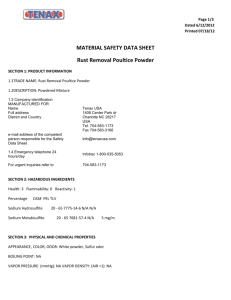

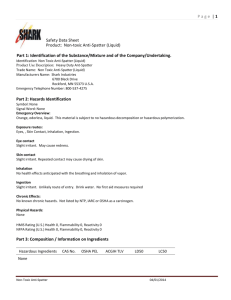

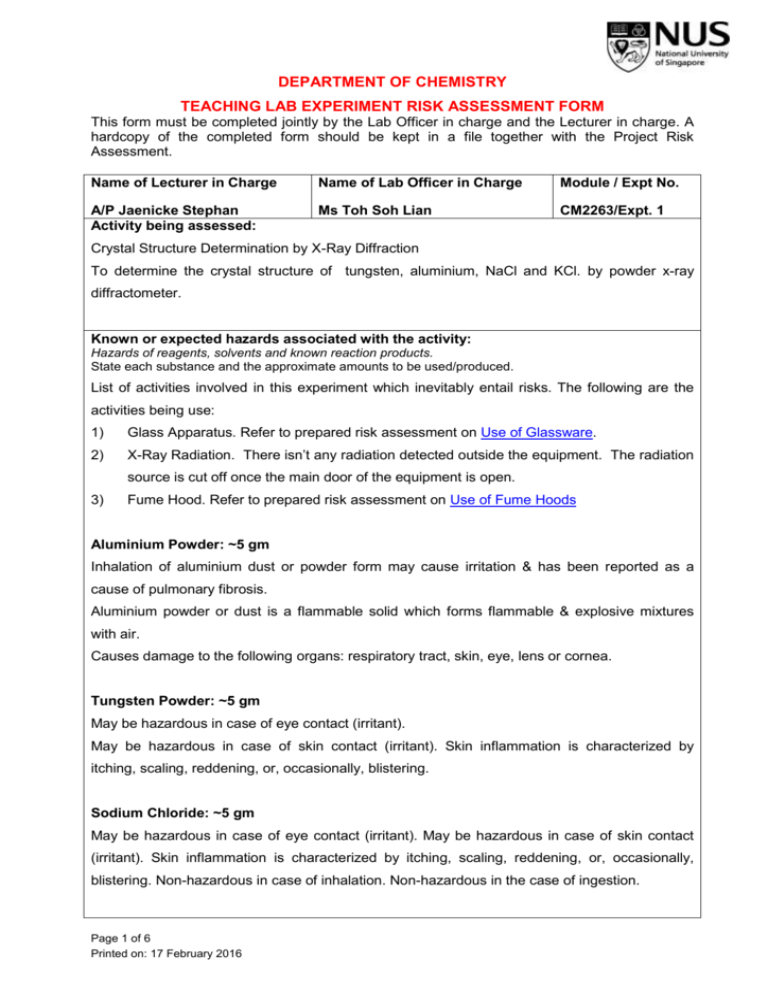

DEPARTMENT OF CHEMISTRY TEACHING LAB EXPERIMENT RISK ASSESSMENT FORM This form must be completed jointly by the Lab Officer in charge and the Lecturer in charge. A hardcopy of the completed form should be kept in a file together with the Project Risk Assessment. Name of Lecturer in Charge Name of Lab Officer in Charge Module / Expt No. A/P Jaenicke Stephan Activity being assessed: Ms Toh Soh Lian CM2263/Expt. 1 Crystal Structure Determination by X-Ray Diffraction To determine the crystal structure of tungsten, aluminium, NaCl and KCl. by powder x-ray diffractometer. Known or expected hazards associated with the activity: Hazards of reagents, solvents and known reaction products. State each substance and the approximate amounts to be used/produced. List of activities involved in this experiment which inevitably entail risks. The following are the activities being use: 1) Glass Apparatus. Refer to prepared risk assessment on Use of Glassware. 2) X-Ray Radiation. There isn’t any radiation detected outside the equipment. The radiation source is cut off once the main door of the equipment is open. 3) Fume Hood. Refer to prepared risk assessment on Use of Fume Hoods Aluminium Powder: ~5 gm Inhalation of aluminium dust or powder form may cause irritation & has been reported as a cause of pulmonary fibrosis. Aluminium powder or dust is a flammable solid which forms flammable & explosive mixtures with air. Causes damage to the following organs: respiratory tract, skin, eye, lens or cornea. Tungsten Powder: ~5 gm May be hazardous in case of eye contact (irritant). May be hazardous in case of skin contact (irritant). Skin inflammation is characterized by itching, scaling, reddening, or, occasionally, blistering. Sodium Chloride: ~5 gm May be hazardous in case of eye contact (irritant). May be hazardous in case of skin contact (irritant). Skin inflammation is characterized by itching, scaling, reddening, or, occasionally, blistering. Non-hazardous in case of inhalation. Non-hazardous in the case of ingestion. Page 1 of 6 Printed on: 17 February 2016 Potassium Chloride: ~5 gm Hazardous in case of eye contact (irritant). Inflammation of the eye is characterized by redness, watering, and itching. May be hazardous in case of skin contact (irritant). Skin inflammation is characterized by itching, scaling, reddening, or, occasionally, blistering. No known acute effects of this product resulting from inhalation. May be hazardous in case of ingestion. 95% Ethyl Alcohol: for washing Danger! Poison! Flammable liquid & vapor. Vapor may cause flash fire. May be fatal if swallowed. May cause blindness. If swallowed cannot be made non-poisonous. Birth defect hazard. Contains material which can cause firth defect. Harmful if inhaled or absorbed through skin. Cause respiratory tract, eye & skin irritation. Contains material which causes damage to the following organs: blood, kidneys, reproductive system, liver, gastrointestinal tract, respiratory tract, skin, central nervous system, eye lens or cornea. Highly flammable & explosive in presence of open flames, sparks and static discharge, of heat, of oxidizing materials. Flammable & explosive in presence of shocks. *amount stated are computed for the whole experiment. Incompatible materials (special precautions): Aluminium Powder Reactive with acids, alkalis. Tungsten Powder Incompatibilities: Strong oxidizers, halogens Sodium Chloride & Potassium Chloride Not available. 