4 Conclusion

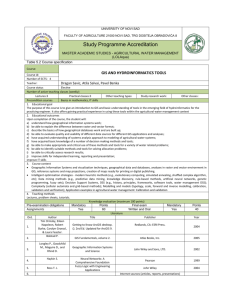

advertisement

Intelligent Agents Embedded with Computational Techniques for Power Systems ELENI E. MANGINA Department of Computer Science University College Dublin Belfield, Dublin 4 IRELAND http://www.cs.ucd.ie/staff/emangina/deafault.htm Abstract: - Electrical utilities need to use their equipment closer to their design limits and require extending their operating life through automatic condition monitoring systems. Data interpretation is of high importance to infer the state of the equipment and is achieved by converting the data into appropriate information. This paper describes the use of agent-based technology for classification of partial discharge signatures of Gas Insulated Substations. The objective of this work is to take the next step and promote a decentralised, objectoriented, agent-based approach for data interpretation by making use of different artificial intelligence techniques embedded within intelligent agents. Key-Words: - Intelligent Agents, Computational Techniques, Gas Insulated Substations 1 Introduction By definition condition monitoring is concerned with detecting and distinguishing faults occurring in plant that is being monitored [1], therefore the early diagnosis and identification of faults has a number of benefits (improvement in the plant economy, reduction in operational costs, improving the level of safety etc). In extra high voltage gas insulated equipment, partial discharge (PD) occurs when a defect enhances the local electric field. If the limit of the insulation medium is exceeded, this can lead to flashover and then breakdown. Various types of defects, depending on the type of equipment, may cause partial discharge activity. In Gas Insulated Substations (GIS), PD can be initiated by free metallic particles or by sharp protrusions located on the electrodes, for example. For cost reasons, it is a necessity to avoid breakdown. Various techniques can be used to detect impending failures and monitor the problems on-line. Continuous monitoring systems based on the principle of detecting the UHF signals emitted by partial discharges (PD) in SF6, originally developed at Strathclyde University [2,3], are now installed at many substations world-wide and the technique is established as the most sensitive available for avoiding breakdowns and outages at critical nodes of the power transmission network [4,5]. This work introduces the application of agentbased technology in advanced condition monitoring for data interpretation of a large volume of data from a Gas Insulated Substation. Interpretation of the parameters is complex but essential to assess possible performance deficiencies. By measuring these parameters on-line, the data can be gathered in a form that is ideal for the application of an intelligent agent-based condition monitoring system which will select the most appropriate interpretation technique under varying operational conditions. Within this paper, section 2 discusses the problem domain of Gas Insulated Substations. The analysis of recorded signals can be simplified and automated through the application of classification tools and the use of intelligent agents which apply Artificial Neural Networks, K-means clustering and C5.0 rule induction method is described in section 3. Finally, section 4 outlines how the latter software system can enhance the capability of the partial discharge detection system by adding new intelligent tools specialising in the recognition of partial discharge sources. 2 Problem Domain 2.1 Gas Insulated Substations (GIS) Gas Insulated Substations (GIS) are used in many power transmissions networks for switching and as transformation units for the control and management of electrical power. A GIS substation might be very large and complex in its design, as it is made of many chambers connected together through supporting barriers, corners and circuit breakers. The GIS chamber is a large coaxial transmission line with a central part consisting of a high voltage busbar. The enclosure is earthed and contains the pressurised SF6 gas. The barriers are made of insulating epoxy resin; they maintain the positioning of the busbar, centred in the chamber, and act as gas tight seals. The chamber is approximately 300 millimetres in radius. The busbar diameter is about 100 millimetres. Due to the proximity of electrodes, stresses within the chamber are very high and failure might occur due to small defects. For detection purposes the GIS has been equipped with sensors affixed to the chambers. A portable PD detection unit is connected to the coupler and displays detected signals as shown in Fig. 1. GIS chamber Busbar Coupler 4bar(g) SF6 Busbar Supporting barrier PD monitoring system Earthed enclosure Fig. 1: GIS chamber and PD monitoring system According to the method based on UHF measurement, which was developed and implemented in the high voltage laboratory at the University of Strathclyde, the GIS chamber acts as a resonating cavity for a large range of VHF and UHF electromagnetic EM waves. When small defects emit electric pulses, EM modes are excited into the wave-guide during a long period of time, with a low loss factor. An appropriate coupler detects the signal, which is then sent to the diagnostic monitoring system. Interpretation of the detected signals can lead to the evaluation of the cause of the PD, which currently is achieved based on expertise, and this introduces the need to look for methods to automate the process. 