95% Ethyl Alcohol Highly reactive with oxidizing agents. Slightly reactive to reactive with metals, acids. The risk of injury and its severity likely to arise from these hazards: Aluminium Powder Eye: Dust may cause mechanical irritation to eye. Skin: No known acute effects of this product resulting from skin contact. Inhalation: Irritates. Ingestion: No known acute effects of this product resulting from ingestion. Skin Contact: Irritates Skin Absorption: Harmful (powder) Eye Contact: Irritates Page 2 of 6 Printed on: 17 February 2016 Inhalation: Harmful (powder) Ingestion: Harmful (powder) Sodium Chloride & Potassium Chloride Skin: Irritates. Eye Contact: Irritates. 95% Ethyl Alcohol Eye: Hazardous in case of eye contact (irritant). Inflammation of the eye is characterized by redness, watering, and itching. Skin: Hazardous in case of skin contact (permeator, irritant). Skin inflammation is characterized by itching, scaling, reddening, or, occasionally, blistering. Inhalation: Hazardous in case of inhalation (lung irritant) Ingestion: Extremely hazardous in case of ingestion. May be fatal or cause blindness if swallowed. Who is at risk? Persons handling the chemicals and as well as those present in the vicinity. Measure to be taken to reduce the level of risk: Proper laboratory attire and safety measures must always be used in order to reduce the level or risk. Wash thoroughly after handling. Do not take internally. Eye protection: Chemical safety goggles. Hand protection: Gloves. Refer to PSSO SAFETY Information Center website: http://www.chemistry.nus.edu.sg/PSSO/Safety.htm Training prerequisites: This assessment should be read by everyone who will be using the above mentioned chemicals. Refer to Completed Risk Assessment forms for common activities: http://www.chemistry.nus.edu.sg/PSSO/Safety/Risk/risk.htm#Common Level of risk remaining: The level of risk is low although constant vigilance is necessary to avoid injury. For X-Ray radiation, the level of risk is none (can not be detected by X-Ray radiation detector). Emergency action if : Spill: Aluminium Powder Small Spill and Leak: Use appropriate tools to put the spilled solid in a convenient waste disposal container. Large Spill and Leak: Stop leak if without risk. Do not get water inside container. Do not touch spilled material. Cover with dry sand or other non-combustible material. Prevent entry into sink. Page 3 of 6 Printed on: 17 February 2016 Eliminate all ignition sources. Call for assistance on disposal. Finish cleaning by spreading water on the contaminated surface and allow evacuating through the sanitary system. Tungsten Powder Wash site of spillage thoroughly with water and detergent. Sodium Chloride & Potassium Chloride Small Spill and Leak: Use appropriate tools to put the spilled solid in a convenient waste disposal container. Large Spill and Leak: Use a shovel to put the material into a convenient waste disposal container. Finish cleaning by spreading water on the contaminated surface and allow evacuating through the sanitary system. 95% Ethyl Alcohol Small Spill & Leak: Dilute with water and mop up, or absorb with an inert dry material and place in an appropriate waste disposal container. Large Spill & Leak: Keep away from heat. Keep away from sources of ignition. Stop leak if without risk. Cover with DRY sand or other non-combustible material. Do not touch spilled material. Use water spray to reduce vapors. Prevent entry sink. Call for assistance on disposal. Fire: Aluminium Powder Small fire: Use DRY chemical powder. Large fire: Use water spray or fog. Cool containing vessels with water jet in order to prevent pressure build-up, auto ignition or explosion. Tungsten Powder Moderate fire hazard in the form of dust when exposed to flame. Extinguishing Media: Carbon dioxide, dry chemical Sodium Chloride & Potassium Chloride Non-flammable. 95% Ethyl Alcohol Small Fire: Use DRY chemical powder. Large Fire: Use alcohol foam, water spray or fog. Cool containing vessels with water jet in order to prevent pressure build-up, autoignition or explosion. Is the experiment suitable for out-of-hours operation ? References if any: Page 4 of 6 Printed on: 17 February 2016 Yes No http://www.emdchemicals.com/analytics/doc/msds/msds-display.asp?materialid=B27064 http://www.emdchemicals.com/analytics/doc/msds/msds-display.asp?materialid=B30541 http://www.emdchemicals.com/analytics/doc/msds/msds-display.asp?materialid=2406 http://www.emdchemicals.com/analytics/doc/msds/msds-display.asp?materialid=B10198 http://www.emdchemicals.com/analytics/doc/msds/msds-display.asp?materialid=EX0280 Signature of Lab Officer in Charge:……………………………………………………………….. Date:………………………… Signature of Lecture in Charge:………… …………………………………….. Date:… …………………….. Prepared Risks Assessments for standard equipment and operation are with the kind permission of Dr. Ken MacNeil, School of Chemistry, University of Bristol. Page 5 of 6 Printed on: 17 February 2016 Activity being assessed: Note any activity to be used which entail risk (e.g. use of glass vacuum apparatus, high pressures, high voltage, radiation, high temperatures). Give reference to any special protocols to be followed, and if appropriate attach copies to the risk assessment form. State any additional precautions taken to minimise risk. Known or expected hazards associated with the activity: FOR EACH CHEMICAL, read the MSDS and note:a) Particular hazards (e.g. highly toxic, carcinogenic, corrosive, flammable, pyrophoric, explosive, volatile, dust hazard). Note any dangerous combinations of properties (e.g. volatile and toxic). b) Requirements for safe handling (e.g. fume cupboard, inert atmosphere, low temperature). c) How to dispose of residuals Dispose to drain, with water dilution Neutralise, then to drain with suitable dilution To flammable liquid waste receptacle To non-flammable liquid waste receptacle Keep for recovery/recycling Keep for special disposal later (e.g. heavy metals) Double bag and dispose to dry waste Special procedure (specify) Incompatible materials (special precautions) Note any dangerously incompatible materials and hazards arising from contact of any reagents and substances used with common materials such as paper, benches, hoses, etc. Measures to be taken to reduce the level of risk Include hazards of previously unknown products. Location of work – laboratory, open bench, fume cupboard Level of risk remaining: Likelihood and consequences of any accident or unforeseen events whilst carrying out the activity. When this has been done, choose the appropriate procedure:a) Close supervision and/or attendance of trained first-aider needed. b) Specific approval of supervisor needed. c) Training is needed prior-to or during the operations specified. d) Training is complete and only general laboratory competence required. e) No risk perceived. Emergency action: a) Any special requirements to deal with accidental spillage or leakage. b) What to do in the event of accidental exposure (skin contact, inhalation, etc.). Page 6 of 6 Printed on: 17 February 2016