2.2 Partial Discharge (PD) Partial discharge (PD) is the electric phenomenon where small voltage and current pulses are generated by fast electrons and ions in electrical insulated systems. In extra high voltage gas insulated equipment, PD occurs when a defect (i.e. small protrusion on the inner conductor or a free metallic particle) enhances the local electric field. The electrical and chemical activity associated with the presence of such defects may lead to significant degradation of the insulation and sometimes to complete breakdown [6]. Various types of defects, depending on the type of equipment, may cause PD activity. In Gas Insulated Substations (GIS), PD can be initiated by free metallic particles or by sharp protrusions located on the electrodes, for example. There are various types of defects that can cause Partial discharge. Commonly found defects fall into the six main categories quoted below: Free particles: when detached metallic particles are liable to the AC voltage cycles, they hop at the bottom of the chamber and emit very fast current pulses. Busbar protrusion: sharp needles on the high voltage electrode cause partial discharge with a corona effect. Chamber protrusion: same as above but the needle is on the enclosure. Floating electrode: this is particular to situations where one of the electrodes has one part which is not directly connected to the main body. Sparks cross the gap between the two components. Surface contamination on insulating barrier: metallic particles that are glued on to the surface of the spacer may cause surface discharge. Cavities in insulating barrier: internal voids trapped in the insulating material can initiate partial discharge. Not only do the standard defects need to be monitored, but also external sources that can be detected by the actual system like communications noise, radar signals and motor noise and any other external source whose signal can be detected. The PD monitoring system used displays the detected signal in three dimensions: the phasecycles-amplitude display as shown in Fig. 2 for two different defects. The phase axis divides the AC cycle into equal phase windows, the cycle axis indicates the cycle number of the AC wave and the third axis is the actual amplitude of detected PD pulses. Signal patterns vary with respect to the type of source that created the discharge. Through experience, typical patterns are easily recognisable. The objectives of this work are to investigate several methods of partial discharge classification embedded within intelligent agents and study the feasibility of integrating them into an agent-based condition monitoring system. The goal is to extract the meaningful information from the database of the PD signals supplied by the PD monitoring system, in order to evaluate the cause of the PD. The resulting classification program will be derived from redundant analyses based on computational intelligence techniques and their combination will guarantee a high level of confidence in the outcome. Interpretation of the parameters is complex but essential to assess possible performance deficiencies. By measuring these parameters on-line, the data can be gathered in a form that is ideal for the application of an intelligent condition monitoring system, which will select the most appropriate interpretation technique under varying operational conditions. The experts’ knowledge of interpreting the detected signal’s 3D display can be captured and embedded within a software system. The goal is to extract the meaningful information from the database of the PD signals supplied by the PD monitoring system, in order to evaluate the cause of the PD. The resulting classification program is based on computational intelligence techniques and their combination. Next section describes the application of various classification techniques through a multi-agent system in advanced condition monitoring for data interpretation of a large volume of data from a Gas Insulated Substation. This multi-agent software system will be the basis for an integrated approach of condition monitoring and plant lifetime modelling of GIS. The final software system will process the results of the data interpretation from different groups of intelligent agents, diagnose any faults occurring and assess the state of the GIS. 3 Multi-Agent System (MAS) for GIS Fig. 2: Typical 3D displays for (a) free particle & (b) protrusion 2.3 Current problems The problems associated with monitoring GIS for PD signal identification include: There are a number of different diagnostic techniques (PD-detectors, chemical, optical, acoustic, electrical), which have individual advantages and disadvantages depending on the type of defect, where one type of defect remained totally or almost undetected. With these conventional PD-detectors no reliable results could be gained. The specialists must interpret the detected signal’s 3D-display. The number of experts is limited and it is infeasible to monitor the GIS on a 24-hour basis. Following the data preparation and the evaluation of different classification techniques, there could be identified cases where one individual method could not classify the type of defect accurately, or could identify only certain type of defect. Consequently, a number of software entities have been developed and form the hybrid solution for COMMAS-GIS (COndition Monitoring Multi Agent System for GIS) [7], the generic framework of which is given in Fig. 3. The different software agents, which interact in a dynamic way to support the required data interpretation functions include: Kohonen-map agent: classifies data using Kohonen maps Kmeans agent: classifies data using Kmeans clustering algorithm C5.0_rule_induction agent: classifies data using rule induction Case Based Reasoning (CBR) agent: reasons based on past cases of the same type of defect Engineering Assistant Agent (EAA): informs the user of the final result with details based on the users’ profile For the software development of this case study there have been developed 5 different intelligent software agents, while the number of the EAA depends on the number of users. MKRA_GIS (final data interpretation) Kohonen_ map Agent Kmeans Agent C5 rule CBR induction Agent Agent Database Fig. 3: MAS for monitoring PD of GIS The research within this case study, although a two-layer multi-agent system, denotes how the theoretical framework of COMMAS for intelligent data interpretation has been applied and implemented in the identification of partial discharge signal defects of Gas Insulated Substations (GIS). Monitoring the PD signals and interpretation of the parameters is complex but essential to assess possible performance deficiencies. The coupler within the GIS detects the signal, which is then sent to the diagnostic monitoring system. The “fingerprint” representation of the partial discharge record, as described previously, is based upon statistical analysis of the raw data (which within future development can be achieved by ARA agents). This reduces the amount of data to be stored, and picks out the salient features within the data. Within this application there were approximately 600 different cases in the database covering 7 distinct classes (types) of defect. The data provided to the software system are in the form of text files to be read and processed from the intelligent agents: <Casename, Feature 1, Feature 2… Feature 30 > COMMAS-GIS will identify new cases based on the most appropriate classification technique by calling the different classification agents. Currently, this is a two-layer architecture as opposed to the COMMAS general three-tier approach. However, the system will conform to the three-layer architecture once the implementation of COMMAS for GIS is complete, where other parameters will be monitored in a similar way to PD signals. The fully developed software system will evaluate the state of the GIS, by collecting the results of all groups of agents. COMMAS-GIS has been implemented using the ZEUS Agent Building Toolkit [8], where each agent individually interprets and classifies the data using its embedded technique, and communicates its results using KQML messages. The training of each algorithm has been implemented off-line, and the accuracy of each method has been evaluated from the agents, which call the external programs responsible for testing. For each unidentified new case, the agents execute each method and the final result is the outcome of their combined interpretation (based on the “majority voting system”) through the MKRA_GIS agent. Within each type of classification agents (Kohonen_map, K-means, C5.0_rule_induction) each clustering algorithm has been implemented to classify the data based on the classification role model. Although each classification agent is using a different method (by calling different external programs), they all belong to the same role model, because the database has to be accessed and after (off line) training, the accuracy is calculated. For the identification of each case the results are sent to the MKRA_GIS to be processed and the EAA informs the user of the procedure in detail. Fig. 4, 5 and 6 show the general execution of each classification agent (Kohonen_map, K-means and C5.0 rule induction respectively). Each type of agent embodies the final vector of weights or rules from the training executed off line. The testing and the accuracy evaluation are accomplished on line from each classification agent. MKRA_GIS Agent (final data interpretation) Send the final result of the identified new case Kohonen_map Agent New data fingerpt int LVQ_PAK (Supervised learning, training off line) SOM_PAK (Unsupervis ed learning, training off line) Fingerprint Database TESTING, Final vector with neurons’ weights, Accuracy evaluation Fig. 4: Kohonen_map Agent MKRA_GIS Agent (final data interpretation) Send the final result of the identified new case MKRA_GIS Agent (final data interpretation) Clementine v5.2 Kmeans Agent Data mining software system using K-means clustering algorithm 5 New Case 1 Fingerprint Database CBR Agent 2 Fingerprint New data fingerpt int TESTING, Final vector with clusters’ weights, Accuracy evaluation Fig. 5: K-means Agent 3 Database 3D Display Database Send the final result for the new identified case 4 1. Receive a new case 2. Find the most similar cases from the fingerprints case memory 3. Given the most similar cases, retrieve their representative 3D displays 4. Get feedback from the user 5. Send result to the MKRA, which will form the final decision in association with the other techniques 6.Store the case with its classification, confidence factor and 3D display in the case memory MKRA_GIS Agent (final data interpretation) Send the final result of the identified new case C5.0 Rule Induction Agent APPLY_RULES ON_LINE New data fingerp tint Clementine v5.2 Data mining software system using C5.0 rule induction algorithm Fingerprint Database Final rules for data classification Fig. 6: C5.0 Rule Induction Agent During discussions with the experts it was identified that there are certain characteristics of each type of defect that could be seen from the 3D display provided by the existing monitoring system. These allowed the expert to come up with a conclusion on which type of defect a case belonged to. For example, certain defects tend to appear at certain times, or phases. The expert would therefore look at parameters like time and phase dependency. Any symmetry that existed within the pattern on both the negative and positive cycle would provide information about the physical reality of the defect. To emulate the experts’ reasoning, representative cases of each defect could be identified, which would then be provided to the user through the Case Based Reasoning (CBR) software agent within the COMMAS-GIS. Along with the fingerprints for each case, the 3D display from the raw data is stored to be used by the CBR agent, to display it to the user. Fig. 7: CBR Agent within COMMAS-GIS Based on the given images (as shown in Fig.8) the user will select which one is the most similar and will give feedback to the CBR agent along with the confidence factor representing the user’s belief of the new case being of a certain type of defect. The result will be sent to the MKRA_GIS and the new case will be stored to the case memory of the agent and will be used for testing another new case in the future. The impact of the CBR agent to the overall multi-agent system is of high importance, especially for cases where the software system cannot identify and there is the need for the experts’ input. The feedback from the experts is then stored in the case memory as new cases and the knowledge can be reused and the accuracy of the system will be increased over time Fig. 8: CBR display for user’s feedback 4 Conclusion This paper has presented the analysis undertaken upon GIS Partial Discharge monitoring data using clustering and classification techniques. The Kohonen map can be used successfully to classify most of the data classes by assigning a class identifier to each neuron in the map. The K-means clustering algorithm had a very good performance as it could accurately classify the input data according to which cluster the data is nearest. The C5.0 performance is comparable to that of the Kohonen map, where again certain classes could not be differentiated from the other classes and it provided rules, for future rule-based intelligent system implementation. Although most of the classes could be identified using the previous techniques, problems were encountered due to an uneven distribution of the data between the classes. Provided more data the different techniques will be used and evaluated again. The next stage of implementation for COMMASGIS is to embed knowledge elicited from experts who manually analyse the PD signals and to integrate it with knowledge based systems to emulate the experts reasoning. This will allow tacit expertise gained over many years to augment the existing classification techniques. The results from the initial discussion with problem domain experts lead to the following conclusions: There is phase dependency associated with most of the defects. Symmetry in the patterns on both negative and positive cycle gives information about the physical reality of the defect (e.g. floating electrodes cause discharges during the first and third quarter). There are specific differences between some of the defects (e.g. protrusion on busbar has the exact reverse pattern of that of a protrusion on enclosure). There are similarities between defects (e.g. floating electrode has quite a small signal because it is like a particle discharging). Digital interference (noise) can be easily identified due to the “blanket effect”. There might be the case where two or more defects occur, which makes the identification more complex. The agent-based approach offers a flexible condition monitoring architecture, which can be applied to any plant item. The distribution of the intelligence allows for scalability and ease of integration of new intelligent reasoning modules. Additionally, it allows the reasoning to be performed across a number of processors at a number of locations. Although currently only fingerprints of the PD signal data can be analysed the software system can be extended to monitor other parameters in association with other techniques of intelligent reasoning. For example, once all the important parameters are identified and different models of the GIS specified, there can be included intelligent agents to embed model based reasoning, or in case of optimisation problems to use genetic algorithms. References: [1]. J. H. Williams, A. Davies and P. R. Drake, (1992), Condition – Based Maintenance and machine diagnostics, CHAPMAN & HALL [2]. J. S. Pearson, B. F. Hampton and A. G. Sellars, “ A continuous UHF monitor for gas-insulated substations”, IEEE Trans. Electrical Insulation, Vol. 26, No 3, pp. 469-478, 1991 [3]. J. S. Pearson, O. Farish, B. F. Hampton, M. D. Judd, D. Templeton, B. M. Pryor and I. M. Welch, “Partial discharge diagnostics for gas insulated substations”, IEEE Trans. Dielectrics and Electrical Insulation, Vol. 2, No 5, pp. 893905, 1995. [4]. CIGRE Working group 15-03 “Diagnostic methods for GIS insulating systems”, paper 15/23-01 presented at the request of Study Committee 15, CIGRE, 1992. [5]. W. Boeck et al, “Sensitivity verification for partial discharge detection systems for GIS with the UHF method and the acoustic method”, Task Force 15/33.03.05 on behalf of Study Committee 33, CIGRE (Paris), 1998 [6]. Schlemper H. D., Kurrer R., Feser K., “Sensitivity of Onsite Partial Discharge Detection in GIS”, Proceedings 8th International Symposium on HV Engineering, Yokohama, Vol. 3, pg. 157-160, 1993 [7]. E. Mangina, S. D. J. McArthur, and J. R. McDonald, "Autonomous agents for distributed problem solving in condition monitoring", The Thirteenth International Conference on Industrial & Engineering Applications of Artificial Intelligence & Expert Systems, June, 2000. [8]. Nwana S. H., Ndumu D., Lee L., Collis J., ZEUS: A tool-kit for building Distributed MultiAgent Systems, in Applied Artificial Intelligence Journal, Vol. 13 (1), pg. 129-186, 1999